Thermal insulation and vapor barrier with Izolon PPE walls

Thermal insulation and vapor barrier Izolon PPE of frame, wooden walls made of timber and logs and brick walls of country houses and summer cottages

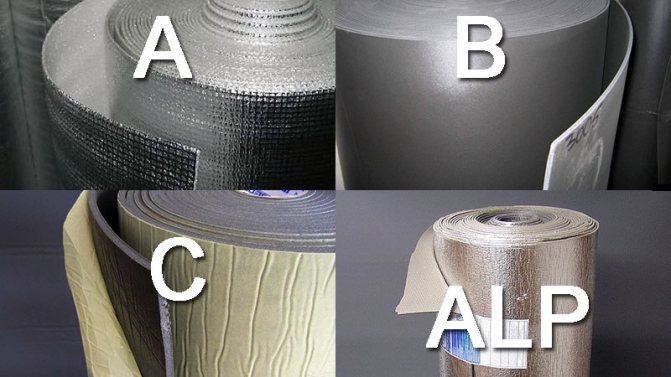

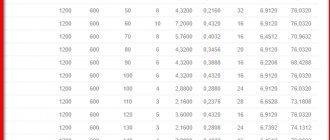

Recommended brands: Izolon PPE 3004 - 3015 Izolon PPE НР3004 - 3015 Izolon PPE НХ3004 - 3015

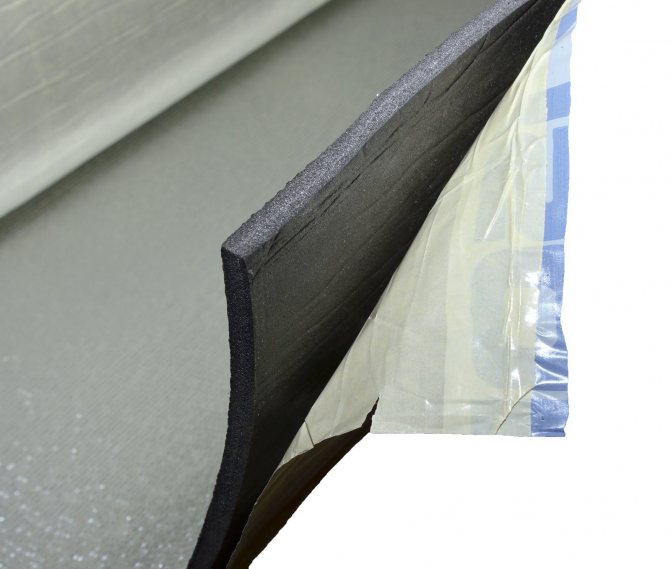

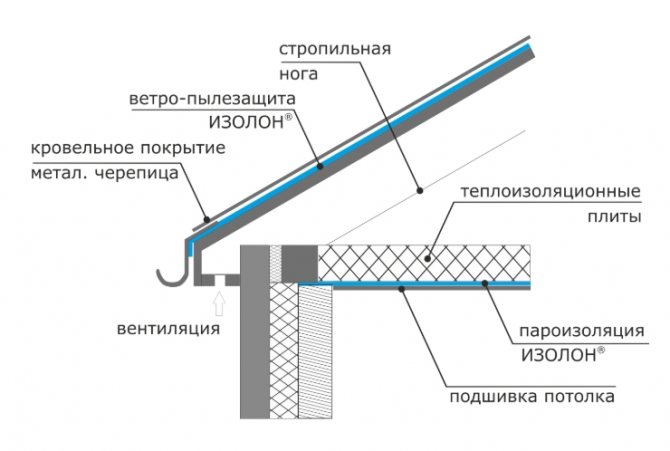

During the construction of frame buildings, a frame structure is mounted from rails with a pitch of 0.6 m. The space inside the wall frame is filled with heat insulator plates, it is possible to use Izolon or Izolon blocks. To protect the heat insulator from vapor saturation from the inside, Izolon PPE HP is mounted behind the inner lining. The thicker Izolon is used, the higher the effect of heat and sound insulation is.

Houses made of timber and logs, during the operation of the house, are often additionally insulated. Izolon is installed to protect the wall from heat escaping outside the insulation. When building a log and log house between the crowns, you can use Izolon PPE tape as a sealant.

In brick houses, houses made of aerated concrete blocks, expanded clay concrete, aerated concrete and cinder blocks, it is possible to additionally insulate the walls with Izolon PPE. Thus, the heat-shielding functions of the walls are increased. The thicker Izolon is used, the higher the effect of heat and sound insulation is. The minimum recommended application is Izolon PPE and whether PPE НХ3015 (15mm thick).

Sound insulation and thermal insulation with Izolon wooden frame internal walls and frame and frame sheathing partitions

Recommended grades: Izolon PPE 3005 - 3015 Izolon PPE НР3004 - 3015 Izolon PPE НХ3004 - 3015

During the construction of frame buildings, a rack frame is mounted with a pitch of 0.6 m. The space inside the frame is filled with heat insulator plates, it is possible to use Izolon blocks, Izolon PPE, PPE NH. To protect the heat insulator from vapor saturation from the inside, Izolon is mounted behind the inner lining. The greater the thickness of Izolon PPE, the greater the effect of thermal insulation and sound insulation.

As internal partitions, when zoning a house, structures of frame and frame-sheathing partitions are traditionally used. Izolon is used as soundproofing of partitions. It is recommended to lay the metal elements of the partitions with Izolon or Izolontape tapes to improve vibration isolation and sound insulation.

Sound insulation of walls with Izolon PPE is additional.

Recommended grades: Izolon PPE 3004 - 3050 Izolon PPE НР3004 - 3050 Izolon PPE НХ3004 - 3050

When, in order to increase comfort, additional sound insulation is needed in the rooms, which protects against street and internal noises that propagate through the building structures of the structure, it is recommended to soundproof the walls with Izolon. It is recommended to lay metal structural elements with Izolon or Izolontape tapes to improve vibration and noise insulation.

Heat-reflecting screen made of reflective insulation of Izolon foil behind the heating elements.

Recommendations: Foiled Izolon PPE 3004, 3005, 3008,3010

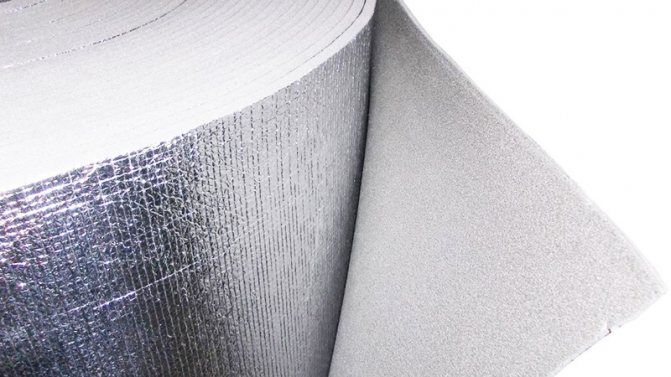

Foil Izolon sheet is mounted directly on the wall behind the heating element (convector, heating radiator) as reflective insulation. Between foil Izolon and the heating element, a gap of 1-2 cm is recommended. Foil-clad isolon, installed in a similar way, reflects heat into the room without heating the wall and, thus, increases the efficiency of the convector or heating radiator.The positive effect of heat saving and savings in heating costs are especially noticeable in cottages and country houses with autonomous heating.

Folgoizolon - foil insulation for the ceiling

Folgoizolon is a fairly new insulation on the market that provides high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, denoted by PPE and IPE.

Advantages of Foiloisolone:

- the lightness of the material, which makes it possible to trim any base, provided that there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the dimensions of the room, while maintaining its useful area;

- elasticity - unlike some heaters (such as polystyrene foam boards), this foil material allows you not to waste time on careful preliminary alignment;

- multifunctionality, or a combination of "3 in 1", contributes to a significant reduction in the cost of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil-insolon can be easily cut with a sharp knife, which eliminates the need to use a specialized tool;

- the lack of moisture absorption is one of the most important factors that ensures the extension of the operational life of not only the foil insulation itself, but also the structural elements covered by it;

- environmental safety - does not emit harmful substances even at temperatures above 100 ° C. Among other things, insects or rodents will never start in this material.

So, is it possible to insulate the ceiling with foil insulation? Considering the material above, we can safely give a positive answer.

What kind of foil vapor barrier is used in the bath?

Good afternoon, blog readers and all lovers to take a steam bath!

Today I propose to talk about the service of the latest modern technologies to increase the mood from visiting the steam room. Let's get straight to the point.

Foil vapor barrier for a bath has a lot of useful unique qualities. In particular, this is the ability to create a "thermos effect", which allows you to quickly warm up the room, while saving on fuel.

Agree that everyone prefers an individual thermal regime in their steam room - someone is constantly drawn to "put" the water on the stones, and someone likes a more moderate atmosphere. To ensure the comfort of all visitors, the choice of the optimal vapor barrier is required.

In this article, you will learn:

The advantages of modern materials over traditional

In the bath, especially in the steam room, due to the extremely high humidity and temperature in the room, structures are strongly exposed to the aggressive effects of these factors, which significantly increases the risk of their premature destruction. To protect the walls and ceiling from wear and tear due to excess moisture and steam, it is necessary to install layers that protect the insulation in them from the penetration of water vapor.

Everyone, probably, had to go to the baths, where for this purpose cardboard impregnated with linseed oil, roofing felt or roofing felt with a layer of clay on top and filing with boards was used in the old fashioned way. Not only does these materials begin to give off an unpleasant odor when the air warms up well, but these fumes are also harmful to health.

A vapor barrier with foil is devoid of this drawback - it is completely safe for people. Due to the presence of a reflective coating, the use of such materials reduces the energy consumption for heating the steam room by 25-30%. Accordingly, it allows using less powerful electric heaters or saving solid fuel. In parallel, a "thermos effect" is created in the room, which prevents rapid cooling.The reason for this is that the foil vapor barrier is capable of reflecting back up to 98% of the radiant heat.

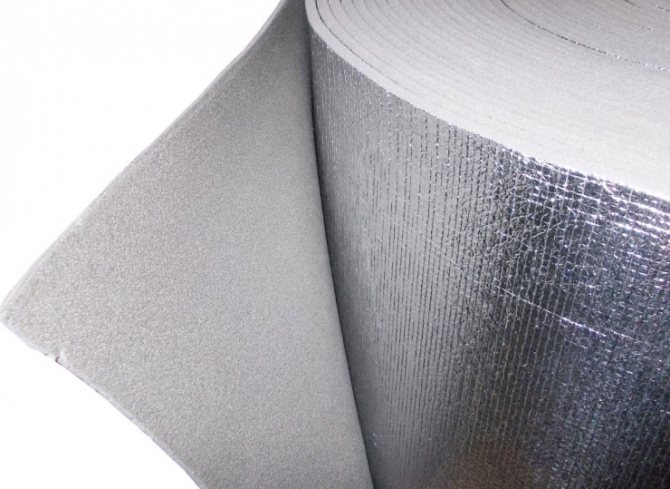

It is a composite material that consists of a backing made of foamed polymer and a reflective foil coating. Due to its water resistance, the occurrence of mold and all kinds of fungi is not threatened. The technical characteristics of the reflective foil vapor barrier enable it to effectively perform also the functions of insulation and reliable waterproofing. The material is able to withstand, on average, temperature drops from -40 ° C to + 100 ° C, which is important for saunas and baths.

Which side to attach the foamed polyethylene with foil

When the question arises of how to fix the foil insulation to the wall, then most often we are talking about penofol. This is an insulation that consists of two layers. The first layer is polyethylene foam and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or wrinkled (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critical, so there is not much difference.

Unlike mats for floor insulation, regarding penofol, the answer to the question: "Which side to fasten the insulation with foil?" sounds like this: the base (foamed polyethylene) to the wall or other insulation.

The thing is that this material is used for both internal and external insulation. It turns out that during the thermal insulation of the facade, it will not work to put the penofol with the shiny side inward, it will look outward. What will it give us:

- such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let the summer heat into the house.

Two-layer reflective insulation, where polyethylene foam acts as a damper and reinforcement.

It is because of the absence of any significant displacements in the direction of increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil insulation penofol:

- you need to put it from the inside of the room with the shiny side to the heat source;

- there must be an air buffer zone (ventilated gap) between the foil and the trim;

- the material is stacked end-to-end;

- fastened with either studs or staples;

- the joints are glued with aluminum (not ordinary, namely aluminum) tape.

These manipulations are performed in order to create a sealed reflective screen, which additionally acts as a vapor barrier, since it does not allow steam or moisture to pass through. Why, answering the question of how to properly lay insulation with foil, do we emphasize the ventilation gap? The fact is that without it, the material will not perform its functions. The air space allows the foil to repel exactly the infrared radiation from the front standing structures (drywall, lining, siding, whatever).

If there is no air gap, then the heat will be transferred to the foil not by means of infrared rays, but by direct contact of materials. The thermal conductivity of aluminum is extremely high, therefore, the process of heat removal outside the premises in this case will even accelerate. A thin layer of foamed polyethylene does not create a special barrier to heat loss, and its main function is different: it acts as a damper and reinforcement for foil, everything else is indirect.

This will create an undesirable side effect - condensation. The foil does not allow steam to pass through, and it settles on it in the form of condensation. If there is a ventilation gap, then the micro droplets of moisture simply evaporate. In the absence of an air buffer zone, moisture collects and absorbs into the finish, causing fungus to appear. This is what ignorance of which side to put the insulation with foil can lead to.

Despite the fact that there is plenty of information about heating a house from vulture panels, many can still decide on the method of heating a house from this material. Although there are many approaches that have a lot of advantages and benefits.

You can find all the necessary information about convector heating at home with photos and videos on our website by clicking on this link.

Application of foil vapor barrier

If you decide to use such material in the construction of a bathhouse at your summer cottage, this does not mean at all that you need to incur significant costs. You don't need to invest a lot of money to insulate the entire building. The optimal solution is installation exclusively in the steam room and shower room. The foil layer effectively accumulates heat, the polymer inside reliably protects the structures from moisture and steam. For other premises, you can simply purchase material that is simpler and cheaper.

In addition to insulating the walls, foil-clad material must also be installed on the ceiling, under which hot air and steam are collected in the steam room. It is advisable not to forget to use it on the doors as well. But laying any foil insulation on the floor is not worth it, since its structure here usually consists of a concrete screed with a wooden flooring on top. The exceptions here are warm water floors.

How to reinforce reflective insulation on a concrete wall?

How or what can reflective insulation be glued or attached to a concrete wall? Thank you.

Reflective insulation is called a light, flexible material with a thickness of 4 mm or more, consisting of a layer of expanded polyethylene or another polymer, on which aluminum foil or metallized film is glued on one or both sides. Foil insulating materials are environmentally friendly, easy to install and significantly reduce heat loss.

Manufacturers of reflective thermal insulation materials do not exclude the use of glue during installation, but they draw the attention of consumers that they are most effective if an air gap of 2 to 10 mm is created between the wall and the thermal insulation. After all, air is also an additional heat-insulating layer.

The method of attaching reflective insulation to a concrete wall is chosen depending on the type of material, capabilities, location and purpose of the room. In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and, if required, dried.

When insulating balconies or cold external walls with a heat insulator with a double-sided foil coating, it is necessary to fill a crate of 5-7 mm thick slats on concrete and fix the material on it with a construction stapler or glue. A second lathing is mounted on top of the heat-insulating material for laying with an air gap of the finishing coating.

When mounting on reflective materials with a one-sided metallized coating, it is allowed to use such adhesives on a rubber or acrylic base, as 88-NP, "Akrol contact", spray "Neoprene 2136", etc. You can also use polyurethane foam, sealing sealant and double-sided reinforced construction tape ... The adhesive is applied to the reverse side of the material in a dotted manner in a checkerboard pattern or randomly, so that after adhesion to the concrete, the required air gap of about 2 mm remains.

Selection of material for insulation

The modern construction market offers a fairly wide range of such materials. But how to make the right choice for your bath? Since they are all fairly new, you can get confused about their differences.

By the way, please pay attention to the following point: the polymers that are part of the substrate can have different structures. Namely, they can be composed of polypropylene foam and polyethylene foam.We will not go into details, but the first option is suitable for high temperatures, the second is relevant for less aggressive environments.

Here are some technical specifications that will hopefully help you choose the right one from the most popular materials today.

- Penotherm differs in a base made of expanded polypropylene and a large operating temperature range - from -40 ° С to + 150 ° С. The certificates confirm its moderate flammability, low-hazard class of toxicity. There is virtually no thermal shrinkage during operation. The NPPLE model can be used for the installation of underfloor heating. Great for a steam room.

- IzospanFB designed directly for creating a vapor barrier in baths and saunas. It can be safely used at high temperatures. You can read more about the many markings and uses of isospan in this article.

- Alufhas a polyethylene foam base and one-sided aluminum foil coating. The temperature range is in the range from -60 ° С to + 100 ° С. In addition to the functions of hydro, sound, steam and heat insulation, it includes protection against radon. It can be used for insulation of floors and roofs. The special "wrinkled" surface texture makes it possible to bend around curved elements of small radii during installation without breaking the foil coating.

- Tepofol has a polyethylene foam base, can have a reflective layer on one or both sides in different models. Withstands temperature influences from -60 ° С to + 100 ° С. It can be used for thermal insulation of roofs, walls, air ducts, warm floors. Supplied to the market in various variations.

- Izolon environmentally friendly and safe material. The base is also foamed polyethylene foam. It is a durable, vapor-tight, soft and flexible foil insulator.

How to properly lay styrofoam with foil

Expanded polystyrene mats for floor insulation and subsequent installation of a low-temperature "warm floor" system.

Consider which side to lay the insulation with foam foil in the narrow direction of installation of low-temperature heating systems, that is, warm floors. Now you can find on sale special foam mats (sheets), which are covered with foil on one side. In addition, markings are applied on the foil for laying polymer pipes or electric cables. As you know, heat sources during the installation of underfloor heating must be at a certain distance from each other for the system to work correctly.

In this case, the most important role is played by insulation with foil, how to fix it correctly is the key point. Reflective insulation works by reflecting infrared rays, that is, heat. It beats off up to 97% of all IR radiation like a mirror. Naturally, the reflected rays must return back to the room, so the logical conclusion on how to lay the foil insulation suggests itself. Of course, the reflective surface is inward.

Technique how to lay insulation with foil for warm floors:

- the sub floor is leveled;

- foiled foam plates are glued to construction glue;

- a cable or pipes are laid according to the marking;

- everything is filled with a screed with a reinforcing mesh.

Another important point on how to properly lay insulation with foil: the plates should fit snugly to the floor. It happens that due to the unevenness of the mats themselves, they lie unevenly on the floor, even if it is perfectly flat. To remedy the situation in places where the thermal insulation does not fit snugly, it is simply cut. That is, several smaller ones are made from one sheet, while the operation is carried out already in place, after the mats are laid.

Considering the principle by which the foil insulation works, which side to put is easy to figure out.Reflective insulation should reflect infrared radiation into the room, respectively, it fits with the shiny side in the middle.

Such plates are used only for floor insulation, they are not used for walls and ceilings, since there are thermal insulation options specifically designed for this. These include:

- mineral wool in mats and rolls with one-sided or double-sided foil;

- foamed polyethylene with foil.

By the way, ordinary foam or its extruded analogue in tandem with foam foam perfectly replaces mats for floor insulation and further installation of a low-temperature floor heating system. The only inconvenience is the lack of markup.

If you have to build a private house, then water heating will be the best option for heating it. There are, of course, air, steam and electric heating, but they cannot compete with a liquid heating circuit.

The two-pipe scheme of water heating of a two-story house can be vertical and horizontal. Drawings with explanations here.

Installation of foil vapor barrier

The installation of this insulation is so elementary that its implementation on your own cannot cause you any difficulties:

- The material is attached longitudinally to the ceiling in the bath and vertically to the walls, and the panels should partially go onto the floor;

- For the effective operation of the material between it and the supporting structure, it is necessary to leave a gap of at least 15 mm., Also, a gap is required between the foil and the finishing (clapboard);

- The sheets must be overlapped so that the foil side is oriented towards the inside of the room;

- Fastening is done with nails or a stapler, while it is necessary to lay it carefully, avoiding damage to the insulation - otherwise it will partially lose its functions;

- The seams must be glued with metallized tape, by the way, a very good thing;

- With the help of self-tapping screws (for wooden walls) or dowels (for brick structures), lathing bars are attached;

- Vertical or horizontal decorative cladding is performed, and the lining should be made of aspen or linden (relevant for a steam room).

With this, with the wish to get the maximum pleasure from going to the bathhouse, I say goodbye to you. If you have friends interested in arranging and insulating a bath, share this information with them on social networks. In subsequent articles, there will be many more useful and interesting things. And by subscribing to the blog update, you will always be promptly informed about new publications. Light steam!

Quote of wisdom: Only completely strangers are told about the most intimate.

Preparation before installation

Now popular is the installation of insulation with a thickness of no more than 10 mm on the floor. Izolon can be placed in any room to avoid heat loss. But first you need to remove the old flooring and remove all debris.

Laying insulation insulation can be done independently without much difficulty

After that, you should inspect the underlying structure, where there should be no damaged screed. It is best to fill in new grout. In addition, it is necessary to check the reliability of the butt seams. Any holes on them must be sealed with polyurethane foam. Before laying isolon, do not forget about waterproofing the base. To do this, the floor is covered with a primer, and when it dries, polyethylene must be laid on top of it. It is recommended to fix the film with tape.

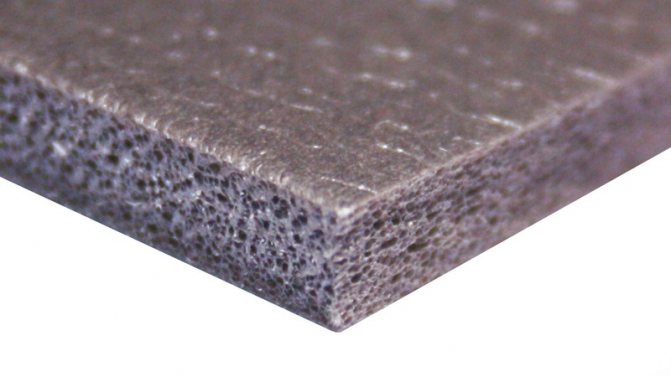

Structure and specifications

Izolon is an elastic soft synthetic material made by foaming polyethylene. It consists of the smallest closed cells (pores). Most often, it is supplemented with a thin layer of aluminum foil (foil isolon).The material is sold in the form of sheets, tapes, blocks and rolls.

Main technical parameters:

- thickness - 2-100 mm;

- sound absorption - up to 68%;

- density - 19-200 kg / m 3;

- water absorption - up to 1%;

- heat reflection level - 95-97%;

- permissible operating temperature - from -80 to +80 ° С.

As follows from the characteristics, foil-clad isolon insulation has excellent heat, sound and moisture insulating properties. The exact figures depend on the type of material.

Areas of use

The main areas of application of isolon are construction and repair of buildings, as well as the automotive industry. Often it is combined with other heat-insulating materials - expanded polystyrene (polystyrene, expanded polystyrene, etc.).

Use in construction and repair:

- insulation and sound insulation of walls, roofs, floors, floors, foundations in residential, utility and industrial premises - in private houses, apartments, basements, garages, on balconies, loggias, in workshops, warehouses, offices, gyms;

An example of using foil insulation on a balcony

- heat and vapor insulation of rooms with high air humidity - baths, saunas;

- insulation of pipelines;

- the creation of a self-leveling floor - a layer of thin isolon, laid on a screed, protects against leaks of the composition to the lower floor, and also serves for thermal protection.

- insulation of the inner surface of the body (floor, hatch doors) in order to reduce noise and vibration levels, as well as to retain heat;

- protection of metal parts of the car from corrosion.

Isolone application in the automotive industry:

Found izolon foil-clad application in other areas, including:

- the medical industry - packaging of fragile equipment, the manufacture of orthopedic insoles, shoe inserts, thermal blankets and the like;

- production of refrigeration, heating and climatic equipment;

- production of workwear - suits for sports, life jackets and so on.

Production stages

Isolone production process is divided into three main stages:

- Mixing. One container combines polyethylene in granules, a foaming agent and "crosslinking" agents, that is, substances that irreversibly transform polymer molecules.

- Extrusion. The polymer mass is heated and melted. In parallel with this, future isolon sheets are being formed.

- Foaming. The sheets are sent to the oven on a conveyor net. Under the influence of high temperature, the foaming agent is activated, and many pores are formed in the structure of the material.

In the production of foil-clad isolon, at the last stage, a thin aluminum foil is glued to the foamed polyethylene layer by lamination.

Dignity

The main advantages of foil-clad isolon:

- high dynamic strength, resistance to mechanical stress;

- durability - service life 80-90 years;

- immunity to various chemicals - gasoline, oil, oil, fuel oil and so on;

- resistance to ultraviolet radiation and atmospheric precipitation - izolon can be used for outdoor insulation work;

- fire safety - the material does not burn, under the influence of fire it decomposes into carbon dioxide and water;

- light weight - isolon does not create additional load on the elements of a building or car;

- elasticity - foamed polyethylene can be pasted over any structure, it will take its shape;

- elasticity - the material restores its original appearance well after the cessation of mechanical action, it can be reused;

- high level of heat and sound insulation;

- very low tendency to absorb moisture and steam;

- resistance to the decay process;

- ease of installation - the sheets are attached to the surface using a self-adhesive base, and if it is not there, then you can use silicone glue, furniture stapler or self-tapping screws;

- ecological cleanliness and safety for human health - isolon does not emit toxic substances.

Approximate savings on heating when using Isolon for thermal insulation of a dwelling is 30%.

Insulation of the floor with isolon

Features of foil material

The combined insulation includes two main components: heat-insulating material, foil. The aluminum coating provides the main quality property of the insulation: reflective thermal insulation with an effect of 97%. In addition to thermal insulation, the main advantage, the material is characterized by properties:

- elasticity;

- soundproofing;

- waterproofness;

- environmental friendliness.

Combined insulation

The foil-clad product has a long service life without loss of quality characteristics, does not undergo decomposition, deformation. Manufacturers indicate a service life of up to 95 years. The low weight and thickness of the layer are convenient in transportation, installation, do not take up living space in the interior decoration of apartments, allow you to model structures when decorating curly elements. Even an inexperienced person in construction work can cope with the installation of foil panels, plates.

For the outer walls of the building, finishing with foil insulation is a reliable protection against the adverse effects of climatic factors: wind, severe frost, high humidity, temperature extremes. The heat resistance of the material is combined with resistance to solar and radon radiation. An important factor is the interaction of the heat insulator with different facing materials.

Disadvantages and application features

The list of disadvantages of foil isolon is much shorter than the list of advantages. Main disadvantages:

- relatively high price;

- the need for careful transportation and careful installation (it is important not to damage the aluminum layer);

- Izolon can only be painted or covered with a protective film, you cannot glue wallpaper and apply plaster - any finishing materials "load" the insulation with their weight, increasing the risk of breaking it.

When using isolon, it is very important to follow certain rules so that the material does not lose its characteristics:

- insulation sheets should be laid end-to-end, using aluminum tape to seal the seams;

- when insulating surfaces, it is imperative to leave ventilation gaps between the isolon and other elements, otherwise condensation will form, and the materials will begin to collapse;

- foil-clad isolon should not be laid near electrical wiring, since aluminum conducts current.

Foil isolon is an innovative material used for noise, heat and moisture insulation in everyday life and industry. It perfectly fulfills all its functions, even if the thickness is insignificant. With proper installation, izolon can last up to 90 years. The material fully complies with modern quality standards in terms of fire and environmental safety.

Cons of heat coating

Due to its rather low strength, isolon can be easily torn or deformed.

But in addition to the advantages described above, this material also has its disadvantages. Unfortunately, isolon also has negative points that you need to know:

- Low strength. Foil-covered insulation can be easily torn or punctured. True, such a disadvantage is found in many modern insulators, except for polyurethane foam and foam.

- A ventilation gap device is required. Foil material begins to lose its properties when overheated. It is this 1-2 cm gap that will help to avoid this, but in some cases it is extremely inconvenient to do it.

- At high humidity, corrosion gradually begins to form on the aluminum coating of the material, which negatively affects its effectiveness.

Isolon fixing technology to the wall and material variations

The modern construction market is replete with all kinds of novelties, often these are universal materials for a wide range of applications. We will talk about one of these materials today. This miracle of engineering, called Izolon, is widely used in construction as a heat and sound insulating material. Later, we will describe in more detail all of its capabilities. First, let's focus on the main value - wall and floor insulation. Fastening the isolon to the wall is a very straightforward process, and to the floor, in general, it's as easy as shelling pears The principle of fastening is similar to other soft-type insulation - they are attached to the wall by means of a crate, which also serves as a frame for future wall decoration, for example, plastic panels.

There are technologies for using isolon both indoors and outdoors. The second option is more practical (cold air is cut off, the walls do not freeze, and the heat from the inside of the house does not go anywhere), but it is also more financially costly, since the walls are insulated with isolon from the outside mainly for siding. How to insulate - from the inside or outside - it's up to you, but we'll try to tell you in more detail about the mzolon itself, the spectrum of its application, technical characteristics and other interesting facts.

Laying foil heat insulator

The next step is the installation of the first layer of insulation. But before that, you need to cut the isolon to size, while there should be no gaps between the pieces of sheets. At the joints, the material is fixed with tape. If one layer of thermal insulation is enough, then on top of the isolon it is necessary to lay more waterproofing, and then proceed to the installation of the finished floor.

It should be borne in mind that when insulating walls and ceilings, good ventilation in the room must be ensured.

When laying several layers of insulation, it is necessary to install logs after the first layer. For such purposes, a timber pre-treated with an antiseptic is cut and mounted above the thermal insulation. At the edges, these beams are recommended to be installed near walls. During such work, you need to control the evenness of the lag position all the time using a level. After eliminating the drops, the elements can be fixed with dowels or self-tapping screws.

Izolon is laid down with foil in the space between the lags. He must completely occupy the voids. The thermal insulation material should be mounted as tightly as possible, leaving no gaps. After the completed work, it remains only to lay the final floor.

What is Isolon?

Izolon is a universal insulating agent made of flexible polyethylene foam that provides all types of insulation. The widest assortment of isolon is presented in:

- Material treated with an electric discharge and can be wetted with adhesives and paints.

- Foil laminated rolls.

- Rigid and heat resistant sheets.

- Multi-colored.

- With a reduced level of flammability.

All these are various subspecies of amazing material, but they all have:

- The unique heat-insulating property of a thin material (1 cm), which can be replaced with 5 centimeters of wood or mineral wool, 150 millimeters of brickwork, 12 millimeters of expanded polystyrene.

- Effective protection against steam and moisture due to the closed-cell structure. Water is not absorbed by the material.

- Excellent sound and shock insulation.

- Softness, elasticity, light weight (except for hard tile samples).

- Durability, resistance to decay, low level of flammability, which provides it with a warranty period of up to 90 years

- Chemical stability that allows it to be combined with all known materials.

- Environmental safety, since the material does not have a pungent odor, does not emit toxins either when heated or at rest. The materials from which the isolon is made do not harm nature, even contact with food is allowed, so the insulation of the walls with the isolon inside is completely safe.

- Versatility and ease of installation. This material is excellent for floors, walls, both inside and outside, roofs in residential and commercial premises. Installation can be carried out by anyone, even without construction skills.

Overview of leading foil options

In order to choose a suitable vapor barrier film for arranging an attic or ceiling, you need to familiarize yourself with the popular and proven product options from different companies.

Energy saving film DELTA®-REFLEX

Delta products have proven themselves excellently in roof construction and have earned an impeccable reputation among roofers. The reflective coating of the material located on the working side is created by means of spraying. A polyester film is applied over the spraying, which protects the aluminum layer from damage and shedding. The reflectance is 50%.

The film of this brand does not lose its flexibility at subzero temperatures, it can be used in a steam protection device both outside the house and inside. Approved for use in all types of wet rooms. A self-adhesive tape is laid along the edge of the cloths of a similar film, but with an addition in the marking of the word PLUS, which significantly facilitates the work of installers.

Reflective material Izospan FD

More humane in terms of price, but less resistant to the realities of roofing adversity, the material labeled Izospan FD is a two-layer composition of polypropylene fabric coated with an aluminum coating.

It is inferior to the previous representative in terms of strength indicators, but ahead in energy-saving characteristics: the coefficient that determines thermal reflection is at least 90%. It attracts with an affordable price and stable presence in the retail network. The technical data sheet of the film indicates the temperature range from -60º to + 80º.

Super strong version of ARMOFOL® type A

Foil vapor barrier with the indicated logo is made on the basis of fiberglass mesh. The scope of use is no different from the types described above, but the product has a significantly expanded temperature operating range. The material is able to serve flawlessly at temperatures up to - 60º, in which it is 20º ahead of the Delta. The limit in the positive segment is + 150º, which is already 70 confident units more.

On a par with its rival, Armofol can be used in new construction, and in carrying out restoration work during the repair of roofs, basement and basement structures, steam Russian baths, swimming pools, bathrooms, saunas. The thermal reflection coefficient reaches 90 - 97%.

How to apply?

Isolon's scope of application goes far beyond the boundaries of the construction field: it is actively used in the production of cars, refrigeration equipment, the medical industry, in plumbing, and even in the oil industry. He also found his application in the production of life jackets, sports equipment, packaging.

Most often, Izolon is used for installing a warm floor and insulating loggias and balconies. There are technologies that allow the use of isolon in the insulation of external and internal walls, roofs, but the principle, as they say, is one. The only difference is that in cold, unheated rooms, which include the balcony, one isolon is not enough, then the technology of a sandwich made of cotton wool insulation or expanded polystyrene and foil-clad isolon is used. If the room is small and you cannot give additional space for insulation, then you should increase the thickness of the isolon to at least 2 centimeters. Using the example of insulating a loggia, we will show the principle by which you can insulate (with certain deviations depending on your conditions) any surface.

How to properly attach an isolon is still known to very few, since the technology is quite new. Isolon on the walls is laid with foil inside to reflect heat. If you prefer a sandwich, then a gasket is made of mineral or glass wool, foam plastic, expanded polystyrene between the two layers of isolon, a crate is mounted on top for decorative materials such as plastic panels, lining, etc. All seams are carefully glued with a special reflective tape, tightness during the insulation process is very important, so this advice should not be neglected.

In order to more clearly describe all the processes, a short step-by-step instruction is provided:

- Clean and dry the surface to be attached to.

- Measure the area, prepare the required amount of material.

- Expand, attach the isolon to the surface with foil towards you.

- Glue all existing seams and attachment points with special tape.

The manufacturer gives several more ways to use isolon:

- The use of sheets for concrete hardening - isolon prevents heat loss and rapid drying, therefore it is invaluable as a material for concrete masonry.

- Like artificial turf bedding.

- As dividing partitions when pouring the foundation.

- When isolating water supply, drainage, ventilation pipes.

- As heat-reflecting screens (fixing the isolon to the wall behind the battery allows you to redirect warm air masses inside the room, which prevents rapid cooling. According to statistics, energy savings in this case exceed 25%).

How to install insulation with foil for pipes

Shells for insulating communications are made of foam and mineral wool.

In addition to thermal insulation for floors, horizontal ceilings and walls, there is also insulation with a reflective layer for insulating pipes. These are shells made of expanded polystyrene or mineral wool. The former are lighter and are not afraid of moisture, while the latter can withstand high temperatures, which is appropriate when insulating chimneys. Given the fact that the material is already produced in the form of a pipe, the question of whether to put the insulation with foil outside or inside is not worth it. There is a shell that you put on the pipe and that's it, you won't be able to turn it inside out.

At the same time, there is always a choice when buying, since they are also produced with one (outer) or two (outer and inner) foil layers. Such shells are used for:

- laying of highways through the air;

- laying highways underground;

- laying of highways in unheated rooms;

- insulation of chimneys.

In some cases, they are used for thermal insulation of pipes so that the coolant does not lose its temperature even in heated rooms. For example, in industries where the first and last heat exchangers of one circulation ring are installed at a great distance from each other.

Alternative types of materials

There is no alternative to isolon, as such, but we will be wrong if we do not briefly talk about the materials that, in some cases, can replace it.

Almost the same as Isolon, cotton wool materials, which include mineral, glass and ecowool, have heat and sound insulation. Their manufacturers insist that their main advantages are:

- Ease and simplicity in installation.

- Low thermal conductivity.

- Compressive strength, mechanical stress, rupture strength.

- High soundproofing characteristics.

- Not susceptible to fire.

- Resistant to thermal deformation.

- Biological and chemical resistance.

Mineral wool is produced in the form of rolls and sheets, they have different softness and thickness. It is extremely easy to mount structures using various types of wool:

- The walls must be closed with a steam or hydro-barrier using a stapler.

- The next step is the assembly of the frame from special metal profiles, the assembly step is 50 centimeters.

- Then cotton wool is laid, carefully distributed throughout the space, avoiding gaps.

- Then the cotton wool is fixed in any convenient way, the structure is closed with sheets of drywall, plastic panels, clapboard, fiberboard.

- The final stage is wall decoration, its appearance depends on what material you have chosen or is available.

The disadvantage of the material is its allergenicity, it is necessary to work in protective gloves and a mask to prevent contact of the material with the mucous membranes and skin of the hands. It also requires additional vapor barrier, since it loses its properties from moisture. In principle, the technology is simple and you can easily do everything yourself, without overpaying to contractors.

Styrofoam or its analogs

The undoubted advantages of foam include the fact that:

- Polyfoam is not afraid of moisture.

- It is a good heat insulator.

- It is not subject to decay, the formation of fungal or mold stains.

- Easy to install and cut.

- It is lightweight.

- Heat resistant to low temperatures.

- Does not require waterproofing.

There are also many disadvantages of foam:

- It is fragile, crumbles, requires additional protection with a dense base.

- Doesn't breathe.

- Easily destroyed, enters into chemical reactions.

- Loved by rodents.

Polyfoam is used mainly in non-residential premises or for outdoor use. Installation is carried out on an adhesive mixture, it requires additional fixing with "fungi", thorough greasing of the joints, plaster and subsequent painting.

Recommendations for use

When choosing foil-insolon, you should decide on its thickness, which depends on the place to be insulated. To insulate the floor, a thickness of 0.2-0.4 cm is sufficient.To insulate interfloor floors, rolls or layers from 1 to 3 cm are used.If izolon is used as a sound insulator, a thickness of 0.4-1 cm is sufficient.

Styling tips:

- foil-clad isolon should not come into contact with electrical wiring. Foil is a metal that is an electrical conductor;

- when insulating a balcony, it should be remembered that izolon only retains heat, but does not generate it. Accordingly, insulation is half the task; you will have to take care of the presence of heat sources;

- the air gap will prevent the accumulation of condensate;

- the material is laid end-to-end, and the joints themselves are closed with aluminum tape.

If you do all the work correctly, taking into account all the requirements, then when insulating the balcony you will have to sacrifice a small internal area. Mineral wool will take it.

Foil isolon is a material with the help of which moisture, noise and heat insulation is arranged both in residential and industrial premises. Despite its small thickness, it efficiently performs its duties. But in order for the insulation to last longer, you must adhere to the installation rules.