Home Installation

Date of publication: 03.08.2015

0

9485

- Construction Basics

- Construction technology

- What you need to install

- Construction stages

- External finishing

- How to avoid the cold bridge

If we turn to the dictionary, we find out that the pediment is the end (most often triangular, sometimes semicircular) of the facade of the building. The pediment is limited by two roof slopes on the sides, and a cornice is located at its base. There are more than 10 types of pediments that can be found on various buildings, both historical and modern. But today we will take a look at the frame pediment.

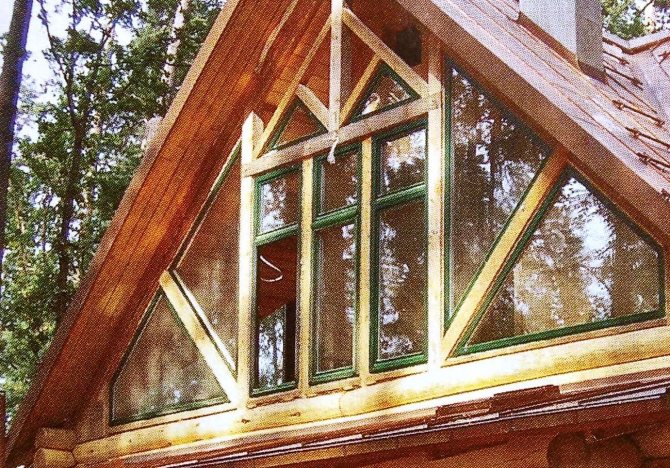

The frame pediment looks very advantageous if it is trimmed with glass.

Probably, even at the level of project development, you had a question about how to make every element of your home safe, durable and strong. As for the frame pediment, this is doubly correct - a poorly designed part of the house can lead to uneven shrinkage of the building, provoke weight distortion and cracks in the walls. The pediment should be arranged in such a way as to evenly distribute the loads on the frame of the entire building.

Modern technologies today have greatly simplified the construction of the pediment. The rafter system with accompanying elements is a single structure that descends freely and evenly during the shrinkage of the building.

It is frame construction that allows you to create roofs of various shapes, sizes and devices.

You can build an attic or attic, or use the free space under the roof in a different way. The construction of the entire structure is simple and convenient, but it requires some experience and knowledge.

The frame type of construction, due to its lightness, can be considered the simplest in execution, durable and reliable. The main thing is that its elements are correctly and efficiently treated with wood protection.

What is a pediment?

Before proceeding with the warming of the pediment, it is advisable to understand what it is and understand its role in the structure of the house.

And so, briefly about the gables:

- basically the pediment plays the role of a support for the cross beams, which significantly increases the pressure that the roof exerts;

- as a rule, gables receive a large amount of wind action, in this regard, on the leeward side, they perform a blind pediment without doors and windows;

- the pediment should be erected only after the roof has been created, otherwise this structure may collapse due to the skewing of the rafter system;

- the pediment is the least protected relative to other parts of the house, therefore it is imperative to insulate the attic pediment from the inside or outside;

- the pediment is insulated according to the same rules and standards, using the same insulation as other parts of the house.

Device and thermal insulation of gables

To begin with, let's explain what a pediment is: these are the end sides of the structure, located between the slopes. Their purpose is to protect the attic or attic room from wind, rain and snow. This is the least protected part of the building, so high-quality thermal insulation is very important for the whole house.

The shape of the gables can be any: triangular, trapezoidal, in the form of a triangle with broken sides, semicircular: it all depends on the design of the roof. The material can also be different: for the construction of this part of the roof, bricks, blocks of foam concrete, timber, rounded logs are used. Frame-panel structures are very popular due to their low cost and ease of construction.

The construction of gables is carried out simultaneously with the construction of the walls of the house or before the installation of the rafter system. In the latter case, there is a risk of collapse in strong winds, in addition, the accuracy of the geometry should be monitored in order to avoid problems with the compatibility of the rafter system and the roof. Gables often serve as supports for cross beams: distortions in this case can lead to deformation and destruction of the roof, since the pressure exerted by the roof is added to the wind loads.

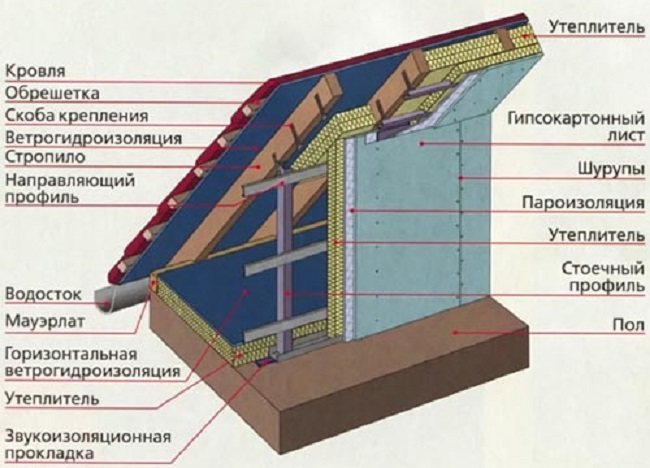

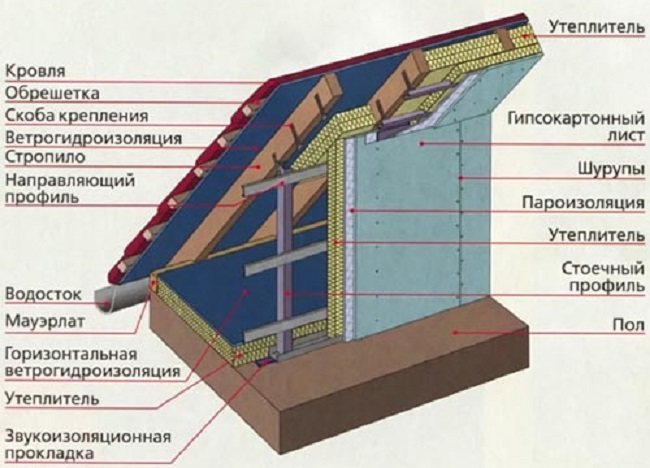

In most cases, the insulation of the roof and gables is carried out according to well-known technologies in a certain sequence: first, we make the inner sheathing, then the vapor barrier, insulation, hydro and wind insulation, and finish the work with the outer sheathing or roofing

The height of the end part of the roof determines not only the appearance, but also the functionality of the under-roof space. This is especially important if the attic is to be used as a living space. In this case, the minimum height can be 2.5 m.The strength characteristics of the bearing walls are taken into account first of all if the project provides for the construction of this part of the building from bricks: the increased load on the base and walls can cause the destruction of the entire building, especially if it is planned to erect a complex roof with four pediments.

In order for the brick pediment to be stronger, the brick wall is reinforced with a reinforcing mesh. The corners of the outer bricks are cut in such a way as to minimize the number of gaps between the roof and the end wall. This will facilitate further work on the insulation of the building.

The windows on the pediment should not be placed on the leeward side: this will worsen the thermal insulation characteristics of the entire structure. To protect against atmospheric precipitation, there should be an overhang over the gables, the width of which depends on the length of the ridge beam outlet and the elements of the sheathing.

The difference between external and internal insulation of the gable

To determine the difference between these types of insulation, let us turn to the term "dew point", since the effectiveness of the insulation work depends on it. The dew point (TP) is called the air temperature at which the moisture in it reaches its maximum saturation and, as a result, falls out in the form of condensation on the surface of the wall (or other plane).

Important! To determine the dew point, it is necessary to take into account the relative air humidity (RHC), besides, the higher this indicator, the more t˚C TP tends to the actual t˚C air. In this regard, it is necessary to create such insulation so that the Ross point is maximally displaced towards the street or is in the thickness of the insulation.

Insulation of the attic pediment from the inside is as effective as from the outside, but the insulation procedure must be performed taking into account the smallest nuances. Poorly insulated areas, more than others are susceptible to condensation on their surface. Particular attention should be paid to corner and butt joints, since these are the places most susceptible to moisture settling. To determine the "dew point", you can use a special technique using special physical and mathematical functions, but not everyone has a technical mindset, therefore, to simplify this procedure, the following table was created:

| t˚C air | ОВВ, Rh | |||||||

| 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.95 | |

| -10 | -23.2 ° C | -20.4 ° C | -17.8 ° C | -15.8 ° C | -14.1 ° C | -12.6 ° C | -10.6 ° C | -10 ° C |

| -5 | -18.9 ° C | -15.8 ° C | -13.3 ° C | -10.9 ° C | -9.3 ° C | -8.1 ° C | -6.5 ° C | -5.8 ° C |

| -14.5 ° C | -11.3 ° C | -8.7 ° C | -6.2 ° C | -4.4 ° C | -2.8 ° C | -1.3 ° C | -0.7 ° C | |

| 5 | -10.5 ° C | -7.3 ° C | -4.3 ° C | -2.2 ° C | -0.1 ° C | + 1.6 ° C | + 3.3 ° C | + 4.1 ° C |

| 10 | -6.7 ° C | -3.2 ° C | -0.3 ° C | + 2.2 ° C | + 4.4 ° C | + 6.4 ° C | + 8.2 ° C | + 9.1 ° C |

| 15 | -2.9 ° C | + 0.8 ° C | + 4.0 ° C | + 6.7 ° C | + 9.2 ° C | + 11.2 ° C | + 13.1 ° C | + 14.1 ° C |

| 20 | + 1.0 ° C | + 5.2 ° C | + 8.7 ° C | + 11.5 ° C | + 14.0 ° C | + 16.2 ° C | + 18.1 ° C | + 19.1 ° C |

| 30 | + 9.5 ° C | + 13.9 ° C | + 17.7 ° C | + 21.3 ° C | + 23.8 ° C | + 26.1 ° C | + 28.1 ° C | + 29.0 ° C |

| 40 | + 17.9 ° C | + 22.6 ° C | + 26.9 ° C | + 30.3 ° C | + 33.0 ° C | + 35.6 ° C | + 38.0 ° C | + 39.0 ° C |

In this regard, insulating the attic pediment from the outside is a more acceptable method, since the "dew point" is already by definition outside, where, when exposed to winds and sunlight, excess moisture will evaporate and not accumulate on the surface of the wall.

How and what to insulate the attic pediment

An important condition for the creation of any habitable space is the insulation of the surfaces of the premises. The use of heat-insulating materials will help to significantly reduce heat loss and create a comfortable microclimate inside the house. Knowing how to properly insulate the attic pediment, and what materials to choose, you can independently carry out the entire technological process.

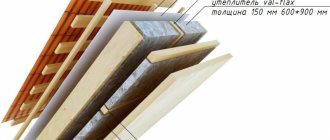

The choice of thermal insulation materials for warming the attic pediment is wide enough. The most commonly used roll insulation material is mineral wool. High heat and sound insulation characteristics and low cost make it very popular. Polyfoam and other foamed polymers are also often used to insulate the attic. A modern, effective, but rather expensive method of insulation is the use of polyurethane foam. It is a liquid thermal insulation material that is applied directly to the surface without preliminary preparation.

Warming of the pediment can be carried out both from the outside to the final cladding, and from the inside. To insulate the attic pediment from the outside, it is necessary to perform a number of sequential actions.

- First, a layer of waterproofing layer is laid on the surface. For wooden surfaces, a roll material is used, for example a polymer membrane. For concrete or masonry substrates, it is preferable to use a coated waterproofing barrier.

- Then a metal or wooden crate is mounted, in the section of which pieces of insulation corresponding in size are installed. Wooden elements must be treated with an antiseptic to protect them from rot.

- A vapor barrier layer is placed on top of the insulation. Cover the top with a facing material.

The decision of how to close the attic pediment depends on the material from which the house is made or with which it is faced. Also, the choice may depend on the design decisions of the external design of a country house. Wood materials are traditionally used for wooden houses - block house, imitation of a bar. Popular use of siding in cladding external surfaces of the house. It can be metal, wood, vinyl. The combination of various materials for finishing the pediment and lower floors can give the house an unusual and attractive look.

Video - The process of warming the attic and pediment

Recommended for viewing:

- Waterproofing the basement of a private house - the solution to the issue of protection from moisture - 02/17/2015 05:39

- Thermal insulation of a house with mineral wool - a solution to the issue of protection from winter cold - 02/16/2015 05:30

- Well insulation technology for the winter for its safety - 02/13/2015 05:27

Related Topics:

- Insulation of a boiler room - we reduce heat loss at home and heating costs - 06/02/2015 05:28

- Laying of engineering networks and communications - ensuring the life of the house - 03/02/2015 10:12

- Soundproofing a wooden house - creating favorable acoustic conditions - 02/02/2015 05:26

Materials for insulating the attic outside

Various materials can be used for thermal insulation of the attic outside, but whatever material the choice falls on, it must have the following performance characteristics:

- resistance to mold and moss germination;

- durability;

- maximum thermal insulation;

- environmental friendliness;

- fire safety;

- maintaining performance over time.

As relevant for this type of work, the following types of insulation can be distinguished, since they have all the above properties:

- Glass wool. The material known to all has a long history.High resistance to fire, low thermal conductivity and a democratic price make this material a fairly acceptable material, but the inconvenience of work significantly increases the time of insulation measures, and in some people it causes allergic reactions associated with the content of glass fibers in the composition.

- Minvata. It is a safer and more environmentally friendly glass wool option. In addition, it does not tend to absorb moisture and has excellent sound insulation. Therefore, attic insulated with mineral wool are suitable for creating living rooms or libraries (if the house has a high roof).

Insulating material such as expanded polystyrene requires special attention. This material comes in two versions, consider them:

- Styrofoam. The classical modification of expanded polystyrene, which consists of 98% of weightless granules with an impermeable shell. They undergo short-term high-temperature sintering, which gives the foam all the necessary qualities. As a result, the granules are pressed together and form a slab of the required size.

- Penoplex (extruded foam). The foamed mass of polystyrene is passed through the head of a special extruder, which leads to the formation of foam. In all respects, this material is superior to polystyrene, therefore, the insulation of the attic pediment from the outside with penoplex is, one might say, the most acceptable option.

Materials used

Various insulation materials can be used to insulate the pediment.

First of all, let's figure out the materials that can be used for insulation. Taking into account the specifics of their operation, heaters should have the following properties:

- antiseptic - mold and fungus should not start in the thermal insulation material, moss should not grow and rodents should not equip their nests;

- durability - thermal insulation must maintain its operational properties (especially low thermal conductivity) for a long time;

- good heat-retaining properties - the material must be such as to effectively protect the room from the cold;

- environmental friendliness - the insulation should not release substances hazardous to humans into the air, especially if you are still going to use it indoors;

- fire safety - this quality is very important for the attic, since in the event of a fire on the upper floors, human casualties are more frequent.

Mineral wool is a classic insulation based on basalt fiber.

Several materials are suitable for warming the gable. I have compiled a table with the technical characteristics and features of each of them, and you can choose the one that suits you.

| Material | Description |

| Glass wool | This material has long been used to insulate anything. Cotton wool has low thermal conductivity, and its price is affordable for any home craftsman. The downside is that when wet, the material ceases to perform the functions assigned to it, and the installation process itself is quite laborious. |

I would also not recommend insulating the walls with glass wool indoors. The material forms glass dust, which is hazardous to health and may cause allergic reactions.

Mineral wool is perfect for internal and external insulation of the attic, but it also needs to be carefully protected from getting wet.

Polyfoam is very light, therefore, after installation, it does not have much effect on the structural elements of the building, but it is fire hazardous. In addition, the material does not tolerate external mechanical stress, so it must be protected with a durable finishing material.

EPPS is suitable for insulating any surfaces, so they can safely insulate the gables of the attic floor. The only drawback is the higher cost (when compared, for example, with foam).

Attic insulation with foam

Insulating the attic gable with foam is a very laborious work with the use of scaffolding, therefore, before starting such a procedure, you need to take care of the appropriate safety measures, since the insulation will be performed at a height where you need to be extremely careful. And so, the process of external insulation of the attic consists of the following stages:

- Preparing the walls. The surface of the wall must be cleaned of dust and dirt, and then opened with a special primer, which will ensure reliable adhesion of the foam to the wall. The primer is applied in several layers. The application of each new layer is possible only after the previous one has completely dried.

- Installation of the lathing. The lathing is needed so that at the end of the attic insulation, the wall can be covered with decorative facing material (siding). For the lathing, two types of materials are used: wood or metal profile. There is more fuss with the tree, it must be covered with a special anti-corrosion solution so that it does not rot and mold under the influence of moisture. The lathing consists of a layer of horizontal beams, the size of which should be equal to the thickness of the foam (at least 50 mm). The step between the beams should also be repelled by the width of the insulation plate.

Warming of the attic gables - choose the material

The choice of insulation can rightfully be called the most important step, because the final result depends on it. Today on the construction market there are many different insulating materials, so it is very easy for a person who is not closely related to construction to get confused. Much depends on the climate here, because in some regions the temperature does not drop below -10 ° C, while in others it can reach -40 ° C. There are special programs that calculate the thickness of the insulation depending on the region, the depth of the walls, their composition and other parameters, it is reasonable to use these informational innovations.

Generally speaking, the insulating material should have low thermal conductivity, moisture permeability and have a low weight, since the work is carried out at a minimum height of the second floor. In addition, fire safety is important, as well as resistance to temperature extremes. It is also necessary that the insulation for the roof gables keeps its shape perfectly and has a long operational life.

Alternative insulation of the attic

The peculiarities of the climatic environment of our country require the use of a special highly effective material, such is polyurethane foam, which has managed to prove itself well in a short time. To spray it, you will also need to create a crate, but in this case, one layer will be enough. The polyurethane foam is applied to the wall using a special high pressure unit that sprays the polyurethane slurry and thus covers the wall without creating voids. When this material interacts with air, it foams and a moisture-resistant vapor-proof layer with the highest thermal insulation values is formed. At the end of the spraying and drying of the material, you can install the decorative facing layer in the attic.

Whichever option of warming the gable is chosen, you should always use only high-quality materials. In addition, careful and painstaking work always brings good results. Warming a house is a very delicate procedure that does not tolerate neglect. Quality and high-tech execution - these two concepts are the key to success in any construction work.

Building a private house with a warm attic is a difficult task. But in the mass of construction and finishing work, you can find those that you can do on your own. For example, thermal insulation with a mineral wool pediment of a wooden house from the inside.But even in this issue there are many questions that should be resolved - which materials are better to use in the work, where to carry out the work: from the street or from the inside. Let's try to figure out all these questions in this article.

The thermal insulation of the brick and wooden pediment of the house does not tolerate trifles, especially if you decide to equip a room for children. First, you should consider the technology of work, materials for thermal insulation, think over the ventilation of the dwelling. Using proven materials, you will never go wrong. But what is the best way to insulate the gable of the house so that there is no condensation inside the room?

How to insulate the pediment of a private house

With all the importance of insulating the attic with mineral wool, do not forget about the need to install high-quality metal-plastic windows, which must also be insulated, as well as about waterproofing the rafter system. In the first case, you will reduce heat loss in the house through the roof, in the second, you will significantly increase the service life of the entire roof in a private house, protecting the tree from fungus and mold.

Warming of the pediment with expanded polystyrene

Polyfoam does not meet modern fire safety standards and is harmful to human health, but at the same time, this material is the cheapest and most convenient to use. As for extruded polystyrene foam, URSA XPS or Technoplex is an excellent insulation for damp rooms. Expanded polystyrene plates can be easily installed on absolutely any surface, outside or inside.

Warming the gable of the house with mineral wool

Mineral insulation is considered a good option for a pediment. Mineral wool is harmless, has excellent heat and sound insulation. Glass wool has not lost its relevance today, URSA PureOne is non-flammable, easy to use and has low thermal conductivity. All modern heaters can be used. The main thing is what will be easier and more convenient for you to work with.

Differences between frame and brick pediment

The frame pediment is sheathed with sheet material. It is convenient to use a cement-bonded slab here. Outside, final work is carried out, then a layer of insulation is laid, and inside, the final surface finish is performed.

If the pediment is planned to be made of brick, then the work is simplified. The same brick, which was used for laying the walls, is used in the future and for the construction of the pediment. In this case, it is not required to carry out internal work, except for plastering the surface.

How to insulate the pediment at home with your own hands

It is always better to carry out insulation outside, especially if the pediment of the house is made of brick. The fact is that when working from the inside, brick walls are under the influence of negative temperatures, a dew point arises between the masonry and the thermal insulation. When insulating from the street - all structures are reliably protected from freezing, and the dew point in the wall shifts to the insulation.

How to insulate the gable outside at home

Thermal insulation boards are attached from the street to glue for expanded polystyrene or to dowels between the bars of a pre-made frame. When self-warming the pediment with mineral wool, holes are pre-drilled onto which vertical bars of the required thickness are attached. In this case, the pitch of the bars depends on the width of the thermal insulation plates. Further, the pediment is covered with a roll vapor barrier.

To create a ventilation gap between the vapor barrier film and the cladding, slats of at least 20 mm thick are nailed onto the vertical bars. Further, the front is sheathed with vinyl siding. For insulation, it is better to use fiberglass or Paroc stone wool - the material perfectly retains heat, does not decompose, does not change its parameters at high temperatures outside.

How to insulate the gable of a house from the inside

It often happens that it is impossible to carry out insulation from the outside - decorative sheathing is made or the insulation will protrude too much. In this case, you will have to insulate the gable of the house from the inside - for this, the thermal insulation is placed between the beams of the wooden frame. For the attic laid out in half a brick, it will be necessary to additionally build a frame from a bar.

To begin with, all wooden beams should be treated with an antiseptic, then the entire structure is covered with roll waterproofing. Ideal when the gable frame is a fixture for basalt insulation. That is, the insulation is placed close to the wooden frame, it is advisable to lay the plates in two layers in order to avoid cold bridges in the structure.

Foil foam combines reflection and absorption of thermal energy, which reduces heat loss in the house in winter.

Due to the absorption of moisture from the warm air by the mineral wool, the thermal conductivity of the material increases. Therefore, a vapor barrier should be laid on the basalt insulation from the side of a warm room. Additionally, you can cover the front of a wooden house with foil foam, which is able to reflect up to 90% of thermal radiation back towards the living room in the attic.

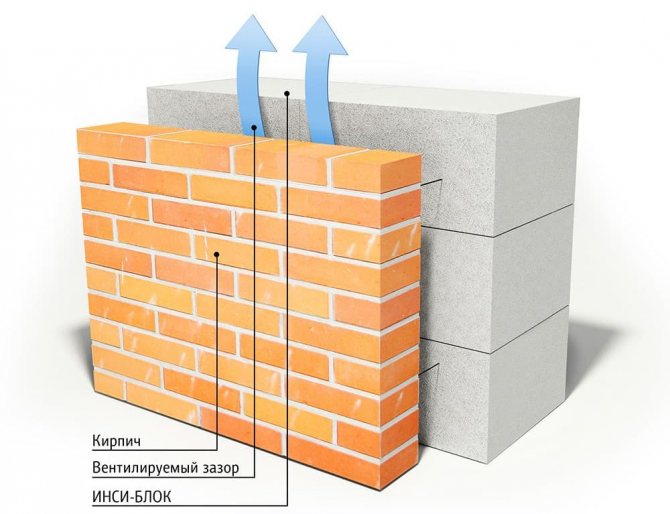

Warming the gable in houses made of block materials

In houses of this type, experts recommend insulating the gable from the outside of the building, this excludes the appearance of condensation and freezing of the walls.

Violation of technology can cause a number of problems:

- a shift in the dew point inside the room leads to the appearance of moisture on the walls, temperature drops lead to its destruction;

- the appearance of dampness contributes to the development of fungus and mold - an unhealthy microclimate in the house;

- a cold bridge is formed along the wall;

- internal space decreases due to the thickness of the insulation;

- not all materials can be used in living spaces.

Stages of work

- Installation of the lathing. It is made from wooden blocks or a metal profile. The frame racks are installed at a distance of 58 - 59 cm in the light.

- Insulation is inserted between the elements of the crate and, if necessary, attached to the wall with special dowels.

- The windproof film, which protects the insulation from the external environment, is laid close to the insulation and is attached to the crate.

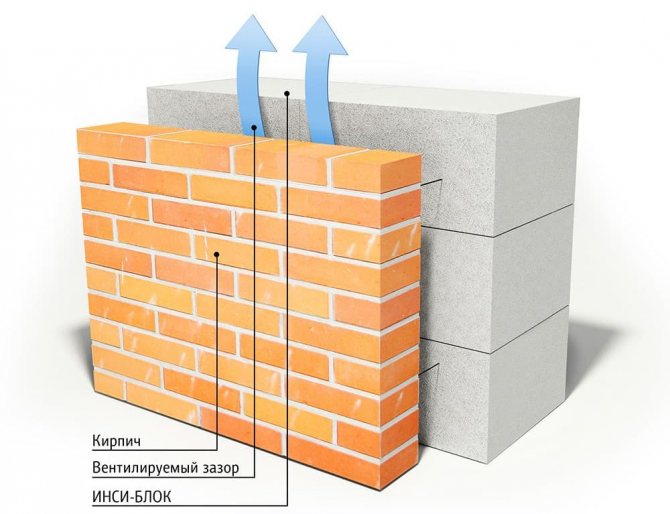

- A ventilated gap is made between the outer trim and the protective film, which is needed to remove moisture from the structure.

If the lathing is wooden, use bars about 2 cm thick, they will be used for external finishing materials: siding, block house or lining.

The effective operation of the entire insulating contour of the under-roof space, warmth and absence of dampness in the house largely depend on the correct insulation of the gable.

Before starting work

The decision to insulate the gable of the house should be taken carefully and deliberately. The very location of this structural element requires care and caution in the work, and the technology and method of insulation - to meet the set goals.

First you need to figure out what should happen in the end after the completion of the work. Installing one or more layers of insulation on the outside of only one attic pediment will not give the desired effect when it comes to creating a comfortable temperature under the roof. For the arrangement of the attic, even the insulation of all the gables of the house will not lead to the desired effect - here you also need to insulate the roofing part and install a multi-layer insulation between the rafters.

But in order to provide an air cushion under the roof, in principle, insulation is not needed - it is enough to simply seal the cracks hermetically.

Therefore, if a decision is made to insulate the pediment of the house, then the process itself should be considered as one of the few operations in the total volume of work to ensure resource savings and create comfortable conditions in the home.

How to insulate the attic pediment outside and inside - a step-by-step scheme

Step 1: material preparation

First of all, you need to decide on the choice of material, and if we are talking about internal work, then expanded polystyrene, foam and mineral wool are suitable. As for the exterior, the insulation must have a certain rigidity for it. In addition, it is also necessary to prepare steam and waterproofing, without which the attic space will become damp, which contributes to the appearance of mold, which is very harmful to health.

Step 2: Installing the battens

It is best to use a galvanized profile for these purposes, which will perfectly withstand the load and will not rot or corrode. Moreover, it is very important for external insulation so that the material does not slide off the roof, therefore it is necessary to nail a rail of the same thickness as the insulation, from below to the rafters... She will act as a support. For internal insulation, the role of the lathing is performed by beams, while it is necessary that their thickness is not less than the insulating layer, otherwise the frame must be increased with the help of strips.

Step 3: Installation of insulation

The selected material is placed either between the profiles of the battens or between the beams. The layer must be solid and have no gaps, otherwise all the work will be done in vain. At the joints, the strips should be laid with an overlap of at least 10 centimeters and sealed with construction tape. Please note that sheet insulation must not be compressed in any case. Insulation with polyurethane foam is carried out using a special installation that supplies the foam under pressure, thus obtaining a monolithic layer without gaps.

Step 4: Hydro and vapor barrier

Depending on whether work is carried out from the outside or from the inside, and the sequence of installation of waterproofing and vapor barrier is determined. However, the bottom line is that the layer of material should always be on the inside so that warm air, which tends to rise upward, does not spoil either the insulation itself or the wooden beams and, of course, does not leave the room. But the waterproofing goes already from the outside and prevents soaking, which is possible as a result of a rainstorm, melting snow, etc. If foam polyethylene was chosen, then a vapor barrier layer is not needed, since one of its surfaces is covered with foil, which will perform these functions.

Step 5: decorative finishing

For these purposes, a variety of materials are used. On the inside, drywall, plastic, wood, etc. are very often used. For exterior decoration - siding and decorative plaster, the pediment is often sheathed with corrugated board. It is very important that there is an air cushion between the insulation and the finishing material. In order for the effect to be maximum, and the work to be carried out easily and quickly, the question of how to insulate the gables of the attic must be resolved at the construction stage.

Insulation methods

When developing the sequence of work and methods of their implementation, you should not invent something new, it is enough just to use the experience of professional builders. In this regard, nothing supernatural has been invented. There are two ways to insulate the gable at home:

- From the outside;

- From the inside.

In principle, if funds and time permit, you can combine these two methods and install insulation on both the inner and outer sides of the pediment.

Both methods are used for all technologies for applying heat-saving coatings and materials, except that mats made of natural technical wool and rags are not installed from the outside - they are too hygroscopic in the open air. Otherwise, literally all materials can be attached both from the inside and outside of the structure.

Insulation of the pediment from the inside

This method, in comparison with external insulation, is not only safer, but also allows the use of some non-standard technologies and materials. Working under the roof allows you to make the insulation better and not to look back at the weather conditions. Working under the roof also allows for the comprehensive implementation of the task of insulating the roofing structure in preparation for the arrangement of the attic.

Warming the gable of the house from the inside

For insulation from the inside, the following are used:

- Mineral wool;

- Styrofoam;

- Penoizol;

- Natural natural materials;

- Foamed polyethylene;

- Gas and foam blocks.

The technology for installing an additional coating for wall insulation allows the use of materials with a higher density and weight. This is especially true for the insulation of the gables of buildings with interfloor floors made of reinforced concrete slabs. Considering that the slab is capable of withstanding a load of 450 kg per 1 square meter, the construction of an additional wall from foam blocks does not seem such an impossible undertaking.

The difference between internal and external insulation

Having dealt with the gables as such, I want to substantiate my own position on why I consider the insulation of the gable from the outside to be more effective than the internal one.

In support of my position, I will cite the following considerations:

- If you install thermal insulation material inside, the dew point will shift towards the attic. That is, the wall of the pediment will freeze over a greater distance than before insulation. Accordingly, the material of the enclosing structure will quickly deteriorate and collapse.

- If you use, for example, polystyrene for internal insulation of gables (especially in the case when people are not supposed to live in the house all year round), then rodents can start inside the insulation layer.

- External insulation does not lead to a decrease in the usable area of the attic room. The entire insulating cake will be outside.

However, below I will talk about both methods of warming the gables so that you can choose the right one for yourself.

Insulation of the gable outside

The external location of the insulation elements has several advantages over the location of the insulation inside. The first thing that needs to be emphasized here is that the internal space does not decrease, this is essential in conditions of a shortage of attic space. Secondly, external insulation is most often installed as part of a general house insulation plan, which means that the facade of the entire building will be reliably protected from cold penetration at joints and transitions.

Warming the gable of the house outside

Alas, external insulation somewhat constrains the maneuver for the use of certain technologies, but given the quality of the insulation, its density and installation system in no way affect the result of the work. It should be noted that for outdoor installation do not apply mats made of rags and natural cotton wool and natural plant insulation - mats made of pressed straw or reeds.

For installation outside the building, the following are used:

Mineral wool insulation

Basalt mineral wool today is considered one of the most promising insulation materials. Cotton wool is used for both outdoor and indoor installation, while choosing the dimensions of the plates, you can select not only the material according to the thickness and dimensions of the plates, but also according to the density of the material.

Among manufacturers, it has recently become fashionable to produce not just material for installation, but to create entire systems for work. Mineral wool is no exception in this series. Several types of material are supplied to the market for thermal insulation of facades, including facade systems for fastening with adhesive mixtures. Plates for installation in the factory are impregnated with a primer, as a result of which the plates themselves are more rigid.And the ease of installation is achieved by the presence of figured protrusions on the ends of the plates.

Technology for installing mineral wool on the outside of the pediment:

- A special perforated profile (or special brackets) is attached along the line of the lower edge of the floor slab from the outside of the building.

- On the roof, the wind board is removed from the side of the pediment.

- For brick or other block-type wall materials, a coat of primer must be applied.

- For pediments made of wood or fiberboard, an antiseptic treatment is carried out.

- Glue and slabs are being prepared.

- The glue mixture is applied to the slab in large 5-6 points and smeared. The slab is inserted into the profile and pressed tightly against the building.

- To enhance the adhesion, the plate is additionally fixed through the body of the screen with plastic dowels with large caps.

- Plates are installed on wood with self-tapping screws and washers.

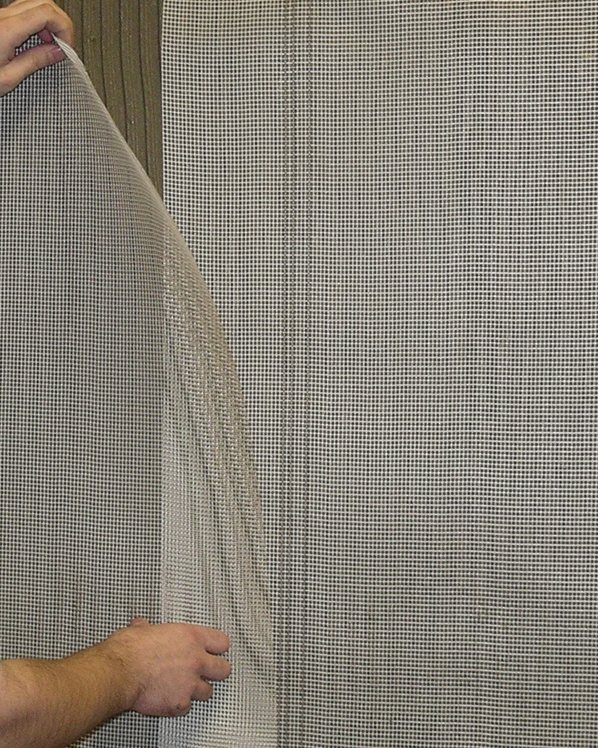

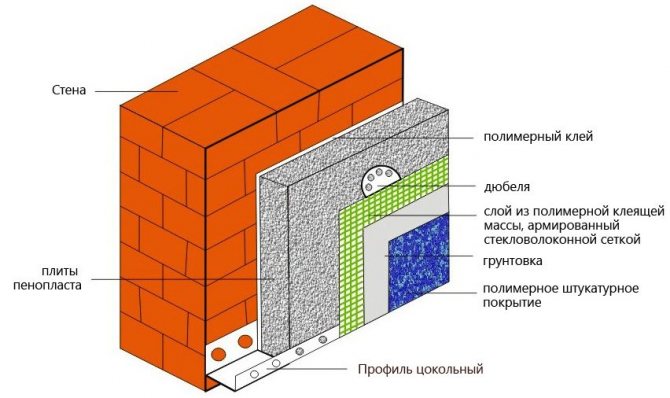

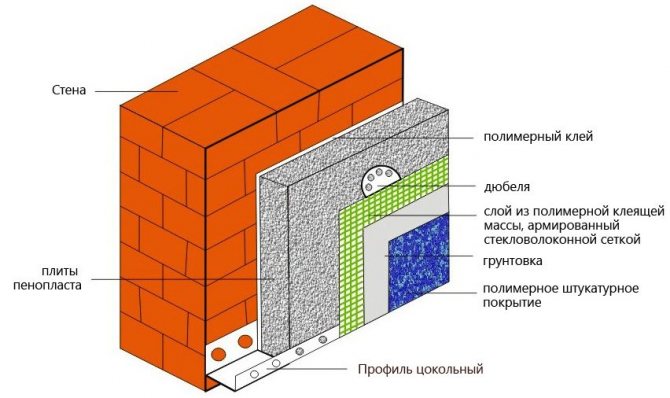

- After installing the entire gable cover, the cotton wool is treated with a primer (or the same glue), and a reinforcing mesh is installed on it.

- Plaster is applied to the surface and facade paint on top of it.

- The wind boards are returned to the roof.

As a result, the layers should look something like the image below:

Assembling the gable of a frame house

How to make a pediment of a frame house - How to make a pediment of a frame house

Due to the responsibility of this stage of construction, all dimensions were checked again before sawing the boards: this increased the time for assembling the gables, but avoided unnecessary waste and rejects. The sequence of work was as follows:

- prepared, laid and secured (for ease of assembly) boards of the lower strapping;

- the side boards of the pediment (adjacent to the side walls of the frame attic) were sawn and laid according to the markings;

- sawn and laid exactly according to the markings of the board of the upper trim of the pediment (inclined); at the same time, these boards were rigidly fixed in a straight line with bars (to avoid bends during the further installation of internal racks);

- the boards of the central (prefabricated) rack were prepared and laid;

- all the characteristics of the outer dimensions of the pediment have been checked again;

- all the listed elements are fastened together with nails.

As a result, we got a kind of large wooden frame, the internal space of which had to be filled with racks or other necessary elements.

Pediment of a frame house with an attic - Pediment of a frame house with an attic

- from a board 150x50 mm, two templates were prepared with a length equal to the step of the posts;

- according to the design drawing, these templates were applied at an angle of 900 to the post (one - next to the lower strapping, the other in such a way as to enter between the post and the inclined strapping of the pediment; first to the central post, then in order ...);

- using a tape measure, the actual required dimensions of the inner rack were removed, after which it was sawed off and placed inside the pediment frame;

- if everything was fine, the rack and frame were connected to each other.

Insulation with penoizol

The technology of applying liquid polyurethane foam to the pediment, both from the outside and from the inside, allows you to make a durable and reliable coating of the house structure. Foamed penoizol allows you to reliably seal any, even the most difficult surfaces, with a guarantee of excellent service for 30 years. To apply it, you must have a certain qualification and special equipment, so it is unlikely that you will be able to do the work yourself. But the cost of thermal insulation with polyurethane foam will pay off with interest - this material is of such high quality.

Warming of the pediment with penoizol can be done both outside and inside

The technology of spraying the coating ensures the spraying of liquid foam insulation on any surface, while the high adhesion of the composition literally sticks it to any surfaces and materials. Processing is carried out using a spray gun. The maximum thickness of spraying for 1 pass is not more than 1 cm on the ceiling surface. After spraying, the layer dries up within 1 hour, after which the treatment can be repeated.

The maximum number of passes through one place is no more than 5. To obtain a larger thermal insulation layer, it is necessary to install a reinforcing screen made of fiberglass or metal mesh. From the inside, when spraying a layer of penoizol, it is recommended to fill the pediment with wooden blocks to the thickness of the required layer. The bars are installed vertically after 50-70 cm. The foam is sprayed in 4-5 passes, allowing the previous layer to dry completely.

After the entire volume is filled, the excess nodules are simply cut off with a knife, and then the wall is plastered with plaster mixtures.

Foam insulation

Foam is available on the market today in several material variants, in particular, conventional foam and extruded. The first type of material is in the form of slabs consisting of compressed granules. The second has the form of a monolithic formation with a large number of air cells. The difference in these two materials of the same type lies in density - the first has several density categories, but the densest conventional foam is lower in density than the extruded lowest density.

The usual type of foam is used mainly for external insulation, extruded - mainly installed inside the building. The first is combustible, the second has fire-fighting properties.

The installation technology is in many ways similar to the installation technology of mineral wool slabs. A zero rail is also mounted, glue is also applied, and the plate is fixed with dowels. The difference lies in the fact that the joints of the slabs are still processed with glue, which gives the structure more rigidity and excludes the penetration of air into the space under the slabs.

Wall insulation scheme with foam

Warming with natural materials

The popularity of environmental programs could not ignore the topic of the production of heaters. One of these new materials used to create a thermal insulation layer is straw or reed fascines.

The structure of this material consists entirely of natural fibers. Before getting to the construction site, the material is thoroughly dried, treated with antiseptics and bound into mats. Actually, insulation with the help of straw or reed stalks was used in housing construction until the mid-50s, so, given the service life of such a heater, there is nothing strange in the fact that it has received a second wind today.

On the inside of the pediment, after installing a wooden lattice, steam and waterproofing, the insulation elements are installed on top of each other and fixed to the lattice with self-tapping screws with large caps.

To strengthen the insulation, it is treated with a primer and a reinforcing fiberglass mesh is attached with self-tapping screws. The plaster solution is applied in the same way as on a regular wall, with the only difference that the reinforcement will have to be done for the second standing plaster.

Recently, the method of application is often used for internal thermal insulation. clay solution with natural fillers. This method is also environmentally friendly as it does not contain harmful chemicals. The method is based on the principle of increasing the wall thickness by installing an additional layer of clay plaster with fillers from natural materials.

The filler is sawdust or small shavings and finely chopped straw.The filler mixed with clay is poured with water and mixed thoroughly. Wooden blocks are installed on the pediment in the same way as for penoizol. Using a painting bucket, the solution is poured onto the wall and leveled with a trowel. The filled niches should dry well before proceeding to the next stages of work. After drying, a dense and reliable layer of plaster forms.

Rules and methods for the construction of the attic pediment

Since the pediment part bears significant loads, formed not only by the weight of the rafters and the roof, but also by the influence of the environment: wind, snow, its construction requires strict implementation of technologies and additional strengthening of the structure. In addition, do not forget about the aesthetic function of the pediment, which largely depends on the choice of material for the construction and decoration of the pediment.

There are two main ways to erect the gable part: before installing the rafters or after. If you plan to use the pediment as a support for the rafter structure, then first build a wall. The advantage of this method is that the rafters will not interfere with the work. Nevertheless, there are significant arguments in favor of installing and sheathing the pediment after the construction of the rafter system. In this case, the risk of roof distortions due to errors in geometric shapes that are possible during the initial erection of the pediment is significantly reduced. Design errors can cause cracks or wall collapse. This method of creating the attic pediment is also used to facilitate the construction of the house.

Choice of gable construction - brickwork or wooden frame

To create a pediment, either brickwork is used, which is, as it were, a continuation of the main building, or a wooden frame with subsequent sheathing with sheet material. Brickwork does not require subsequent external finishing. In the case of creating the frame of the attic pediment, the ends of the beams can be brought out. The frame method allows you to avoid problems with skewing of structures during the settlement of the building. After installing the wooden frame, it is sheathed with sheet materials: plywood, cement-particle boards, fiberboards, drywall.

Insulation with foam and gas blocks

The gables of private houses are mostly of a small thickness. It is for this reason that they are not able to provide reliable thermal insulation of the attic space and require additional thermal insulation. When implementing the project for rebuilding the attic space into the attic, it is rational to insulate the gable from the inside, additionally building a wall of foam or aerated blocks.

An increase in the thickness of the pediment wall by 30 cm will significantly reduce the penetration of cold into the attic through the pediment on one side, and on the other hand, such a wall makes it possible to improve the sound insulation of the room.

For installation, solid blocks are usually selected, but if it is possible to build a wall from blocks with voids, such an additional air gap will definitely provide better thermal insulation. Laying is carried out from the inside of the pediment:

- Waterproofing is first installed on the slab - a layer of roofing material or polyethylene;

- The first row is laid on a layer of mortar and leveled in height;

- Laying of the second row is carried out in compliance with the rule of block displacement by 1/2 block;

- During the work, the blocks are adjusted in size to the slope of the roof.

- The finished wall is primed and plastered.

The second version of the construction of the wall provides for the formation of an air gap of 5-10 cm between the pediment and the blocks.At the same time, so that cold air does not penetrate into the space, the extreme blocks of the rows are installed so that they touch the wall tightly and thus form a completely sealed space.

The use of different technologies for warming gables allows you to obtain significant resource savings due to the formation of a sealed attic space above the living quarters, which can reduce the heat loss of the building to 12-13% of the total heat loss. And this means that the work performed on warming the gables will pay off literally in the first heating season.

How to insulate

Considering the variety of designs of private houses and cottages, there are also a lot of variations on the construction of gables, and yet, it is still easy to choose the option of insulation.

There are two main types of gables:

- Formed from the material of the wall - is an integral part of the wall and the supporting structure for the pitched roof.

- The gable is represented by part of the roof structure and there are support beams for the rafter system.

- The gable is shown as part of the pitched roof, but does not include supporting elements.

In the first version, everything is quite simple. Wall insulation of any format extends to the pediment.

If it was a ventilated facade, then the pediment is sheathed with the same set of materials. With only one caveat, the pediment itself along the border of the wall is separated by a lintel, a visor, moreover, from the base to the necessary removal required for the removal of atmospheric precipitation. Taking into account the mandatory thermal insulation of the floors, the separation of the gable and the wall will help maintain the correct distribution of heat along the building envelope.

If penoplex or expanded polystyrene with a wet finish is used, then the entire plane of the wall with the pediment is covered by an unbreakable layer of insulation, and the visor or other way of visual highlighting the pediment is carried out already on top of the outer finish.

In the second case, the pediment is formed along the logs, the upper part of the wall and includes several support beams. In fact, such a pediment can be sheathed from the outside as you like. However, for the supporting structures and, accordingly, the lag, it is required to create similar conditions as for the rest of the roof structure, so that insulation from the inside is chosen in the same way as the thermal insulation of the roofing pie. An alternative can be a combined option with the distribution of insulation from the outside and from the inside, especially if the option with a ventilated facade is chosen for the walls.

In the third version, as such, there is no division into internal and external insulation. The pediment is limited only along the perimeter, and there are no important load-bearing elements in its plane. It is enough to decide on the appearance of the pediment so that it is combined with the walls in the general view of the facade, and then apply the frame method of insulation using materials identical to those used for roof insulation.

Even if it concerns the insulation of an already operated building, in which the pediment is protected by wooden boards, but they do not bear any load, this does not give any significant restrictions on the choice of the type of thermal insulation. It is better and easier to dismantle the cladding and form an adequate sandwich panel than to fence around it with insulation.