When arranging flue gas ducts, many details must be taken into account. Including, and solve the issue of high-quality insulation. Its absence can lead to premature destruction of the chimney.

In this article, you will learn how and how to insulate an iron chimney pipe in a garage, bathhouse, private house or any other room. We will consider all the important aspects of solving this problem.

Why is the gas duct deteriorating?

The lack of insulation negatively affects the condition of the chimneys. To avoid premature failure of the smoke exhaust system, it is imperative to resolve this issue.

The main causes of breakdowns are associated with:

- Exposure to aggressive substances. When the fuel burns out, there is a large volume of elements that negatively affect the metal. First of all, these include acids. During the downtime of the chimney, aggressive substances settle on the walls of the chimney. This leads to the destruction of metal structures.

- Humidity. High humidity is present in the flue. Although water vapor escapes along with the smoke, a fairly large volume of condensate still remains on the walls of the structures.

Thermal insulation of the gas duct can prevent the occurrence of negative chemical processes that lead to the destruction of the system. If you do not take action, the condensate containing acids will damage the walls of the structure over time. The most dangerous period is the thawing period of the flue after winter.

Chimney damage factors

Conducting poor-quality thermal insulation or lack of such leads to the fact that the chimney collapses prematurely. There are two factors that directly affect the integrity and correct operation of the chimney:

- Humidity. It is constantly present in the chimney due to the fact that warm air circulates systematically in it. The water carried with its vapors condenses on the chimney.

- Aggressive chemicals. When burned, many harmful chemical elements appear. When the chimney is in operation, they are released into the atmosphere. When it is inactive, the chemical products of combustion settle in the pipe in the form of soot, thereby destroying its structure.

Chimney insulation principle

Conducting thermal insulation makes it possible to stop or avoid irreversible processes occurring under the influence of moisture and combustion products.

If you do not take the necessary measures to preserve the chimney, then the consequences can lead not only to its destruction, but also seriously disrupt the structure of the dwelling itself. Condensation, together with chemistry, gradually corrodes the material from which the chimney is made.

Humidity is especially dangerous during the spring thaw. It seems that now you will not have a question, why insulate the chimney, after the information received.

The importance of insulation

The creation of high-quality insulation of furnace or other round flue pipes is an important preventive process. Of course, this procedure will not 100% protect the structure from the negative effects of rain and other atmospheric precipitation. However, insulation of metal gas ducts can significantly extend the service life of all systems.

This operation must be carried out in order to:

- Eliminate the possibility of condensate entering the walls of pipe products, which contains hazardous chemical elements. The presence of an insulating layer will ensure their complete volatilization along with the rest of the smoke.

- Reduce the likelihood of temperature changes in the system.

- Create an energy saving effect. Arrangement of insulation reduces the rate of energy losses.The presence of this layer reduces the fuel consumption of boilers or furnaces.

- Increasing the durability of the gas duct. Insulating steel pipes helps to strengthen the structure of the flue system. The frame becomes more resistant to wind loads.

It is important to choose the right material for insulation. Only in this case can the system's resistance to low temperatures be significantly increased. Also, with its help, you can eliminate the negative impact on the roof in the form of corrugated board or slate. These preventive measures will extend the life of the chimney.

Why it is necessary to insulate the chimney pipe

There are several negative points that can be prevented by properly insulating the chimney:

- Preventing the destruction of the chimney itself.

- Prevention of roof destruction.

- Protection of the building from fire.

Combustion products contain many aggressive volatile substances. Some of them, mixing with water, form corrosive substances - acids. Moisture condenses on the cold walls of an uninsulated chimney and acids destroy the structure. It acts especially quickly on metal pipes, which literally corrode over several heating seasons.

Note! High-quality thermal insulation of metal stove pipes extends their service life by 2-3 times.

In addition to the destructive effect on the walls of the pipe of the smoke channel, condensate clogs the inner lumen during operation of the furnaces in the mode of long-term fuel burning. A black, viscous mass, with a specific smell, flows from the walls of the cooled chimney and poisons the lives of the owners. The pipe has to be cleaned frequently. This is a laborious, unpleasant task.

During intensive operation of the stove, which in our natural conditions lasts more than 3-4 months a year, the heated chimney pipe is constantly in contact with the cold roof. The temperature drop has a destructive effect on the roof of the building. Burning out or overheating of a chimney in severe frosts is perhaps the first cause of fires in the private sector.

High-quality thermal insulation prevents temperature differences between the hot products of fuel combustion and the wall of the chimney. Steam, carbon dioxide and soot leave the flue ducts unhindered, leaving it dry. The roof remains cold. When a pipe burns out, additional layers protect the roof from hot gases and sparks.

But not every insulation can be used to thermally insulate a chimney pipe.

Which material should you choose?

In order to insulate the steel pipe of the gas duct, it is necessary to take into account that the temperature of its heating can reach three hundred or more degrees. To do this, you need to use a material that is completely devoid of flammability. For this purpose, as a rule, mineral wool, slag concrete slabs or other analogs are used. In addition, the insulation process can be carried out by using a plastering solution.

It is important that the weight of the insulation material is comparable to the supporting capacity of the roof. Since items that are too heavy can damage it.

Most experts prefer mineral wool. It is lightweight and therefore ideal for this task.

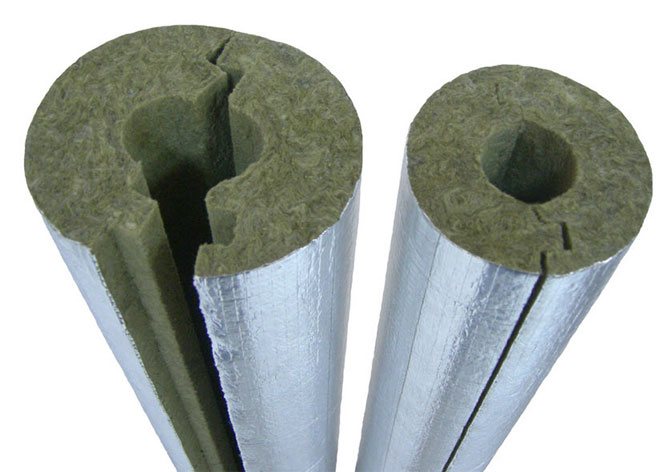

You can also purchase special cylindrical heaters. They provide an adequate level of protection for the chimney. Since their construction has a protective foil layer. The sizes of the products under consideration are different. Therefore, you can easily choose an option for a pipe of the required diameter.

Safety when insulating a chimney at a height

Before insulating a metal or any other pipe, you need to inspect the workplace to assess possible risks in order to minimize them.Pre-prepared and durability-tested ladders, slate or tile flooring boards, strong, tested ropes - all this will ensure your safety during the work.

When laying boards on slate, observe the following rule: boards are laid across the waves. If you do not have an industrial safety harness, make it from a strong and thick rope or belt. One end of such belay should be firmly fixed to a strong fixed structure of the house or roof. Clothes should not be unbuttoned, have dangling sleeves or a dangling collar, but it is best to use overalls.

When laying the chimney through the thickness of the ceiling, do not save on insulation - lay it in this place, even if the ceiling material is non-combustible: heated concrete can ignite the decorative finish of the ceiling. You do not need to lay basalt or mineral wool next to a stove or heating boiler, but such areas should be no more than 50 cm wide.If the insulation material is able to withstand high temperatures (read the instructions for it), then it is better to lay it in these places too.

How to insulate a gas duct with your own hands?

To insulate a steel pipe, it is necessary that the installation of the chimney is carried out correctly. The design must comply with existing technological standards.

The following requirements are imposed on gas ducts:

- A sufficient level of thrust occurs only for pipes with a length of five or more meters.

- The distance between the chimney structure and the roof must be at least 25 cm.

- If the roof is made of combustible materials such as ondulin, roofing felt or slate, the pipes must be equipped with a spark arrestor. Its design consists of a mesh plate that surrounds the gas duct from above. To prevent debris from getting into the spark arrester, it is closed with a special cap.

To equip the flue, be sure to observe the indicator of the fire distance between the ceiling of the room and the stove ceiling. For stainless steel structures, a distance of 1.5 meters is required.

To complete the winding of metal chimney pipes, a system diagnostic stage is required. If there are no faults, then you can start solving the problem. Use only non-combustible insulation.

Types of heaters for the chimney

The choice of heaters for gas chimneys is quite limited due to the high requirements for heat resistance and fire safety.

Obviously, popular foam sheets, expanded polystyrene and similar polymers will not work. When exposed to high temperatures, they can not only easily deform, but also ignite if a spark hits them.

We offer you to familiarize yourself with the passage of the pipe through the roof made of metal tiles

Insulation for a gas chimney must meet the following requirements:

- The minimum indicator of thermal conductivity, ensuring fire safety standards;

- Light weight to reduce the load on the roof;

- Plasticity and flexibility for simple thermal insulation of geometrically complex areas;

- Neutrality to the effects of chemical environments, precipitation and condensation;

- Long service life.

The ideal option is considered to be the device for thermal insulation of the chimney of a gas boiler using mineral heat insulators. Due to their low cost, bulk materials were previously most often used, which have lost their positions due to low efficiency and large mass.

They yielded the palm to cotton wool insulation made from minerals of basalt wool and fiberglass. These materials are characterized by high fire resistance, they are able to withstand temperatures over 400 degrees.

The class of mineral wool includes materials: slag fiber, fiberglass, stone wool.Each of the three groups is distinguished by its structure - fiber thickness and length, load resistance, moisture resistance and fire safety.

To understand the technical characteristics of mineral wool, we will consider each of the groups separately.

It is immediately important to divide the insulation into 2 groups:

- Self-sufficient - which does not need additional protection and steam, waterproofing. These include cylinders for insulation (shells).

- In need of protection - protection from the external environment is required. These include basalt wool for the chimney, EPS and the like.

Before making a choice, it is important to consider several factors:

- What is the temperature of the exhaust gases. The higher, the less the pipe needs insulation, but the material must also be heat-resistant and fire-retardant. Accordingly, a thinner thermal insulation layer can be used.

- The chimney is inside or outside. If the entire pipe runs along the outer wall of the house, it needs particularly high-quality insulation. It takes longer to warm up, which means more moisture condenses during this time.

- What the chimney is made of. If the pipe is metal, it can be insulated using heat-insulating cylinders. Brick - with basalt wool or even EPS.

So, these were the general rules to help you choose how to insulate the chimney. Now let's move on to a direct examination of each of the main materials for insulation.

Let's start with this material, which closes the question of how to insulate a metal chimney. It consists of 2 pipes, one of which is of a smaller diameter and plays the role of a chimney itself. Usually it is better to take it from high-quality stainless steel with special additives that make it resistant to aggressive acids that form in the chimney.

You can make such "sandwiches" yourself, or you can purchase ready-made shells for insulating chimneys.

When making such a heat insulator with your own hands, several requirements should be taken into account before insulating a metal or asbestos chimney pipe:

- The thickness of the insulation layer for a stainless steel pipe should not exceed 10 cm.

- If there is a high temperature of the exhaust gases in the pipeline, you should use loose basalt wool. It is non-combustible material. It has no binders in its composition, and the ignition temperature rises to 900 degrees.

If we talk about the insulation of an asbestos pipe, then it is practically no different from a metal one. It needs more thermal insulation due to the fact that it absorbs moisture better than metal.

Some people make the following mistake. Most often, when you need to create a temporary chimney. Insulation for chimneys is purchased, for example, basalt wool in rolls or mats. The chimney pipe is wrapped with an overlap and the insulation is fixed with metal tape or even ordinary tape. You can't do that!

Any mineral wool must be protected from water and wind. If you leave it open, after a while some of it will be blown out by the wind, and some will crumple under the influence of precipitation. If you want to insulate, therefore, be sure to provide a protective casing. For example, do it yourself from ordinary galvanized iron. In this case, the mineral wool, as a heater for the chimney, will last long enough.

Mineral wool

By mineral wool we mean basalt (stone) wool, because it has higher fire resistance rates. Therefore, it is recommended to use it for heat insulation of chimneys with a high temperature of exhaust gases.

It can be used both when insulating a chimney inside the attic space, and outside. If we talk about the attic, then the chimney can simply be overlaid with cotton wool mats and secured with metal strips or a tourniquet. Because there is no intense air movement and excessive moisture in the attic, basalt wool does not need protection from the outside.If we are talking about insulating the chimney outside the building, then the approach here is completely different.

When insulating with mineral wool, you should opt for high density stone wool. Usually, the area of insulation is small, so you won't be able to save a lot on the purchase. It is better to take high-quality thermal insulation for chimneys of a well-known manufacturer, such as Rokwool, Ursa or others presented in your region.

We suggest that you familiarize yourself with Fastening floor beams to an armored belt

The denser the material, the easier it is to mount it on the chimney. For fixing, we recommend using mortar instead of foam. The foam will not withstand the temperature and will break down. it is not fire retardant material. Additionally, it is required to fix the mineral wool slabs with dowels-fungi.

Extruded polystyrene foam is actively used for the external insulation of brick chimneys with your own hands. The material is highly dense and does not allow moisture to pass through. Most often, EPPS of the Technoplex and Penoplex brands are used, as the most common in Russia.

Choosing EPSP as a heater for pipes, special attention should be paid to the flammability indicator of the material. Usually it is G3-G4, which means a high degree of flammability. Some manufacturers bring this figure to G2. In view of this, EPS cannot be used to insulate brick chimneys of wood or coal stoves.

When mounting the EPS, it is imperative to leave a ventilation gap between the pipe and the foam. For this, the installation is carried out on the adhesive mixture, and not on the foam. You can read in more detail about how to insulate an EPSP chimney in our previous article on this topic.

Plaster

The use of plaster for insulating the chimney of a wood-burning or coal stove is relevant, i.e. where the gas outlet temperature is high.

You can use a special mixture for thermal insulation, sold in bags, or make a regular mortar from cement, sand and some clay.

The plastering layer should not exceed 3 cm, otherwise there is a risk of destruction. It is also necessary to lay a metal mesh for reinforcement inside the layer.

The process is quite laborious and more often it is replaced by insulation of the chimney with mineral wool or EPS, followed by lining with a profiled sheet.

How to insulate the chimney? This can be done through:

- basalt;

- become;

- wood;

- cinder block;

- reinforced concrete.

If basalt is chosen as what to insulate the chimney on the street, then it is heat-resistant and durable. Resistant to corrosion, fungi, mold. Does not burn, no harmful substances are emitted into the atmosphere. Service life is about 50 years. Basalt insulation for the chimney does not require frequent replacement. But the cost is also higher than that of “colleagues in the shop”.

Basalt insulation is the most reliable, but expensive

Another non-combustible chimney insulation is steel. Of course, steel itself will not insulate. This requires an interlayer between the chimney and the steel casing. Cheap and cheerful! A steel casing is put on from the outside, and mineral wool and the like are laid in the space between.

The cheapest way is to insulate the pipe with wood. Such a casing must have reliable waterproofing, slate or something similar is placed on top of it.

How to insulate a chimney is simple and safe? Cinder block or reinforced concrete. Reinforcement must be carried out.

When deciding how to insulate a chimney, it is important to understand that not all materials are universal and suitable for every type of stove system.

Insulation for chimneys must be selected in strict accordance with the material from which the exhaust system is made:

- if the passage for smoke is made of brick, then it is plastered or insulated with minerals;

- if the course is asbestos-cement, then it is insulated with steel, cinder block, wood;

- if the course is steel, it is protected by steel, metal concrete.

Do-it-yourself chimney insulation requires tools such as: puncher, drill, brushes, scissors, knife, screwdriver, rulers, level.

Chimney and chimney wrapping

To equip decorative stoves that do not serve as a source of heat, metal pipes are often used. Isolating them is easy. For this purpose, it will be sufficient to use a plaster mortar.

The required mixture is prepared according to a specific technology. First, water is poured into a special container. Then add the previously prepared dry mixture. Next, you need to mix these ingredients until a homogeneous mass is obtained.

With this solution, you need to isolate the surface of the structure by using a spatula.

It is distributed evenly over the entire length of the canal. Next, you need to create a fiberglass reinforcement mesh. Only in this way can the protective layer last a long time.

Next, plaster is applied to the reinforcing frame. Then the operation is repeated. Thus, the pipe receives reliable protection. Alternatively, you can use mineral wool. It is fixed with masking tape.

The main thing is that moisture does not get on the surface of the insulation. Otherwise, the material will lose its protective properties.

Thermal insulation of a brick chimney

The question of how to insulate a brick chimney has two answers - insulating the chimney with mineral wool or using plaster. Consider both options for insulating a brick chimney. Let's say right away that insulating a brick chimney from the outside using plastering on a grid is ineffective. What they do in this case:

- The chimney is cleaned from the outside;

- The reinforcement mesh is fixed.

A solution is prepared by mixing cement, lime and slag. Add water. You can use modern "warm" plaster, which is famous for its thermal insulation qualities.

The solution is applied to the brick in a layer of 2-3 cm. After drying, the next layer is applied. The extreme one is leveled and overwritten. Deficiencies are checked and eliminated. The pipe is painted with lime or chalk.

It is more reliable to insulate the chimney pipe with your own hands using mineral wool. The issue of insulation is solved as follows:

- The surface is cleaned of dirt, irregularities are eliminated;

- A frame is assembled in which the insulating material will be placed;

- Slots and gaps are not allowed;

- Then the chimney is insulated with mineral wool, and this is done with an overlap of 0.15-0.2 m;

- The joints are glued with construction tape;

- The attic section of the pipe is insulated with drywall sheets.

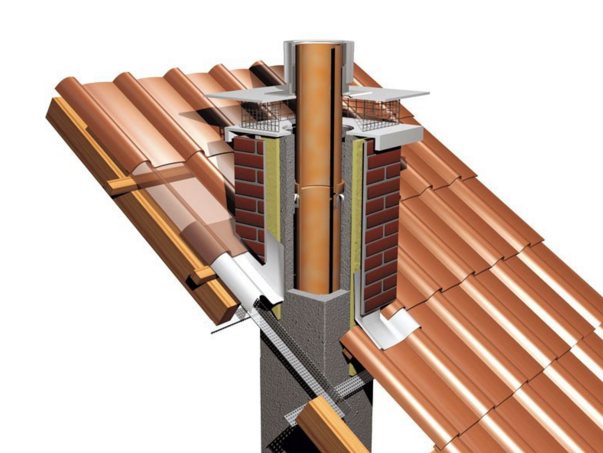

Gas boiler flue insulation

Various technologies are used to equip the protective layer of chimneys. The best way to insulate a gas boiler is to use a sandwich pipe. They are considered to be the most effective. The design of these products consists of an outer and an inner pipe, between which a heater is located. These products are fireproof. They can even be used to insulate pipes from wood and other combustible materials.

To create a chimney sandwich:

- holes are created in the ceilings and the roof itself, which should be 250 mm larger than the structure itself;

- the thickness of the basalt wool insulation must be at least five centimeters;

- the fixing of the protective layer is carried out using a wire;

- a larger tubular product is put on the resulting structure;

- the casing of the upper metal layer must be iron.

Next, you need to put insulated pipes on the nozzle of the furnace or boiler through the hole in the ceiling or roof. After finishing the installation, you need to fill the metal sheet around the riser with a special non-combustible material. To solve this problem, you can use asbestos, clay or expanded clay.

Watch the video:

The choice of the method of thermal insulation depending on the material of the chimney

Plaster

Insulation of the chimney structure differs depending on the base material, but in each case, a preliminary inspection of the facility is required for the reliability and fire safety of the system.

When arranging the thermal insulation of a chimney in the form of a brick shaft, plastering is mainly used. This results in a reduction in heat loss of up to 25%.

Plastering technology includes the following stages:

- On the basis of a heat-resistant mixture, a very dense solution is prepared, with which the seams of the brickwork are sealed, filling all the voids.

- The reinforcing mesh is fixed and the first plaster layer is applied with a thickness of 3-4 cm.

- The second layer is performed after the previous one has set, the thickness is 5-7 cm.

- After the plaster coating dries up, a finishing layer is performed. To do this, the surface is carefully leveled, rubbed with a trowel, and the resulting cracks are covered.

The finishing stage is performed using bleaching solutions, which are applied in 2-3 layers for greater decorative effect.

Plastering a brick chimney

After inspecting the structure for defects and eliminating them, the mineral insulation is attached to the brick surface using wire stitching. In this case, it is necessary to ensure that voids do not form, special attention is paid to the joints. Next, a finishing coating of galvanized steel sheets is performed, the metal casing helps to eliminate the risk of reducing the operational properties of the mineral insulation.

We suggest that you familiarize yourself with: How to calculate the dew point

For insulation of asbestos-cement smoke channels, mineral wool is used, complete with a metal casing.

Stages of work:

- it is necessary to prepare the estimated amount of fiber insulation and a tubular structure of the required size made of galvanized steel. Most often, a folding casing of several elements is used, the cross-section of which should be 6 cm larger than the diameter of the asbestos chimney;

- the lower part of the casing is fixed on the base of the chimney structure and the gap between the walls of the asbestos-cement pipe and the steel lining is carefully filled;

- then the second casing element is fixed and the voids are filled with insulation. This will work the entire length of the asbestos chimney.

The upper border of the gap is carefully sealed with cement mortar to ensure the tightness of the thermal insulation.

Insulation of an asbestos-cement chimney with mineral wool

Heat protection of a steel chimney structure is performed in various ways:

- equip a frame from improvised means and fill the gap with a non-combustible insulation in the form of mineral wool, household bricks, sifted slag;

- a metal chimney is wrapped with mineral wool, a cladding structure made of galvanized steel sheet is installed on top;

- for thermal insulation of the iron chimney, a ready-made heat-shielding cylinder is used.

To build a frame for insulating a gas outlet made of steel, a box is made of sawn timber and the structure is sheathed with asbestos plates. Between the perimeter of the metal smoke exhaust duct and the inner surface of the box, a distance of 10 cm is maintained, depending on the type of insulation chosen.

It is recommended to give preference to lightweight insulation options made of basalt wool, glass wool or slag wool. This reduces the local load on the roof. If the load-bearing capacity of the roofing system is beyond doubt, broken brick or screened-out slag can also be used. The upper end of the box and the joints should be protected from moisture penetration; for this, cement mortar is used.

If a heater is chosen in the form of a basalt cylinder, a workpiece of the required diameter is selected, taking into account the parameters of the steel gas outlet to be equipped.The finished cylinder is installed (put on) on the pipe, after having pretreated its inner surface with heat-resistant sealant and the “thorn-groove” connecting elements.

Insulation of a steel chimney with expanded clay

When organizing chimneys for gas heating boilers, sandwich-type pipes have recently been used quite often. This is not only convenient, but also quite effective, because condensate does not accumulate inside the chimney, and heat loss is significantly reduced.

You can supplement your furnace unit with pipes made of a material such as stainless steel. First of all, before carrying out subsequent manipulations, you need to make sure that the system fully complies with all the requirements and safety standards.

Requirements for stainless steel chimneys:

- To create a properly working traction mechanism, it is necessary that the height of the pipes, in total, be at least five meters;

- A small gap must be left between the brick, stainless steel pipe and the roof, other non-combustible materials, a free space of at least 30 centimeters;

- Outside, at the very top of the chimney, a spark arrester is installed, which can protect the surface of ondulin, slate, roofing material from accidental ignition.

When passing through ceilings, this surface is sealed and insulated accordingly

Do-it-yourself insulation of a metal two-layer pipe

In the last step, the stainless steel pipes are wrapped on the outside. What for? In order to strengthen, isolate and seal the structure as much as possible. But winding can be done only after you are fully convinced that the structure is working correctly, without interruption.

The simplest, affordable variation, which you can install if you wish, with your own hands, is a sandwich pipe. They are two pipes of different diameters, inserted one into the other. The space between them is filled with mineral fiber insulation. A pipe with a larger diameter acts as a protective sleeve, while the smaller one performs a smoke-evacuating function.

The winding in this case is made of stainless steel or galvanized steel.

How to properly form a sandwich structure:

- We make a certain number of holes in the roof slab, so that their diameter is 20-30 centimeters larger than the chimney section;

- We carry out the winding with a small overlap. In this case, we use mineral fiber, the thickness of which will be at least 6 centimeters;

- We fix the cotton wool with a wire that turns 2-3 times;

- Next, we put on a previously prepared casing of a larger diameter. If necessary, we carry out a screed or fixing with adhesive tape (in the event that the steel is very thin).

We suggest you familiarize yourself with: Decorative possibilities of using Himalayan salt in the interior

The best draft will be for the unit, the chimney of which rises higher than the buildings on the roof or near the house.

Chimney insulation scheme in a private house

At the last stage, the pipe must be fixed with the branch pipe of the furnace unit, led through the roof overlap. The space near the riser must be filled with non-combustible materials.

Before starting work, you need to decide on the insulation material. You can use almost any, you just have to take into account that the chimney heats up to high temperatures, which means that the insulation must be heat-resistant and non-combustible.

Gone are the days when chimneys were made mainly of bricks. With the advent of gas and solid fuel boilers, they began to be made of metal, and asbestos pipes are also not uncommon. Insulation of different pipes requires an individual approach.

For thermal insulation of pipes of fireplaces and stoves, which are not the main source of heating, but are used periodically, it is enough to plaster the pipe.Most often this method is used for brick pipes, but it is also applicable for metal ones.

A different method is used for the chimneys of stoves and heating boilers. These are the so-called sandwich chimneys. Such designs are commercially available, but they are not cheap. With a limited budget, you can make them yourself.

A sandwich chimney can be bought on the construction market or made by hand

The asbestos pipe is insulated according to the same principle. In addition to mineral wool, you can use bulk insulation.

Before proceeding with the installation of thermal insulation, prepare everything you need for work. Clean the pipe from dust, repair cracks and chips. It is important that the surface is dry, otherwise the quality of the thermal insulation will decrease.

Plastering

- The mixture is mixed with water using a construction mixer in the proportions indicated by the manufacturer. It is more correct to first pour water into the container, and then add the dry mixture.

- With a spatula or trowel, the solution is applied with spots over the entire surface of the pipe and leveled. The plaster is leveled over the entire pipe surface

- The pipe is covered with a reinforcing mesh over the mortar spots, which will fix it to the surface. The mesh is necessary to strengthen the plaster layer, it plays the role of a frame.

- The first layer of plaster is applied over the reinforcing mesh. It is important that it covers the entire surface without gaps. In order for the plaster layer to stay on the surface of the chimney, use a reinforcing mesh

- The plaster is leveled and left to dry.

- After that, several more layers are applied, each of which needs to be dried. For good thermal insulation, 3-5 layers are required.

- After the last layer has dried, the pipe is painted in the color of the roof for aesthetics.