Possibilities of using foam fillers

Balloon thermal insulation although in all respects it is better than analogues, but in the past it was not widely used due to its high cost. And the use of such insulation was limited by the need to use special equipment, which is practically inaccessible outside the professional sphere for the price and complexity of development. Much easier and more profitable, although not always more convenient, remained the use of mineral wool and polystyrene boards, which were made by the extrusion method.

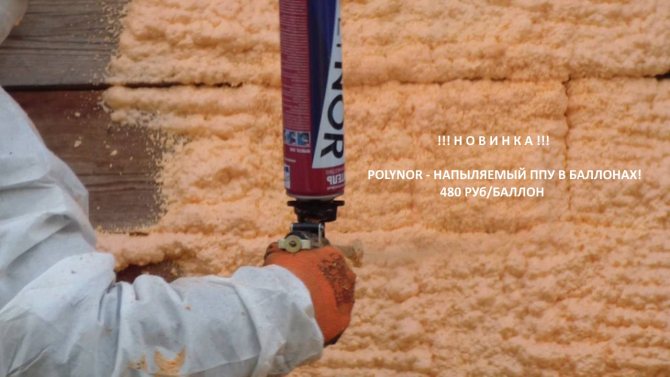

Then manufacturers began to produce sprayed insulation in compact cylinders, which led to a decrease in the cost of the method. Spraying such a mixture of steel does not require complex installations and specialists in thermal insulation finishing, since the material itself is filled in small containers and the possibility of manual spraying is provided. Each cylinder is designed to cover one square meter of the base (layer up to 60 mm thick). One person can process up to one hundred squares per daylight.

As a result, the calculations showed that to work with such a heater as Polyno

r is much more profitable in terms of labor costs, the costs of the materials themselves and the preparation of surfaces. If a professional team of workers asks for insulation of one square of the wall up to one and a half thousand rubles, then using Polinor insulation with a similar amount of material, you need to spend only about 500 rubles. You can work independently, which eliminates the need to look for experienced workers, reduces finishing time, and saves money.

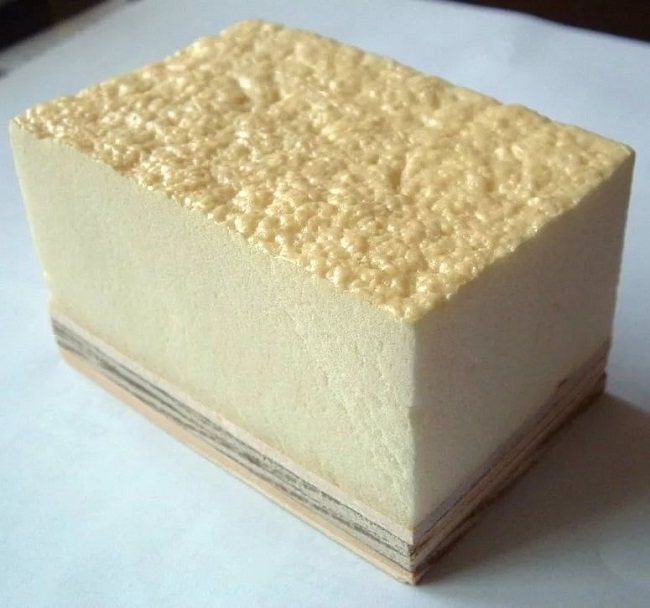

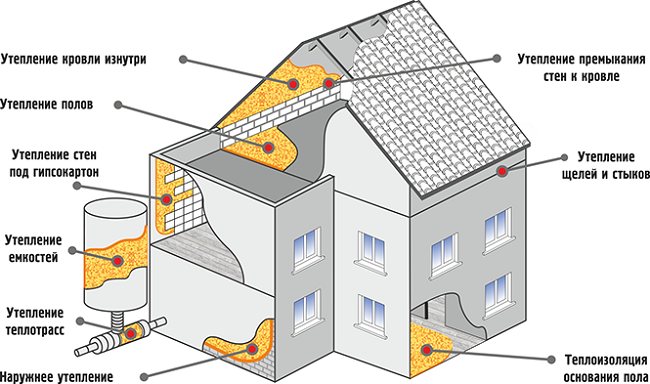

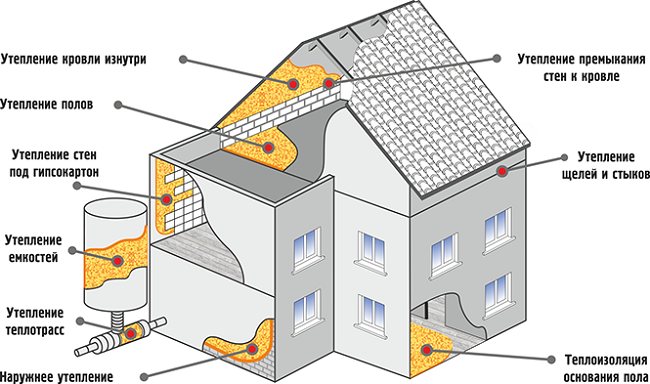

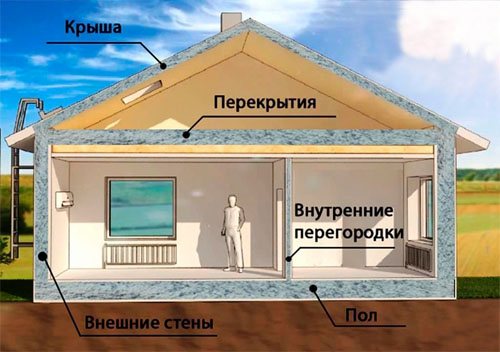

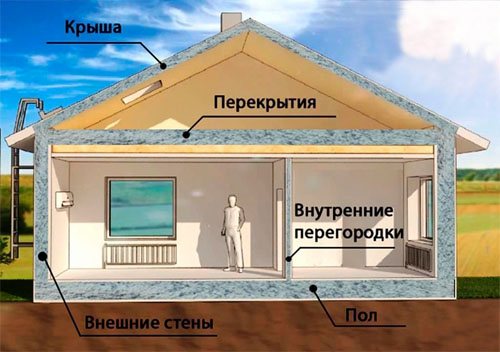

The choice of this type of thermal insulation remains the only optimal option that is available to people without special training. Foam can be used to create insulation of foundations, basements, walls inside and outside buildings made of brick, stone, concrete, blocks. This option is also suitable for thermal insulation of unloaded coatings, including floors on logs, as well as pitched roofs, attic floors.

Since Polinor is suitable for application to substrates made of almost any material, it can be used as thermal insulation for plumbing fixtures and sewer pipes or fittings. In such cases, it is possible to use foam insulation in cylinders indoors or outdoors. There is only one limitation on the use of balloon thermal insulation, which is that the material cannot be used for foaming voids. It is allowed to apply it only on a solid base.

Scope of liquid urea foam

As already noted, Liquid Penoplast is absolutely universal. Today we can talk about successful application:

- For interior work (gluing light structures, thermal insulation of shower cabins, bathtubs (both tin and metal), sound insulation).

- For outdoor work (facade work, waterproofing of joints, bodywork, installation of concrete blocks (round) and a number of other areas).

The method of using foam insulation is quite simple. The surface is preliminarily cleaned of dirt, moistened with water (except for situations when the process is carried out at a temperature below 0 ° C).

According to reviews of foam in a liquid state, the optimal temperature is + 20 ° C, but if it is lower, then it is recommended to warm up the packaging in advance using a container with warm water, but not higher than 50 ° C. In hot seasons, overheated packages are also cooled with water.

We recommend that you familiarize yourself with the reviews of people who have already tested liquid foam insulation in the case to make sure that its description and characteristics are correct.

Testimonials

“Last year I faced the problem of insulating a private house. I decided to take the advice of friends and use liquid foam. In principle, I was satisfied, but the unpleasant smell lasts for a long time in the premises, which is why, after work, my family and I had to move to my parents. "

Igor Rumyantsev, Chelyabinsk.

“Last fall I flooded a private house with liquid foam. I decided to do the same as my neighbors, who praised this product very much. The price of Liquid Penoplast was fine. He did not take up the work himself, he hired a team of specialists. At the end of the work, I had to move in with friends, as the house smelled terribly of chemicals. Now there is no smell, and it has become warmer. "

Nikolay, Moscow.

“In June of this year I made repairs in the apartment. Since I live on the 8th floor, the house is cold as at the North Pole. After reading reviews on the Internet, I decided to use Liquid Penoplast insulation in cylinders. In principle e, I was satisfied, and only because the price is low. The disadvantages of liquid foam are a strong pungent odor that did not disappear for a long time, a mass came out of the cylinder poorly (without pressure), which made it worn out. Maybe the reason is that I purchased a low-quality product (fake). "

Vasily, Yekaterinburg.

Material characteristic

Polyurethane foam (PUF) looks like a homogeneous structure of foam material, consisting of air bubbles filled with gas. Various versions of PU foam are deservedly popular, because they can be made directly at the construction site. The most common method is to spray the material onto the surface. Spraying is used for thermal insulation of houses, industrial workshops, pipelines, and in addition, it is actively used in the interior of premises.

Filling is used if it is necessary to fill the cavity between the walls or the gap between the installed finishing layers.

The thermal conductivity of the material is 0.023-0.025 W / mS. The Teplis heat insulator is lightweight and can be easily applied to surfaces made of any materials (concrete, brick, glass, wood, aluminum, PVC).

Due to the optimal ratio of open and closed cells in the structure, the insulation "breathes". Accordingly, the treated surface always remains clean and dry.

Other benefits of the product include:

- resistance to temperature changes;

- environmental friendliness;

- duration of operation (at least 20 years);

- seamless application, excluding the occurrence of cold bridges;

- good sound insulation;

- low flammability;

- immunity to harmful rodents and insects.

Teplis polyurethane insulation is sold in 1 liter cylinders. Included with this product, the manufacturer offers to purchase a mounting gun with nozzles for uniform spraying.

Plinth of a house with sprayed insulation

Material advantages

Sprayed insulation is characterized by high adhesion to any surface

Construction specialists prefer polyurethane foam in favor of analogues such as insulating shells, matte and solid insulators.

Pros of PPU:

- Ecological cleanliness. The foam does not contain substances harmful to humans and the environment. It can be safely used indoors and outdoors.

- Low coefficient of thermal conductivity. This figure is significantly lower than that of such popular insulators as basalt wool and polystyrene.

- Lack of hygroscopicity. The coating does not absorb water, it always remains light and dry.

- Excellent soundproofing. The material cuts off street noises, prevents loud sounds from leaving the room.

- Biological inertness. The foam does not start fungus and mold, rodents, birds and insects avoid it.

- Resistance to active chemical reagents. The substance does not react to the effects of motor fuel, acids, alkalis, parasitic agents, oil and acrylic paints.

- Long service life. The service life is 30-50 years depending on the type and brand of the manufacturer. This foam does not require any maintenance.

- Corrosion protection. Due to its tight fit to the surface of the PU foam, it prevents the formation of condensation on it and the ingress of moisture from the outside.

- Lack of joints and voids. Foam fills all the smallest cracks and holes, covers the surfaces with a monolithic layer, in which there are no cold bridges.

- Fire safety. The material is not flammable, but on contact with an open flame emits toxic fumes.

- Resistant to extreme low and high temperatures. The range of application is from - 80 ºС to + 120 ºС.

- The ability to process surfaces of any complexity and hard-to-reach elements of engineering structures.

- Maintainability. If part of the cover is damaged, it is sufficient to fill the cavity with a similar material purchased from a hardware store.

- Profitability. There is no need to install vapor barrier and windproof films, pretreatment of frames and bases.

- The speed of application. The finishing speed is an order of magnitude higher than that of roll and tile counterparts.

An important factor in favor of choosing a PPU is its cost. On average, the consumption of polynor per m2 is 55-65 rubles, depending on the selected manufacturer and the equipment used.

Description and characteristics

Polinor is released in a liquid state, and is applied to the surface by spraying. Such popularity of the material is not caused by accident, because it has the following advantages:

- Fast drying. The surface hardens after 1 hour.

- Not influenced by rodents and insects.

- Does not form cold bridges.

- Does not harm the human body.

- There is no need to buy expensive equipment for application.

- The material is characterized by high efficiency.

- Has a long service life.

- The structure of the material is a closed cell that does not allow water or steam to pass through.

- The material is self-extinguishing if there is no direct effect of fire.

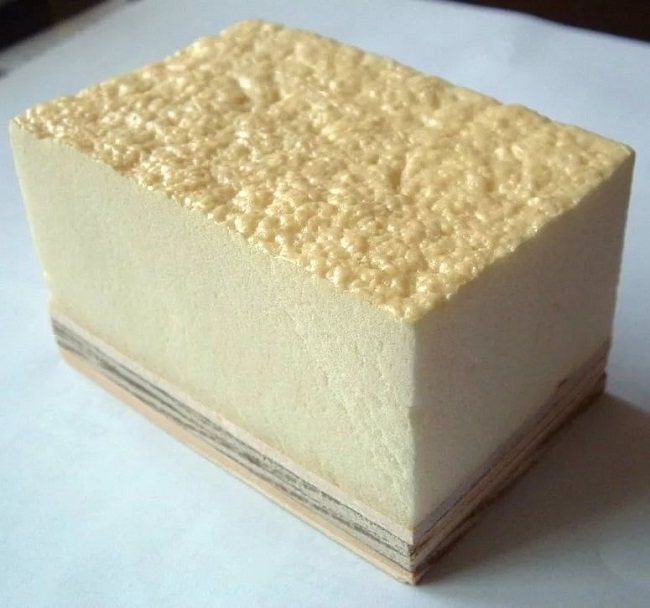

In the photo there is a liquid insulation in cylinders polinor

Polinor is not without its disadvantages, which include:

- The surface made of Polinor is afraid of the direct influence of UV rays, constant contact with water, and the process of applying the material should take place while observing the temperature regime of 15-25 degrees.

- When working with insulation, you must adhere to safety rules using a mask and respirator.

Compared to the existing analogues of liquid thermal insulation for walls, Polinor insulation is significantly different. First of all, the changes concern the structure, or more precisely, the percentage of open and closed cells in a solid mass. This criterion is very important, as it affects the level of thermal conductivity, moisture absorption and water permeability. With the help of Polinor, about 70% of the cells can be obtained, meanwhile, when using similar spraying agents, the number of closed-type cells will only be 30-40%. However, it cannot be used as a seal for interior doors.

On video - liquid insulation in cylinders polinor:

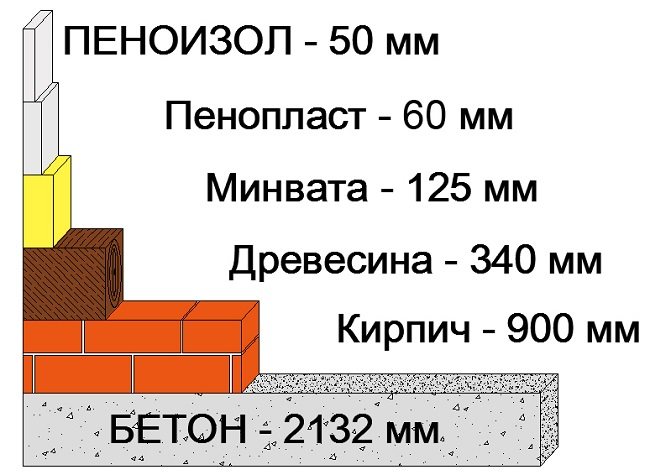

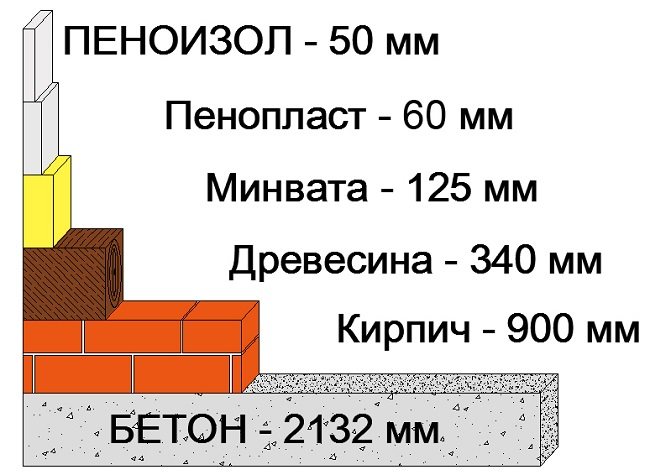

The material in question has a low heat conductivity among all heaters that are currently available on the domestic market. For example, for mineral wool, the thermal conductivity coefficient is 0.045, for expanded polystyrene - 0.033, and for Polinor - 0.023 W / m2 * ° C. Thanks to these properties of the heat insulator, it is possible to reduce its consumption. One balloon will be enough to treat 1.2-2.0 m2.

The sprayed heat insulator Polinor can be applied at temperatures ranging from -25 to +125 ° C. If it is affected by a temperature of 450 degrees, then its length is deformed by 85%, and the damage by weight is 50%. The duration of its self-combustion will be 5 minutes.

Polinor is an environmentally friendly insulation, thanks to which it can be used when arranging a residential building. The material has high adhesive properties in relation to various surfaces, resistance to moisture, chemicals and aggressive environments.

How to make urea liquid foam foam with your own hands.

Description of liquid foam - penoizol.

Urea insulation is a foamed plastic 98% composed of air and 2% of urea-formaldehyde resin with approximately the same number of both open and closed pores. The structure of its liquid foam is similar to the well-known meringue-type soufflé, and from afar many people confuse it with expanded polystyrene (polystyrene), but upon closer inspection, a material completely different from foam is guessed. Other names for insulation are mipora, liquid foam - penoizol, liquid insulation, urea foam, bipor and mettemplast.

Video: Appearance of liquid foam - penoizol and its mechanical properties.

Thermal insulation with liquid foam - penoizol.

- insulation of hollow walls: timber frame houses, timber houses with insulation for siding, hollow pockets in brickwork;

Video: Thermal insulation of the wall of a frame house with liquid foam - penoizol.

- floor insulation, for example, if the house is on piles with a ventilated underground;

- insulation of attics;

Video: Filling the floor and attic with liquid foam - penoizol.

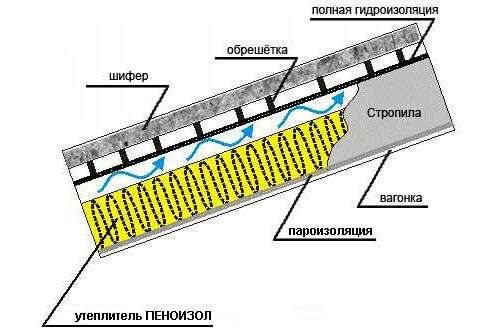

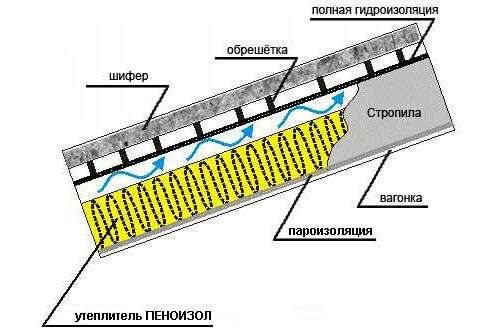

- insulation of the attic roof;

- insulation of industrial refrigerating chambers and containers;

- insulation of industrial premises.

Obtaining urea liquid foam - penoizol.

It is quite simple to obtain liquid foam - penoizol - it is a process consisting of several stages:

- Preparation of components: pouring resin and water into working containers, mixing the foaming agent and hardener with water, heating the water to 40 C;

- Filling the hydraulic system of the unit with resin and mortar;

- Trial pouring into a test container to control the quality of the insulation;

- Direct pouring of insulation into a building structure or mold.

The price of liquid foam - penoizol.

The cost of raw materials for obtaining liquid foam - with a 10th density at 2020 prices does not exceed 1000 rubles, even taking into account delivery.

Per cubic meter of liquid foam 10th density

required:

15 l. resin * 45 rubles = 675 rubles;

0.085 l. orthophosphoric acid * 120 rubles / l = 10.2 rubles;

0.170 l. foaming agent ABSK * 160 rubles / l = 27.2 rubles.

Total: 712.4 rubles / m3

Per cubic meter of liquid 20 density foam

required:

30 l. resin * 45 rubles = 1350 rubles;

0.085 l. orthophosphoric acid * 120 rubles / l. = 10.2 rubles;

0.170 l. foaming agent ABSK * 160 rubles / l. = 27.2 rubles.

Total: 1387.4 rubles / m3

One liter of resin contains 1.3 kg. The usual packing is 200 liter drums, about 260 kg in a drum.

In one liter of orthophosphoric acid - 1.75 kg. The usual packing is 20 liter cans of 35 kg each.

In one liter of ABSK foaming agent - 1.25 kg. The usual packing is 20 liter cans of 25 kg each.

For Siberia and the Far East:

LLC "Sibtem" Diller, Nizhny Tagil

Novosibirsk, Bordernaya street 3 (Pervomaisky district, Matveevka),

tel. 8-913-923-30-72 Yuri Gennadievich

Delivers: Resin: Criterm, phosphoric acid, ABSK foaming agent

OJSC "UralChemPlast"

Nizhny Tagil, Northern Highway, 21. Supplied by: Resin Criterm

Liquid foam

This type of insulation includes almost all foam materials based on polymer resins. It is on them that the quality of the final product largely depends, including its environmental friendliness. There are raw materials, the use of which is not permissible for residential premises, due to the high toxicity of the polymer and its long-term emission.At the same time, such materials are quite suitable for insulating technical structures, or isolated elements of a building (if there is confidence in their isolation and the conscientiousness of working specialists).

At the moment, such types of liquid foam are common as polyurethane foam, penoizol, as well as a number of products in compact cylinders.

Polyurethane foam (PPU)

Viscous heterochain polymers in a liquid state are used as the main component of this insulation. In the course of chemical reactions, urethanes foamed, which leads to their increase in volume by more than 50 times.

In the solidified state, polyurethane foam resembles ordinary polyurethane foam, the main difference in the structure is lower porosity.

Used mainly for:

- Insulation of walls of frame structures;

- Roofing structures;

- Facades of houses;

- Thermal insulation of basements and lower floors.

To apply polyurethane foam, a special unit is required, which first mixes and foams the insulation components, and then the finished mixture is supplied under pressure to the surface to be treated.

The final polymerization takes place within 24 hours, after which the finish can be mounted. Polyurethane foam is suitable for the treatment of surfaces made of bricks, concrete, wood, metal, cinder blocks and gas silicate blocks.

The average cost of work together with the material is 1000-1500 rubles per m2, with a layer thickness of 50 mm.

Penoizol

A budget analogue of polyurethane foam insulation, since it is based on a relatively cheap, but more toxic urea-formaldehyde resin. In structure, this insulation is very similar to ordinary foam, but its use is more preferable due to the absence of cold gaps in the insulating layer, typical of sheet and roll materials.

The density of penoizol, even in a liquid state, is noticeably lower than its urethane analogs, which does not allow its use in loaded structures. The rest of the area of application is similar to polyurethane foam. Thermal insulation qualities are also not exceptional and are comparable to mineral wool, and two times less than that of the polyurethane foam described above.

It is applied under pressure after pre-mixing the components and foaming. Increases in volume by no more than 30 times relative to the original mixture.

Roof insulation with penoizol

Working with the material costs about 2000 r per 1 cubic meter.

Polyurethane foam

The products are mainly used in the processing of joints between insulation elements. Polyurethane foam is relevant as a means for sealing structures; it is also used for fastening construction and finishing materials to the base being equipped. In terms of operational characteristics, the resource has an average level of efficiency. Do-it-yourself polyurethane foam for insulating the walls of a house is produced in small-capacity cylinders, the products are presented in a wide variety of models. When applied, the composition expands 20 times. The material is easy to use independently, even an amateur can handle the job.

Polyurethane foam

The building material of this category attracts with its versatility of purpose. Polyurethane foam as thermal insulation demonstrates a high level of efficiency. The composition of polyurethane foam has excellent properties of resistance to aggressive environmental influences. After foaming, the primary production volume increases 40 times. The presence of many microbubbles in the two-component compound determines the extremely low thermal conductivity of this foam insulation. The use of polyurethane foam for wall insulation involves significant costs, since the composition is applied using special equipment. The service life of PU foam reaches 50 years.

Polyurethane foam for wall insulation

"Polinor"

It is a liquid insulation based on polyurethane.A common form of release is small cylinders, externally similar to those for polyurethane foam. Using one balloon, you can insulate about 1 m2 of the surface with a layer thickness of 6-7 cm.

Strength and heat-insulating qualities are similar to polyurethane foam, but unlike it, Polinor is more suitable for domestic use, since it does not require special equipment for application. Relatively high cost (about 500r per bottle) makes it impractical to use it in large areas.

The insulation is applied by spraying, which allows it to be used on almost any surface, for example, for thermal insulation of outdoor pipelines.

As for filling voids in the walls, this procedure cannot be performed due to insufficient pressure in the cylinder.

Polinor has the following technical characteristics:

- Thermal conductivity - 0.025 W / (m * K);

- Moisture absorption coefficient - no more than 0.03;

- No toxicity, non-flammable;

- Solid density - not less than 28 kg per m3;

- Retains all operational properties for 50 years;

- Use temperature should not exceed + 121 ° C;

In addition, the mixture is quite chemically stable and does not interact with most reagents common in everyday life. Chloroform, dichloroethane and high concentration hydrochloric acid have a negative effect (promote swelling) on Polinor. Nitric and sulfuric acids react with polyurethane, thus destroying the insulation mixture as a whole.

Actual prices for your city:

The use of penoizol for home insulation

Penoizol is produced by foaming urea-formaldehyde resin and its further polymerization. The convenience of this material lies in the fact that it is produced directly on site. Penoizol under pressure in liquid form is supplied to the insulated surface, filling it with itself. Insulation with penoizol not only significantly saves time and effort, but also has a fairly reasonable price. At the same time, money is not spent on loading and unloading operations, transport services, fastening materials, and there is no need for an area for storing insulation.

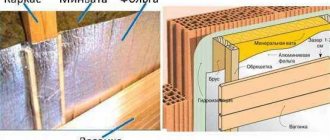

Roof insulation scheme with penoizol.

Differences and advantages of penoizol

- Penoizol differs from other materials in the peculiarity of the insulation work. The process consists in the fact that a hinged facade is initially built, and then the cavity is filled with penoizol under the vapor-conducting membrane. This method can be used to insulate walls, attics, roofs, and so on.

- Having low thermal conductivity, the material also has a low bulk density. After drying, it has a fine-mesh elastic structure, absolutely odorless. Its air absorption is almost zero, it is not hygroscopic, fungal mold does not form on its surface, and mice do not eat this insulation.

- It should be noted that working with penoizol is possible only at a certain temperature, it should not be lower than 5 ° C.

- The material is environmentally friendly, for which manufacturers must have licenses and certificates. Penoizol is not only high-quality insulation, but also excellent sound insulation.

Insulation of houses with penoizol

Wall insulation scheme.

To insulate a house, you will need a foam generator, with the help of which not only penoizol is produced, but also it is poured or foamed directly. The technology of work with this insulation allows you to fill it almost anywhere. This material is very convenient because it can be used almost anywhere. They can:

- insulate loggias and balconies;

- fill the gap between the main wall and drywall;

- to make pouring for siding, wooden floors, panels;

- insulate the bosom of the inner and outer walls.

It is very convenient to insulate ready-made, finished structures. For example, to fill voids in the walls, it is not at all necessary to disassemble the structure, it is enough to drill several holes taking into account the diameter of the steam generator hose and fill the voids with foam insulation through them. In such cases, experts recommend pouring from the bottom up.

For this job, you will need very few materials and tools.

The best manufacturers of polyurethane foam

The rating of well-known manufacturers of polyurethane foam is headed by brands that have earned recognition in the construction industry.

Soudal

The brand has factories in Poland, Belgium and Slovenia. The Soudal brand products provide a structure that meets high European standards and a good output volume. The sealant does not darken and does not deform over time, the product's durability indicators are impressed.

Krimelte

A manufacturer from Estonia (brand Penosil) offers a variety of models of polyurethane foam for various purposes. Krimelte products are known in the professional environment for their decent price-quality ratio.

Titan

The Orion brand, with production facilities in Turkey, Spain and Poland, ranks third in popularity among foam suppliers. Products of this brand foam well without secondary expansion.

Installation moment

Products of a well-known brand are in demand due to decent quality and availability of solutions.

Ultima

The brand produces good quality polyurethane foam, the products are convenient to use. Judging by consumer reviews, the sealant of this brand does not have an acceptable level of efficiency.

Foam for wall insulation

Axton

The company produces a sealant with high odorless polymerization characteristics, while reviews indicate low adhesion and high porosity of the structure.

Titan02

Polyurethane foam of high popularity Titan02 is produced in winter version and with increased fire resistance. The product demonstrates extremely high efficiency in the installation of window and door structures. It is actively used in the repair of engineering communications systems, sealing and thermal insulation of buildings. Titan02 sealant is sold within 230 rubles.

Penosil

The products are distinguished by their density and uniformity of structure with a large yield. It is used for assembling structures, filling joints and cavities of varying complexity. The range also includes special versions for foam. The cost varies from 220 rubles.

Collection of herbs for the bath - Donnik

The healing power of sweet clover was noted by our distant ancestors. In the ancient herbalist, even several pages are devoted to him, on which one of the first recommendations for the use of sweet clover is the use of its bath procedures. Using the advice of great-grandfathers, you can heal your own body and relieve nervous tension, up to the elimination of attacks of hysteria or melancholy.

The collection of herbs for the bath sweet clover, due to its healing power, helps to relieve cardiospasms and strengthen the cardiovascular system. In addition, inhaling the "delicious aroma" of this plant, the steamed one gets rid of respiratory diseases, because this herb has excellent expectorant and phlegm-thinning properties. The herb for the bath melilot will help in the treatment of all kinds of skin diseases, as well as the healing of cuts and wounds.

However, it is not only healing and relaxation that becomes available to you when you take a steam bath using the collection of this plant. If you believe the magicians and sorcerers, it turns out that the aroma of sweet clover protects from the evil eye, removes damage to a person and at the same time neutralizes negative energy. It is difficult to judge whether it is true or not. But the fact that after a bath with a sweet clover the feeling as if he was born again is true!

Getting PPU

When mixed, the polyol and the isocyanate produce a foam that expands and then hardens. In the manufacturing process, it is necessary to adhere to a number of requirements: observe the required temperature and mix all components well, which makes it possible to obtain polyurethane at the output, in which there are no seals and large air cavities.

If you change the production method, you get polyurethane foams that are different in their main characteristics. Some are better suited for insulating openings for doors and windows, others for brick and panel buildings or pipelines. By changing the proportions of the ingredients, when they are mixed, polyurethane foam with different mesh sizes is obtained.

The most popular materials in this group are the following:

- Foam rubber. It is widely used in everyday life and is familiar to every person. It is used as an upholstery filler for upholstered furniture and lining material.

- Rigid polyurethane foam used when performing installation work. It is noticed that acids and solvents negatively affect this insulation.

Popular manufacturers of sprayed PU foam

Among the most famous brands it should be noted:

1. Ecotermix. The main advantage is that it does not contain harmful chemicals. Ecotermix sprayed polyurethane foam insulation contains vegetable oils, which are foamed on a water basis. There are different types:

- Ecotermix 300 is a closed cell used for outdoor work.

- Ecotermix 600 - designed for internal processing.

Reviews of the sprayed thermal insulation Ecotermix indicate an economical consumption. After application, a comfortable temperature is established in the house, which is maintained throughout the year.

2. Polinor is produced in cylinders, which allows you to correctly calculate the required amount of polyurethane foam. Sprayed polyurethane foam insulation Polinor is easy to use; you do not need to purchase additional equipment to apply it. Ease of use affects the cost, the price of Polynor for a cylinder is on average 400 rubles.

3. Heatlok Soy can be used for outdoor and indoor use. The composition includes natural ingredients: soy and vegetable oils. It is a monolithic mass that envelops the base, adheres well to it and prevents the formation of corrosion.

How to apply with your own hands?

Before proceeding with the surface insulation with sprayed polyurethane foam, you need to prepare it. It should be dry, clean and even. The optimum temperature for the substrate to be treated is 13 to 15 ° C. To carry out the work, cylinders are needed, into which the components are placed in liquid form. With the help of a pump, substances are taken to form foam. Then the mixture of 2 components enters the spray gun.

Sprayed insulation is a relatively new method of insulating building structures. It consists in the application of liquid compositions, which, when solidified, turn into a continuous coating with low thermal conductivity. Such a "fur coat" fills all the cracks and seams, so the insulation is maximally effective.

The most popular material for thermal insulation of structures by the method of seamless application is sprayed polyurethane foam. For large-scale work, a two-component composition is usually used. After mixing, it is fed to the surface to be treated and there it increases in volume due to the action of pore-forming agents.

Produced in a very wide range. The most popular types:

Heatlok Soy.

A universal two-component composition with a density of 45-50 kg / m3 with increased adhesion, which makes it possible to glue the walls of cracks and unreliable seams during the spraying process.

Ecotermix-300.

Designed for external application, it has a closed cell structure and high density (35-40 kg / m3).

Ecotermix-600.

It is used for interior work, as it has open pores and higher moisture permeability. A distinctive feature is the minimum specific weight (9-12 kg / m3).

Foam Kit.

A wide range of polymer thermal insulation with various characteristics and structures. Closed cell spraying has an average density of 28-30 kg / m3, open - only 8-10 or 16-20 kg / m3.

The manufacturer offers not only polymer compositions, but also all the equipment necessary for work at a reasonable price. The scope of application of two-component insulation is very wide, since polyurethane foam shows excellent adhesion to most materials and adheres well even to vertical surfaces.

Separately, it is worth considering products from Polinor - a one-component composition available to most buyers. Polynor spray insulation is chosen for internal insulation of small areas. It has a density of 18-28 kg / m3, is easy to use, and the best part is that Polinor is supplied in 0.9 liter cans (enough for a 3-cm layer on the surface of 1.5 m2).

DIY application technology

To apply liquid insulation, no professional skills or expensive equipment is required (with the exception of liquid foam). For work, you need a roller (brush or spray). When using a roller, you will also need a container to evenly rub the mixture over its surface. The process itself includes the following actions:

- We prepare the surface (we clean the walls from excess mortar, sweep it with a brush and wash with water).

- We prepare the material (if necessary, we dilute it to the desired consistency).

- Pour the paint into the roller container.

- We dip the roller in the paint and roll it out on a special platform until the mixture saturates the roller evenly.

- We carefully apply the insulation to the wall, no need to press hard. The first layer is applied from bottom to top.

- Subsequent layers are applied after the first one is completely polymerized, as a rule, after 24 hours (to find out the exact values, see the instructions for the insulation).

During drying of any of the layers, it is necessary to avoid getting them wet, since most liquid heat insulators are water-soluble. Because of this, the effect of water on an incompletely cured insulation can cause it to be completely or partially removed from the surface.

Application technology - video instruction:

Consumption for 1 m2

As noted in the advantages, this insulation is quite economical. The consumption of polyurethane foam in cylinders is as follows: 1 liter is enough to cover a wall of 1 m2 with a layer of 4 cm thick. For comparison, when working with mineral wool, you will need to spend more. In addition to the material, additional elements are needed for insulation, that is, a crate, fasteners, etc., which also costs money.

Required layer thickness

It all depends on the region in which the object is located. For clarity, there is a table where it is indicated how thick the layer should be for a particular element.

Application features

Thermal insulation by spraying polyurethane foam needs protection from the sun's harmful rays. That is, an opaque finish must be performed on top of the applied layer. It is also undesirable to use combustible polyurethane foam for insulating wooden buildings. Despite the presence of fire retardants in the mixture, the manufacturers failed to achieve absolute fire safety.

Another disadvantage of polyurethane foam is toxic substances released from the foam during the polymerization process. So during work, you must use a good respirator and generally take care of your own safety. Well, the cost of insulation with polyurethane foam is very high, for 1 sq. m, it fluctuates within 550-680 rubles with a layer of 5 cm. But PPU has a low thermal conductivity of about 0.019-0.028 W / m ∙ K and, with proper spraying, can last at least 20-30 years.You can read more about working with such material in this article on PPU.

The main stages of application

If you independently carry out insulation by spraying polyurethane foam, for work you will need special equipment with a compressor and a pneumatic gun. Ideally, this should be an automated foam generator that controls all mixing and feeding parameters.

After that, you will need to order from the manufacturer a two-component composition for the preparation of polyurethane foam insulation. In further work, follow the instructions:

1. Stir the first ingredient with a construction mixer to evenly distribute blowing agents, regulators, flame retardants and polyesters.

2. Prepare the hardener in a separate container - the second component of thermal insulation. If a precipitate appears in it, heat up to +70 ° C, re-stir and filter.

3. The combination of the two ingredients must be carried out in an absolutely dry room, where foreign objects or substances cannot enter the mixture.

4. The finished thermal insulation is fed by a compressor into a special sleeve and from a gun is applied to the surface to be treated under pressure.

Usually the proportions of two-component mixtures are kept at the level of 1: 1, but the dosage should be checked with the manufacturer. The process of spraying insulation itself, judging by the reviews, does not require any skills or complex preparation. It is only necessary to clean the base from dust and peeling pieces before insulation, and also dry it thoroughly. Immediately after that, the polyurethane foam is applied in a layer of 10-15 mm. The repeated pass is performed on the already solidified base.

Ecowool

This insulation is completely different from polyurethane foam, since it consists of natural components (cellulose), and costs 40 percent less. True, its thermal conductivity is also higher - 0.032-0.041 W / m ∙ K. In our review, we will consider ecowool, which provides for spraying with a wet-glue method. This is the most expensive, but also the most effective method of using it. The lucky ones who live in areas where there are manufacturers of thermal insulation from paper raw materials can count on the minimum price. For application, it is enough to dilute the dry ecowool and the adhesive component with water in the correct proportion and spray it with a pneumatic gun in a continuous layer over the surface. According to reviews, you can do without glue, but it is safer with it.

The density of ecowool is approximately 52-65 kg / m3, which guarantees its normal operation as a heater. But unlike polyurethane foam, it does not have the proper moisture resistance, therefore it requires additional protection. However, with a slight moisture content (up to 14%), ecowool does not lose its properties - it "acts" like wood, giving off excess moisture, rather than accumulating it. A really serious drawback is the flowability and shrinkage of the insulation - every year cellulose insulation loses up to 1.2% of its original volume. For 5-10 years of service, ecowool will sag by 6-12%, so manufacturers and craftsmen in their reviews recommend making the layer thicker.

When to use spray-on insulation:

1. Since spraying creates a continuous layer, it is ideal for machining irregular surfaces with ridges, non-rectangular cells and irregularities.

2. This type of coating is indispensable for thermal insulation of any building structures with a large number of metal elements. PPU spraying provides them with reliable protection against moisture penetration and subsequent corrosion.

3. For insulation of pipes and containers for various purposes.

Features of the technology of applying insulation

The technology of installation of sprayed insulation in cylinders provides for the following stages:

- the cylinder is equipped with a special tube or pistol, after removing the cover;

- shake the composition thoroughly for at least 60 seconds;

- before applying foamy thermal insulation, the surface is treated with water;

- the container is held upside down, filling the voids by 1/3 of the volume, leaving room for expansion of the composition.

When the foam fills the entire volume of the gap, it is recommended to spray the mass with water to improve the polymerization process. The curing time of foam insulation varies depending on the model and brand, manufacturers produce products of different quality. Surface hardening is observed approximately 20 minutes after spraying. The correction of the mass with the help of a cutting tool is started not earlier than after 4 hours. The full polymerization period of foam insulation for the floor in cylinders provides for a period of at least a day.

Provision of means of protection

When applying polyurethane foam in cylinders for floor insulation, it should be borne in mind that the composition is poorly washed off the skin and clothing. Working clothes should be worn and protective goggles and gloves are also important. Manipulations for spraying polyurethane foam with special equipment are carried out using professional equipment in order to completely exclude contact of the skin and mucous membranes with the substance.

When insulating the floor with foam, you need to use protective equipment

Thermal insulation of the floor by spraying

Installation of polyurethane foam for floor insulation using spraying technology provides for the use of special installations. The foam insulator components are contained in separate containers. The working composition is made directly at the facility before use. The substances enter the mixing device, then they are sent to the spray gun and are applied under pressure to the treated surface.

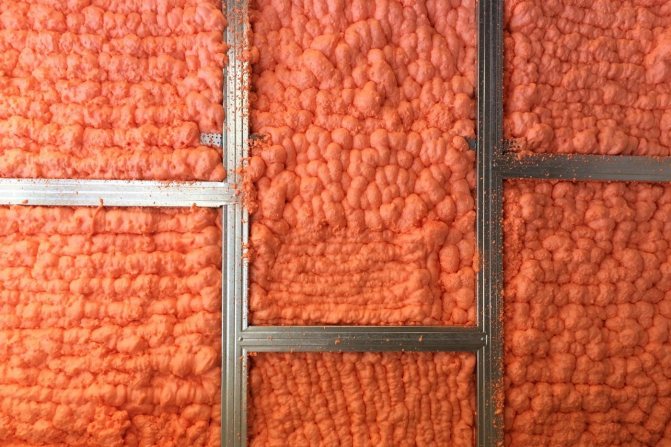

Features of installing foam insulation:

- a frame structure is being constructed for applying sprayed thermal insulation. Experts recommend to carry out the crate, depending on the nature of the treated area. For example, for effective thermal protection of a wall structure, it is advisable to build a wooden or metal frame with an interval of 30 cm between the guides. If you plan to insulate the floor with sprayed polyurethane foam, you should create a crate with a step of up to 1 m;

- foam composition is applied by smooth movement of the jet over the surface to ensure an even distribution of the mass;

- when processing vertical planes, the foamy insulator is sprayed from the lower perimeter, gradually filling the openings upward;

- during manipulations, the spray gun is kept at a distance of at least 25 cm from the surface to be treated. When moving to another sector, you must release the trigger of the gun to block the stream.

If you plan to insulate the floor with foam by two-layer spraying, it is necessary to withstand the time for complete polymerization of the previous layer. After hardening, the masses begin to correct: cut off all protruding fragments with a sharp knife, level out irregularities.

The flooring is laid after the foam insulation has finally polymerized.

Floor insulation by pouring

The technology implies the creation of monolithic thermal insulation in the floor structure by pouring foam into specially made cavities. For example, a rough plank floor is being built on logs, small holes are made on the surface in dedicated places for pumping polyurethane foam. If you plan to heat the walls by pouring polyurethane foam, sheathing is performed with a technical gap between the base and the finishing material. Next, the foam composition is poured through special holes on the facing panel.

Pouring is carried out on the basis of the same spraying installations, having reconfigured the equipment parameters. In a professional environment, special units are also used for pouring polyurethane foam, which determines a high-quality level of thermal insulation work. The foamy substance fills exclusively all voids to the smallest crevices, as a result of which a sealed thermal barrier with high performance is formed.

Application features

Polyurethane insulation is applied to the walls by spraying using special equipment. Therefore, most often such work is entrusted to specialists, but every homeowner is quite capable of coping with this task on his own, but subject to mandatory compliance with safety precautions and the use of special equipment and personal protective equipment.

In addition to spraying, which is carried out mainly on vertical surfaces, the pouring method is sometimes used, but in this case only horizontal planes can be processed, as well as insulation can be made by pouring it into previously prepared forms.

Polyurethane is especially indispensable for insulating various voids, the insulation of which is practically impossible using traditional materials.

For example, often when installing window structures and doors, foam is used to insulate walls in cylinders, the application of which allows you to ideally seal the opening and protect the room from cold and noise.

After the surface is cleaned and repaired, you can proceed directly to the application of thermal insulation, the technology for performing the work of which involves the following mandatory steps:

- production of lathing, for which you can use lumber or special metal and plastic profiles;

- directly the process of spraying or pouring insulation;

- creation of decorative and protective surface cladding.

The need to manufacture the lathing is explained by the need to control the thickness of the applied insulation layer, therefore the size of the materials for it is selected taking into account this parameter.

In addition, the lathing device also performs a leveling function, allowing you to eliminate surface defects.

After the lathing has been made, polyurethane foam is applied to the prepared base, the spraying intensity of which, and accordingly the resulting thickness, is regulated by the power of the assembly gun.

At the same time, it is important to take into account such a nuance: they always start spraying thermal insulation from the bottom of the surface and produce it along its entire width, gradually moving upward.

How to choose porcelain stoneware for your floor? How to cut and stack? - here is more useful information.

In the event that the thickness of the applied layer turns out to be insufficient, it is allowed to apply polyurethane foam in several layers.

It should be noted that the above procedure for performing the work is also relevant if insulation is carried out with penoizol, which is a liquid type of foam.

You will be interested in this article - Polyurethane foam characteristics. Review of manufacturers.

This material is mainly used for thermal insulation of buildings and industrial facilities, as well as for filling special voids in hollow building blocks and other structures.

But it should be noted that although polyurethane and liquid foam are competitors in the method of application and scope of application, the former has the best thermal conductivity, but the latter is more affordable.

After the insulation acquires its final shape and size, work is done to level it: it is recommended to cut off the protruding parts with a sharp knife.

Next, decorative cladding is installed or plastering of the surface is performed, which can later be painted or pasted over with wallpaper, for example, if insulation is performed indoors.

The Teplis heat insulator is very easy to use. Its application is carried out in this way:

- Dirt, dust and oil stains are removed from the working surface.

- The insulated cylinder is heated to 18-20 ° C and shaken thoroughly.

- A mounting gun is screwed to the tip of the cylinder.

- A special nozzle is put on the pistol and placed in a horizontal or vertical position (based on the method of applying the mixture).

- By pulling the trigger of the gun, the surface is covered with the first layer of heat-insulating material. After 20 minutes, the product is sprayed again.

Important! During operation, the container must be shaken periodically.

Insulation Teplis is economical, because it does not require the installation of a frame. In addition, installation is carried out without additional materials (glue, membrane, films).

In terms of the complexity of arranging insulation, Polinor foam insulation differs from roll and plate thermal insulation materials for the better.

With the help of PPU Polinor, they can perform thermal insulation of any surfaces: horizontal - floors, flat roofs; vertical and inclined - walls, facades, roofs; and objects with a complex shape - water supply pipes, well caissons, etc.

Warming by Polinor is feasible by one person, without the need for any outside help. Foam thermal insulation is produced in compact cylinders containing a sufficient amount of insulation to cover one square meter (based on the thickness of the thermal insulation of 6 centimeters).

It is worth noting that such packaging has a positive effect on savings, since it is extremely simple to calculate the number of cylinders required for insulating an object, knowing their productivity.

Before starting thermal insulation with Polinor, it is necessary to carefully prepare the surface to be insulated. The wall, floor, or roof of the house is cleaned of dust and mechanical impurities.

If any damage is found in the structure of the house, the defects must be eliminated in order to avoid their further spread. In case of cracks in brick, concrete or gas silicate walls, the damage must be repaired with a mixture of glue and cement.

Further, the surface to be insulated is degreased using any organic solvent - acetone, toluene, 748. This must be done due to the fact that the adhesion of Polinor with an oily surface is much worse than with a clean brick wall.

Preparing the nail gun Polinor

The PPU cylinder, before starting work, must be stored at an air temperature of 18 to 30 degrees. Prior to application, the balloon is shaken for 2-3 minutes.

We invite you to familiarize yourself with Self-tapping screws for grooved floorboards

The thermal insulation is sprayed with a special gun, which must be purchased separately, since it is not included with the Polinor cylinders.

Together with a polyurethane cylinder, you will receive a universal nozzle that controls the flow rate and supply of polyurethane foam, which allows you to spray Polinor with any foam gun.

It is necessary to mount the nozzle on the pistol barrel (until it clicks), after which the cover is removed from the end of the cylinder, after which the pistol rod is screwed into the vertical PPU cylinder.

As a rule, the thickness of the Polinorom thermal insulation layer should not exceed 6 centimeters. The foam flow rate is regulated by the pressure of the trigger handle of the assembly gun. The cylinder itself must be shaken every few minutes of operation (it is necessary to hold on to the cylinder itself, and not to the assembly gun).

When spraying thermal insulation, it is necessary to strictly adhere to safety rules, since polyurethane foam in an uncured form can harm the human body.

Polyurethane foam can irritate the eyes, mucous membranes, and areas of the skin with which it comes into contact, therefore, the installation of Polinor must be carried out in a protective suit, or, in the absence of special protection, use construction goggles and gloves.

Thermal insulation of the attic walls by Polinorom

Which liquid insulation to choose?

As you know, long-term or improper storage significantly degrades the properties of materials, especially liquid insulation.In this regard, when choosing a composition, first of all, you should pay attention to the date of its manufacture. In addition, it is recommended to give preference to well-known brands that have proven themselves, because the efficiency of the entire thermal insulation system depends on the quality of the liquid insulation.

In order to make sure of the quality of the liquid insulation produced in the form of paint, experts recommend:

- Clarify the weight of the bucket - the lower the density of the composition, the higher its heat-saving properties. Therefore, if a ten-liter plastic bucket weighs more than 6.5 kilograms, then you should not purchase such a composition.

- Check paint for light as light microspheres rise upward. Therefore, the thicker the top layer of insulation, the better its thermal insulation characteristics.

- Rub a small amount of paint with your fingertips - a good material should have a large amount of rough microgranules. The absence of such an effect indicates the low quality of the product.

- Make sure of the whiteness of the composition - a color change indicates gross violations of the technological process. However, this rule does not apply to paints with mineral color additives.

It should be noted that in this case it is not worth focusing on the cost of the goods, since some manufacturers deliberately sell low-quality products at inflated prices in the hope of triggering the stereotype of choice.

Collection of herbs for the bath - Mint

Perhaps even a child knows how useful mint is. Therefore, the collection of herbs for the bath mint is most popular among our compatriots (by the way, abroad too!). After all, getting rid of headaches, relieving fatigue and stimulating brain activity are simply necessary for a modern person.

However, not only for these qualities mint has gained its fame. According to various beliefs, this miraculous herb helps young girls find a better husband. Our great-great-grandmothers also sent their growing beauties to the bathhouse to take a steam bath with an obligatory bunch of fragrant refreshing mint, "so that the girls do not stay too long." Quite a long time has passed since then, but the current representatives of the fair sex resort to the magical power of this powerful herb.

People also believe that mint bath herb can help in finding a way out of a financial predicament. Whether it is true or not is unknown! But as the mint buyers themselves say, thanks to the use of mint in the bath procedure, many of them managed to get rid of debt obligations and increase their regular income. Agree that such an effect from a bath is very good to get during economic instability.

Advantages and disadvantages of liquid insulation

Among the positive qualities are the following:

- The ability to apply to surfaces with almost any relief;

- Resistance to atmospheric factors;

- Low cost of installation work;

- Liquid insulation forms a monolithic layer, without joints that occur when using sheet materials.

- There is no need to coordinate the insulation with the supervisory authorities, since after application the appearance of the building remains unchanged;

- High adhesion properties of liquid insulators eliminate the need for thorough surface preparation;

Disadvantages:

- If the rules of storage and transportation are not followed, there is a high probability that the mixture will prematurely lose its performance;

- Short service life compared to traditional heaters;

- The high cost of some products;

- Many foam materials cannot be applied without special equipment;

Main technical indicators

Foam insulation in all respects much better than conventional insulation materials, since its technical characteristics are comparable to industrial samples sprayed by pneumatic units.These main parameters of Polynor include the following items:

- thermal conductivity in the range of 0.023-0.025 W / mk;

- material density after hardening - more than 28 kg / m³;

- vapor barrier at the level of 70%, which is similar to "Izospan V";

- moisture absorption - up to 2% (immersion in water at a temperature of about +100 ºС for 1.5 hours);

- maximum operating temperature - up to +121 ºC with exposure time up to one year;

- resource of material without reduction of technical characteristics - at least 50 years;

- ecological cleanliness and the possibility of using in residential premises.

Sprayed thermal insulation in cylinders withstands mechanical deformations (up to 50%) while maintaining volume and without destruction or loss of a given shape.

Insulation can be applied on surfaces made of metals (aluminum / cast iron / steel), bricks, concrete structures, wood materials (plywood, board) with an adhesion level of 1–2.5 kg / cm². At the same time, sprayed thermal insulation in cylinders is resistant to moisture and chemicals in the form of organic solvents, oils, soap solutions. The ingress of methyl chloride, dichloroethane, hydrochloric acid leads to swelling, and sulfuric or nitric acid completely destroys the structure of the insulation.

Application

It is allowed to use Polinor insulation both inside the house and outside. At the same time, make sure that it is not directly affected by sunlight and moisture. The installation process is very simple and fast, and even an inexperienced person can cope with the task. All that is required is to install the balloon on the polyurethane foam gun.

But before that, it is important to properly prepare the surface. It must be free from dust, dirt and moistened with water. The foam application process is carried out with smooth movements, without jerking. Thanks to this, a uniform layer of insulation can be obtained. Polymerization is carried out by reaction with moisture. If you additionally moisten the surface, then the composition will be more voluminous. Rubber door seals can provide additional insulation.

On the video, the use of sprayed polyurethane insulation polynor:

In addition, the material becomes lush at a temperature of 20 degrees. But at a temperature of 15 degrees, the composition acquires density. The material can be applied both to the frame and to the wall. The choice of a particular method depends on the subsequent facing.

The following options are provided here:

- paint application;

- applying a layer of plaster;

- use of drywall, OSB, lining, siding.

Sprayed to insulate Polinor is applied in several layers. It can be used not only for thermal insulation of walls, but also for floors and roofs. Often it is used to insulate various metal tanks and communications.

The sprayed compound is able to pass through all cracks and hard-to-reach places, forming a monolithic seamless layer. It will not allow heat, steam and moisture to pass through. It is necessary to apply the material only with gloves and goggles, as it has a strong and pungent odor. It is very difficult to be in an unventilated room, but after installation the smell disappears very quickly.

You may also be interested in knowing what kind of insulation for external walls under plaster is best to use.

But what is the cake of the wall of a frame house with basalt insulation and in what cases it is used, this information will help to understand.

What are the characteristics of mineral wool insulation and where can it be used and how exactly. is described in great detail in this video.

And this information will help you compare the thermal conductivity of heaters.

What is and where is the most often used insulation for the water supply pipe Energoflex, this article will help you understand.

Where to use sprayed insulation

Due to compliance with safety standards, sprayed insulation can be used for the arrangement of public and residential buildings. The range of its application is quite versatile:

- Roofing and attic structures

- Warming of floors

- Thermal insulation of wall surfaces

By objects, you can make a classification as follows:

- Industrial buildings

- Outbuildings

- Refrigeration equipment

- Pipeline communications

- Tanks for technological purposes

It is important to consider! Although spray-on insulation is considered environmentally friendly, thoughtful precautions must be taken when insulating residential buildings. At the time of application of the material, a polymerization reaction occurs, accompanied by a high degree of toxicity. And only after the final solidification, the risk of poisoning disappears completely

And only after the final solidification, the risk of poisoning disappears completely.

As for the type of materials for which it is possible to carry out insulation, there are no restrictions in this regard.

Do-it-yourself sprayed insulation

Many owners of private houses, and even apartments, try to do all the housework with their own hands. But in this case, it is not easy to do this without theoretical training and the necessary equipment.

In any case, for self-insulation with polyurethane foam, you will need a balloon installation and the components necessary for this procedure, namely:

- Polyol to be mixed in a container with freon

- Isocyanate, also combined with Freon 134

Both cylinders must be inflated until the pressure in them is at least 8 atmospheres.

Further, spraying is carried out on the treated and prepared surface - just press the spray gun and direct a stream of insulation to the desired area.

Attention! When working independently with sprayed insulation, it is imperative to use personal protective equipment!

Sprayed insulation in cylinders

Since an independent process is not as difficult as preparing it, it will be easier to immediately resort to ready-made sets of insulation in cylinders. In addition, there will be no tangible difference in cost.

Sprayed insulation in cylinders is more practical, since it has a professionally performed factory training, including the optimal pressure regime.

The price of sprayed insulation

The cost of this insulation may seem slightly higher than materials in other categories. However, the economic efficiency of this thermal insulator is obvious when calculating, of course, the cost of costs for other materials with the inclusion of additional equipment - profiles, sealants, fasteners and payment of the cost of professional work.

In the long term, the cost of insulation with sprayed insulation pays off by reducing energy costs.

Spray-on polyurethane insulation Polynor

An example of a successful choice of such insulation is the Polynor insulation. Its advantages are evidenced by reviews of the sprayed polyurethane insulation Polynor and instructions provided by the manufacturer in video format. The price for sprayed polyurethane insulation Polynor is identical to similar sprayed insulation in this category.

Thus, this type of thermal insulators is a priority in the choice of material for a number of technological indicators and for reasons of practical and budgetary value.

Consumer properties

Like any insulation material, Polynor has a number of advantages:

- Differs in excellent heat saving. These indicators are higher for insulation compared to expanded polystyrene and mineral wool.

- Non-toxic. Consumer reviews are not bad about the "Polinor" product, since it is not poisonous and does not require protective equipment when used.

- Ease of use.When using POLYNOR, a heat-insulating layer is created, which does not require a frame as an attachment. Also, no tools and auxiliary materials are required.

- Excellent grip. The composition quickly adheres to any surface - brick, wood, plastic, stone, concrete, which significantly expands the scope of its application.

Polynor insulation is very popular due to the fact that it is applied by spraying. This results in better adhesion of different surfaces, even if they are not very even. Very often, this insulation is used to finish hard-to-reach places, for example, where pipes or cables are laid.

Positive traits

PPU as a heater has excellent performance. Its significant characteristics:

- the ability to stick to any surface, no matter what material it is made of: brick, wood, metal or concrete;

- the ability to cover the surface of any shape and configuration;

- the ability to manufacture on site, which reduces transport costs;

- light weight does not make the structure heavier, which is important when insulating a roof;

- lack of joints and seams.

The polyurethane foam layer not only insulates walls and partitions, but also makes them stronger and more stable. The material has proven itself excellently at various temperatures.

How to choose material

There is a wide range of foam insulation materials on the market. The European wall insulation foam guarantees high quality, but has a high price. Domestic manufacturers have mastered the production of licensed compositions and materials of their own design, at a significantly lower price, providing a decent quality of thermal insulation and a guaranteed service life. Experts highlight manufacturers such as

Their advantage over unnamed Chinese crafts is their precisely known composition and quality control at all stages of production.

When choosing foam intended for insulation of external walls, you should check whether a particular material is recommended for outdoor use, whether it corresponds in density to the available equipment and the final design foam density.

And if the savings on equipment are even more or less reasonable - it will come in handy only once, then it is definitely not worth saving on materials.

Foam for wall insulation has a unique potential and is able to provide a high level of thermal insulation for a building. Depending on the composition, the material is also successful as a reliable sound and waterproofing agent, a sealant for joints and cavities, and a fixing element.