Features of insulation

First of all, it should be noted that there are two technologies for external insulation of wooden houses:

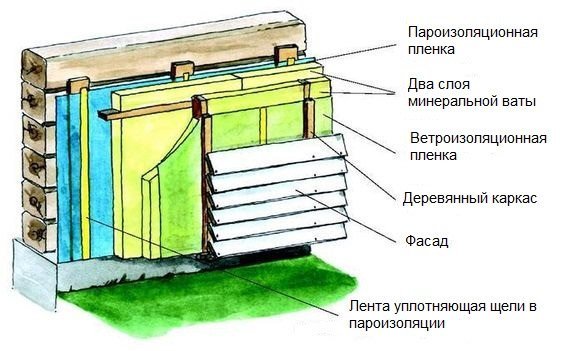

- hinged (ventilated) facade - the principle of this technology is to install the frame on the walls, which is subsequently sheathed with siding, clapboard or other finishing material. At the same time, the insulation is located in the space between the wall and the finishing material. This technology is the most preferable, since wet works are excluded. In addition, the facade is stronger and more durable;

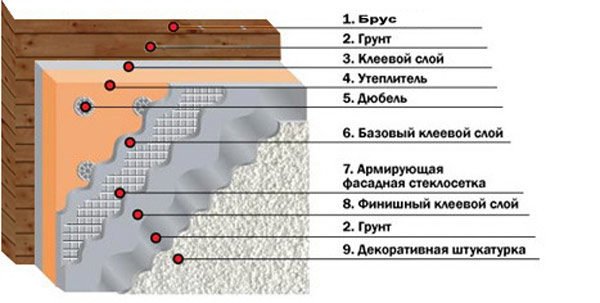

- wet facade - in this case, the walls of the house are pasted over with insulation, after which they are plastered using a special technology.

Below I will tell you how to properly insulate a house in both cases.

The scheme of the device of the curtain facade

What are condensate traps and how they help to increase the heat transfer of the heating system

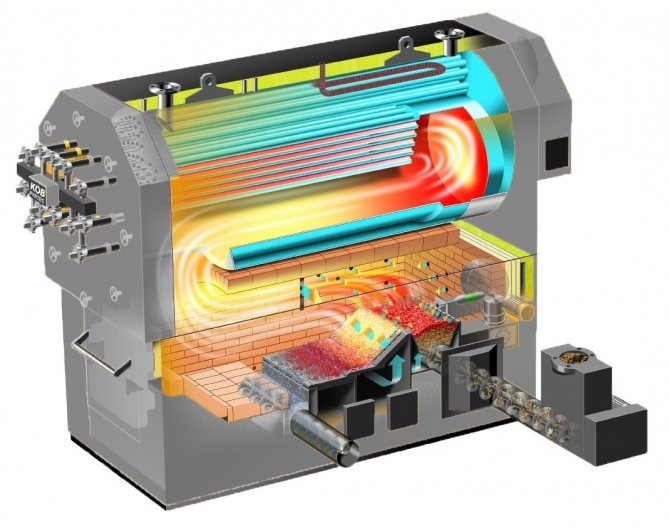

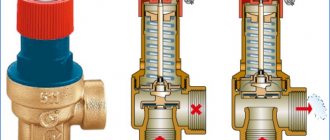

They are also called "steam trap" or in English Steam Trap. These are devices for automatic condensate drainage, the task of which is also not to release steam. Condensate in steam heating systems reduces the efficiency of the entire system, narrowing the working cross-section of the pipes, lowering the steam temperature, provoking the occurrence of water hammer. By installing steam traps, you will significantly increase the thermal and economic efficiency of the system, and save money on fuel and repairs.

You can find out more about steam traps, how they work and the benefits of using them on our catalog page.

Video: the principle of operation of the steam trap

Frame construction

1 - bars; 2 - the gaps between the bars for ventilation; 3- bars around doors and windows; 4 - indent from the floor and ceiling for ease of installation of the lining; 5 - pegs for installing skirting boards

Correct fastening of the lining on the walls inside and outside the house presupposes the preliminary arrangement of a special lathing for it, which is the basis for the formed surface of the coating. Most often, such a base is made from pre-prepared and well-dried wooden beams, the section of which is selected depending on the type of finishing material (for finishing inside or outside).

Please note: The external lining differs from the same products for finishing inside the house only in characteristics, so that their difference cannot be detected in appearance.

If necessary, instead of a base made of beams, a frame made of metal profiles can be used. Installation of individual elements of the frame can be carried out both vertically and horizontally. Their orientation in space depends on which type of cladding you have chosen. With their vertical arrangement, individual bars or frame profiles must be fastened horizontally and vice versa.

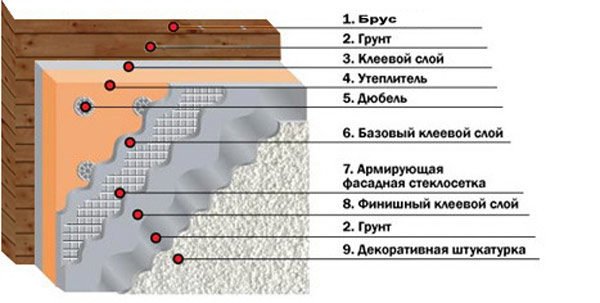

Wet facade

The main stages of installation of a curtain wall

Materials (edit)

| Materials (edit) | Features and purpose |

| Insulation | The optimal solution is mineral wool. I must say that people are often interested in whether it is possible to insulate the walls of a wooden house with foam plastic? In principle, the use of foam is allowed, however, it should be borne in mind that this material is quite flammable, moreover, it does not allow steam to pass through, which will negatively affect the indoor microclimate. Therefore, it is better to overpay a little, but still use mineral wool for these purposes. |

| Stands for the frame | As a rule, beams or even boards are used. You can attach them to the wall using metal corners or brackets.I must say that as an alternative to boards or beams, you can use a profile that is used for mounting drywall. |

| Vapor barrier film | Protects the insulation from getting wet. |

| Finishing material | It can be lining, block house, siding or any other facade material. |

| Mezhventsovy insulation | Jute tow is usually used, however, you can fill the gaps with special foam or other suitable materials. |

| Wood preservative | Protects walls from the negative effects of moisture, decay and other biological influences. |

Mineral mats

Before making a purchase, you should calculate the square of the facade, and then calculate the materials. At the same time, keep in mind that they should be purchased with a small margin so that you do not have to interrupt work later.

Filling the gaps in the house

Facade preparation

Before insulating a wooden house from the outside, carry out the following preparatory work:

- dismantle all attachments that can interfere with work - these are ebb, visors, window sills, antennas, etc.;

- then treat the walls with antiseptic impregnation;

- at the end of the work, it is necessary to fill with insulation all the gaps between the joints, if any.

Wireframe example

The next stage is the installation of the frame. The instruction looks like this:

- start installation of the frame with the arrangement of the ventilation gap. To do this, attach boards about two centimeters thick to the walls. You can arrange them both vertically and horizontally, the main thing is that later you can attach racks to them;

- then a vapor barrier film is attached to the boards with a stapler. It must be overlapped and stretched so that a space forms between it and the wall. It is advisable to glue the joints of the film with tape. I must say that the network offers many schemes for wall insulation without a ventilation gap, however, in this case, moisture can accumulate in the space between the wall and the insulation, which leads to negative consequences;

- after that, the racks are installed. You should start with the installation of the two extreme racks, between which the ropes are stretched, which serve as beacons for the intermediate rails. The end posts are installed at the same distance from the wall, strictly vertically. If you use boards as racks, then fix them on the walls with metal corners and self-tapping screws, as shown in the photo above. After that, install intermediate slats, which are located in increments of one to two centimeters less than the width of the mineral wool slabs.

Laying mineral wool in the space between the racks

Then, heat-insulating material should be laid in the space between the racks. Mats should fit snugly to each other and to the racks so that no cracks form in the insulation;

- then a vapor barrier film is attached to the frame. As in the first case, it must be overlapped. The film can be fixed using horizontal slats, which will additionally hold the insulation;

This completes the insulation of the facade with your own hands.

Siding installation

Frame sheathing

The final stage of the work is the frame sheathing. As mentioned above, there are several finishes. If you do not know what material is better to sheathe the facade, then focus primarily on cost, practicality, individual preferences, etc.

For example, the lining is an environmentally friendly material, moreover, it allows you to preserve the attractive appearance of a wooden house. Vinyl siding is more practical, easy to clean and requires no maintenance.

So, if you decide to use siding for cladding, then the work is carried out in the following sequence:

- Before attaching the panels to the wall, it is necessary to install a starter profile, which is located horizontally around the perimeter of the house.In this case, you should leave a distance from the ground or blind area to the profile of about 10 cm;

- then corner profiles are installed in the corners of the house;

- after that, the first row of panels is installed. The lower part of the siding is inserted into the starting profile, and from above it is attached to the crate with self-tapping screws;

- according to this scheme, the whole house is sheathed with siding;

- before installing the last panel, the finishing profile should be fixed;

- at the end of the work, additional elements are installed - slopes, ebb, etc.

This completes the siding of the facade. I must say that the lining is attached approximately according to the same principle, the only thing is that a profile is not used for its installation.

Wet facade device diagram

Installation of a wet facade

Let's take a closer look at each of these stages below.

When choosing what kind of insulation it is better to insulate the walls, in this case it is also better to give preference to mineral wool. Of course, in addition to insulation, some other building materials should be purchased:

- glue for mineral wool;

- dowel-umbrellas;

- fiberglass reinforcement mesh;

- perforated corners

- decorative plaster;

- primer;

- facade paint.

After preparing all these materials, you can get to work.

Bonding mineral mats to the wall

Wall insulation

As in the previous case, the work begins with the preparation of the facade. This procedure is performed according to the scheme described above.

Then the walls are glued with mineral wool for plaster:

- first of all, you should prepare the glue, according to the instructions on the package;

- then apply the adhesive to the mineral mats with a notched trowel. If the walls are uneven, the mortar should be applied with "bloopers", which will allow you to adjust the position of the slabs relative to the wall.

Applying glue to mineral wool

In the process of gluing the mats, use a building level, and also stretch the beacons so that all the plates in each row are in the same plane;

- according to this principle, all walls of the house are pasted over;

- then the mineral wool is additionally fixed to the wall with umbrella dowels. To do this, drill holes in the wall directly through the insulation and hammer the dowels into them with a hammer. Umbrella caps should be slightly recessed;

Installation of dowels

- after that, you need to paste over the window openings with mineral wool. This procedure resembles the installation of slopes - cut the cotton wool on the panels of the required dimensions and paste over the openings with them. Dowels are usually not installed on window slopes, but they must be installed on door slopes.

- then you need to check the quality of the work done by applying the rule to various sections of the walls. If there are bumps on the wall, they can be removed with a special float;

- then glue the perforated corners to all outer corners using the same glue;

- at the end of the work, glue all the dowel caps with glue so that in the end the facade has a smooth surface.

In the photo - gluing the mesh to mineral wool

Reinforcement

The next stage is reinforcement. In fact, this is a rough plastering. It is carried out in the following sequence:

- Prepare the mesh by cutting it into the correct size canvases. In this case, keep in mind that on the wall it should overlap about 10 cm;

- then cut the canvases for the slopes;

- then glue the mesh to the slopes. To do this, the glue should be applied in an even layer several millimeters thick on the surface of the mineral wool, and then immediately apply the mesh. To "drown" the mesh in the solution, draw a spatula over it from above, as shown in the photo above;

- after reinforcing the slopes, according to the same principle, the mesh is glued to the walls;

- after the surface has dried, the adhesive is applied again in a uniform thin layer. In doing so, use a wide trowel to remove any existing irregularities on the surface of the walls. This procedure is carried out according to the same principle as filling.

Decorative plastering

Air heating pipes

Our Western friends from America never cease to amaze us. One of the novelties in the house heating segment is air heating with gas boilers. In this case, air, which is heated by gas, acts as a heat carrier. Only contact occurs through a special heating element. Operating principle:

- gas heats the metal;

- the metal gives off heat to the air;

- the fan blows air through the pipes into the premises.

There should not be any special problems with the choice of pipes for individual heating with air. These are either thin-walled metal products or soft foil corrugations. That is, everything that is applicable for air conditioning systems is suitable.

There is no pressure and high temperature in such circuits. The difficulty is that this type of heating must be provided already at the stage of housing construction.

Air heating piping

Air heating pipes are often laid in walls or ceilings. It should be noted that it is quite bulky, while making a lot of noise during operation. There are several options for circulating warm air:

- forward flow;

- closed recirculation;

- recirculation with air make-up from the street.

For more information about these processes, as well as about air heating of housing in general, read our article on air heating systems at home.

Preparing the wooden base

To obtain a properly equipped frame made of beams, you will need to prepare the following consumables and tools:

- a set of bars with a section of 30 by 30 mm;

- trimming thin boards used as substrates for bars;

- a set of screws and dowels;

- hacksaw or jigsaw;

- screwdriver;

- electric drill;

- a set of chisels and screwdrivers;

- hammer (mallet).

In addition, you will need a tape measure, a corner, a set of plumb lines and a building level. It is recommended to start the installation of the lathing with the fastening of the extreme frame bars, after which all other bars are attached between them (with a step of about 50-60 cm).

You can properly prepare a flat surface by placing pre-prepared planks under the bars in the required places. The correctness of the frame is checked using a level and a plumb line. Stuffing of all intermediate beams is carried out taking into account the framing of window and door openings, which is necessary to fix the cladding elements.

How to establish the slope of the pipeline in practice?

The optimal method is to use a bubble level with additional risks. When a flask with a bubble has 3 lines on all sides, this level will be ideal. Each dash corresponds to a slope of 1 cm / m. This unusual tool is attached to the top of the pipe. Then, using the shims, it is necessary to set the slope of the pipeline so that the bubble touches the required mark.

You can also use one of the following technologies: • Measurement of the distance from the horizontal plane of the ends of the section. The ratio of the height of the top side to the length of the pipeline corresponds to the required slope ratio. • Installation of 2 level marks at the extreme points of the route. It is necessary to pull a string or thread between them and navigate along it in the process of drawing up the pipe. • The most convenient method is to use a laser level and a level to align the desired plane. This will be the best option if you are laying a pipeline in a groove and stitching it into the walls of a house using a box.

Vapor barrier device

When installing insulation using fiberglass insulation, they use respirators so that flying small particles do not get into the respiratory tract

Before stuffing the elements of the lining, if desired, it will be possible to organize the insulation of the walls of the house (inside and outside) by laying mineral wool plates between the base beams.Insulation plates, pre-cut to the size of the cells of the frame, are simply placed between the bars (sometimes, for reliability, they are fixed with special brackets or glued).

Upon completion of the installation of the insulation plates, a special film is laid on top of it, used as a hydro and vapor barrier and avoiding the formation of condensation. The protective vapor barrier is fixed to the frame elements of the crate with a construction stapler. When installing it, make sure that the film to be laid is turned with a rough surface towards the wall.

The walls are preliminarily covered with a material that prevents moisture from entering the insulation from the inside of the house. As a vapor barrier, you can use plastic wrap or some other more modern analogue. In the event that the walls are thick and assembled from logs, the material can be fixed directly to them.

In this case, there will be enough free space between the crowns for effective ventilation. If they are knocked down from boards or made of timber, you will need to arrange an additional gap for ventilation. In this case, the film is stretched onto thin slats pre-fixed to the wall.

For oven heating

If you have a stove, take your time to get rid of it. It is unlikely, of course, that someone has a large Russian stove with a stove bench in their house, but small stoves are still quite common. And it turns out that such a novelty as heating by air is not really a novelty. The principle of stove heating is that the heated air passes through specially equipped channels in the walls. This is the same direct flow, only it is not a gas boiler that acts as a heater, but a wood stove or fireplace.

In addition, you can improve an existing furnace and add a water heating circuit to it. For this, a water collector is placed above the firebox, in which the coolant is heated. Then it is carried through the pipes to the radiators. What pipes can be used for heating the stove:

- metal-plastic;

- PP;

- PEX;

- PVC;

- steel;

- copper.

In other words, everything is suitable as for conventional water heating. The difference is only in the form of a heater. Let's not forget that many autonomous circuits run on solid fuel and the principle of operation of such systems is the same.

Self plating

Do-it-yourself wall cladding with clapboard should be made taking into account the chosen direction of laying the material, which can be mounted in the following ways:

- horizontally;

- vertically;

- diagonally;

- in a mixed way.

Fastening the lining horizontally is a classic version of its installation, traditionally used when decorating the interior spaces of a house and allowing you to visually expand their perception. A significant disadvantage of this mounting method is the high probability of dust and moisture accumulating at the joints. To avoid this, the installation of individual elements of the decorative coating is carried out in such a way that the grooves in the joints of the boards are directed downward.

With vertical installation, it is possible to achieve the effect of visually raising the height of the room to be finished. That is why this method of fastening is most often used when decorating attic rooms with a low ceiling (installation is carried out from the most difficult corner).

The last two options for laying lining, despite their aesthetics, are considered quite difficult for independent execution and are used to decorate rooms and facades of buildings only in rare cases.

Scheme of mounting a lining on a wall from a bar

When laying horizontally, installation starts from the ceiling, and when they are placed vertically - from an angle that requires the boards to be adjusted to size (trimming them).

Special removal should be given to the installation of the first covering board (this requirement also applies to the installation of the outer lining), which determines the quality of the preparation of the entire decorative structure. It is set strictly in level, and then fixed on the base at several points.

To obtain a high-quality and solid coating, the boards or panels to be laid are best fixed on the beams using special clamps (that is, in a secret way). After installing the first panel, the next blank is inserted into its free groove, fixed on the base in the same way.

Before installing the last panel, it is sized using an electric jigsaw or a hacksaw. The gap remaining at the floor is subsequently closed with a plinth.

Structural joints and corners of the coating are finished with special decorative slats and corners.To control the correct laying of the finishing material, it is necessary to periodically use the building level.

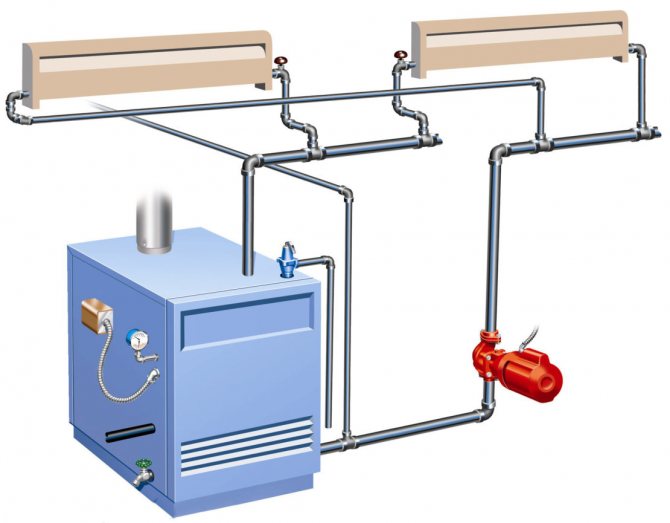

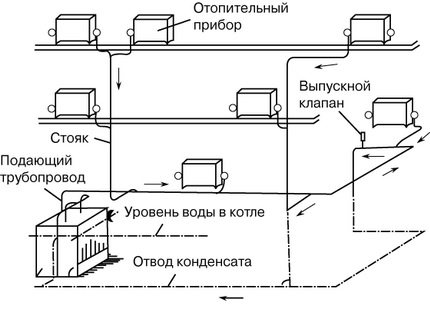

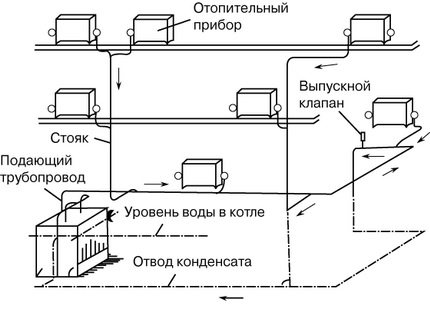

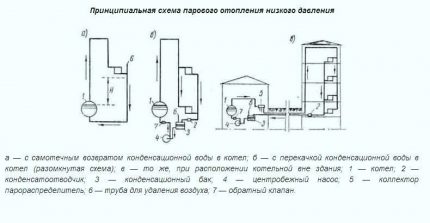

Varieties of the heating system

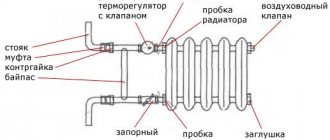

In practice, you can find a fairly large number of variations in steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, steam moves continuously through the pipe. In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensation. To avoid obstacles in the path of the coolant, the pipe diameter must be large enough.

It happens that steam does not partially condense and breaks through into the condensate pipeline. In order to exclude its penetration into the branch intended for the drainage of condensate, it is recommended to install condensate drains after each radiator or group of heating devices.

A significant disadvantage of the one-pipe system is the difference in the heating of the radiators. Those located closer to the boiler heat up more. Those further down are smaller. But this difference will be noticeable only in buildings that are large in area. In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature equal in all radiators.

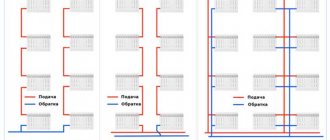

But at the same time, the consumption of pipes increases significantly. Like water, steam heating can be single or double-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. Heating wiring also differs. Three options are practiced:

- With top wiring. The main steam line is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, at the very floor, a condensate line is laid. The system is the most stable and easiest to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves along the same pipe, which should be slightly larger than the usual diameter, and condensate moves in the opposite direction. This provokes water hammer and depressurization of the structure.

- Mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in a top-wired system, thus maintaining all its advantages. The main disadvantage is the high risk of injury due to easy access to the hot pipes.

When arranging a circuit with natural compulsion, it must be remembered that the steam line is mounted with a slight slope in the direction of steam movement, and the condensate line is for condensate. The slope should be 0.01 - 0.005, i.e. for each linear meter of the horizontal branch, there should be 1.0 - 0.5 cm of the slope. The inclined position of the steam and condensate lines will eliminate the noise of steam passing through the pipes and ensure free drainage of condensate.

Steam heating systems are built according to a one-pipe and two-pipe scheme. Among the one-pipe, options with horizontal connection to heating devices prevail.In the case of constructing a circuit with vertical connection of devices, it is better to choose a two-pipe version (+)

According to the level of internal pressure of the system, two main types are distinguished:

- Vacuum. It is assumed that the system is completely tight, inside which a special pump is installed to create a vacuum. As a result, steam condenses at lower temperatures, making the system relatively safe.

- Atmospheric. The pressure inside the circuit is several times higher than atmospheric pressure. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system heat up to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

The figure shows a diagram of an open-loop steam heating system

Types of panels for raw materials

In total, there are two main types of lining, depending on the raw material - wood and PVC. To talk about which option should be preferred, and how plastic differs from wood, you can only study their features.

You can also sheathe the house with plastic panels.

Features of plastic clapboard:

- long service life (no decay process);

- no need for care;

- external plastic lining is not affected by the environment.

Features of wooden lining:

- elegant design;

- high rates of sound insulation;

- thermal conductivity is low.

Lining made of wood

Lining made of wood, also known as lining for outdoor decoration, can be divided into a simple version and eurolining. The separation is based on the use of estimates for comparison with generally accepted standards.

The main standard for the production of this material is GOST 8242-88, abroad DIN 68126. At the same time, import indicators are somewhat different from Russian ones due to external indicators of wood, more deliberate geometric properties, which cannot but lead to the fact that the price of the material is significantly above.

The manufacturer is obliged to indicate the conformity of products to regulatory documents

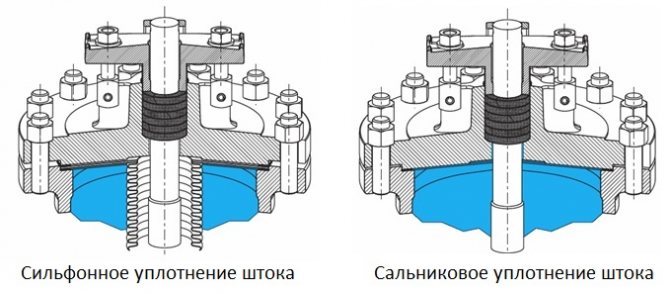

What are the types of steam traps

Below we will look at the main types of modern steam traps. If you are in doubt which type or model to choose, please contact us at “RU100” company - we will select! Our contacts are here.

Float steam traps

These are mechanical steam traps, the principle of which is based on the difference in density between condensate and steam. The condensate is located in the lower part of the trap body, and a float connected to the valve floats in it. With the accumulation of condensate, the float floats higher and higher and opens the valve through which the condensate is discharged. When the steam trap is completely filled with steam, the valve is closed and the steam does not leave the housing. Non-condensable gases (air) are also removed.

They have a number of advantages over other types of condensate drainage devices: high throughput, air removal, stable operation even with small volumes of incoming condensate, continuous drainage, ease of operation, etc. Of the shortcomings, only sensitivity to low temperatures can be noted (you need to insulate) or use it indoors. These steam traps are used for low and medium pressures (up to RU40).

Example of a float steam trap - ADCA FLT17 threaded dP = 4.5 bar

FLT17 is a ball float steam trap with built-in thermostatic valve (for the removal of air and other non-condensable gases). Designed for medium and high pressure systems. Typical applications are heat exchange equipment, steam-jacketed vessels and other applications with continuous condensate drainage. Manufactured by the Portuguese company Valsteam ADCA.

- Permanent condensate drainage. The condensate is discharged at the saturation temperature. Unaffected by sudden changes in load and pressure drop

- This modification has a threaded connection to the system. Flange versions are also available.

- Version for pressure dP = 4.5 bar. Modifications for other pressures are available:,.

- Equipped with a proprietary air and non-condensable gas evacuation system.

The principle of operation of the air and non-condensable gas removal system in ADCA float steam traps

When the steam system is started up, cold air will initially flow through the pipes and the air vent valve will open, preventing air from being trapped in the system. Float steam traps from the Portuguese manufacturer Valsteam ADCA are equipped with an air and non-condensable gas evacuation system. It consists of a thermostatic element and an associated bimetallic venting valve. Such a system has increased reliability, which is important for systems in which water hammer can occur.

- As hot steam enters the pipeline, the thermostatic element will expand by closing the air vent valve: steam will not leave the condensate drain.

- If the body of the float steam trap is completely filled with condensate, it will also be discharged through the vent valve: the valve will open under the cooling effect of the condensate.

Inverted Bowl Steam Traps

Click to go to the product in the catalog

If in the previous type of steam traps the float was closed, then here an inverted glass acts as a float, which is filled with condensate and steam. If the float is filled with steam, then the valve is closed, but with an increase in the amount of condensate in it, the float loses its buoyancy, lowers, opening the condensate outlet valve.

Inverted bowl ADCA steam traps also extract air. There is a small drainage hole at the top of the float for this. Coming out of the glass, they remain in the upper part of the steam trap body. When the drain valve is opened, they are immediately drained out before condensation begins to drain.

Example - ADCA IB12 and IBB12 inverted bowl steam trap made in Portugal

Recommended for use in systems with increased requirements for efficiency and reliability. Works cyclically. Suitable for medium and high pressure systems. Flanged or internal thread connection.

Basic properties

- Discrete condensate drain, condensate is removed at saturation temperature.

- Unaffected by water hammer and vibration.

- With a sharp drop in pressure in the system, the water seal may boil out and steam may pass.

- Built-in filter (model IBB12).

Bimetallic steam traps

Click to find out more

In this type of steam trap, the separation of steam from condensate is carried out due to the difference in their temperatures using a bimetallic plate (consisting of two different metals). When heated, the metal expands, but the two metals have different degrees of deformation when heated. Due to this, the bimetallic plate bends in an arc. When there is hot steam in the trap body, the plate is bent and closes the outlet valve. When condensate or air - the plate is flat and does not close the valve through which they are discharged.

Example - bimetallic steam traps ADCA BM140 made in Portugal

BM140 is a bimetallic condensate drain with the function of venting air from steam systems. It is mainly used in systems where subcooling of the discharged condensate is required, satellite pipelines, steam jackets of tanks or as an air vent in steam systems.

The connection is flanged, threaded, butt weld and overlapped.

Basic properties

- Permanent condensate drainage. Condensate is discharged supercooled.

- Can be used as an air vent from steam systems.

- Unaffected by water hammer and vibration.

- Built-in filter.

Thermostatic steam traps

Click to view the model

This type of steam trap also works due to the temperature difference between the incoming steam and condensate. But here the control element is not a bimetallic plate, but a capsule or bellows, to which the drain valve spool is attached. Inside the capsule is a liquid (usually a mixture of alcohol and water) that expands and contracts as the temperature rises or falls. When there is steam in the body of the thermostatic steam trap, the valve is closed. When condensate or air - the capsule cools and contracts, the valve opens, condensate is discharged.

Example - thermostatic steam traps ADCA TH32Y

TH32Y is a thermostatic condensate drain with a function to remove air from steam systems. Designed for use in systems such as cooking kettles, sterilizers in the food, chemical and other industries. Connection to the pipeline - internal thread or flanged.

- Permanent condensate drainage, condensate drainage is subcooled, depending on the type of capsule, by a value from 5 ° C to 30 ° C.

- Built-in filter.

- Options: LC-reduced bandwidth. Built-in non-return valve. Drain valve

- Working medium: Saturated water vapor.

- Versions: TH32Y, TH32Y-CK (built-in non-return valve)

- Sizes: DN1 / 2 ″ –1 ″; DN15 - DN25.

- Connection: female thread ISO7 / 1 Rp (BS21), flanged EN 1092-1 PN40, ANSI install in any position.

Thermodynamic steam traps

Click to go to the product

The simplest type of steam trap. The only moving part is the disc, which is also the control element. Being in the body of the steam trap, it experiences increased pressure when steam enters the chamber. Under pressure, it leans against the seat, blocking the outlet. When condensation begins to enter the body, the disc moves away from the seat, the condensate is discharged.

Air entering with condensate can cause the disc to seal off when there is a sudden pressure drop. To avoid this, air vents are installed in front of the device.

Example - thermodynamic steam trap ADCA DT46

Used in medium and high pressure systems, including for tracing steam lines. It is lightweight and lightweight, easy to install. The insulated cover ensures stable operation and makes the trap resistant to the harsh environmental conditions that could affect normal operation. The only moving part is the disc. Does not require tuning across the full range of workloads. Connection - flange. There is another version with a threaded connection.

- Heat insulating cover.

- Use with superheated steam is allowed. The seat and disc are replaceable without dismantling the steam trap.

- Not susceptible to water hammer and vibration. Maintenance-friendly built-in filter.

Condensate drain for compressed air.

Click to find out more

A separate group of steam traps that are capable of operating at elevated pressure. Used to drain condensate from pneumatic pipelines. Traditional installation locations are after compressors, separators, air coolers. The principle of operation is the same as with float steam traps, or with an inverted bowl.

Float steam trap ADCA FA20 for compressed air (Portugal)

- Serves for automatic drainage of condensate from compressed air systems.

- Connects to female BSP threads.

- The maximum pressure is 40 bar.

Preparing the wooden base

Before you start choosing a material for cladding, you should study a few rules:

- To avoid further deformation of the material, which occurs as a result of shrinkage and leads to the formation of cracks, you should choose the type of lining, the moisture content of which will lie in the range from 10 to 15%;

Checking moisture with a moisture meter

- Be sure to inspect the material for wormholes and foreign spots;

- The number of knots in the selected material should be minimal.

Conifers are preferred

Installation stages

- Vapor barrier fasteners;

- Installation of the frame itself;

- Installation of thermal insulation;

- Waterproofing;

- Erection of the frame of the second;

- Clapboard exterior.

Vapor barrier fasteners

Initially, you should choose a material that will act as a vapor barrier, usually roofing material, aluminum foil or even ordinary plastic wrap are used for these purposes.

Upholstery with vapor barrier foil

A prerequisite is the presence of ventilation of the facade of the house, for which the vapor barrier layer is nailed directly to the slats nailed to the wall. The slats should be fixed at a distance of one meter, and their width should be about 2.5 centimeters. For additional ventilation, holes (20 mm) are made at the bottom and top between the slats.

Installing the frame

The frame can be made with your own hands from the boards, fixing them to the wall of the building in an upright position. The thickness of the boards should be in the range of 40-50 mm, and the width is about 10 centimeters.

The distance between the boards must be left less than the width of the insulation sheets by 1-2 centimeters.

Thermal insulation placement is a further stage, which requires finishing the house with clapboard outside.

It happens through the following steps:

- Installation of layers of mineral wool occurs without gaps between them;

- To achieve this, it is necessary to lay two layers of mineral wool at the same time, thickness 50 mm;

- The main feature of the masonry is that the joint of the lower slabs is covered with the middle of the upper layer, while, due to natural elasticity, additional fasteners are not required, which can be seen from the photo.

In the photo - the use of waterproofing materials

- In order to prevent moisture from entering the house, a waterproofing film should be installed, which is mounted on top of the thermal insulation layer;

- Fastening of the film is carried out by means of construction brackets to the boards;

- Leaving an overlap of about 5-10 cm, you should glue it with tape, which will allow you to get the best effect.

According to the steps described in the instructions above, then you should start installing the second frame.

- The slats should be nailed onto the boards of the first frame on top of the hydrofilm. Their thickness should be 2-3 cm, width 0.5 mm. This enables additional ventilation and removal of condensate on the hydraulic film;

Timber frame for panels

- To prevent rodents and insects from entering the space below, it should be sealed with a metal mesh.

The final stage is the external wall cladding with clapboard:

- The process begins with the preparation of the boards of the required length, it should start from the bottom, while the starting board is placed with grooves up, a prerequisite is the use of a level to ensure its even position;

- After making sure that the board is secured, you should fasten it with nails (clamps). The workpiece must be leveled before fastening;

Installation on clamps - kleimers

- Next, the second lining sheet is installed according to the standard groove-tenon system. In order for the spike of the upper board to fit tightly into the groove of the lower one, a wooden hammer should be used;

- After securing the second board, you should insert the rest.

Some installation secrets are shown in the photo.

After the lining on the outside has undergone complete installation, proceed to the vertical fixation of the boards at the corners of the boards. Here, a mandatory moment is the presence of an overlap when one comes over another.

Window platbands are formed along a similar path, the pediment is sheathed most often by horizontal fixing of the boards. Only after completing the entire sheathing process should you start painting.

What pipes for heating are

Considering pipes for heating systems, we are primarily talking about the materials for their manufacture.Naturally, different heating systems require different characteristics from the lines through which the coolant will circulate. And completely different substances also act as a coolant.

In addition, you need to understand that tubes in a heating system are not only highways with a coolant. These include chimneys. Material of pipes used in heating systems:

- metal;

- plastic.

Each of these categories is quite extensive. So, metal pipes are made from various grades of steel and non-ferrous metals. They can be thick-walled or thin-walled with different diameters.

Steel pipes used in heating systems are made of stainless steel or ferrous metal, which may have a zinc coating. Galvanizing is protected from corrosion, while being cheaper than stainless steel. Metal products are:

- smooth-walled;

- corrugated.

Corrugated pipes are flexible, while their characteristics allow them to be used even for gas supply, not to mention the transportation of liquids. Products made of non-ferrous metal (copper) are only in their usual form - smooth-walled.

Plastic pipes are made from various polymers such as:

- propylene (PP);

- cross-linked polyethylene (PEX);

- polyvinyl chloride (PVC).

Their maximum temperature is 95 degrees, with a nominal pressure of up to 25 atmospheres. Their strengths are that they:

- do not rust;

- chemically inert;

- plastic;

- durable.

We described the characteristics of all of the above polymer pipes for home heating in one of the previous articles.

Metal and ceramic products are used for chimneys. These are multilayer structures, in which insulation is provided. Based on the fact that the heaters operate on different types of fuel, it turns out that the combustion product (smoke) also has different temperatures. In addition, the condensate that forms on the walls of the chimney contains a large amount of acid. Based on this, requirements for resistance to high temperatures and acids are imposed on materials for chimneys. We talked about this in more detail in the articles about "metal-sandwich chimneys" and "coaxial and ceramic chimneys".

What materials will be needed

As a heater for wooden houses, mats made of stone or mineral wool are most in demand. It is not recommended to use polyfoam for insulating wooden structures, since it does not have vapor permeability and does not remove moisture vapor from the surface of the log house. Stone wool or mineral wool mats come in a variety of thicknesses and densities.

The denser the insulation, the easier it is to install and the longer it retains its performance characteristics. Soft and loose mats often slide down, disintegrate, forming dust harmful to health. Therefore, you should not save on high-quality insulation. Other advantages of stone or mineral wool include its incombustibility and unpopularity with rodents, in contrast to foam.

Mineral wool is an excellent tool for home insulation

In addition to insulation, two layers of film are needed: one is waterproof and protects the frame from moisture penetration. It is laid on a protected wooden surface. This film must be vapor permeable and remove moisture from the log house through the insulation to the external environment. The second is wind and water protection, it is attached over the thermal insulation.

From the outside, the insulation is closed with any facing material with the obligatory arrangement of a ventilation gap. This cladding is called a ventilated facade. Thanks to the air circulation between the cladding and the walls, the formation of fungus and mold is excluded, moisture is successfully removed from the insulation and all conditions are created for a long service of the log house and the entire building.

Laying structure of layers for insulation

In order to perform high-quality insulation of wooden walls, you will need to prepare:

- A bar with a section of 50 x 150 mm for the crate. Another option can be used. In this case, it all depends on what thickness the insulation is chosen. Its slabs must be completely recessed into the crate.

- Mineral wool is an excellent answer to the question of how to insulate wooden houses from the outside. The slabs must be sufficiently rigid. This will negate the risk of slipping in the future.

- Vapor barrier and waterproofing films. These materials are necessary to protect the heat insulator from getting wet from the outside and from the inside.

- Bars 40 x 40 cm. They will be used to attach the waterproofing film.

- Siding, block house or lining. These materials are just perfect for upholstering a wooden house.

- Means for treating walls from fungus. It is also advisable to purchase a composition that increases the fire resistance of wood.

Galvanized products

In liquid and steam heating, the temperature of the coolant is different. The temperature of the water leaving the boiler can be 90 ° C. It gives off heat in the main line, the indicator decreases to 60-70 0С. The outlet steam can have a temperature of 150 ° C. In the system, this parameter is reduced to 120-100 0С.

When installing the heating system, these indicators must be taken into account. For heat supply with a steam heat carrier, only galvanized and copper products are used.

Heating from plastic pipes is used if the heat carrier is a liquid: most often it is water or a mixture with antifreeze. Steel products will not work. The material is rapidly oxidized; after a short time, the line will become unusable. What is the characteristic of galvanized pipes?

- Galvanized steel has increased strength. The line, with the correct calculations of the diameter, can withstand the force of a water hammer, which is very important for steam heating. The crackling in the pipes should alert the household.

- The material has sufficient elasticity to withstand significant loads: elevated temperature and pressure. Pipes do not deform with constant exposure to steam that enters the pipeline.

- Products undergo a galvanizing process from both the inner and outer surfaces. The material is resistant to corrosion: does not react with water and salts.

- Zinc has antiseptic properties, which is the advantage of galvanizing.

- The products are lightweight and easy to install. Welding skills are required when using hot-dip galvanized pipes.

Galvanized pipes

Galvanized steel is used to make water, gas, electric-welded, profile pipes. Only seamless products are suitable for steam heating. Wall thickness 5.5 mm. Alloy or carbon steel is used for their production, which makes them durable and reliable. There is no risk that the seam may break at high loads. The service life is more than 50 years.

We recommend: What are the types of steam heating radiators?

During installation, pipes are cut, special devices are used. When joining parts, welding is not used. The high temperatures that are reached during welding have a negative effect on the zinc plating. It is burned. In addition, zinc vapors cause severe poisoning.

The connection is made with fittings, couplings, and tees are installed. All parts must be galvanized. Otherwise, they can rust. FMU is not used as a sealant, tow, a dye with heat-resistant properties is used.

For steam heating, it is recommended to choose pipes with thermal diffusion galvanized. The coating is applied with zinc vapor. For this, special techniques and equipment are used.

The vapors distribute the substance evenly over the entire surface of the product. This creates a protective layer of increased strength. It does not burn or deform when exposed to high temperatures during welding: it can withstand, without any changes, a temperature of 470 ° C.

Pipes have high thermal conductivity, quickly give off heat, but they also cool down in a short time.It is necessary to maintain a certain temperature of the coolant in order to create a comfortable temperature in the room. Steel heats up quickly. This means that the heating system will warm up in a short time.

Insulation of windows and doors

The question of how to insulate a private house comes down, among other things, to the insulation of openings. Of course, there should be no gaps between window frames and walls. Otherwise, the effect of rather expensive work on the insulation of the building itself will be reduced to zero. If there are gaps, they should first be sealed with concrete mortar.

The same goes for the door jamb. The canvas itself will also be nice to insulate. You can buy a ready-made door with a built-in insulator. By the way, the same goes for windows. There are always microcracks in old cracked wooden frames, through which precious heat leaves the house. Therefore, if funds allow, it is worth buying and installing new euro windows. In this case, the profile can be used wooden or cheaper PVC "woodgrain".

Insulation of the foundation

How to insulate the walls of a wooden house, we will consider below. First, let's figure out what needs to be done before that. Of course, the first step is to expand the base of the house. The cake of the walls should rest against something from below. Otherwise, the heat insulator will start to slip. For expansion, reinforcing bars are drilled into the main foundation.

Further, formwork is installed along the perimeter of the house. Sand is poured onto the bottom of the resulting "trough". Next, a footing 5 cm thick is poured. Reinforcement is installed on it and connected to the rods drilled into the main foundation. Then the filling is done. After the concrete has hardened, the formwork is removed. From above, the new part of the foundation should be waterproofed with two layers of roofing material.

In order to make the house as warm as possible, the foundation should be insulated before the walls are insulated. A very good solution would be to use polyurethane foam for this purpose. This material is quite expensive, however, since it retains heat much better than other insulators, it will be needed much less. For a fairly effective insulation, a layer of 3 to 10 cm is needed.

Of course, you can also use expanded polystyrene for this purpose. However, in this case, it is better to purchase products from trusted manufacturers. For example, the foam insulation of the Penoplex brand, the price of which is not too high (100-300 rubles), tolerates the effects of aggressive substances dissolved in the soil very well.

Scheme and order of the device

After the necessary geological surveys have been carried out and the level of the location of the groundwater has been established, it is possible to proceed with the construction of drainage on a site located on a hill.

First of all, it is necessary to exclude soil erosion by spontaneous drainage, provoked by the steepness of the slope. For this, the following construction work should be carried out:

- Install a horizontal drain at the highest point of the lot.

- Create a similar drainage system at the bottom of the slope.

- Connect both of these structures by perpendicular canals.

- From the drain located at the lower level, drain to the drainage well.

The device of the drainage system largely depends on the terrain on which the site is located. It may be necessary to install point drains for transition platforms and retaining stairs, which will then go into the linear drainage system.

Important! Even before the start of construction work, you should determine the place where the liquid will drain. You can drain water from the site into a nearby reservoir or ravine.

Following the instructions of SNiP, the parameters of the slope of the drain are correlated with the indicators of the movement of wastewater. The minimum slope of drainage pipes with a diameter of 150-200 mm is 8-7 mm, respectively.

When using trays to drain water, the slope is set so that the liquid can naturally self-clean.The filling of a tray with a width of 20 millimeters or more should not exceed 80%.

Insulating the walls: preliminary stage

So, let's start to figure out how to insulate a private house, or rather, its facades. First of all, all surfaces must be cleaned of dirt. Further, the timber or log is treated with a means that prevents the appearance of fungus. It is also worth smearing them with compounds that increase fire resistance and destroy insects.

Further, all the available slots and grooves are sealed with tow. Caulking should be done in dry weather. Instead of tow, you can use jute or hemp. These materials are pushed into the cracks using a special tool - caulking. After that, you can start actually doing the work on assembling the cake of the walls.

What you need to know about a heat insulator

You already know how to insulate wooden houses outside. Why basalt wool? This material is considered the best choice because the foam or expanded polystyrene practically does not allow moisture to pass through. Even in the presence of ventilation gaps, a lot of it accumulates under these materials. As a result, the cake loses some of its thermal insulation properties, and the log or timber begins to rot.

Even high-quality foam insulation is not suitable for cladding wooden walls. For example, the same Penoplex. The price of mineral wool is lower than that of it. Consequently, the owners of the house do not lose anything in any case. Instead of basalt, you can use glass wool.

Installation of slabs

So, we found out how to insulate wooden houses outside. How to install the plates correctly? The insulation is mounted on top of the vapor barrier film between the beams of the assembled sheathing. Unfortunately, wooden walls are often a little uneven. Therefore, gaps may form between the slabs and the battens in some places.

It is allowed to seal them with materials such as basalt, jute or flax. To prevent the slabs from falling out and slipping, it is worth additionally securing them with special plastic dowels with wide caps. If the lathing is mounted vertically, sheathe the walls with cotton wool from any corner. If the bars are horizontal, installation is carried out from the bottom up.

Usually insulation is done using a material 5 cm thick. In this case, the installation is carried out in two layers. In this case, the joints of the second are located above the center of the plates of the first. The bottom of the cake will need to be covered with a metal mesh so that mice and insects do not enter it.

Installation of waterproofing film

So, the best insulation for a wooden house is mineral wool. What material should be chosen for a waterproofing device? In this case, it is worth using a special superdiffusion membrane. This material will protect the walls not only from rain, but also from the wind. For wooden houses, it is allowed to use a waterproofing material with a vapor permeability of at least 1400 g per m3.

The film is attached directly to the batten using 40 x 40 mm blocks. This will create a ventilation layer between it and the finish. Lay the film perpendicular to the location of the battens. The overlap between the individual strips should be about 10 cm. Sometimes the joints are additionally glued with construction tape.

Calculation of the pipe diameter

For the line, you need to select pipes with a certain diameter. The indicator depends on many parameters: heat transfer of the material, the rate of passage of the coolant, the power of the heating equipment. It is difficult to calculate the pipe diameter yourself. They turn to specialists. For the calculation, certain tables are used.

According to the tables, 1 kW of boiler power is required to heat 10 m2. With an equipment power of 10 kW, metal pipes with a wall diameter of 40 mm are chosen. With a boiler power of 35 kW, the pipe diameter is 76-80 mm. For condensation, use a smaller diameter wire. Plastic is not considered for steam heating.

If you choose a product with a smaller diameter, then under steam pressure, the material may deform, the seams will not withstand a strong load and will break. If too large a diameter is selected, with a low boiler output, incomplete condensation of steam may occur. The coolant will be used ineffectively.

We recommend: How to make steam heating in the country?

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- What are the types of steam heating radiators?

- Which wood stoves are suitable for steam heating?

- What are the features of steam heating "Leningradka"?

- How does a low pressure steam heating system work?

- Features of a steam heating device in a private house

- What is the scheme for organizing steam heating of the garage with your own hands?

The basics of choosing eurolining

The finishing material is attached to the counter-lattice obtained after installing the waterproofer. There are only two main ways of fixing the lining: nails and special clamps. The first method can be considered the simplest. However, in aesthetics, such a cladding of the one made in two other ways loses a lot. After all, the heads of the carnations will be clearly visible in any case.

Therefore, the lining is often fixed on the lathing with clamps. These fasteners are first put on the lamella groove flange, and then on the timber. In this way, a very beautiful coating can be made. In the same way, a block house is attached to the crate.