What is sawdust concrete and where is it used

The material is based on strong brands of cement. When mixed with sand, mineralizers, as well as sawdust, this building material is obtained, which has high versatility. Today, a variety of designs are made from it, and also used for insulation purposes. But the main range of application, of course, is low-rise private construction. In this case, sawdust concrete is used both for the construction of residential buildings and for the construction of adjacent buildings and structures.

Grades M5 and M10 have insufficient strength for construction, being used for insulation purposes. As for the M15 and M20 brands, they are strong enough for the construction of houses.

Important! The more organic component in such concrete, that is, sawdust, the lower its strength, but at the same time the higher the insulating qualities. That is why such material is used to insulate basements and other already erected premises. With an increase in the proportion of sand and concrete, not only strength increases, but also water resistance, as well as frost resistance. These types of material are good at preventing corrosion of reinforcing elements.

The cost

Here, I did not count everything as meticulously as with the roof of my house, where in the estimate you can see everything from and to up to every screw and nail. I have already mentioned the cost of the main materials in the text of the article. And for the total amount I will say that I had a budget in my calculation of 25,000 rubles. on the floors, but even 2 tr remained. (i.e. it's all-all together with delivery). Floor area - 31.4 sq. m. (minus the foundation tape, it protrudes 30 cm for me.)

Wooden stone, or stone wood, as sawdust concrete is called, is also a fairly cheap material. Sawdust concrete, the price of which is low, is considered the most affordable when compared with other materials. For example, one wall block, which has dimensions of 390x190x188 mm, made from sand and screening, costs about 23 rubles on the market. A stone that has the same dimensions, but is already made of sawdust concrete, will cost 3-4 rubles cheaper, and at the same time it is lighter and warmer.

By the way, it can replace 7 bricks (the cost of one is 5-7 rubles). It is easy to calculate that a wall made of a mixture of sawdust and concrete will cost 2.5 times less than a brick one. In other words, to build a box of a house of 8 by 8 meters, 20,000 bricks will be needed, the owner will have to pay 140 thousand rubles only for stones, the same amount for masonry to the craftsmen and 40,000 rubles for sand and cement. If you use sawdust concrete, then the price of such a building will vary from 100 to 150 thousand rubles. Agree, a tangible benefit.

Let us compare sawdust concrete with other materials: the price per cube of brick will be 3 times higher than the cost of a cube of a cinder block, a cube of natural stone - 2 times, a cinder block - 1.5 times.

The advantages of sawdust concrete

- Sawdust concrete may well be made independently;

- Low weight allows you to save time and money on the construction of a large-scale foundation;

- Like gas silicate or foam blocks, sawdust concrete is extremely easy to process. If necessary, you can easily cut off the excess from it in order to perfectly fit for masonry;

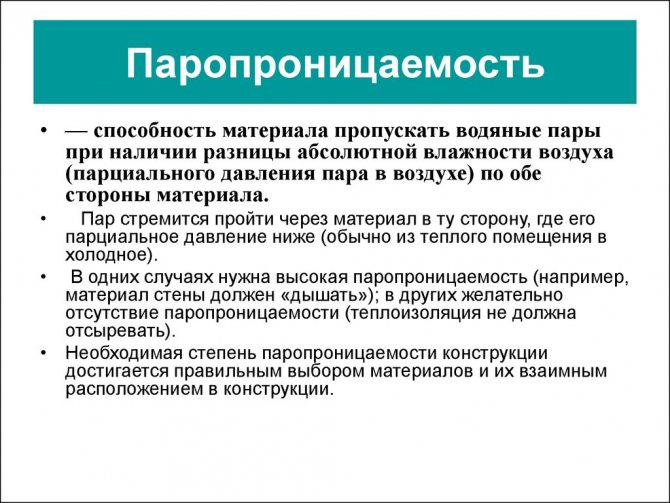

- The material has high vapor permeability, which allows the walls to "breathe";

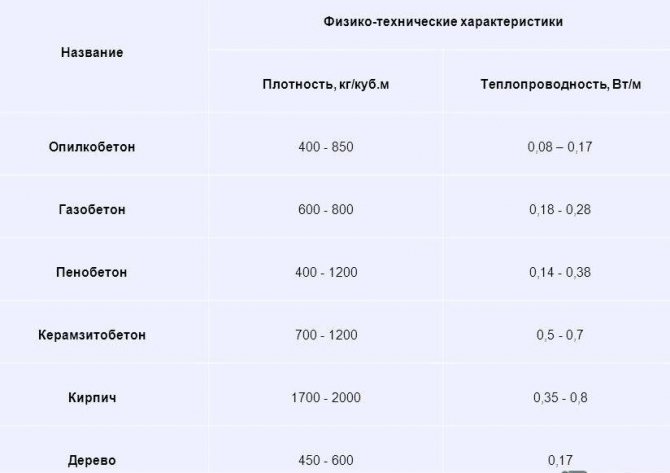

- Low thermal conductivity and resistance to moisture is achieved by changing the percentage of organic and inorganic components;

- Ecological cleanliness.All components of sawdust concrete are of natural origin. Its safety is much higher than that of cinder blocks;

- Fire resistance;

- The ability to work independently without the need to involve professional builders. Naturally, for this you should adhere to the rules;

- When insulating a building, or reconstructing it with sawdust concrete, it is not required to strengthen the foundation;

- The material has a long service life. And in houses built from it according to all the rules, there is not only warmth, but also very good sound insulation.

The main stages of work

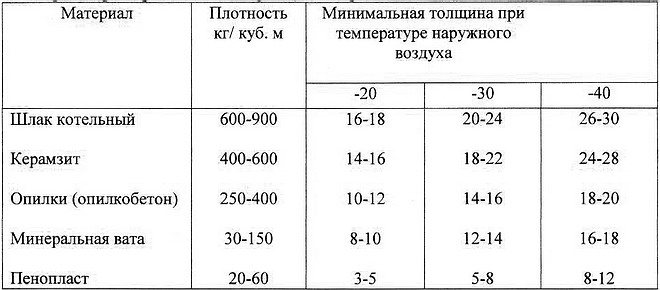

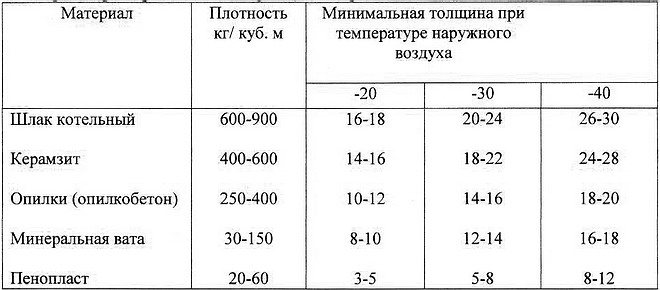

Table of characteristics of materials for wall insulation.

To ensure good thermal insulation of walls in country houses and utility blocks (baths), sawdust diluted with lime is actively used. This substance acts as an excellent antiseptic and an unattractive agent for rodents. The prepared composition is poured onto the waterproofing layer little by little, after which it rolls well. The result is an excellent community with quality thermal insulation.

Insulation of walls with sawdust is associated with their finishing with plywood or clapboard. Glassine is laid under them. The outside is covered with edged boards or moisture-resistant plywood. After that, the ventilation system is installed. It is done as follows: a bar with a section of 40 × 40 mm is taken, which helps to build an appropriate gap. Wall insulation from the outside is completed with siding or block house cladding.

The process of finishing the partitions of the house and the bath with the selected raw materials should be regulated by a certain wall thickness, which must correspond to 15-17 cm. The ceiling thickness is 25 cm. As a result of such insulation, a pleasant and healthy microclimate will be maintained in the room in any season.

The area of such buildings is 35-40 sq.m. Heating the oven 2 times a day will help maintain a stable indoor temperature. With a permanent residence in a building, the insulation of the walls should be slightly increased by changing their thickness. For this, it is necessary to install a complementary base of boards; it is also important to fill this layer with a "warm" composition. Such a building is not afraid of the most severe frosts.

Wall insulation with sawdust should be inextricably linked with strict adherence to fire and electrical safety standards. The chimney points are equipped with special dividing spaces, which are covered with non-combustible materials. The electrical wiring must be located on the outside, then, as a result of a short circuit, the insulation layer will not be able to catch fire. It is placed in metal cases in the form of tubes, their thickness must be more than 3 mm. The room in which the main work takes place should be thoroughly ventilated.

Disadvantages of sawdust concrete

- Blocks of this material are springy during installation, and retain this condition for a long time. The deformation is small, but it is present;

- In many cases, the material lacks its own insulating properties, and it is necessary to carry out additional hydro and vapor barrier;

- The material gains strength for a very long time - three months after production;

- The need to focus on quality. Sawdust concrete can be made even in artisanal conditions, so the technology is often not followed. Therefore, buy such materials only from those sellers in whom you are confident, or do everything yourself in compliance with all the rules;

- Sawdust concrete walls are not very strong, therefore, it is only necessary to mount something that will have a serious load on them with a good anchorage;

- In sawdust houses, maintaining a constant humidity of less than 75 percent is an important factor. For the same reason, the use of this material in regions characterized by constant high humidity is undesirable.

Pros and cons of sawdust insulation

Considering the issue of the relevance of sawdust as a heater, we note that the material slightly inferior in popularity other, modern types of insulation. To understand all the pros and cons, at the stage of choosing a suitable insulation, we will compare the main characteristics of sawdust with the widespread mineral wool. So, choose sawdust insulation if you are looking for organic, porous and natural product with high environmental friendliness, excellent thermal and sound insulation... According to the results of tests and reviews of real people, the insulation of a frame house with sawdust can withstand from 30 to 40 years of operation. The material is moderately flammable.

Mineral wool, in contrast to sawdust, is inorganic in nature (but includes organic components), fibrous, melts at 100 ° C, emits dust and cannot be recycled. To exploit mineral wool as a heater can be about 30 years old... In their reviews, fans of mineral wool insulation make arguments about rotting sawdust and the invasion of rodents into the space of the insulating layer. However, experienced builders say that insulating frame houses with sawdust, dried and processed using the correct technology, negates all biological factors of influence. Sawdust as insulation is one of the smartest and most beneficial ways to dispose of waste after working with wood.

Useful: Extension of the veranda to the house

Making sawdust concrete with your own hands

First of all, we need to decide what kind of wood will be used. The thing is that during the reaction of an alkaline medium, which is cement, with sawdust, sugars are formed, which prevent rapid hardening. In this case, pine and spruce grasp most quickly, and larch the longest.

To reduce the setting time, it is necessary to reduce the amount of water-soluble substances in the sawdust by keeping them in the sun for several months, or in water. The process can be accelerated by processing sawdust with a solution of water glass or calcium chloride. The latter is mainly used for coniferous sawdust, but the former is much more versatile and can be used with all types of wood.

This method is called mineralization, and allows the sawdust concrete to dry out in a day, which will allow the blocks to be stored. Well, after a week they can be used in construction work.

The proportions depend on the strength of the sawdust concrete. The higher the last material, the less water is added. You need to understand that the sawdust themselves absorb a lot of water, therefore, when adding the latter to the M5 and M10 brands, about 350 liters per cubic meter are required. In the case of the robust versions M15 and M25, consumption is reduced to 250 liters for the same volume. As for the other components, their consumption is usually as follows (sawdust, sand, cement, lime or clay):

- M5 - 4: 1: 1: 4

- M10 - 4: 4: 2: 3

- M15 - 4: 7: 3: 2

- M20 - 4: 10: 4: 1

The easiest way to prepare a solution is to mix all the ingredients, after which water is gradually added using a watering can with parallel mixing using the same shovel. According to one of the alternative technologies, the concrete mix is first mixed with sawdust, and then the remaining components and, if necessary, water are added. If you do not want to do everything by hand, then a mixer can be purchased, but its cost exceeds 40 thousand rubles.

Important! You can check the readiness of the mixture by squeezing a fragment of it in your fist. When squeezed, water should not ooze from the solution, but the lump itself should not crumble when you open your hand.

The finished mixture is usually poured into pre-prepared formwork blocks. It is better to soak it inside with water, so that later it would be easier to remove. The food itself is eaten in four days.Well, the drying of the blocks should be carried out in a draft, while maintaining a small distance between the building elements. The sizes of the blocks, taking into account the fact that their manufacture is often practiced handicraft and for one's own needs, can be very different. However, usually the thickness is not less than 140 millimeters.

You can check the strength of frozen blocks by dropping them from a height of up to a meter. The structure of the material is such that no traces should remain on it.

Important! Previously, the use of lime was justified in terms of economy. However, now this material has begun to cost the same as concrete, so the practice of adding it to cement mortar is gradually becoming a thing of the past. Moreover, lime increases the hardening time.

Tips for building from sawdust concrete

- The thickness of the internal load-bearing walls should be 300 millimeters or more;

- The masonry technique when using sawdust concrete, in general, is similar to the much more popular foam blocks;

- If you are using commercially available blocks, then try to choose options with a strong cement grade and ideal geometric parameters. Also, try to pull the wood chips out of the block. If it is easy to do this, there were violations during production and such blocks cannot be used;

- Sawdust concrete can be laid both on glue for cellular materials and on cement-sand mortar. In the latter case, it becomes possible to correct irregularities;

- The decoration of the outside of the house can be carried out in the same way as with other buildings. Interior decoration can be started with plaster, which will lay down as securely as possible, taking into account the high adhesion of the material;

- In the case of construction from this material in a monolithic manner, pre-moistened formwork with a wall thickness of at least 35 millimeters is placed at a height of 50 to 100 centimeters. In this case, the layers of sawdust concrete are placed in it with a thickness of 15 centimeters, after which they are tamped. After 2-4 days, the formwork is removed. In this case, it is rearranged so that it overlaps the lower layer of concrete by about 20 centimeters;

- Construction of sawdust concrete is desirable to produce at a constant temperature of 20 degrees. It is better to do this at the beginning of summer, so that in autumn the building will gain the necessary strength.

Classification

1. Usage:

- intended for laying internal and external walls;

- partitions are used only for the construction of partitions.

2. Form:

- hollow - have through holes that are formed during the manufacturing process (this is done in order to give the block the necessary performance characteristics);

- full-bodied - partition or wall parts that do not have internal voids.

3. Dimensions:

- in accordance with the above-mentioned GOST, bricks for laying walls can be of the following sizes: 288x138x138 mm, 288x288x138 mm, 290x190x188 mm, 390x190x188 mm, 90x190x188 mm and 190x190x188 mm;

- dimensions of partition parts: 390x90x188 mm, 590x90x188 mm and 190x90x188 mm.

It is also possible to manufacture blocks of other required sizes

We suggest that you familiarize yourself with: Why stone wool is harmful