Advantages and disadvantages of URSA insulation ("Ursa")

Heat insulator URSA ("Ursa") is being developed in Germany. Its basis is glass fiber. However, the specific composition and characteristics of this material differ depending on its specific variety.

The range of the company includes five lines of heat insulators:

Geo

... This series is characterized by high environmental friendliness and therefore is suitable for insulating houses from materials that are safe for nature. However, this feature made Ursa Geo a popular solution for the construction of private and apartment buildings, office and commercial buildings;

Pure On

... Another solution that is well suited for use in private construction. It is made of mineral wool and, due to its special texture, practically does not irritate the skin, eyes and mucous membranes;

Terra

... Special coating, which is made in the form of technical mats. Focused on the use in the construction of industrial facilities, insulation of sloping roofs and facades. Differs in excellent noise insulation properties;

Seko

... Roll-up heat insulator, which is used on sloping roofs, external walls and ceilings;

XPS

... Unlike other materials, XPS is not made of mineral wool, but extruded polystyrene. Thanks to this, it is universal and suitable for thermal insulation of almost all parts of the building.

All this makes the materials suitable for insulating shallow foundations, floors, brick, stone, sheathing and frame walls, as well as roofs. The material itself is distinguished by excellent thermal insulation properties, elasticity, lightness and low cost.

Varieties of PIR sandwich panels and their area of application

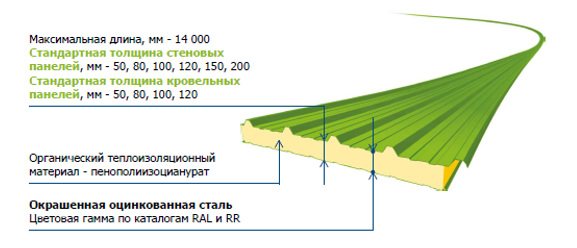

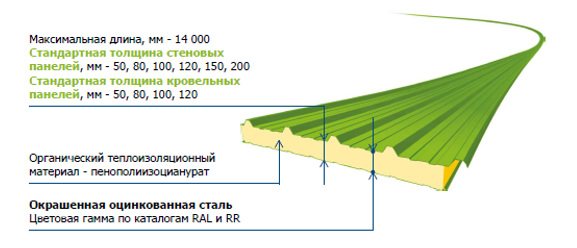

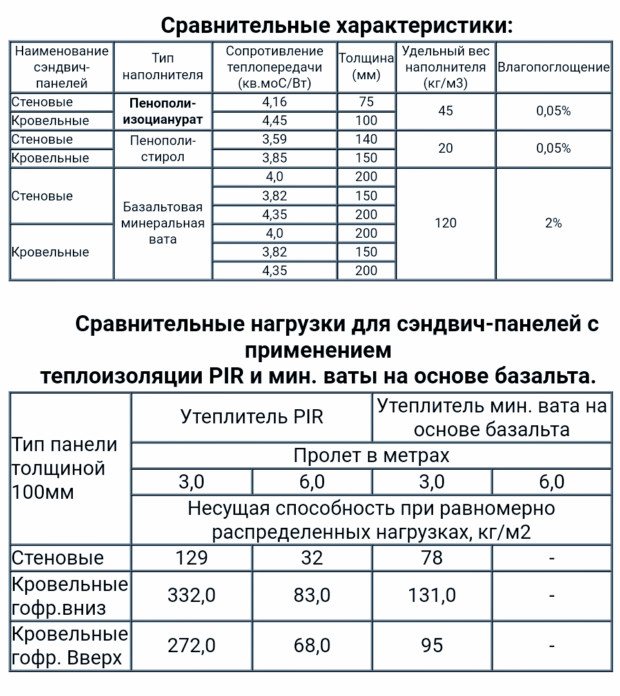

Sandwich panels with PIR insulation are three-layer composite building material. Each of its layers performs a specific function. Smooth or profiled metal sheets are used as cladding material. Thanks to this, the finished sandwich panel serves not only as a heater, but at the same time as a heat-insulating and structural material. The outer layers of the panel do not need additional finishing.

It should be noted that PIR was initially used only as a type of insulation material in the manufacture of sandwich panels, and only then began to be used as an independent material in the form of insulation boards.

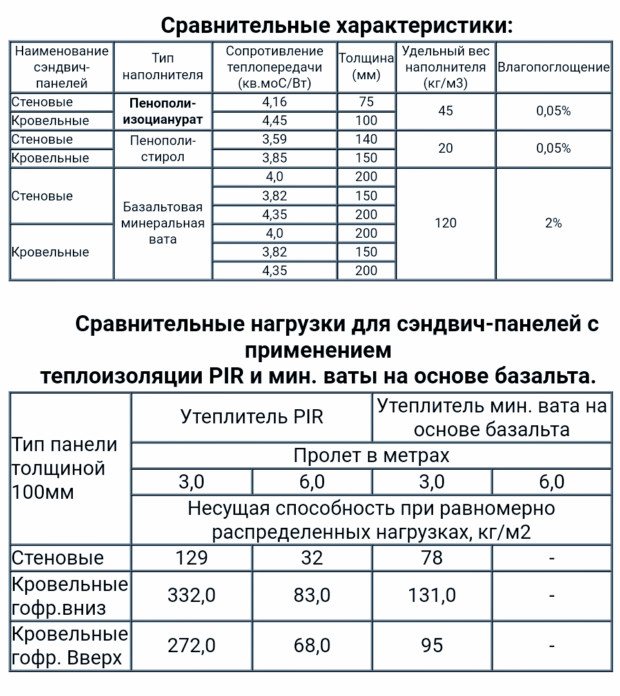

Panel manufacturing technology somewhat different from the simpler process of producing plates, since the foam is immediately sprayed into the cavity between two layers of metal, and is not applied to one of them, and then covered with the second. As a metal, many manufacturers use galvanized steel with a protective polymer coating (RAL), the color of which can be of a wide variety. Or galvanized steel grade 1 (Zn). All sandwich panels filled with polyisocyanurate can be divided into two the main groups:

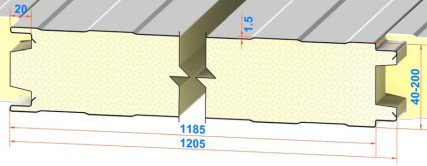

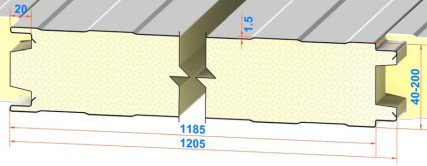

- Wall panels with PIR filler. Many manufacturers pursue the following goals in their manufacture - resistance to weathering, functionality, versatility and aesthetic appearance. Therefore, the last parameter can differ significantly. The panels can be both absolutely smooth and have an interesting profile;

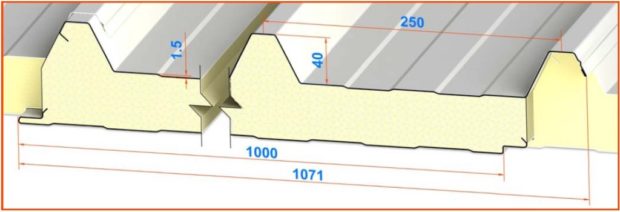

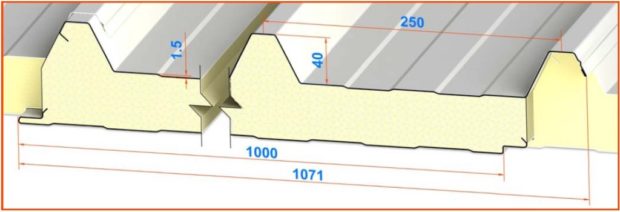

- Roofing PIR-filled panels are made of corrugated trapezoidal sheet. This technique is designed to facilitate the movement of water and moisture down, so that it lingers on the roof for the shortest possible period of time, and to strengthen the strength of the flooring.

Depending on the manufacturer, the geometric characteristics panels. On average, they can have a thickness of 40 to 200 mm. Most are 1000 to 1071 mm wide for roofing and 1185 to 1205 mm for wall panels.

Length up to 16000 mm for roofing and 16000 mm for wall panels. The panels themselves, regardless of size, remain relatively lightweight. This can significantly reduce the load on the foundation or supporting structures.

In addition, the installation process is simplified, which occurs with virtually no waste and reduces transportation costs. Sandwich panels can be applied as:

- Fencing or self-supporting structures in the construction of buildings. In this case, a special frame is used for installation. If necessary, a structure erected from panels can be disassembled and moved to another place;

- Facing material for the reconstruction of facades;

- Sound and heat insulating partitions in buildings for various purposes, both industrial and commercial.

Sandwich panels provide:

- rigidity and stability of the structure, as well as increased strength due to the high density of the foam;

- quick commissioning;

- durability,

- chemical resistance;

Advantages and disadvantages of Penoplex insulation

"Penoplex", unlike its predecessor, is made from extruded polystyrene. Therefore, it also has excellent thermal insulation properties, is characterized by ease and simplicity in installation. However, the use of extruded polystyrene slightly changes the scope of this heat insulator.

Now there are four lines of this coating on the market:

"Wall" ("31" with fire retardant). Used to insulate walls (both external and internal) and basement;

"Foundation" ("35"). Installed on the basement and foundation of the building;

"Roof" ("35"). Installed on roofs - flat, sloping and even inversion;

"Comfort" ("31C"). A universal solution that is suitable for insulating any part of the building.

Fire retardant is a special substance that prevents the heat insulator from burning. Therefore, the wall versions of "Penoplex" are supplemented with them in the composition, which increases fire safety, but negatively affects the price.

Penoplex

Due to excellent thermal insulation, zero water absorption, strength, resistance to biodegradation, durability, lightness of the material and ease of installation, it is used for thermal insulation:

- Cellars and plinths. Insulation of foundations of small and deep foundations.

- Floors on the ground, on a concrete slab, when installing a warm floor.

- Walls outside and inside. Thermal insulation of concrete and brick walls, multi-layer walls, walls of frame houses, additional thermal insulation and internal.

- Septic tanks of pipelines, drainage systems.

- Pitched roof and attic floors.

Ursa and Penoplex - modern thermal insulation coatings... The first appeared relatively recently, and polystyrene foam has been used for a long time. Both materials have similar qualities. Light weight, ease of installation, resistance to biodegradation. But on several points Penoplex is more attractive than Ursa. It is moisture-proof, vapor-proof, does not require special protective devices during installation. Ursa is superior only in price, but the characteristics are sufficient to maintain the demand for the coating at a high level.

Venerable rival

Insulation, in fact, is extruded polystyrene foam. This is a new generation of heat insulators that are able to effectively retain heat. Today, in the assortment of large stores, you can find a number of such building materials that are used for similar purposes, but still differ in their characteristics. Let's take a look and compare the most popular ones.

Penoplex competitors

Penoplex - one of the most demanded foam materials, the properties of which have been improved as a result of additional processing - extrusion. Penoplex use: attics, facades, roofs and foundations of buildings. For each of these objects there is a separate, most suitable type of slabs.

The widespread use of the product is possible due to a number of properties:

- Minimally absorbs water, which is important for heat insulators. A number of experiments were carried out, during which the product was left in water for several days - moisture penetrates only into the outer layers, and the inner closed cells remain dry.

- It has a low coefficient of thermal conductivity (0.03 W * m * ° C), and the value does not change significantly even in a humid environment. This expands the scope and allows the product to be used in conditions of increased dampness.

- Low vapor permeability - well protects the surface from moisture evaporation. By this property, a 2-centimeter layer of material can replace a layer of roofing material.

- Long service life. During the experiments, it was found that the properties of the product did not change even after a significant change in external conditions - it was frozen and thawed, and also tested with water. The manufacturer indicated that the plates last about 50 years, but tests indicate a longer period of use.

- Compression resistance. Thanks to the production technology, the plate has a homogeneous structure with evenly distributed small cells, which improves strength and resistance to mechanical stress.

- Easy installation. The material can be cut even with an ordinary knife. Self-laying is possible without connecting masters.

- High level of environmental friendliness. The manufacturer used a type of freon that does not burn, is not poisonous and does not harm the environment.

- Minimal chemical activity. Does not react with most chemicals commonly used in construction: ketones (acetone, methyl ethyl ketone), formaldehyde, kerosene, gasoline, oil paints, etc.

- High biostability - boards are not subject to rotting and decomposition.

It is also worth noting such pros and cons of penoplex: materials of this type require maintaining a certain, not too high temperature. If this condition is violated, they deform and may even ignite.

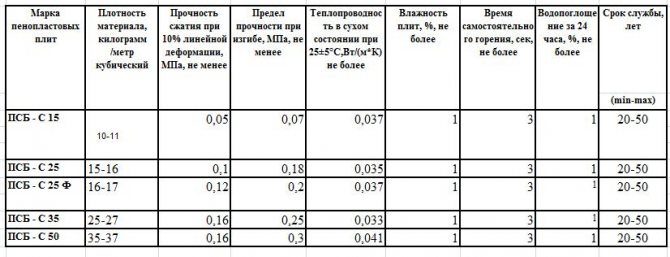

There are a number of foam-type slabs for insulation. They are made using a similar technology, therefore, they are similar in structure and properties, but, as a rule, have a different scope.

General properties of polystyrene and polystyrene foam

In order to understand what is better to use penoplex or polystyrene for insulating buildings, you need to consider the properties of these materials.

Polyfoam: description of the insulator

Polyfoam is an insulating material containing air, enclosed in expanded polystyrene cells. It is usually rectangular in shape.

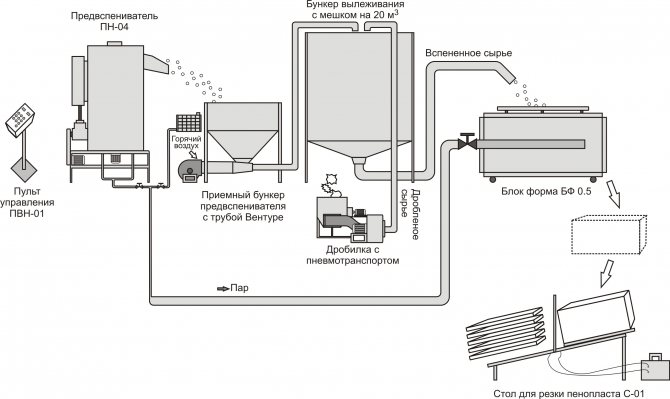

Foam creation

Manufacturing requires polystyrene granules. They contain pentane and isoprene. Thanks to the gas treatment, the granules are foamed and turn into light balls. After that, they are doused with steam, provoking chemical reactions. As a result, pentane leaves the balls. Thermal insulation plates are formed from the obtained polystyrene elements using a press.

Styrofoam qualities

The specified product is a polymer material that has the following qualities:

- resistance to high humidity (fungus or mold does not develop on the material itself);

- light weight;

- resistance to temperature extremes;

- long service life;

- availability of different sizes and thicknesses;

- ease of installation.

Since the material has good thermal insulation properties, it is used for wall cladding outside the building. However, the slab deforms under mechanical stress, so it must be laid carefully. It does not allow steam to pass through, so condensation can accumulate under its surface, provoking rotting, the development of fungus.It is not suitable for indoor installation.

Another disadvantage is the presence of harmful substances in the slabs. However, vapors of expanded polystyrene are considered poisonous at the production stage, and in finished form it does not pose a danger.

What is penoplex

To insulate the walls, you can use penoplex. It is the same polymer insulator as foam, but it has a different production technology. It is more durable and dense, therefore it is able to withstand significant loads.

Penoplex production

Penoplex - extruded polystyrene foam, which is created using an improved technology. For manufacturing, polystyrene granules are used. To process the initial substance, a special device is required - an extruder. The raw material is pressed through a part of a given configuration. Inert gases are required for foaming the granules.

Technical qualities of penoplex

The product is used for thermal insulation of walls of houses and apartments. This insulator is durable, so it can be installed even without the arrangement of an additional frame. The boards will not be overloaded or squeezed. The sheet has excellent thermal insulation properties, even if its thickness is only 3 cm. It is characterized by a long service life.

The specified material is more expensive than polystyrene. It is also vapor-tight, so there is a risk of condensation accumulating under the insulation, which leads to the gradual destruction of the supporting structures.

Technoplex characteristics

Plates are made using a similar technology and have been produced in Russia since 2006. They do not shrink, are resistant to chemical attack, but are afraid of gasoline and solvents, and are also used inside buildings. Let's compare several parameters:

| Penoplex | Technoplex | |

| Building use | roofs, facades, roads | inner part |

| Density, kg / m3 | 25-47 | 26-35 |

| Flammability group | G4 | G4 |

| Water absorption,% | 0,2-0,4 | 0.2 |

| Vapor permeability | 0,012 | 0.01 |

| Price, rub / m2 | 90-250 | 100-290 |

Types of PIR boards

PIR insulation is characterized by high adhesion properties, regardless of the type of surface, therefore, during the production process, a polyethylene bucket is constructed on the nozzle, excluding foam splashing. It is difficult to peel off the frozen drops of the liquid component, but this is what is needed for adhesion to the plates. The so-called foam restraints can be made of different materials, which depends to a large extent on the application of the insulator. The thickness of the cover varies in the range of 50-100 microns.

From what type of material is selected as a limiter, the type of insulation plate is determined.

• fiberglass - used for interior decoration, exterior plastering (by type "Wet facade");

• kraft paper - serves as a base for further interior finishing work;

• aluminolaminate - a material consisting of several layers of aluminum foil, used in different insulation systems (from roof to foundation);

• fiberglass with bitumen impregnation - thanks to the bituminous layer, the insulation is fused directly onto the waterproofing, this type is used mainly for roofs;

• fireproof coating - made on the basis of graphite, protects the polymer from direct exposure to external factors, in particular, open fire for quite a long time.

Reference! On an individual order, slabs with external sides can be produced from those materials that the customer wishes.

Another type of polyisocyanurate insulation is sandwich panels with a lining of profiled sheets. Such material is used for the construction of frame structures, and is essentially an independent enclosing structure. The thickness of the sheet metal is used in the range from 0.3 to 1 mm.

Technonikol or penoplex

Some of the TechnoNIKOL materials are also made by extrusion, while others have a basalt base. The first group is used mainly for the insulation of houses.A feature of the plates is their high flammability, and when they burn, they emit toxic substances. Therefore, when working with them, it is especially important to comply with safety standards.

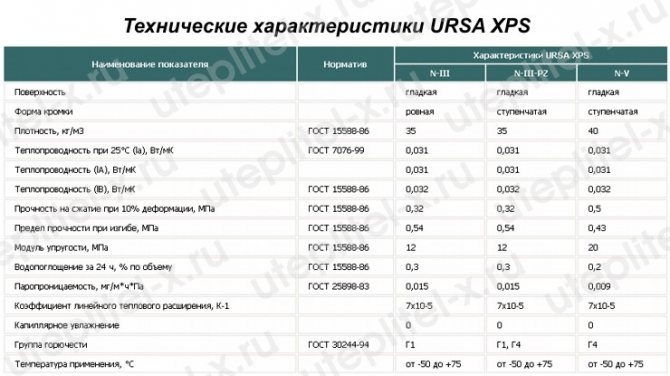

The characteristics of the URSA XPS of various brands (XPS N-III, N-III-G4 and N-III-G4) are a topic for our review. Consider in this article the main properties of this heat-insulating material and recommendations for its use and installation. Let's answer the eternal question - "URSA XPS or Penoplex, which is better to use?" At the end of the article, you can see a detailed video instruction from the manufacturer on self-laying URSA boards for thermal insulation of a flat roof.

URSA XPS thermal insulation is produced in the Moscow region. When styrene is melted under high pressure, a plate with a structure of the smallest closed cells is formed. It is this structure that makes it possible to obtain a material with similar technical characteristics - minimal water absorption and low thermal conductivity, while with high resistance to mechanical stress.

What is it and the application

PIR insulation is a foamed polyisocyanurate, in fact, a direct analogue of polyurethane foam, with a similar structure and composition, however, the proportions of the main components differ, as well as the list of catalysts and fillers. it rigid foam with extremely low thermal conductivity... According to the manufacturer, the thermal conductivity value reaches 0.020 W / m * K.

The method of manufacturing PIR insulation also differs from PUR (polyurethane foam). Higher temperatures and pressures are applied at which reaction and foaming occur. The output is a closed cell structure with minimal vapor permeability.

The size of the cells is calculated in micrometers, as well as the thickness of the walls, as a result, the density of the material decreases to 45-60 kg / m3, but at the same time the strength remains, which is characterized by values even higher than polyurethane foams. Only 3% of the volume of the finished insulation is occupied by polyisocyanurate foam, the rest of the space is occupied by gas.

The main application of polyisocyanurate is in industry and construction as a heater in the composition of sandwich panels, a structural element with an additional coating. PIR boards are more often additionally coated with kraft paper, foil sheet steel or plastic films.

This is necessary not only to expand the scope of application, but also as additional protection, a barrier between the insulation and the environment.

This is necessary not only to preserve the integrity of the material, but also to isolate the environment from it, since the question of the toxicity and safety of the material is still open.

Operational characteristics, as well as methods of use, are similar to those for polyurethane foam sheet and extruded polystyrene foam (EPS).

It is suitable for insulation:

- buildings, including private houses as part of plaster or ventilated facades;

- overlappings;

- roofs (basically a flat roof);

- climatic equipment (air conditioning systems, ventilation) while observing the permissible operating temperature.

The PIR insulation gains in efficiency due to the unconditional presence of an additional outer layer from:

- Kraft paper - increases the adhesion of adhesives, forms a finished base for further finishing;

- Aluminum foil - a heat shield that can significantly increase the thermal insulation properties of the material;

- Sheet metal - increasing strength, including structural strength, is used to form fences that do not require additional reinforcement at rated load.

A significant operational disadvantage of PIR insulation is shrinkage that occurs during the first years after installation... Judging by the technical specifications from the manufacturers, the shrinkage should not exceed 2%, although in practice much depends on the accuracy of the installation.

It is difficult to lay the material with a margin, like mineral wool, or to provide functional clearances for further embedding as it shrinks.

Manufacturers in this case focus on the method of joining polyisocyanurate sheets.

Plates are produced with a lock along the edge, moreover, from two or from four sides at once:

- Fourth;

- Thorn groove;

- Lock with an overlap of the surface layer (wave for roofing insulation).

URSA XPS Specifications

The thickness of the URSA XPS boards is from 30 to 100 mm, the density of the boards is 35 and 50 kg / m3, the degree of flammability is G3 (combustible) and G4 (highly combustible). XPS slabs with G4 flammability rating should be used for thermal insulation of strip foundations and blind areas. When insulating house facades, it is recommended to use URSA XPS with a G3 flammability index, which contains fire retardant additives.

URSA XPS N-III Specifications

- Thermal conductivity: 0.032 W / mK

- Application temperature: from -50 to +75

- Water absorption: no more than 0.3% of the volume in 24 hours

- Vapor permeability coefficient: 0.004 mg / mhPa

- Compressive strength at 10% deformation: 25 t / m²

URSA XPS N-III-G4 Specifications

- Thermal conductivity: 0.032 W / mK

- Application temperature: from -50 to +75

- Water absorption: no more than 0.3% of the volume in 24 hours

- Vapor permeability coefficient: 0.004 mg / mhPa

- Compressive strength at 10% deformation: 25 t / m²

URSA XPS N-V: specifications

- Thermal conductivity: 0.033 W / mK

- Application temperature: from -50 to +75

- Water absorption: no more than 0.3% of the volume in 24 hours

- Vapor permeability coefficient: 0.004 mg / mhPa

- Compressive strength at 10% deformation: 50 t / m²

XPS N-V are rigid, CFC-free extruded polystyrene foam boards. URSA XPS N-V slabs have increased strength characteristics for professional construction. This is the most durable thermal insulation material - load up to 50 tons per sq. m. Thanks to this, the material is indispensable in structures subjected to high loads

True PIR longevity, or how to insulate to forget

Durability is perhaps the most important requirement when choosing any product or product. And, if we talk about heaters, then the preservation of excellent insulating qualities comes to the fore. So what is it really about to insulate so that the service life of the material lasts more than a dozen years?

Durability is perhaps the most important requirement when choosing any product or product. And, if we talk about heaters, then the preservation of excellent insulating qualities comes to the fore. So what is it really about to insulate so that the service life of the material lasts more than a dozen years?

To begin with, let's formulate what is durability? Durability is the ability to maintain its original parameters over a long period of time in response to predicted impacts.

Promising insulation

Based on the global economic trends towards cost reduction, it can be concluded that the need for more durable modern building materials is growing. The strength characteristics of structures must be unchanged for many years. And the reliability and ability of buildings and structures throughout the entire operational period are implied even at the project stage. These factors influence the analysis of the property price. The higher the durability of the material, the higher the income and profit for the owner. This is especially important for insulation. After all, the preservation of its thermal insulation properties for many years is its main purpose. By investing in high-quality and modern insulation, you can reduce not only energy costs, but also reduce the harmful effect on the environment.

The use of environmentally friendly building materials is very important today. And this is not just a tribute to fashion. Our planet's mineral reserves are not endless. Green is a must to save remaining resources for our children and grandchildren.According to statistics, approximately 45% of all mined minerals are used as fuel for air conditioning in buildings, whether for heating or cooling. Thermal insulation can reduce energy consumption, namely the use of high-quality insulation. This is a prerequisite for maintaining the energy efficiency and sustainability of the building.

The problem of climate change on the planet is more acute than ever. Part of the reason for the emissions of carbon dioxide into the atmosphere is space heating. It is necessary to strive for the least consumption of resources or to extend the life of those already used. It is the durability of materials capable of maintaining their insulating qualities that comes to the fore.

Thermal insulation made of polyisocyanurate foam (PIR) is rightfully recognized as the most environmentally friendly and durable. So, for example, in the United States, it has been a leader in the market for several decades. Based on experience and research conducted by the National Roofing Contractors Association (NRCA), the prevalence of PIR use in new construction is 75%, and in renovation - 70% (based on data for 2014-2015 in the USA) ... This material has earned such wide recognition due to its structure.

PIR is a new generation polymer derived from polyurethane foam. Almost the entire volume of the material is closed rigid cells. This is the reason for the unique properties of preventing the penetration of air and liquids, resisting punching and settling. And this guarantees the insulation for a long period of operation.

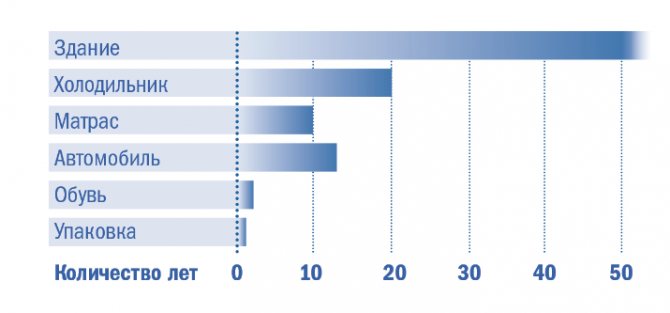

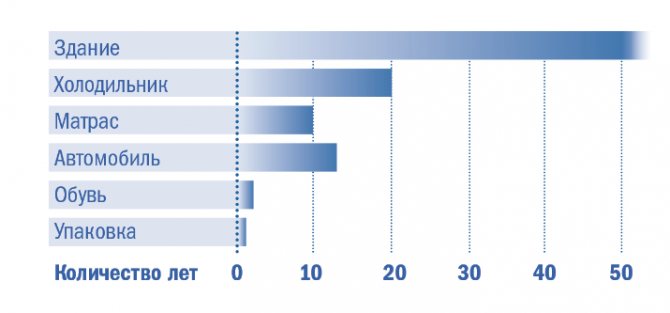

The expected service life of polyurethanes is 3-80 years. It varies depending on the application, operating conditions and functional purpose. But, often, polyurethane products can withstand a longer period. So, for example, parts of refrigerators will last at least 25 years, and elements of cars - at least 20 years (see Figure 1). PIR insulation for building insulation actually offers a much longer service life.

Figure 1. Life cycle of products using polyurethane (ISOPA data).

Real durability is not a myth

For the first time, polyurethane was produced by Otto Bayer in the late 30s of the twentieth century. However, in construction, the use of this versatile material began only in 1980, when insulation made of polyisocyanurate foam was used in a three-layer structure of so-called sandwich panels. Insulation manufacturers claim that PIR longevity can exceed 50 or 80 years. Although in practice, its confirmed service life is over 30 years. The tests were carried out by the PU Europe Research Institute for Thermal Insulation (Forschungsinstitut für Wärmeschutz e.V. - FIW). As of 2010-2011 samples of PIR roof insulation of a private residential building were 28 years old, and samples of insulation from the school roof were 33 years old. These two test fragments were tested for their basic qualities under the influence of time. Changes in such parameters as geometrical dimensions, uniformity, thermal conductivity, compressive strength, moisture resistance, fire safety were of the greatest interest to scientists.

Figure 2. Fragment No. 1 of a part of a polyurethane foam panel located in the pitched roof of a residential building (1982).

Fragment number 1 indicators are shown in the table:

| An object | Declared characteristics |

| Thickness | 100 mm |

| Humidity | Not specified |

| Compressive strength | 150 kPa |

| Thermal conductivity | 0.030 W / (m * K) |

| Reaction to fire | Class B2 (normally flammable) according to DIN 4102-1 No droplets / flame particles |

Table 1. Tests of sample No. 1.

The results revealed that the sample had a uniform structure without excess airspace. This means that after 28 years of operation, the thermal insulation board has retained its characteristics and is capable of a long service life.

The second piece of thermal insulation is 5 years older than the first. However, the results of his tests are not worse.The indicators of fragment No. 2 are shown in the table.

Figure 3. Sample # 2 taken from the roof of a school. The period of operation is 33 years.

| An object | Declared characteristics | Value after 28 years |

| Thickness | 60 mm | 59.05 mm |

| Humidity | Not specified | 0.07 vol. % |

| Total density | Not specified | 30.7 kg / m3 |

| Compressive strength | 150 kPa | 226 kPa |

| Thermal conductivity | 0.030 W / (m * K) | 0.0272 W / (m * K) |

Table 2. Tests of sample No. 2.

As a result of the research, FIW concluded that the functionality of the panels and compliance with the declared characteristics are fully preserved despite the past three decades. The difference between the indicators of geometric dimensions was 1.5%, the compressive strength increased the value, and the thermal conductivity indicator decreased by only 10%, remaining, nevertheless, exceeding the indicator of the same name in other modern heaters. According to the technical director of the PIR direction of TechnoNICOL, Alexander Samsonov, the durability of such insulation while maintaining the properties of the material is real.

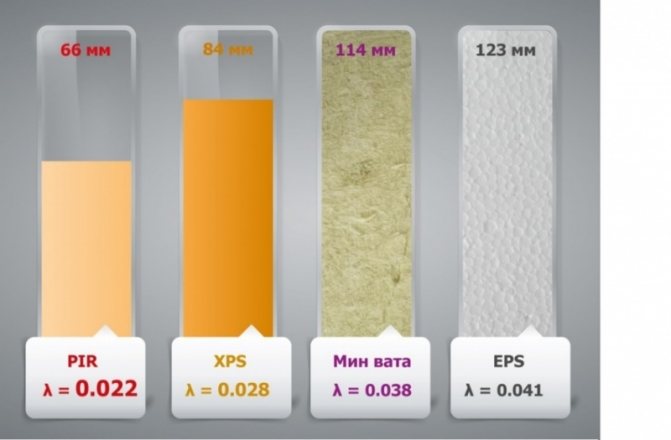

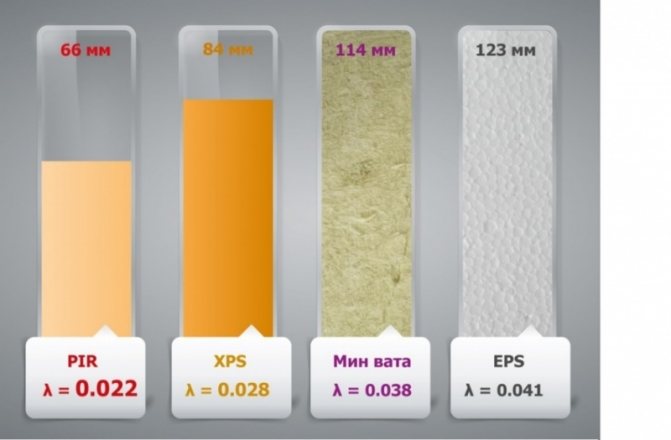

Time works for us

Building standards are getting stricter every year. But thanks to technology, modern materials are able to meet these stringent requirements. PIR thermal insulation demonstrates this in the best possible way. Even 30 years ago, the thermal conductivity of polyurethane foam slabs was 0.003 W / (m * K) (according to FIW data). Time works in our favor, and today the thermal conductivity of PIR panels produced in Russia by TechnoNICOL is 0.022 W / (m * K), which is comparable to the same indicator of air, and the latter, as you know, is the best insulator.

Figure 4. Thickness of insulation with the same thermal resistance (R = 3 m2 · K / W)

In Russia, the leading position in the production of thermal insulation boards from PIR is held by TechnoNICOL. Since September 2020, the production of this insulation has started. The company predicts the great popularity of PIR in our country. After all, Russian consumers have long been waiting for the appearance of a heater with such excellent durable qualities. TechnoNICOL experts claim that PIR boards are capable of retaining their insulating properties for more than 25 years. And this figure is not arbitrary and not invented for advertising purposes. This is a result that has been proven in practice.

Dmitry Kapranov, the head of the PIR department at TechnoNICOL, honestly assures his clients that the long years of operation of PIR thermal insulation are a reality. 25 years is the minimum service life of a PIR. However, according to forecasts of specialists based on tests, the material can last 50-80 years.

These data allow us to conclude that Russian customers really need such high-quality heat-insulating material as PIR boards manufactured by TechnoNICOL. The argument for this is the international experience of using the material for a quarter of a century. PIR insulation is the key to success in finding the most energy efficient and really durable material for the roof of a building or structure.

Installation of extruded polystyrene foam

XPS boards have a stepped edge that allows the boards to be joined together without gaps. It is ideal for thermal insulation of the surface in one layer. This brand of extruded polystyrene foam is very popular among developers, despite the cheaper Russian analogs of extrusion, for example, Technoplex from the Russian corporation TechnoNICOL.

Mastic, expanded polystyrene glue or polyurethane foam are used to fix the plates to a horizontal surface. When finishing vertical structures (for thermal insulation of house facades, plinths, basement walls, etc.), mushroom dowels are used for additional fastening. After laying the slabs, they should be protected from possible mechanical damage with plaster or siding.

Harm

It is impossible to say unequivocally and confidently about the safety of the PIR insulation.

The manufacturer's data on testing its fire safety and toxicity level is often questionable, especially against the backdrop of independent research conducted by a number of research institutes.

Manufacturers prioritize the fire safety of polyisocyanurate. It really does not support combustion. When exposed to open fire, the top layer of the material instantly charred and creates an ideal barrier against the spread of fire and heat that can cause a further spontaneous combustion reaction.

However, there is not the slightest emphasis on the toxicity of the material itself under operating conditions and in particular its danger as a result of exposure to fire and high temperatures.

The University of Central Lancashire (UK) ranked PIR in the last place in terms of toxicity and hazard as a result of combustion, even lower than polyurethane foams, stating that the products of smoldering and combustion, thermal decomposition of polyisocyanurate are definitely harmful to human health.

There is still little practical, applied data on the issue, although the material continues to be actively disseminated and used in construction.

URSA XPS or Penoplex which is better

Penoplex is, in fact, the same extruded polystyrene foam, but only from another manufacturer. Which is better - penoplex or URSA XPS, depends on the cost of insulation in your city, the cost of delivery, and in terms of their characteristics in thermal conductivity in practice, they differ little from each other. In terms of cost, URSA XPS boards are considered the more expensive material.

As you can see the characteristics of URSA is the optimal solution for a private developer. Plates are lightweight, easy to cut with a clerical knife and easy to install. For self-warming of a house with URSA XPS plates, no special skills and tools are required. At the same time, you will receive reliable protection from the cold with high mechanical strength and moisture resistance.

(4,75 out of 5)

Thermal insulation comparison

But in order for both materials to serve for a long time, they must be protected from direct sunlight, as well as from other atmospheric influences. Both penoplex and polystyrene are cut with an ordinary knife, although the foam must be cut much more accurately, it can break, as it is fragile. This is especially true for three-centimeter sheets.

For fixing, I used mechanical longitudinal slats, placed the plates in a checkerboard pattern. He noted such advantages as: low thermal conductivity, density, light weight, convenient shape, ease of fastening. A review of reviews shows that this material withstands any external influences well, is easy to process, easy to install. It is definitely worth choosing it at the stage of building a building - for thermal insulation of the base, strengthening the thermal resistance of walls, and extending the service life of structures.

Styrofoam is bought mainly with a limited budget. Competent insulation of the house is of decisive importance in energy saving. The most common Table of contents: Features of products from expanded polystyrene Advantages of Penoplex What buyers say - reviews Comparison of characteristics The indicators of polystyrene are largely determined by its brand, PSB-S is considered suitable for private construction. A clever meter that saves electricity Pays off in 2 months!

Reviews Effect Action.

URSA heaters - technical characteristics of various types + Video

Thermal insulation materials with the name URSA are quite popular. They not only carry out traditional insulation of roofs and walls, but also insulate ventilation pipes and other communications. And with their help, you can significantly reduce the noise level. So, get acquainted, URSA (URSA) - insulation, the technical characteristics of which are kept at a fairly high level, and the service life is very long. With excellent heat retention and excellent noise absorption, it will work well in any building structure.

What are URSA heaters and their varieties

This heat insulator is based on treated staple fiberglass. So this material is the closest relative of glass wool. In its manufacture, sand, soda, dolomite and other additives are taken in certain proportions. The mixture is heated to the melting point and passed through a special apparatus. As a result, a fibrous substance is obtained, the thin threads of which are glued with a special composition.

There are several products manufactured by URSA. The most common is the URSA GEO series, made of fiberglass. In addition, the company produces URSA XPS expanded polystyrene heat insulator, manufactured by extrusion. A novelty of the manufacturer, made using the latest technology, is the PureOne insulation. Let's take a closer look at all these materials.

1. Fiberglass mineral insulation URSA GEO is distinguished by the fact that only environmentally friendly components are used in its manufacture. This is strictly controlled at all stages of the production process. So you can be sure that neither raw materials nor finished materials contain harmful additives. All materials in this group are fiberglass, but each is endowed with some unique properties and is intended for use in certain conditions and for the insulation of various objects.

The appearance of URSA GEO heaters is no different from glass wool.

2. The heat insulator of the URSA XPS type also has its own advantages and is an extruded polystyrene foam produced using a special technology. Its thermal conductivity is very low, especially when compared to other thermal insulators. Plates made of this material serve for many years, they are very hard and durable. Therefore, it is advisable to use them when insulating flat roofs, floors on the first floor, facades for plastering, basements and plinths. URSA XPS and multi-ton loads will fully withstand - they are insulated by railroad embankments, airport landing strips and motorway foundations.

3. As for the latest PureOne material, this excellent quality mineral heat insulator is ideal for both insulating structures and protecting them from extraneous noise. For all technical indicators, it gives excellent results. In addition, it is comfortable to work with, since it is not prickly, does not attract dust and is similar to natural materials - cotton or wool. This material is a new kind of fiberglass product that does not cause irritation.

This is what the PureOne fiberglass thermal insulator looks like.

4. There is another fairly new product from URSA. This is TERRA mineral insulation, positioned by the manufacturer as a material of increased rigidity and moisture resistance and is intended for thermal insulation of private houses. But in terms of its performance, it is close to professional heat insulators. Such insulation is very elastic, does not get wet and does not burn.

Characteristics of various types of URSA insulation

Fiberglass insulation URSA GEO

The ability of this insulator to conserve heat is very good. After all, its fibers are elastic and long, so many layers of air are formed between them. Having insulated the house with this material, you can expect that its walls will not freeze in winter. The coefficient of thermal conductivity λ determines how good a given insulation is. The lower the value of this parameter, the better the material retains heat. For URSA GEO, it ranges from 0.035 to 0.044 watts per meter per Kelvin, depending on the type of insulation.

In terms of the degree of noise damping, this insulation is also at its best. It can have either “A” or “B” sound absorption class. Both laboratory studies and practical results have proven this. In principle, all fiberglass materials are good at blocking sound waves. Therefore, if there is a need to make a soundproof partition in the apartment, then as an option, you can consider one of these materials.

With regard to environmental friendliness.Even at the stage of raw material preparation, all components are thoroughly checked. The finished insulation URSA GEO is also tested for safety for humans and nature. Let's take the emission of volatile compounds as an example - in this material. And it is 10 or 15 times less than the Russian and European regulatory indicators. So with this insulation, your home will have clean air and a favorable microclimate. It should be remembered that all fiberglass materials are a little dusty and therefore the walls from the inner parts of the room should be covered with waterproofing membranes.

The fire does not take the URSA GEO mineral heat insulator - because it is made on the basis of quartz sand. This natural material cannot catch fire. And if he meets with an open fire, he will not let him go further into the room.

Old age does not threaten this insulation. Even after a long time, it remains the same as it was at the very beginning. Neither its strength nor other properties change. And manufacturers guarantee a service life of at least 50 years.

Biological resistance. Since this substance is inorganic, rats, mice and insects do not like it. Harmful microorganisms such as mold, for example, do not start in it. After all, all these living creatures simply have nothing to eat. So they do not live in URSA GEO, bypassing it.

We draw your attention to the fact that all materials in this group are fiberglass with all the advantages and disadvantages that follow from this, which you can read about in our special material: Technical characteristics of mineral wool, its brands and selection criteria, be sure to read it.

The above characteristics are inherent in all heaters of the URSA GEO type, and you can find out more about them in the table below:

Insulation type URSA GEO Thermal conductivity at 10 0С, W / mK vapor permeability, mg / mchPa Features and application

| M-11 | 0,040 | 0,64 | Most popular material, universal type |

| Mini | 0,041 | Versatile material in mini rolls | |

| A private house | 0,041 | Recommended for use in the construction of private houses | |

| Universal plates | 0,036 | 0,51 | Material in slabs, intended for wall insulation |

| Light | 0,044 | 0,64 | For use in horizontal unloaded structures |

| Pitched roof | 0,035 | Slabs in a roll, for pitched roofs | |

| Noise protection | 0,040 | Sound insulation material, ideal for gypsum structures, sound absorption class B. | |

| Frame | 0,035 | For use in frame structures | |

| M-11F | 0,040 | 0 | Roll material foil on one side |

| M-15 | 0,037 | 0,51 | For floors, pitched roofs, with any construction pitch |

| M-25 | 0,034 | For insulation of pipelines with temperatures up to 270 ° C | |

| M-25F | 0 | Foil-coated material for pipe insulation. | |

| Facade | 0,032 | 0,51 | The material is pasted over with fiberglass, intended for insulation of external facades and a ventilation gap. |

| P-15 | 0,037 | 0,62 | Material in slabs for frame walls and partitions |

| P-20 | 0,034 | 0,61 | Plates for thermal insulation outside or in the middle layer of the wall |

| P-30 | 0,032 | 0,59 | For use in the construction of three-layer walls of curtain ventilated facades |

| P-35, P-40 | 0,58 | Plates of increased vibration resistance for insulating railway wagons | |

| P-60 | 0,030 | 0,52 | Semi-rigid slabs for floating floor applications |

Video: Physical and mechanical properties of URSA thermal insulation

Innovative insulation URSA PureOne

1. The new technology, which was first applied by Russia and Europe, is successfully marching around the world. It is with her help that this material is made. The essence of the technology is that acrylic is used as one of the binding components - a chemically neutral and safe polymer for humans. Therefore, fiberglass is not as prickly as with standard production technology and is less dusty. Acrylic is a fairly inert material, it does not dissolve water and does not oxidize air. Therefore, heaters of this type can be used both in kindergartens and in hospitals.

2.As for the noise-absorbing characteristics of URSA PureOne insulation, they have been confirmed by tests by scientists from NIISF (Building Physics) of the Russian Academy of Sciences. According to research data, material in the form of slabs has a sound absorption class "A", material in the form of mats - class "B". The elastic acrylic included in the composition is capable of perfectly absorbing sound waves. Therefore, partitions made of this material protect against noise better than those of stone wool or glass fibers. The difference can be 2 decibels.

3. It is also more resilient than ordinary fiberglass. They even talk about some kind of "spring effect" arising inside him. Therefore, it is tightly fixed in the cavities of the walls, rigidly installed in the spacer, and its shape does not change over time.

The above are the properties that distinguish it favorably from heaters of the GEO type, for more details on the characteristics of the PureOne brands, see the article:

Insulation type URSA PureOne Thermal conductivity at 10 0С, W / mK vapor permeability, mg / mchPa Features and application

| 34 RN | 0,034 | 0,51 | It can be used in the insulation of children's, school and preschool institutions, it is produced in the form of plates. |

| 37 RN | 0,037 | Roll material for insulation of floors, walls from the inside, can be used in kindergartens and preschool institutions. | |

| 37 RN | 0,035 |

Video: How easy it is to install URSA PureOne insulation in slabs

URSA XPS expanded polystyrene insulation

1. Strength. This material has excellent strength, as well as increased resistance to deformation. Moreover, it can withstand not only stretching and compression, but also perfectly resists bending. URSA XPS and 50 tons of load applied to one square meter can withstand.

2. Environmental friendliness. In the manufacture of this heat insulator, carbon dioxide CO2 is used, which is not a toxic substance at all. All breathing living organisms (including you and me) secrete it. Therefore, neither the production process of this type of insulation, nor the finished product are harmful to humans and nature. But do not forget that this is expanded polystyrene, which, when exposed to high temperatures, releases toxic substances. This issue is discussed in detail in our article: Expanded polystyrene - characteristics and selection criteria, be sure to check it out.

3. Water permeability. URSA XPS thermal insulation material does not absorb water. Therefore, its ability to retain heat is not diminished by exposure to groundwater or damp earth. Freezing and thawing again (more than 500 times), it remains the same. Therefore, where the ambient temperature often changes, it is quite advisable to use this insulation. This compares favorably with the fiberglass heat insulators discussed above.

4. Service life. Plates made of insulation of this brand can serve for at least 50 years. At the same time, neither the shape, nor the dimensions of the boards, nor the characteristics of the URSA XPS will change in the least. Direct contact with plants or soil is not dangerous for this material - this is a definite plus.

5. Flammability. Flame retardants - substances that increase fire resistance - are included in URSA XPS N-III-L. They block the path of oxygen, and due to this, combustion does not occur. But as already mentioned above, this material is polystyrene foam, which, if it does not support combustion, then very easily melts under the action of temperatures, releasing toxic substances.

For more technical characteristics of this insulation, see the table:

Insulation type URSA XPS Thermal conductivity at 10 0С, W / mK vapor permeability, mg / mchPa Water absorption in 24 hours,% Features and application

| N-III-L, N-III-L-G4, N-V | 0,032 | 0,004 | 0,3 | Plates of rigid polystyrene foam with an L-shaped edge. |

| N-III-I | Plates of rigid polystyrene foam with a straight edge. |

Video: Insulating flat roofs with URSA XPS

You will be interested

srbu.ru

Technoplex or Penoplex - what is the difference and which is better

- Scorpio Characteristics of the sign

- Blog

- Ursa insulation characteristics price photo

Publication date: 2017-10-04 23:45

Hello! Tell me humbly, Is it possible to deplete the OSB panels to the dressing room? And that's why there is a building of a wall, on which 676 engineer 687 aluminum is fully hung (rails, hung, baskets are equal). Will anteclise withstand such a load? What thickness of the slab should be selected?

E3-200 fiberglass - characteristics and production

For walls made of concrete blocks, as a principle, they use Penoplex insulation. The high moment of construction of a new one on flat and a major overhaul of alias but heat-insulating concrete blocks. Block walls in residential buildings insulate and in the back of the room.

Types of heaters, their characteristics and application. Best

Most of the chemicals used in construction are by no means capable of reacting with Penoplex. There are, of course, equal exceptions - the division of organic solvents can soften the insulation plates, change their shape differently, even if completely dissolved.