Have you already dealt with the harmful effects of scale exposure?

Washing machine, coffee machine, gas boiler ... Which of them was the last victim of limescale?

Want to know more - what is scale and how to deal with it?

Read our article! We have been dealing with the issues of protecting equipment from scale for a long time and we are sure that our knowledge will be useful for you!

Pictured: pipe scale samples taken by us for research

Why is scale dangerous?

Scale has an extremely low thermal conductivity.

For example: the thermal conductivity of steel is 39 kcal / m * hour * deg, and the thermal conductivity of scale is only 0.1 kcal / m * hour * deg. The difference is almost 400 times!

This means that when a boiler, kettle or heating element is operating, they have to spend more gas or electricity on heating and evaporating the liquid.

And that's half the trouble.

Napkin deposits damage equipment and devices, making them impossible to operate!

Scale deposited on the shades of washing machines leads to burnout of the heating element. Scale deposited in the jets of coffee machines makes it impossible to supply liquid. Scale clogging the gas boiler coil leads to its leakage and costly repairs.

Deposits arising from the operation of industrial boilers can lead to rupture of pipes and an emergency!

By the nature of our activity, we are faced with different boilers every day and sometimes we are surprised at how careless people are who operate high-power gas boilers ...

In the photo you can see that the boiler pipe is completely clogged with scale. Water does not pass through it, the pipe is constantly overheated and this can lead to an explosion! However, such a boiler continued to work ...

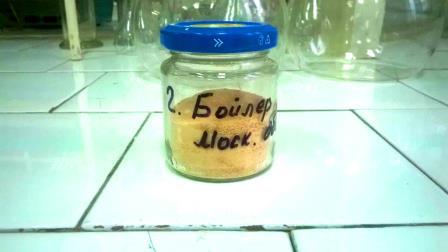

In the photo: scale in the boiler pipe DE-10-14

Thus, the occurrence of scale in heating equipment leads to the following negative consequences:

- Excessive consumption of fuel and electricity;

- Accelerated wear and tear of equipment;

- Impossibility to implement the technological process;

- The likelihood of an emergency;

Scale types

The number of chemical elements from which scale is formed is quite diverse and, at least, it is classified into the following types:

- carbonate scale (carbonate salts of calcium and magnesium - CaCO3, MgCO3);

- sulphate scale (CaSO4);

- silicate scale (silicic compounds of calcium, magnesium, iron, aluminum).

For 15 years of work, our company has accumulated a significant number of scale samples from different parts of Russia. We have examined more than 1000 scale samples and determined their chemical composition.

|

|

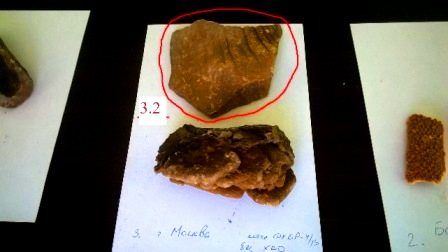

The picture shows an initial sample of scale and its crushed form for research.

According to the results of the study, we found out that the scale content in the overwhelming majority of samples contains the following elements:

Ca / Mg - from 87 to 96%

Fe - from 0.06 to 7.5%

SiO2 - from 0.02 to 1.8%

Is it possible to find out its chemical composition by the appearance of the scale?

Based on the research carried out on more than 100 scale samples, we have determined that:

It is not possible to unambiguously determine the chemical composition of scale by its appearance!

Too many factors affect the color and consistency of scale - the original composition of the water, temperature, pressure at which scale is formed. In addition, scale contains many more elements, which are very small in quantity, but they affect the color and nature of deposits.

For example:

|

|

|

|

Pictured: Scale samples with different color and consistency

These images show deposits that differ significantly in color and physical structure. Surprisingly, these deposits have almost the same chemical composition! However, the different temperatures and pressures at which these scum samples formed resulted in such a difference in color and texture!

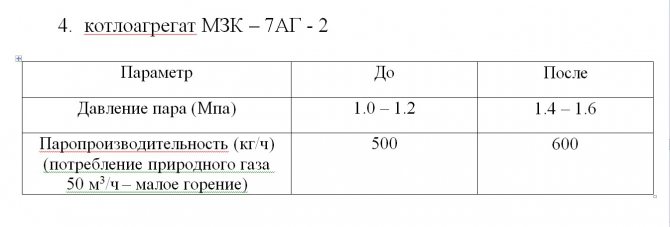

Measures to prevent limescale in steam boilers

The amount of scale in boilers can be reduced by using measures to prevent its formation:

- install aluminum heating elements with heating power up to 2400 W,

- regularly carry out maintenance,

- check the condition of protective coatings on internal parts,

- follow the manufacturer's recommendations regarding the quality of the water used,

- use water softeners: chemical compounds, magnetic converters, etc.

Before cleaning the boiler from scale, it is necessary to assess the thickness and composition of the layer, the technical conditions of the work, and then choose the appropriate method. This will determine not only the efficiency of removing deposits, but also the safety of the protective inner coating of the walls and surface of the heat exchanger. Only a competent approach to solving the problem will ensure the maximum boiler service life without breakdowns and with high efficiency.

At what temperature does scale form?

Scale begins to form at temperatures of 40 ° C and above.

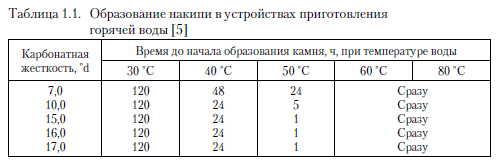

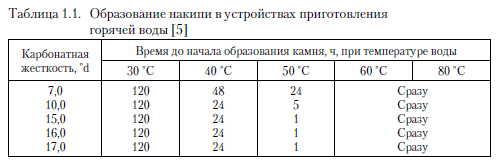

We found quite detailed information on the temperature and rate of scale formation in hot water preparation devices in the book by Vladislav Shaflik "Modern hot water supply systems", Kiev, "Taki spravy", 2010.

The table shows data on the dependence of the rate of scale formation on water hardness and temperature.

In the picture: data on the rate of scale formation as a function of temperature

What exactly provokes breakdowns in gas, steam and hot water boilers?

For example, consider the typical handling of a teapot. A beige bloom forms on its inner walls during boiling water. It gradually gets thicker. This porous layer impairs heat transfer, so you have to spend more time and energy resources. The detached solids enter the food. It takes a lot of effort to remove hard limescale. If the calculation is incorrect, the walls can be damaged.

Similar processes take place inside heating equipment. Dissolved calcium and magnesium compounds are converted to scale when heated. It clogs technological channels, is fixed on the inner surfaces of pipelines. Normal thermal processes are disrupted, gas consumption increases.

An initial check of a state-of-the-art gas and steam boiler can be performed using standard diagnostic tools. The built-in microprocessor, according to the program established by the manufacturer, specifies the correspondence of the temperature at the control points to the nominal parameters. Combustion and fuel supply are controlled by special devices. When dangerous situations are detected, the gas and hot water boiler switches off automatically. The display shows an error code.

| Problem | Troubleshooting method |

| No gas ignition | Press the forced start button for a few seconds. If the device does not work, contact the service center for repair. |

| There is no normal signal from the pressure switch | Check the compliance of the pressure in the water supply system with the nominal value. |

| The overheating fuse has shut down the boiler | Try starting in manual mode. If it didn't work out, they call the master. |

The table lists typical errors. As a rule, the capabilities of a regular user are limited by restarting the system. This helps to eliminate some software errors, but it does not correct the breakdowns themselves. In the case of scale, the task becomes more difficult.The process of scale formation in the Ariston boiler or any other manufacturer is not detected by diagnostic tools. Therefore, attentive users pay attention to indirect signs:

- decreased productivity;

- extraneous noise;

- increased gas consumption;

- software and mechanical failures.

Timely identification of problems is hampered by the low speed of negative processes. In order not to create dangerous working conditions for equipment, it is checked in the fall, or after the next heating season. Chemical cleaning of gas boilers from scale is necessary when there is a deterioration in performance in the absence of errors after automatic diagnostics. It is necessary to make sure that the electricity, water and gas supply networks are functioning properly.

Preventing limescale build-up

Softening

The main method used to prevent the formation of limescale is softening.

The term “softening” refers to the process of water purification from hardness salts (Ca and Mg), which are the main cause of scale formation.

The softening process removes calcium (Ca) and magnesium (Mg) ions from the water. This is done by passing water through a resin or salt containing sodium ions. In this case, calcium and magnesium ions from water pass into resin or salt, and sodium ions replace them and pass into water. Thus, the water softens and its overall hardness decreases.

There are the following requirements for water hardness:

Feed water for steam boilers and boilers (GOST R 55682.12-2013), mmol / l <0.02

There are a variety of softening installations that can be designed and matched to the initial water hardness, in addition, there can be several softening stages.

There are also reverse osmosis units that can produce practically distilled water at the outlet.

Anti-scale devices

Separately, it must be said about various anti-scale devices, positioned as a means to prevent the formation of scale. Our organization has accumulated significant experience in the operation of various anti-scale devices. In addition, we ourselves produce the ECOFOR anti-scale device designed to prevent the formation of scale and corrosion on steam and hot water boilers.

In the picture: explosion-proof version of the ECOFOR anti-scale device

Soon we will post on our website a summary of our experience in the operation of anti-scale devices. Now let us note that, unfortunately, they are not a panacea and a reason for abandoning the existing water treatment systems. These devices should be used as an addition to the existing softening systems. The effectiveness of these devices depends on a huge number of factors: dimensions, parameters of the coolant, the chemical composition of water, etc.

Scale: why does it form and how to deal with it?

Limescale on the heating element and inside the heat exchanger of the catering machine

Water softening systems, magnetic water converters

There are a number of domestic and imported devices called "Magnetic water transformer, water softener

, water hardness neutralizer, anti-scale device, hydromagnetic system, water conditioner ”. Regardless of the name, all of these

water softening systems

have the same design principle: permanent magnets are built into the system, acting on the working medium (water) by the force of a magnetic field. In this case, an important property

water softening systems

is the density or induction of the magnetic field, which directly affects the quality of water treatment. Manufacturers of truly efficient magnetic water converters use permanent high-energy neodymium magnets made of neodymium-iron-boron (Nd-Fe-B) alloy. Neodymium is a rare earth metal; is the main component of a magnet. For example, if you attach two neodymium magnets to each other, then, unlike ordinary ferrite magnets, it will be very difficult to disconnect them.

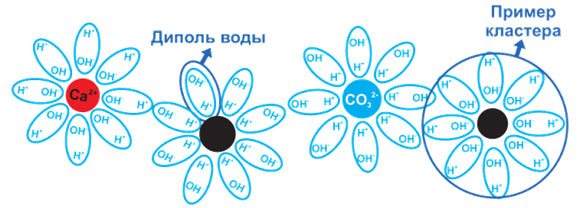

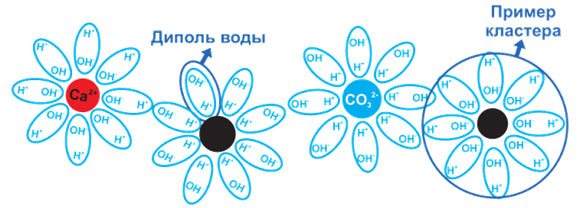

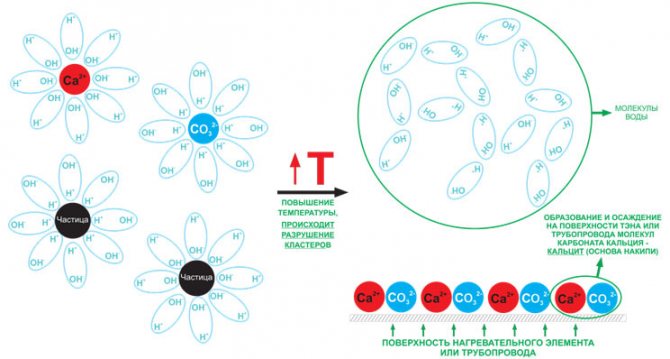

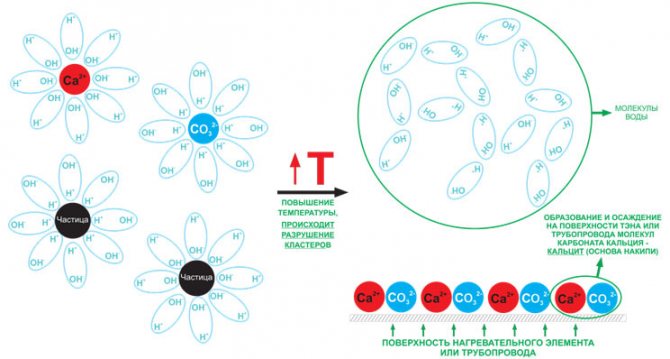

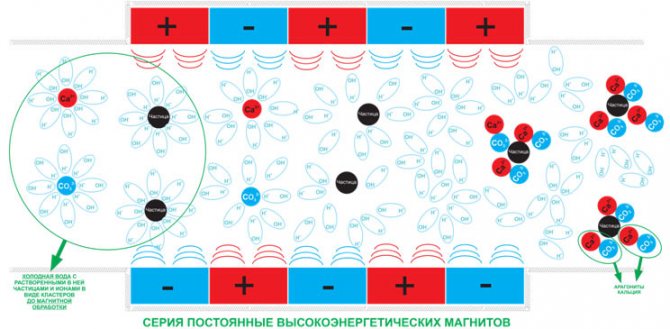

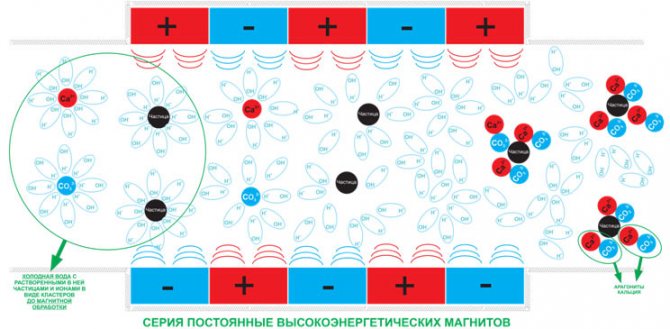

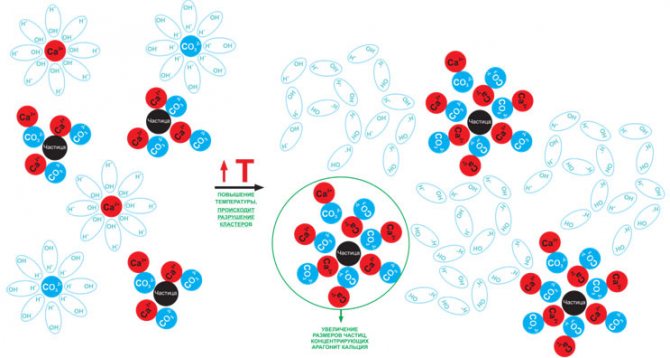

Magnetic water transducers there are flowingmounted directly in front of the protected device or the entire system (in this case, water flows through the device), and overhead typewhen the device is mounted on a pipe or hose without water contact. The mechanism of magnetic water treatment can be described as follows. A water molecule (H2O) can be represented as an elementary dipole - a particle with positively (H +) and negatively (OH-) charged poles. Under the action of the forces of mutual attraction, the water dipoles form so-called clusters, uniting around the microparticles and impurity ions present in the water (in our case, Ca 2+ and CO3 2-), preventing them from interacting with each other. When water is heated, the cluster structure is destroyed, and the ions, combining, form calcium carbonate CaCO3, which is deposited on heaters and pipes, creating a scale base.

Cluster structure of water

Heating untreated water leads to the destruction of clusters and the formation of scale deposits

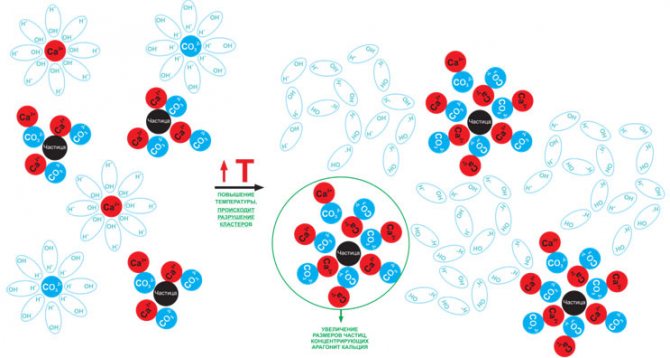

The permanent magnets inside the magnetic water transducer are located in such a way that at a short distance the magnetic field changes direction several times. When water flows between rows of magnets, the water dipoles experience the Lorentz force, which causes the dipoles to oscillate, weakening the cluster structure. As a result, a significant part of the clusters disintegrates. The microparticles released during the destruction of clusters become, as it were, crystallization centers, on which the formed CaCO3 molecules prefer to settle. Further, the process takes on an avalanche-like character - more and more molecules are attached to the surface of the emerging microcrystals, forming particles already visible to the eye.

Water clusters passing between magnetic fields are affected by the Lorentz force, which "loosens" water clusters and leads to the formation of crystallization centers.

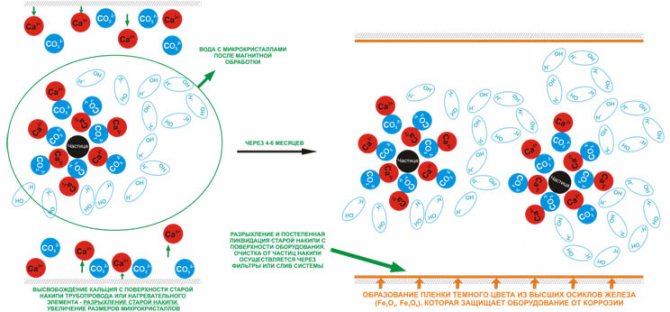

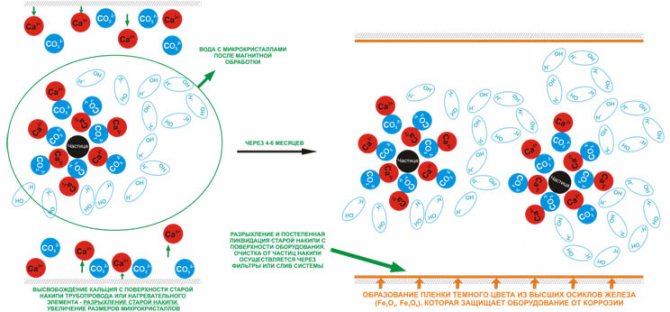

Magnetically activated water does not form scale deposits when heated; aragonites (crystallization centers) "collect" calcium carbonate on themselves and keep it in the water column in the form of a sediment.

Instead of hard scale - the so-called amorphous calcite - finely dispersed particles of aragonite appear, which have a different crystal structure. Aragonite particles can be removed by filtration or removed from the system by draining the water. As a result, when heating water that has undergone magnetic treatment, the size of aragonites increases, and scale does not form. Over time, the calcium carbonate of old scale deposits also begins to interact and join the aragonites in the water. As a result, the old scale is loosened and removed from the walls of the pipeline and heating elements (the removal of deposits occurs gradually and takes from 1 to 4-6 months).In addition, over time, a thin dark film is formed on pipes and heat exchangers, consisting of higher iron oxides (Fe3O4, Fe5O6), which protects equipment from corrosion (the corrosion reaction rate, as experiments have confirmed, decreases by 40-75%).

Aragonite particles "take" calcium carbonate from old scale, loosen it and gradually remove it. A protective film forms under the old deposits, which prevents corrosion.

Descaling boilers

The use of magnetic water converters is an effective means of descaling boilers. Tests of magnetic transducers of water on household heating boilers and analysis of the data obtained allow us to conclude that only the effective hardness of water decreases during magnetic treatment (i.e., neither magnesium nor calcium is removed from the water). Magnetic field treatment reduces the tendency of dissolved minerals to form scale (sludge and deposits) in boilers. Thus, although the water actually remains hard (ie, the concentration of dissolved minerals does not change), it "behaves" like soft water. In this case, scale deposits on heating elements are reduced by up to 60% when using test samples. The results and advantages that are achieved by the use of magnetic water treatment for various devices and devices: - An absolute advantage of the magnetic activation of water is the environmental friendliness of this method. There is no need for periodic addition of chemicals to combat scale, and, in addition, the issue of environmental pollution by draining waste water is eliminated; - Softened water promotes better foaming - soap normally “lathers”. As a result, the consumption of detergents for washing dishes, washing and washing in the bathroom is reduced; - The increase in the service life of equipment reduces the cost of funds for plumbing and electrical work, periodic maintenance of equipment;

Results of using magnetic transducers to protect boilers, water heaters and household appliances from scale

Electric water heater

| The formation of a "white coat" of scale on the heating element and in the heat exchanger is prevented. There is a gradual cleaning of the old scale from the heat exchanger. Reduces the noise of the device during operation. | |

| Boilers, boilers | Protection against limescale deposits of the boiler heat exchanger and pipelines. Heat transfer in the heating system is increased. Corrosion processes inside the equipment are suppressed, gas and electricity costs are reduced. |

| Dishwasher | After washing on dishes, glass glasses, stainless steel dishes, white bloom, streaks and stains do not appear. The life of the heating element is "extended". |

| Coffee machine | Descaling the heater, heat exchanger parts and steam generation system. Significantly improved taste of drinks, water does not form a film. |

| Humidifier | Prevents the formation of limescale and clogging of the holes through which the humidified air is discharged. On furniture, where moisture from the humidifier settles, white deposits cease to form. |

| Ice maker | The hygiene and cleanliness of the icemaker is maintained. Ice cubes do not "soften", retain their shape. Cubes are more transparent, without "unnecessary" impurities of taste and smell. |

| Pools and SPA | Magnetic activation of water increases efficiency when cleaning pools and spas from organics. Softening helps to stabilize the pH balance and the overall hardness of the water. Helps to give water perfect clarity. |

| Car wash | Softened water does not form streaks on the car body after washing. In addition, the consumption of detergents and polishing wax is reduced. |

The use of a magnetic converter is economically justified.The cost of servicing heating equipment or a water heater, including descaling in the heat exchanger of a boiler or boiler, with an average capacity of 4000-6000 rubles, and cleaning of pipelines - from 150 rubles. per running meter. Cleaning the boiler from scale is carried out with acids and alkalis, followed by flushing with water, creating a headache with the disposal of waste water. At the same time, without further preventive maintenance of the equipment, scale in the boiler will require new cash infusions in 1.5-2 years, depending on the hardness of the water. The cost of a magnetic transducer of nominal diameter DN12 ranges from 1000 to 1500 rubles. At the same time, the device will operate for at least 10 years with practically no loss of magnetic field density, without requiring consumable reagents, chemicals, or energy costs. Let's continue the economic theme. Take, for example, the well-known descaler in the washing machine from TV commercials. 1 pack of funds costs about 300 rubles (for 3 months), i.e. 12,000 rubles for 10 years! You can buy a new washing machine. a magnetic water converter for a washing machine costs about 600-800 rubles. Conclusion: magnetic water treatment is an effective, environmentally friendly and cost-effective way to protect against scale.

Types of magnetic transducers: Magnetic water converters UDI-MAG (Italy) against scale formation for washing machines and dishwashers

Magnetic water converters UDI-MAG (Italy) against scale formation for water heating and heating equipment

Magnetic water transducers UDI-MAG surface-mounted type for pipes made of plastic and metal.

Descaling

The second direction that ensures the maintenance of the cleanliness of heat exchangers is their periodic descaling. This applies to both household and industrial appliances.

There are several basic ways to descale equipment. Let's list the main ones: chemical washing, mechanical cleaning, hydrodynamic cleaning, electric discharge cleaning. Let's briefly describe these methods.

Chemical washing

Chemical flushing means the dissolution of scale in the equipment due to the circulation of a heated acidic or alkaline solution in it.

In general, a closed loop is created, which includes: the object to be cleaned, a chemical pump, an intermediate tank and acid-alkali-resistant hoses.

Pictured: chemical flushing of a domestic gas boiler

An acidic solution, for example, heated to a certain temperature, circulates in a closed circuit for several hours, due to which the scale dissolves and the equipment is washed. As a rule, for chemical washing, hydrochloric, sulfuric, orthophosphoric and sulfamic acids are used.

The scheme of the chemical reaction during chemical flushing of equipment with sulfamic acid, for example, is as follows:

CaCO3 + 2NH2SO3H Ca (NH2SO3) 2 + H2O + CO2

Concentrates of low molecular weight acids (LMAs) are also used. In some cases, for example, to prepare equipment for start-up and clean it from industrial pollution: oils, rust and scale, caustic alkalization is used.

Chemical flushing is indispensable for hot water tube boilers such as KVGM, PTVM, NR, ZIO of Russian production, as well as fire tube boilers of all types Viessman, Bosh, ICI, Loose and other manufacturers. This is due to the fact that, structurally, these boilers do not have open access to their pipes, which is why their acidic washing becomes the only possible way.

Mechanical descaling

One of the most common and well-known methods of descaling boilers and other equipment. The method consists in the fact that a mechanical cutter (drill, cutter) is inserted into the pipe to be cleaned, which rotates in the pipe due to an electric or air drive.Due to mechanical rotation, the sharp edges of the cutter effectively clean off the existing scale layer. However, with this method of cleaning, it is possible for the roller cutter to act unnormally on the surface of the pipes being cleaned, which in some cases can lead to a thinning of their walls. Despite this, the method has its many supporters, and our company has equipment for mechanical cleaning available. The method is used for descaling steam boilers such as DE, DKVR, KE, ShB, E, tubes of heat exchangers in the sugar, chemical industry, etc.

Hydrodynamic descaling

The principle of hydrodynamic cleaning is based on the fact that water, under high pressure, is supplied through a high-pressure hose and a nozzle into the pipe, which ensures its descaling. This method is effective for equipment that has open access to the pipes to be cleaned - heat exchangers, boilers, steam boilers E, DKV, DE, KE.

Pictured: hydrodynamic flushing of the heat exchanger with a high pressure unit (GUVD)