Apartment owners use the space of balconies and loggias in different ways. For some, this is an additional storage place where unnecessary things can be taken out - sledges, skis and garden tools get their registration there. But more and more tenants use the area of the balconies to increase the space of the apartment. After all, you can take out a desk or a dining area here. The vapor barrier of the balcony must be carried out if you want to create a comfortable microclimate there before the onset of winter. You can do without outside help. Everything you need for this can be purchased at hardware stores.

What is a vapor barrier for when insulating a balcony

Vapor barrier plays an important role in the well-being of the interior decoration of the balcony, as it prevents the ingress of steam and the formation of condensation. When there is a high level of humidity in the room, then the end result is fungal organisms, growths and mold on the ceiling, walls and floor. Mostly problematic apartments are those in which the temperature regime is constantly jumping. As a rule, the balcony begins to overheat when exposed to sunlight, and cool down sharply in the evening. This leads to the appearance of a large amount of moisture.

When repair work begins, vapor barrier must be resorted to first. Only after proper installation can you begin to insulate the floor, walls and ceiling. Otherwise, unplanned costs will appear in the near future.

To prevent the formation of fungi, it is better to use a two-layer film.

It is worth considering that with the appearance of mold, condensate and steam mass will begin to increase even more due to regular exposure to sunlight and temperature changes. Long-term neglect of harmful formations can significantly complicate their destruction.

The vapor barrier of the balcony rapidly restrains the moisture that forms in the room during exposure to sunlight. If the obstacle is removed, then the following problems will arise:

- Penetration of steam into the insulating material, after which the gaseous mass becomes water.

- Fluid will start to build up on steel structures, which will rust.

- Steam settling on wooden and metal elements of the balcony.

- The formation of a fungus, which will gradually destroy the finishing material, the wooden bases of windows and doors.

- Ultimately, the microclimate of the balcony will be disturbed.

Attention! The vapor barrier can interact with any modern building materials.

Varieties of vapor barrier

Before figuring out how to properly lay a vapor barrier, you need to understand what types of vapor barrier material are and what are their features. Three main groups can be distinguished:

- Film - a material that is completely impervious to moisture. Also, its advantages include budgeting - this is the most affordable type of vapor barrier... There is also a two-layer film on sale - one layer is smooth, the second is embossed (such a film is laid with a relief layer outward, so that moisture drops do not flow down the film, but remain at a certain level until they evaporate).

- Membrane - the material is porous, but with limited vapor permeability. Due to these properties, moisture in the insulation does not linger (that is, the insulation does not get wet, which can significantly affect its effectiveness), but is removed.There are pseudodiffusion membranes (vapor permeability - up to 300 g per 1 sq. M. Per day), diffusion (vapor permeability - 300-1000 g per 1 sq. M. Per day), superdiffusion (vapor permeability - more than 1000 g per 1 sq. . per day). There are also volumetric membranes - in them a ventilated layer is located inside. All of them are mainly used in outdoor work.

- Foil vapor barrier - a material that has not only vapor barrier properties, but also thermal insulation. It is offered by different manufacturers. Depending on the composition of the material, the properties of the insulator vary somewhat.

- Izospan made of polypropylene fabric with a metallized layer.

- Penofol - a thin material made of foamed polyethylene and with an aluminum foil covering, which prevents heat loss at all three stages: convection, thermal conductivity, radiation.

- Megaizol - the line of films from this manufacturer also includes models with a metallized coating.

If you cannot decide what kind of material you need, contact your sales consultant for help. After examining the features of the room and finding out the estimated budget for the vapor barrier layer, he will help you choose the best option.

You can find out more about the characteristics of foamed foam and its properties from our separate article.

Pay attention to our step-by-step instructions for warming balconies with your own hands. It covers the use of the most popular materials.

After the vapor barrier of the loggia, you can proceed to finishing. You can read about cladding with lining here.

How to choose a vapor barrier for insulating a loggia

The main thing in laying a balcony vapor barrier is care and selection of appropriate materials. Correctly selected vapor control elements guarantee:

- perfect noise reduction;

- protection against heat loss and penetration of moisture and gaseous masses;

- reduction of condensation in the room.

Balcony vapor barrier can be divided into two types: deterrent and neutralizing. The first option is designed to protect against moisture penetration. The second one destroys the steam mass and removes moisture. Of course, it is better to use the latter option, since neutralization will help not only get rid of the liquid, but also provide protection from wind and moisture. Moreover, the material has an elastic and durable structure.

As for the choice, the following products can be purchased on the domestic market, which have different properties, prices and methods of installation:

- Tyvek. It is a non-woven material with a membrane structure. Due to its properties, it perfectly copes with the elimination of moisture. The product has the same structure on both sides

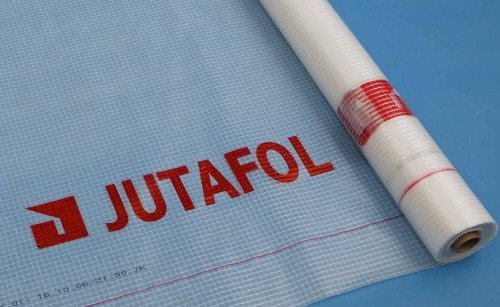

- Yutafol. High-strength film that holds back gaseous and liquid masses.

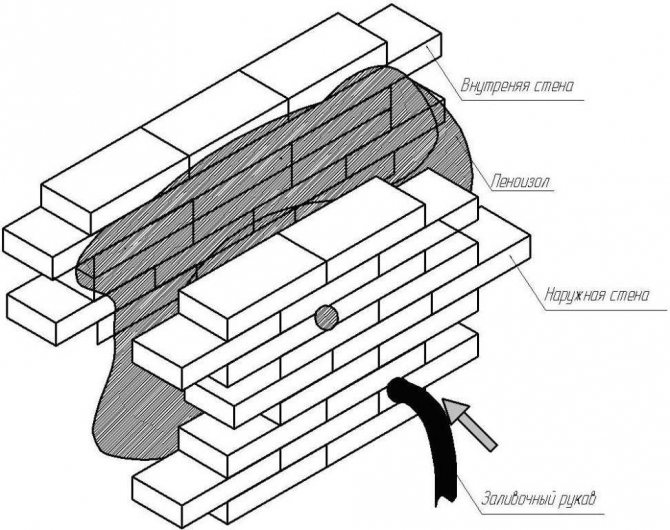

The material has high moisture protection due to its dense structure - Penoizol. An excellent liquid-form foam that is designed to fill the space between walls. Used as a vapor barrier on the balcony, however, the installation is too complicated. It is better to use a product for wall and ceiling decoration

- Penofol. Thin insulation element designed to contain steam and condensation. The material is widely used for covering wooden walls.

- Izospan Delta. A tough film used to contain condensation. Izospan differs in low cost

- Foam polyethylene, provides protection from wind, moisture and heat. The material is one of the most common vapor barrier types.

- Liquid rubber. They are widely used for the treatment of complex surfaces. The plasticity of the structure allows you to penetrate the most difficult places

In order to choose the right material, it is necessary to assess the complexity of the work and the condition of the balcony walls. For the treatment of rooms with strong thermal changes, you will need a two-layer film.

Steam insulation materials

If the vapor barrier material is selected correctly:

Steam insulation materials

- the balcony will be reliably protected from noise, heat losses;

- water vapor will not penetrate into the room;

- the amount of condensate will be significantly reduced.

Vapor barrier materials are of two types:

- some do not allow condensate to penetrate;

- others remove steam by keeping moisture out.

During the vapor barrier of the loggia, the second type is used, because such materials will protect against unwanted condensation, provide water protection, and shelter from the wind. They are durable, elastic.

How to prepare a balcony for the installation of a vapor barrier

Before installing the vapor barrier, it is necessary to prepare the surface of the treated elements. First of all, you should dismantle the door and window frames, then carry out a general cleaning on the balcony and clean the ceiling, walls and floor of debris.

During repairs, unnecessary items should not be present on the balcony

The next step is to clean up cracks and boulders on surfaces. To do this, it is worth applying cement, after which the walls and ceiling must dry. Next, you can start sealing with a protective film. The procedure must be performed in accordance with the following instructions:

- Install on the outside of the balcony.

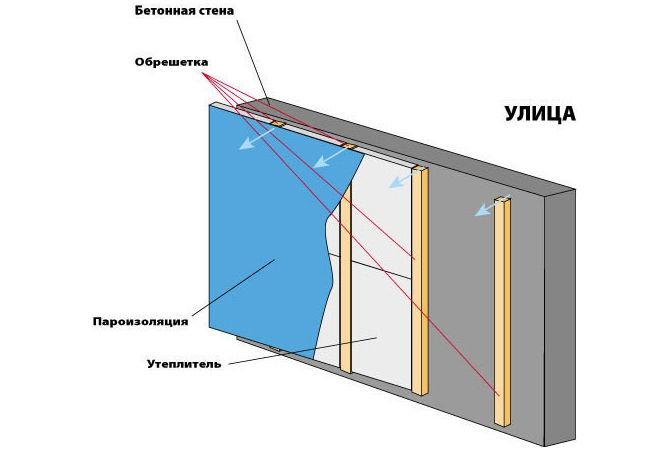

- In the internal vapor barrier of the balcony, it is carried out under the mineral wool, after which the film must be fastened.

- On the ceiling, it can be mounted directly on the insulating layer.

If there is a fabric part on the vapor barrier material, then it should be on the outside of the finish. Foil should always be placed inside.

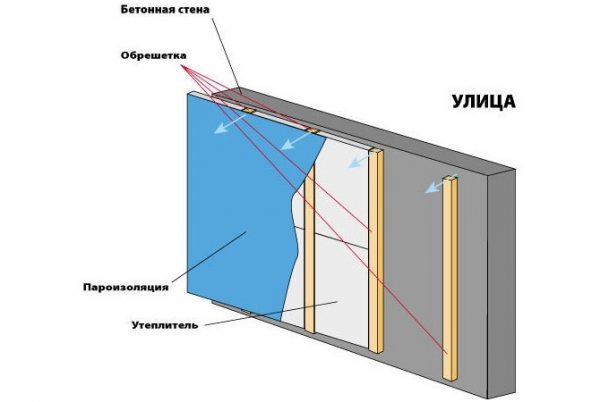

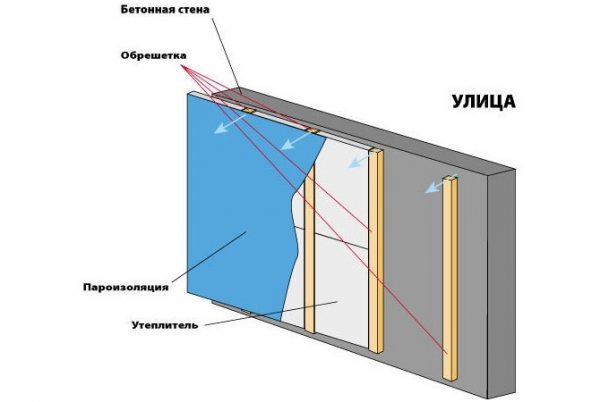

Arrangement of passive vapor barrier of walls

The construction of a balcony vapor barrier system is much more complicated than a simple plastic wrap cladding. The classic version of the balcony vapor barrier system should be built in the image and likeness of the roofing pie insulation system with a warm attic.

The film covering, laid on the balcony insulation from the inside, should freely allow water vapor, but only in one direction, outside the room. The second layer of the film should stop these vapors, and the additional space between the two layers ensures the free removal of water vapor.

Therefore, for a vapor barrier in the passive version, there must be a gap between the two layers for free air circulation. Air is drawn into the space between the two vapor barrier layers along the lower edge through a system of holes. There is also a condensate collection system. Warm air that has passed through the duct partially evaporates the condensate, then moves along the channel to the ceiling and is removed through the ventilation window. If the outside temperature is above zero, there is practically no condensation under the film.

When the temperature drops to minus 5-10 ° C, condensate begins to intensively accumulate in the vapor barrier system and drip into the receiver. If the apartment is located in a multi-storey building at a level of at least 3-4 floors, then most of the condensed water will be carried away by the draft into the ventilation. In this case, it is important that the air flow in the duct does not mix with the atmosphere of the balcony and does not flow around the coldest metal parts of the balcony fittings. Otherwise, condensation will remain inside the room and accumulate in the subfloor and on the ceiling.

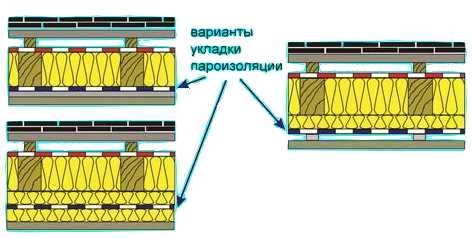

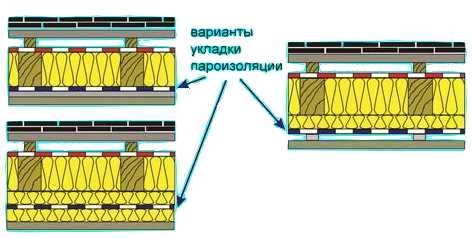

In the same way, the vapor barrier of the balcony floor or its ceiling is performed. A crate of wooden slats is laid on the layer of insulation, after which there is a vapor barrier film and the actual surface of the floor - boards or plywood covered with linoleum. The subfloor space will also need to be supplemented with vents connected to the ventilation duct.

If possible, it is best to make a vapor barrier and at the same time insulate the floor and ceiling with isospan. The continuous canvas is cut into separate pieces, laid with an overlap of 10 cm and sealed with construction tape.

How to install a vapor barrier on a balcony

During the bonding of the film, the layers must be stacked on top of each other, this ensures that there is no empty space. At the edges, the vapor barrier material has a special mesh that will help you navigate during the creation of overlaps. For gluing the joints, use an adhesive tape with a metallized coating.

Balcony ceiling vapor barrier

The very first surface on the balcony, which must pass the vapor barrier, is the ceiling. The gaseous mass primarily tends upward, which means that it will be the central place for the accumulation of mold. In this case, the vapor barrier with penoplex will not help to insulate the loggia, since small cracks will remain.

Don't leave empty space in the ceiling

First you need to lay a vapor barrier layer of film, and then install a sealing element. Next, install polystyrene foam plates, and then lay a waterproofing coating.

Attention! The voids between the vapor barrier and the top layer of the ceiling will always collect a large amount of steam.

Balcony floor vapor barrier

It is most difficult to mount a vapor barrier on the floor of the loggia during insulation, since in this case the surrounding conditions play an important role. The only plus is the uselessness of installing floors on the floor from the side of the floors. First of all, you will need to lay the foam on the floor. It must be installed tightly to the end surfaces, and then insulated. Further, lay the screed with a waterproofing layer, since liquid retention is required. Usually a small amount of steam accumulates on the floor, so cold air will be present in this environment.

One material can be used for vapor barrier walls and floors

Vapor barrier walls on the balcony

The vapor barrier of the balcony along the walls when insulated from the inside is calculated based on the material with which the surfaces are equipped. In any case, it is necessary to use penoplex as insulation, however, not every material can act as a vapor barrier. If the walls are made of bricks or concrete, then a double foil with a foil surface can be used. According to the rules, the reverse side should be located in the inner part of the finish. When the wall is wooden, then such a film is absolutely not needed, since there is enough foam for vapor barrier.

You can strengthen the vapor barrier layer using glazing beads or metal profiles

When the vapor barrier of the balcony is carried out outside, then in most cases it is necessary to use penoplex. The main advantage is that liquid or steam cannot form on the outside, and if moisture appears, it cannot seep into the wall.

Preparatory work

As already noted, insulation from steam should be dealt with before insulating the balcony. Prepare the room, remove all unnecessary things, including garbage. Remove the door frame, balcony sill. Seal cracks, gaps with polyurethane foam. Eliminate unevenness.

When the surface is ready, you can start installing the vapor barrier layer. But before that, it is worthwhile to deal with the question that worries builders (especially beginners): which side should the vapor barrier material be laid on? Vapor barrier materials are produced double-sided. Which side to lay to the insulation is really important, and it also matters which side the vapor barrier is made on - from the outside or from the inside:

Balcony vapor barrier scheme

- if external insulation of the facade is carried out, insulation from steam is laid on the outside of the insulation;

- if the insulation is internal, the insulation should be laid as an inner layer over mineral wool or foam;

- when insulating the ceiling, the film holding the steam is glued to the insulation.

If the material of the vapor barrier of balconies has a fabric side, it should "look" outward, foil - inside the balcony (with internal insulation).

Professional advice

According to professionals, the balcony vapor barrier should be done after thorough preparation of all surfaces. Even a small crack on the wall can contribute to poor material placement, and hence the penetration of steam or liquid.

After general cleaning of the wall, the ceiling must be carefully treated with cement and the irregularities that have arisen must be removed. After the procedure, the balcony should dry out, and only then can the vapor barrier be started. As for the floor, it does not need to be carefully leveled, because liquid collection in the lower part of the loggia is unlikely. For insurance, a thin film with aluminum interlayers can be laid under the foam, however, there is no special need for this.

Main characteristics

Penoplex has many advantages, the heat-insulating material has many positive properties and wins in comparison with other heat insulators. Among the main advantages must be attributed:

- Lack of water absorption - moisture can only penetrate into the part of the slab where the cells are destroyed during cutting or manufacturing of the slabs, water does not penetrate into the rest of the slab.

- Low level of thermal conductivity - Penoplex has the lowest thermal conductivity in comparison with other heat insulators. It is resistant to high humidity, so it can be used without additional waterproofing.

- Low vapor permeability - the material has a high degree of vapor permeability protection. For example, a slab with a thickness of 20 mm in terms of resistance can be compared with roofing material in 1 layer.

- Resistance to combustion - a fire retardant is added to some types of foam during the production process, which gives the material resistance to combustion.

- High compressive strength - the uniform structure of the material makes it especially strong, even with prolonged compression stress, the penoplex continues to remain the same invulnerable, therefore the material is used in the construction of railways and highways.

- Plates are not subject to biological degradation, they do not need special storage conditions, they are not afraid of temperature and humidity differences, they can be stored without shelter.

- Safety - the boards do not harm the environment, there are no toxic substances in them, the material has good environmental characteristics.

- Simplicity and convenience - it is always easy to work with penoplex, at any time of the year, the material is easily mounted without special equipment.

- Durability - according to the board manufacturers, the service life of the material is 50 years, all this time it retains its physical properties and thermotechnical characteristics.

Insulation under the screed

Warming the floor of the loggia with penoplex under the screed is an excellent solution when organizing a system of underfloor heating. Such insulation is done as follows:

- After removing the old coating, a thin leveling cement screed is made. Without a perfectly flat floor, foam sheets can be damaged.

- A film is laid for steam and waterproofing, the joints are glued with tape.

- Stacked foam sheets with a thickness of 40-60 mm. The joints are sealed using polyurethane foam or sealant.

- The second layer of vapor barrier is placed.

- The foil heat reflector is laid with the foil facing up.

- A "warm floor" system of the selected type is installed.

- The screed is poured. When arranging the heating system, its thickness should be at least 7 cm, without it - at least 4 cm.

p, blockquote 25,0,0,0,0 ->

p, blockquote 26,0,0,0,0 ->

To pour the screed over the underfloor heating system, it is necessary to use a special mixture designed for this purpose. Conventional cement screed will crack when exposed to high temperatures.

Thermal insulation of the loggia floor with foam is done in a similar way, but in this case the screed is reinforced:

- After pouring on the beacons of the first layer 2–5 cm thick, a reinforcing mesh is installed.

- The final screed is made with a thickness of 4 cm.

p, blockquote 28,0,0,0,0 ->

Polyfoam for the floor must have a density of 35 kg per sq. m.

If we insulate the floor with expanded clay, before pouring the screed, the surface is leveled and a lattice of metal reinforcement is laid on it, as in the next photo.

p, blockquote 30,0,0,0,0 ->

p, blockquote 31,0,0,0,1 ->

If you want to warm your balcony or loggia, this guide will help you. After the completion of the insulation work, you will only have to think over the design of the loggia: turn it into a cozy corner where you can retire, or expand the space of the living room or kitchen due to it.

Installation nuances

In order for the vapor barrier on the balcony to be installed correctly, you need to take into account some of the features of working with this material. If possible, it is better to consult an experienced finisher before starting work. When organizing work on your own, you must first familiarize yourself with the following rules.

Overlap or butt

The most common question is: how is the vapor barrier correctly installed when insulating a loggia - end-to-end or overlap? The answer depends on the brand and type of material that is supposed to be fastened.

A roll-type vapor barrier material is laid with an overlap. Most of the roll materials intended for the vapor barrier of the balcony have markings indicating the degree of overlap of individual strips. Typically, the overlap width is 100 to 200 mm. According to this principle, diffusion membranes are also laid. The joints of the individual strips are glued with vapor barrier tape to ensure a clear fixation of the material. In this case, water vapor will not be able to pass between the lanes.

If a tile material, such as Penofol, is used for vapor barrier, it is laid end-to-end, since rather thick sheets cannot be reliably fixed with an overlap. The contact points of individual sheets are sealed with vapor barrier tape.

How to glue

To install a vapor barrier on the balcony, use double-sided tape. This type of fixing film or sheets of vapor barrier to the base, provides reliable tightness and is used when insulating walls, ceilings and floors.

Double-sided tape is glued to the base (wooden battens of the crate) along the perimeter of the vapor barrier installation. Then remove the upper protective film, leaving the adhesive surface of the tape open, stick the film or vapor barrier sheets.

Scotch tape is also used to repair vapor barriers when it is necessary to restore torn material. In addition to double-sided tape, a furniture stapler, nails with a wide head, and counter-rails can be used to attach the vapor barrier.

How to pull

The supporters of the tight tension of the material on the base will have to change their approach when working with a vapor barrier. Balconies and loggias are located in a zone of constant temperature fluctuations. Accordingly, the material is acted upon alternately by positive and negative temperatures, at which the structure is compressed or relaxed. At a negative temperature, the material will shrink, and if it was stretched without a little slack, a rupture will occur.

It is allowed to leave a sag of the vapor barrier within 10-20 mm per one running meter.

Views

There are the following options for pronouncing:

- Membrane... Consists of two layers. One of them leads the steam out. IMPORTANT. Do not confuse which side is generating steam.

- Foil-based. A universal tool that can be used as steam insulation, as well as sound insulation and thermal insulation.

- Liquid. It resembles the appearance of liquid rubber. Easy to apply to the desired surface.Dries up after application. IMPORTANT. Check for the quality of the coating. If the coating is of poor quality, then it is necessary to reapply the liquid mixture until the coating is perfect..

- Reinforced polyethylene. A polymer thread is embedded in the polyethylene film, which gives rigidity to the building insulation. This material is much more convenient to use than ordinary polyethylene.