Features of the arrangement of the winter water supply system

Uninterrupted water supply in the country is necessary, provided that living in the house will be year-round, and not temporary.

Sources of water:

- well;

- well.

Winter water supply in a country house is an autonomous water supply system that has both positive and negative features.

Pros:

- autonomy and the possibility of manual water intake;

- longevity of the water source;

- independent construction of a well;

- self-cleaning of the well.

Minuses:

- in case of violation of the rules for installing a water intake, freezing of system elements;

- changes in water level;

- the possibility of contaminated water ingress from the soil surface.

The winter version of water supply has a number of features:

- compulsory conservation system;

- installation under a slope;

- insulation of the water source.

The conservation system can be omitted if the residence is year-round and there is no need to periodically drain the water.

How to properly drain the water

From systems and devices: we free from water everything that is at risk of freezing, first of all - the supply water pipe, the heating system, water heaters. Do not forget about the pump or pumping station, drain and expansion tanks and water filters.

From plumbing and household appliances: washing machine, shower. Experts advise to leave cranes in an open or semi-open position.

The liquid in the knees of sinks, bathtubs, showers and toilet bowls will require special attention. Never drain them by pumping out the water plug! One of its main purposes is to prevent the penetration of the aromas that reign in the sewage system into the house. Authors giving advice of this kind on the forums assure that their septic tanks do not smell. Let me doubt this!

I have acquaintances who considered pumping liquid out of the sewer elbows to be the only correct method of preserving plumbing. Their house was not heated all winter. And in the spring, before we could get inside, we had to arrange through ventilation for at least an hour. I’m already silent about the terrible smells that have permeated the walls and upholstery ...

So what do you do with the water in your knees? Many summer residents are advised to fill in antifreeze (antifreeze) or "anti-freeze" - a liquid for washing glasses. Here, of course, everyone decides for himself what to choose, but I would not recommend using any of these tools. To varying degrees, but they are all toxic and unsafe for humans. You are planning to go to the country house more than once in winter, so why put yourself at risk and inhale toxic fumes?

Try the old folk method - a concentrated saline solution (dilute ordinary table salt in warm water until it stops dissolving) - 3 liters per 1 knee. It works flawlessly, an environmentally friendly method, I highly recommend it!

I repeat: all the manipulations for draining the water will have to be done in winter every time you leave the cottage.

Methods for arranging a winter water supply

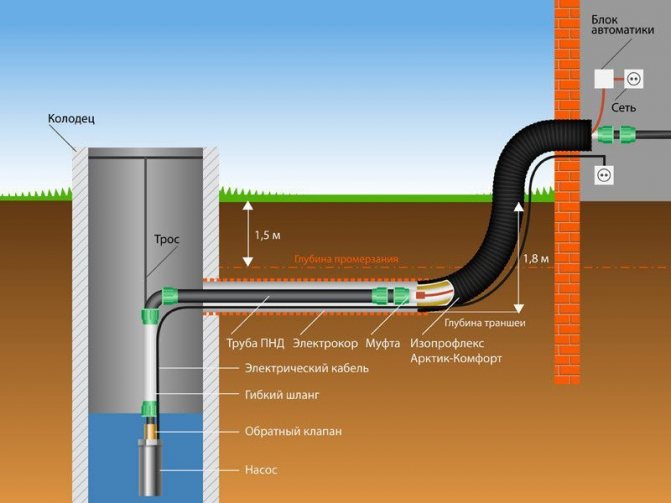

The installation of an underground pipeline should be well thought out. There are 3 ways to install year-round water supply: deepen the water supply system so that it does not freeze through, insulate the water supply system or deepen it with insulation elements. Preparation of a trench is required, into which the winter version of the water supply will be installed.

Below the depth of freezing

The freezing depth depends on the geographic location and climatic conditions. The pipe is laid below the freezing depth by an average of 0.3 m.Before determining the depth of the trench, you should study the statistics of weather conditions for the last 5-10 years.

| Variety of material | Polypropylene | Metallic | Reinforced plastic |

| pros |

|

|

|

| Minuses |

|

|

|

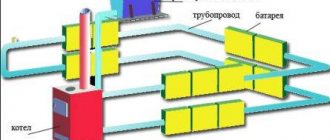

Plumbing scheme in a private house.

During the design of winter water supply from a well or well, it must be borne in mind that the fewer joints in the pipeline, the less chances of a leak. If it is necessary to dock the parts, it is necessary to ensure the tightness of the connection.

Consequences of lack of tightness:

- inaccessibility of the problem area;

- excavation of a trench;

- in winter, a break is possible.

The diameter of the pipes is selected based on the volume of water consumption and the length of the structure.

Water pipe insulation

Not one installation method provides protection against freezing of the water supply system in winter, but if you follow simple rules, you can avoid additional problems. The depth of laying the water line is 0.6 m. The trench is laid out with bricks or concrete blocks.

Pipeline insulation methods:

- extruded polystyrene foam;

- Styrofoam;

- mineral wool;

- electrical wires.

| Type of material | Extruded polystyrene foam | Styrofoam | Mineral wool |

| pros |

|

|

|

| Minuses |

|

|

|

The wires that heat the water supply are located along its entire length. The sensor regulates the temperature regime. The heating cable is available from your specialist store.

Insulation of the pipeline.

How to blow pipes in the country with a compressor?

- Connect a flexible line from the canister to the blown part of the pipeline (do not forget to remove one plug or open the tap before that, as the water will need to go somewhere);

- Close the ball valve;

- Pump the pressure into the canister with a compressor (this is done with a manual or electric compressor);

- Then it is necessary to raise the pressure in the canister to 4-5 atmospheres;

- After that, you need to stop pumping air into the canister;

- Now you need to gradually open the tap, and the air with its pressure will displace all the water from the blown system.

Organization of winter water supply

The installation of the water supply system takes place in several stages:

- Preparatory.

- Installation.

- Checking.

We insulate the pump for water supply

The water supply system completely needs insulation, including the pump.

The material for insulating equipment is the same as for insulating a water supply line:

- Extruded polystyrene foam.

- Styrofoam.

- Mineral wool.

Equipment need not be insulated if it is located below the freezing depth. The place where the water pipes and the pump join is also subject to insulation. The joint is called a pit. The pit is to be covered with bricks, and the floor is covered with a concrete screed.

We insulate the hydroaccumulator

A hydroaccumulator is a storage tank operating under pressure, the container must be tight.The inner shell of the hydroacamulator is an elastic membrane, a vulnerable element of the hydraulic system that cannot withstand sub-zero temperatures. The sheathing of the hydraulic system is made with insulation material.

Do-it-yourself thermal insulation of the accumulator.

Varieties of insulation for a hydroaccumulator:

- Extruded polystyrene foam.

- Styrofoam.

- Mineral wool.

- Basalt wool.

- Fine-mesh insulation.

We take care of water pipes

The elements of the water supply system should be selected of high quality, with a long service life.

We put the drain valve and pressure switch

The conservation system involves the installation of a drain valve. The ability to drain water from the supply system will save the water supply if it becomes necessary to be away for a long time in winter.

The pressure switch is an element of the water supply system that regulates the uninterrupted operation of the hydraulic system. After the structure is completely filled with water, the relay automatically turns off the pump until the next use.

Heating

When planning a winter water supply system, you need to keep in mind that insulation only helps to reduce heat loss, but cannot heat. And if at some point the frosts turn out to be stronger, the pipe will freeze. Particularly problematic in this sense is the section of the pipe output from the underground sewage system to the house, even if it is heated. Anyway, the soil near the foundation is often cold, and it is in this area that problems most often arise.

If you don't want to freeze your plumbing, do pipe heating. For this, a heating cable or heating plates are used - depending on the diameter of the pipes and the required heating power. Cables can be laid lengthwise or wound in a spiral.

Method of fixing the heating cable to the water pipe (the cable must not lie on the ground)

The heating cable is good for everyone, but it's not uncommon for us to have power outages for several days. What will happen to the pipeline then? The water will freeze and can burst pipes. And renovation work in the middle of winter is not the most pleasant experience. Therefore, several methods are combined - and the heating cable is laid, and insulation is on it. This method is also optimal from the point of view of minimizing costs: under thermal insulation, the heating cable will consume a minimum of electricity.

Another way to fix the heating cable. To make electricity bills less, you also need to install an insulating shell on top or fix roll insulation

Laying a winter water supply system in the country can be done using this type of insulation, as in the video (or you can take an idea into service and do something similar with your own hands).

The development of a scheme for laying a water supply system in the country is described here.

Small installation tricks

Before starting work, a diagram or a project of a water supply system is drawn up. The diagram should include all elements of the system with the calculation of the diameter of the pipes used and the number of auxiliary parts (couplings, fittings, volume of insulation material). It is better to prepare a trench for the pipeline in dry and warm weather.

Step-by-step instructions for installation:

- Project preparation.

- Trench preparation.

- Preparation of the pump and hydraulic system, check of the complete set.

- Insulation and installation of pipes in the trench.

- Installation of water intake elements in the well (it must be remembered that you will have to drill concrete rings in the well to install the water intake element, therefore, you must have an impact drill or other powerful tool).

- Connection of all installed elements to each other.

- If the wiring in the house is installed in advance, then the system is immediately checked for leaks. If the supply of water is carried out without interruption, then the trench is subject, if necessary, to further warming and covering with soil.

The tightness of the water supply structure at the joints is ensured with the help of a special silicone-based sealant.

The submersible device is lowered into the water. During water intake, the device should not be interfered with by the filtration elements used at the bottom of the well pit.

Connection recommendations

If you are going to do everything with your own hands, then the first thing you will need to take care of preparing the required equipment.

You will need the following list of tools:

- Special electric soldering iron for polypropylene pipes ("iron"). It will provide reliable welding.

- Gas key number two. It is needed for assembly using fittings (they are used in places of bending).

- Saw for metal or grinder with the appropriate disc.

- Cutter or hacksaw.

- Several shovels (shovel and bayonet) and scrap. This is useful for excavation work.

Non-freezing water supply in the country can be implemented in various ways. Therefore, we will give you only general recommendations.

So, the laying process looks like this:

- First of all, a trench is prepared (the depth is at least 2 meters, and the slope should be placed in the direction of the well). In doing so, you must achieve maximum evenness of the dig.

- Next, sand is poured onto the bottom with a layer of at least 20 cm. After that, a pipe is installed in the trench. In this case, the line must be reliably connected to the pump.

- Be sure to seal the place where the pipe comes out of the well with high grade cement (no worse than 500) and liquid glass. Such a measure will prevent the reservoir from flooding with groundwater. Attach a heating cable if necessary.

If it is not possible to create a deep trench (for example, if the ground is very solid), you can use such thermal insulation. She will save the highway from freezing

- Having checked all the joints (they must be carefully welded and sealed), we fill everything up with sand, and on top with soil (obtained from digging a trench). At the end, we thoroughly tamp everything.

Tip: mark the location of the highway so as not to stumble upon it during gardening work.

- Now you need to dig a pit about a meter deep, with an area of 80x80 cm, not far from the well. Cover its walls with bricks (or boards, having previously applied a protective compound to them). Next, you need to fill the bottom with crushed stone, or pour concrete.

- In the resulting room, you need to start a pipe coming from the pump and a supply cable. By the way, it can be laid directly in a common casing, after putting it in additional insulation.

- At the end, we insulate the pit with foam plastic or other moisture-resistant insulator.

This concludes the work. Of course, the procedure may take place slightly differently, depending on the equipment used.

The bend of the trench should be at right angles