Mineral wool cylinders - produced by SPECIAL TECHIZOLATION plant No. 1

The search for a universal solution for the insulation of pipes intended for the transportation of heat carriers, gases and liquids led the specialists of the SPETSTEKHIZOLYATSIYA plant to the decision to use new materials and technologies that had already been successfully tested and proved their effectiveness. Thus, an insulating material was born, which is a layer of mineral wool with a dense structure. A thin sheet of foil aluminum was applied on top to improve the heat-reflecting characteristics and increase the resistance to Russian climatic conditions. The new insulator also coped well with temperature extremes typical for most regions of Russia, high humidity and exposure to ultraviolet rays. Resistance to mechanical damage and long service life have been demonstrated.

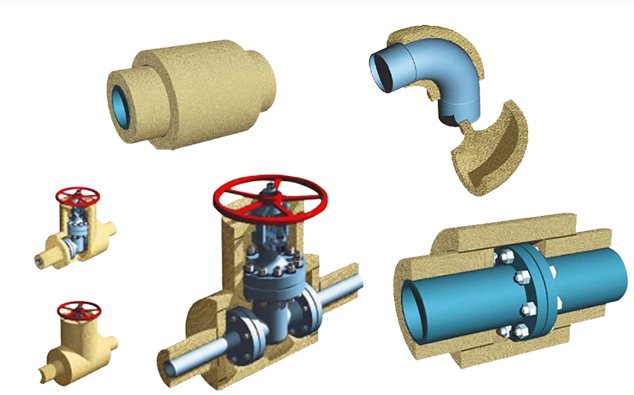

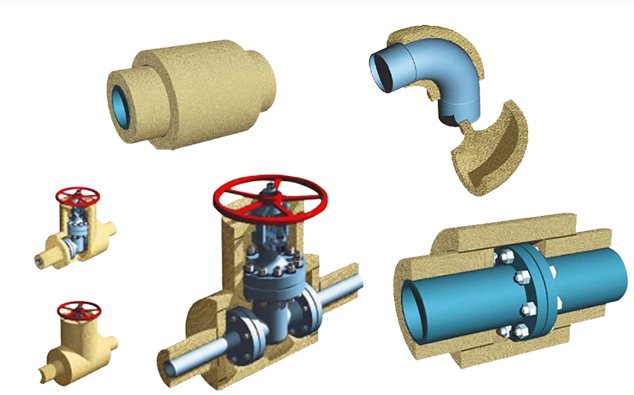

Modern heat-insulating material received a worthy assessment from practitioners, and mineral wool cylinders, lined with aluminum foil in a wide range of diameters and thicknesses, appeared on the market. Since during installation it is necessary to use various additional parts, for example, tees, the company has attended to the release of such products.

The safety of using the products of the SPETSTEKHIZOLYATSIYA plant is confirmed by quality certificates, certificates of conformity, as well as sanitary and epidemiological conclusions.

Installation features

Seams on the foil material are sealed with aluminum tape

Regardless of which type of cylinder is chosen, the following rules for installing protective products will need to be observed:

- For reliable sealing of the joint area, special tape is required. It is used for internal thermal insulation of pipe routes.

- When laying pipes open, a special foil tape with an adhesive base is used.

- Work on thermal insulation and pouring of polyurethane foam of street pipes is carried out only in dry weather.

- Installation of protective cylinders on damp surfaces is not allowed, as this will impair the quality of thermal insulation.

Mineral wool cylinders are put on pipes or pipe sections only after careful surface preparation, which guarantees a reliable fit of the material and a higher level of protection. When insulating metal pipes are pre-painted. For these purposes, it is recommended to use special primer (powder) coloring compositions.

Mineral wool cylinder production

The plant's assortment includes several types of products ER, TechnoNIKOL and ROCKWOOL, each of which is made on the basis of basalt wool obtained by weaving and compaction of stone fibers with the addition of a binder solution. The final product has hydrophobic properties and low thermal conductivity due to the presence of air between the basalt threads, which is a heat insulator. Bonding of aluminum foil enhances the natural qualities of basalt fibers and significantly increases the service life of mineral wool cylinders.

For ease of installation, an incision has been made along the axis of the cylinder, which facilitates and accelerates the seating of materials on the pipes. Some products are characterized by an overlap with an adhesive layer applied, which allows the thermal insulation to be fixed and insulated to the surface.

The products of the SPETSTEKHIZOLYATSIYA plant are suitable for use in closed rooms and in open spaces, for process pipelines and pipes of utility / engineering systems, operated in conditions with high humidity and low temperatures.

Range of products

Among the products of the plant there are mineral wool cylinders, lined with aluminum foil, products without a protective coating, shaped parts - tees with and without foil, as well as shells with a protective coating in the form of a galvanized casing. The range of products covers the needs of the most popular sizes - in diameter (18 - 324 mm) and thickness of the mineral wool layer (20 - 200 mm).

Depending on the availability and type of protection, the shells can be used for outdoor installation - with a metal casing, or indoors - lined with aluminum foil and unveiled.

When choosing a particular type of product, the specialists of the plant are ready to provide free advice on the types of products, and if there is a pipeline plan indicating the dimensions and connection points of the fittings, prepare a complete set of thermal insulation materials with the required number of additional segments.

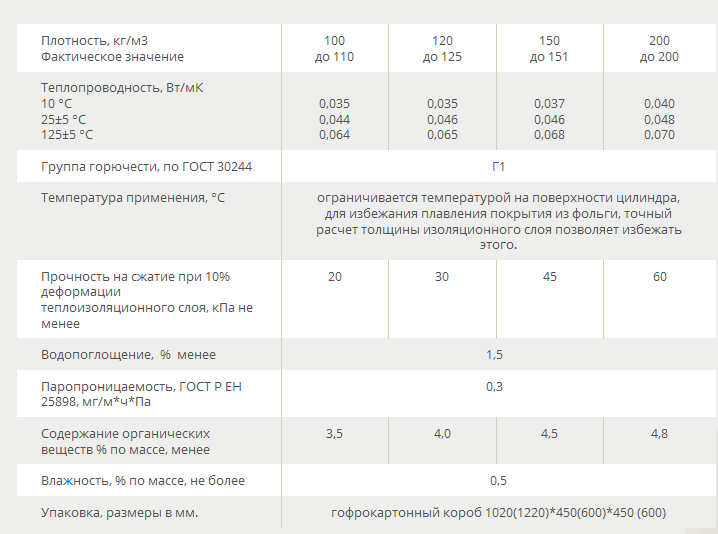

Important technical characteristics and advantages of mineral wool cylinders

Shells produced from mineral wool and coated with a protective coating exhibit a number of outstanding parameters highly appreciated by installers and customers:

- excellent thermal insulation properties;

- resistance to atmospheric moisture and temperature extremes;

- ability to work in a wide temperature range - -180˚С - + 450˚C.

- hydrophobicity, allowing installation in conditions with high humidity;

- resistance to chemicals - oils, petroleum derivatives, alkalis, acids;

- the ability to withstand serious mechanical loads, including breaking;

- high fire safety and non-flammability;

- non-toxicity and safety for indoor installation;

- high level of sound insulation;

- durability;

- convenience in storage;

- ease of installation;

- versatility at the place of application - utilities, production shops, including at enterprises producing food products, gas, oil and other transport systems.

The purchase and installation of foil-clad mineral wool cylinders allows you to obtain a significant economic effect and gain priority in the market for goods and services.

5 reasons to buy the products of the SPECIAL TECHNOLOGY plant

All the most important criteria for the selection of heat-insulating materials, which are important for the buyer, installer and user of piping systems, are inherent both for the SPECIAL TECHIZOLATION plant itself and for its products:

- high quality production and control of product parameters at every stage;

- a wide range of products, and therefore the ability to select products that are optimal in terms of their characteristics;

- free consultation and the possibility of calculating a project for thermal insulation of a pipeline;

- excellent service, implying maximum satisfaction of the customer's needs both in terms of the quantity and quality of products, and in terms of information support;

- the possibility of delivery across the territory of Russia;

- adequate prices for mineral wool cylinders, allowing to reduce overhead and increase the profitability of the enterprise.

If you are still trying to calculate the cost of thermal insulation of pipes, then just trust the company's specialists who will choose the best solution, calculate the project, and organize the delivery of materials directly to the installation site.

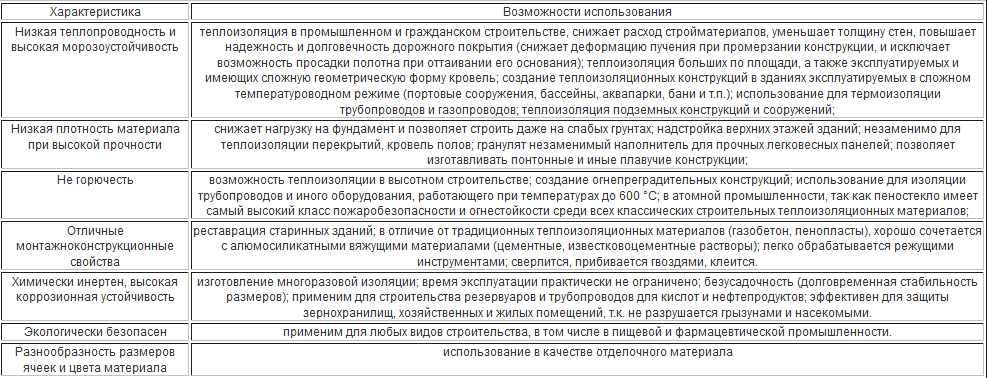

Comparative evaluation

Foam cylinders cannot be used at high temperatures and in the sun

Not all types of insulation materials from which protective products are made are capable of withstanding significant loads.Mineral wool heat insulating cylinders, for example, turned out to be the most vulnerable in this part. After an unacceptable amount of compression, they begin to absorb moisture and quickly deteriorate - they lose their protective properties.

In this case, preference is given to products made of foamed polyethylene, the compression resistance of which is somewhat higher. On the other hand, due to the fragility of the material, the elements made on its basis are more expedient to use for insulating pipes of small diameter, laid only indoors.

Styrofoam cylinders are more effective in thermal protection, and are also moisture resistant and durable. However, they are not protected from rodents and belong to substances that support combustion. In addition, they do not “hold” high temperatures and are not suitable for the protective insulation of FGP pipes.

The most versatile in use are products made of polyurethane foam, which have long operating periods and are distinguished by their incombustibility. They have a low coefficient of thermal conductivity and good sound absorption. "Shells" made on the basis of polyurethane foam are not subject to the threat of destruction by rodents.

Mineral wool cylinders - how to buy and get?

After the main parameters of the order have been determined - technical characteristics, dimensions and quantity of products of a certain article, the order can be left using a special form, sent by mail or by telephone. After a while, the manager will contact you to clarify the parameters of the order and inform the cost by sending you a payment order to the address.

Delivery of mineral wool cylinders, lined with foil and without it, is carried out throughout the territory of the Russian Federation due to the presence of a wide network of branches and representative offices in various regions of the country.

Cylinder concept

The name suggests that this material has the shape of a cylinder, which must be installed on pipes. The dimensions of the cylinder, the thickness, how it was made, and other characteristics depend on the composition of the given insulation. The main composition is polymers.

laminated heat-insulating cylinders

Although we know that today the situation is completely different. Together with glass fiber wool, people began to use foil-based foam, thermoplastic foam and polyethylene foam.

Thermal insulating cylinders and half-cylinders, what is it about them?

It would seem that it is a simple product made of heat-insulating material, how can it help? But in fact, professionals have appreciated the practical value of technical insulation for metal and certified polyethylene pipes. And do not be surprised when you are strongly advised to buy heat-insulating cylinders for your facility in Moscow, the region or another region, because they can be used to solve many problems.

- Warming

... This is the main task of cylindrical thermal insulation. The products themselves are made directly from basalt fiber. The segments of expanded polystyrene are less widespread. The low thermal conductivity of materials perfectly stops the heat exchange of technical

or household water pipe and the environment. - Minimizes heat loss

... This property partially follows from the previous point. It is only worth noting that manufacturers care about the continuity of the thermal protection circuit, therefore they have developed a special thermal lock. This is a special protrusion and depression at the joints of the longitudinal cut of the pipe, which certified materials for pipe insulation can boast of. The price of such products is low and commensurate with the cost of insulating mats, but the installation of the cylinders is much easier. - High temperature protection.

Mineral wool heat-insulating cylinders for pipelines can freely withstand heating up to + 350 ° С, some brands can tolerate + 650 ° С.But if it is necessary to isolate objects with an operating temperature of up to + 1000 ° C, multilayer products are used, where the inner surface is made of mulite-silica fiber. - Fire safety.

Basalt wool, as a fire protection, will give as much as 180 minutes of extra time in the event of an emergency. It explains everything by the fact that the fibers from the stone do not burn, and when exposed to a flame, only an organic binder can melt. Insulation holds back fire in two directions: outside and coming from the pipes. - Corrosion protection.

Thermal insulating cylinders and half-cylinders prevent the temperature conflict that often occurs in pipelines with cold contents and a warm room. A prime example is the "sweating" cold water system in homes. A wet metal pipe will begin to rust, and a propylene pipe can produce so much condensation that puddles of water will form. - Noise isolation.

The chaotic arrangement of threads in a cylindrical insulation reduces the noise level from air conditioning pipes, sewers and air ducts.

Important:

Pipes will last 2 times longer with the use of pipe technical insulation, since the insulation protects them from mechanical damage, corrosion and freezing!

This is how heat-insulating cylinders for pipelines solve most of the technical issues in production. Once installed, you can find your benefits from using the products. Don't forget to share! Now let's figure out how to choose the best pipe insulation.

Video: Installation of wound cylinders Rockwool

See how easy it is to install a cylindrical foil insulation - it's easy!

Variety

Mineral wool is divided into the following types:

- Glass wool. It is a widely used material based on glass fibers. Working with such material requires wearing protective clothing, since contact with fine fibers can cause significant harm to human health.

- Slagged. The disadvantage of the material is that it enters into an acidic reaction when interacting with metal surfaces. It is capable of being saturated with water, which subsequently deteriorates the thermal insulation qualities. When installed, just like glass wool, it requires wearing protective ammunition.

- Stone wool. Such a material is made from two components - gabbro and diabase. The product is very similar to slag wool in its properties, but unlike the first option, this one does not prick. Also, stone wool does not absorb water, therefore this type of cladding is more preferable.

Stone wool