It is not as easy to acquire equipment for heating communications as it seems at first glance. You need to understand which electric boilers are better. This is necessary in order not to get into a mess, but to acquire the most suitable model according to living conditions and established requirements. Which electric boiler to choose depends on a number of factors, which will be discussed further.

Types of non-volatile boilers

Single-circuit and double-circuit

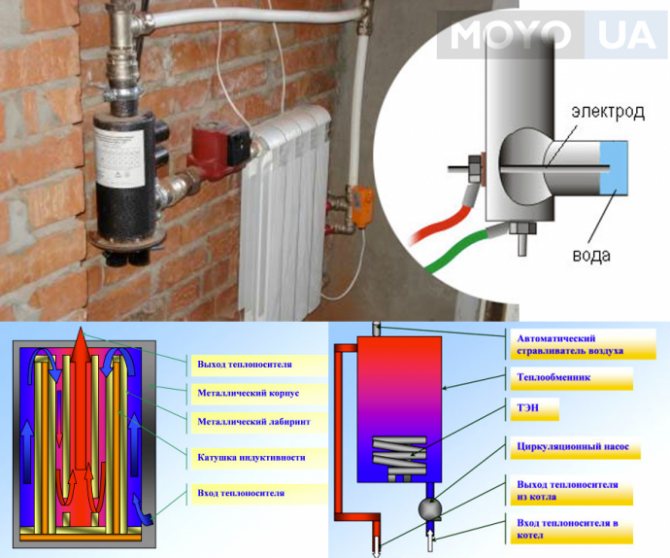

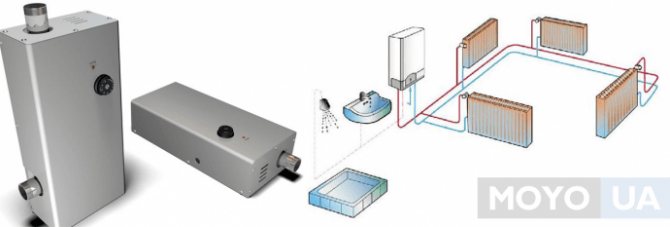

Passing through the heating element, the water temperature rises. This is how it works single-circuit boiler (circuit - the trajectory along which the water moves). Double-circuit boiler works on a similar principle, except that the heated water passes through a system of sensors that measure the temperature and send information to the control panel.

If the temperature exceeds the norm, the gas pressure is reduced to balance it. If the temperature readings turn out to be critical, the system will turn off the boiler for a whileto avoid overheating, then turn it on again.

Floor and wall

Certain systems are too heavy or too bulky to fit on walls, so install them can only be on the floor.

Another reason - a portable pump that can vibrate, thereby weakening the point of contact with the wall. As a rule, only large boilers for large-scale enterprises and warehouses.

Installation, maintenance and heating costs

Before buying, a significant role is given to the cost of installation, maintenance and heating. The issue of reducing heating costs is an important part of arranging such a system in a house or apartment. The cost depends directly on a number of factors:

- type of boiler;

- the need to draw up a project and install networks both inside and outside;

- installation prices with connection to hot water supply;

- installation and connection of equipment and other devices for the operation of communication;

- the cost of additional elements;

- assemblies of wiring and equipment for indoor heating.

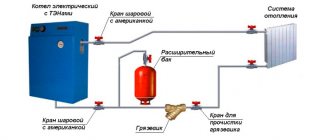

For example, if the Tenko mini KEM 3_220 electric boiler, when it generates heat in the amount of 3000 W per hour, consumes about 3090 W / h of energy. To calculate the amount spent on maintenance and heating, the indicator is multiplied by the cost of resources. The amount for the year is calculated in the same way. The dimensions of the room are also taken into account. If the house or apartment is insulated, then maintenance and heating costs are reduced.

see also "TOP-6 wood-fired boilers for a private house up to 200 sq. M."

How to choose the right model?

- First you need to decide on purpose of purchase... If the boiler is purchased for personal home use, then you should not buy expensive large devices. For heating an apartment or a small private house, a medium-price product is suitable, with a power of 10-15 kW.

- Then it is necessary estimate the budget, which will include purchase, delivery, installation. The last point often does not take part in the calculations, but in vain, because when purchasing an expensive boiler, you need to connect it correctly, otherwise a breakdown is inevitable.

- pay attention to reviews on the internetto find out how easy the chosen boiler is to operate and how difficult it is to find spare parts.

- Consult contact your equipment supplier for this matter. Almost all modern firms offer services of departure of the master to the installation site. The specialist will assess the area and furnishings and offer several options for the buyer.

How to set the required power

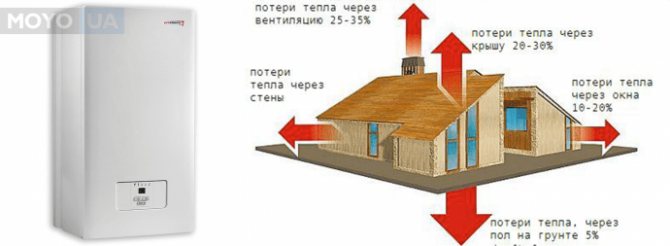

Before purchasing a model, you need to check how well the room retains heat. For this, the temperature is measured near the floor and ceiling of each room. If the values differ by 5 degrees, insulation of walls and windows is initially required. If everything is ok, then a power calculation is required. As a rule, one square meter accounts for 0.08-0.1 kW. This value is approximate, you still need to leave a margin, given:

- climatic features of the region;

- the level of efficiency of heating communication;

- own preferences for cold and warmth.

Thermal power table required for different rooms

| Thermal power kW | The area of the premises in the new building m2 | Premises area in the old building m2 | Greenhouse area made of insulated glass with double foil m2 | Greenhouse area made of ordinary glass with foil m2 |

| 5 | 70-150 | 60-110 | 35 | 18 |

| 10 | 150-300 | 130-220 | 70 | 37 |

| 20 | 320-600 | 240-440 | 140 | 74 |

| 30 | 650-1000 | 460-650 | 210 | 110 |

| 40 | 1050-1300 | 650-890 | 300 | 150 |

| 50 | 1350-1600 | 900-1100 | 370 | 180 |

| 60 | 1650-2000 | 1150-1350 | 440 | 220 |

| 75 | 2100-2500 | 1400-1650 | 550 | 280 |

| 100 | 2600-3300 | 1700-2200 | 740 | 370 |

| 125 | 3400-4100 | 2300-2700 | 920 | 460 |

| 150 | 4200-5000 | 2800-3300 | 1100 | 550 |

| 200 | 5000-6500 | 3400-4400 | 1480 | 740 |

The capacity of the installation must compensate for the losses of all premises and, if necessary, provide hot water supply. The result obtained will help you choose the most suitable model. In calculations, the role of windows and doors, the quality of the structure of the house, area, panoramic glazing, thermal conductivity of the structure play a role. A special formula is suitable for this. To establish the capacity, the area of the structure is multiplied by the specific capacity of the model, expressed in kilowatts, by 10 square meters, which is set for each area. In other words, it turns out W = S x Wsp / 10 m2.

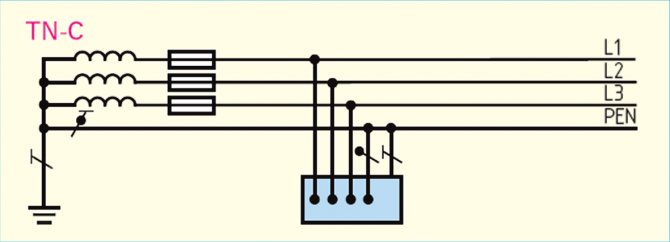

You also need to pay attention to the type of connection. Installations are divided into single-phase, which operate from a 220 V network and three-phase, powered by 380 V.

We recommend that you familiarize yourself "How to choose an electric convector for home and summer cottages."

Boiler operation

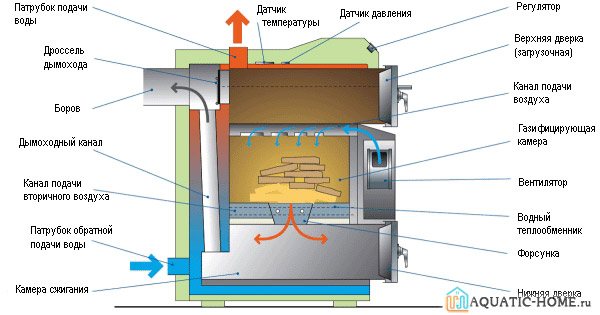

In general, a solid fuel boiler is a compact metal stove equipped with a combustion chamber, a heat exchanger, a smoke evacuation system and a door for regulating the air supply. The built-in electric heating element is located below the grate and is connected if necessary.

During the combustion of fuel, when the temperature of the water in the heat exchanger drops, the heating element heats it up until the solid fuel ignites again. This mode reduces the load on the heating circuits and maintains constant circulation in open systems. Combustion of solid fuel is a process that does not lend itself to precise control and cannot be automatically stopped, therefore, the operation of such equipment should be stopped at night. The use of electric heating elements allows you to extinguish the boilers at night, while maintaining the set temperature. Electric heating is not used as the main source of heat, since it is not profitable in combined-type boilers; for these purposes, there are other types of equipment.

Wood and electricity boiler with semi-automatic regulation

Principles of water circulation

The boiler for heating with wood and electricity heats the water in the system at the moment it passes through the heat exchanger. Heating takes place in three ways:

- water circulates through pipes inside the boiler;

- water circulates through the "water jacket" - washes the boiler outside;

- combined systems using external and internal heat exchange.

When choosing a boiler, preference should be given to those models in which there is the largest number of internal pipes, the efficiency of such boilers is always higher. An important parameter is that the diameter of the inlet of the return pipe must be greater than or equal to the outlet pipe; this configuration also increases the circulation efficiency.

Classic tube heat exchanger

Smoke evacuation

The removal of combustion products from a solid fuel boiler with electric heating elements should be carried out according to general rules using a metal chimney pipe. The efficiency of the draft is not affected by which output is present on the boiler - back or top. More expensive models have a special device that equalizes the rate of gas removal. It is a set of special dampers that the smoke bends around when moving upward, while the heat remains inside the boiler and its efficiency increases.

Standard chimney

Extra options

Important nuances to be aware of:

- boilers must be used for their intended purpose, that is, coal must not be used in appliances intended for burning wood;

- it is better to mount the gate at the chimney, although it is rarely used in combined boilers;

- the combustion regulator is not the most significant detail, as well as complex automation systems, since the adjustment task can easily be handled independently with the help of the blower door;

- a water temperature sensor with a thermometer brought out to the body must be mandatory, otherwise you can miss the moment of boiling and allow an accident.

How it works?

The standard Peltier element is a plate with two outlets for connecting to the network, assembled from cubes of different metals, such as copper and constantan, copper and nickel, lead and constantan, etc.

The plate passes an electric current through itself, and on the one hand it heats up, and on the other it becomes cold.

In the presented electric generator, the opposite principle is applied: one side of the element is heated by burning fuel (in this case, wood chips and wood), the other is cooled by any heat exchanger - liquid or air, and a constant electric current is generated on the wires, which can already be used at will.

It is not necessary to expect high power indicators, even in factory furnace-generators (they, as a rule, have two elements), up to 60 watts are generated. Self-made ones usually give out 5 watts (enough to charge a cell phone or connect a flashlight with LEDs).

The electric current in such a furnace is only a by-product, the main energy from the combustion of firewood is not wasted, but serves to heat the room (enough for a small house, summer cottage or tent).

Boiler construction without electricity

The gas boiler, independent of electricity, has:

- 2 gas burners - pilot and main;

- Combustion chamber - in such devices it is open for better traction;

- Automation;

- Boiler safety system - thermal sensor, backdraft valve (it is needed to adjust the chimney operation);

- Heat exchanger.

The system of a non-volatile gas boiler must have an open expansion tank, since when the coolant heats up, the liquid expands. And this is what promotes the circulation of the coolant. But when it expands, surpluses are formed, which enter this tank.

Ignition in such gas boilers occurs using a piezoelectric element, which acts when a button is pressed. With its help, the pilot burner is ignited, and already from it the main gas burner is ignited, thanks to which the heat exchanger is heated and the required temperature of the liquid is maintained.

After a while, gas does not flow and the burner goes out, after the heat exchanger has cooled down, everything is repeated.

Do-it-yourself electric generator on wood

Do-it-yourself wood-fired generator. For those who like to while away the evening with their hands - the very thing!

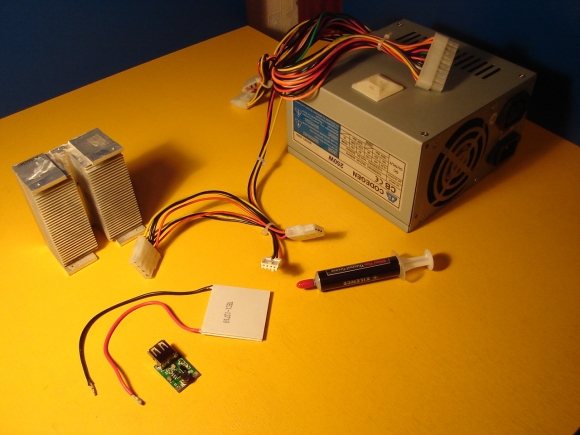

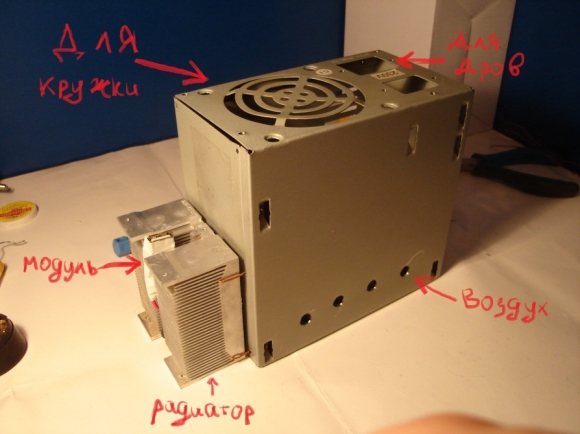

Advantages of this generator: - Fuel - everything that burns or heats. - USB output 5 Volts, 500mA. - Does not depend on the sun, wind, etc. - Simple and sturdy construction that can last forever. - You can cook food on it while your phone is charging. - Versatility. - Anyone can collect at home in 1 evening (even an employee of AvtoVAZ =)). - The cheapness of the design.It was not me who invented, there are commercial copies that are much better than mine. For example, BioLite CampStove, its price is 7900 rubles. My copy was whipped up for this article and further experiments. The basis is the Peltier element. This is a thermoelectric module used in water coolers and portable refrigerators, and is also used to cool the processor. When voltage is applied to it, one side cools and the other heats up. On the contrary, we will heat one side to get electricity. The main principle is that one side is heated, and the other remains unchanged, for maximum efficiency, a temperature difference of 100 degrees Celsius is needed.

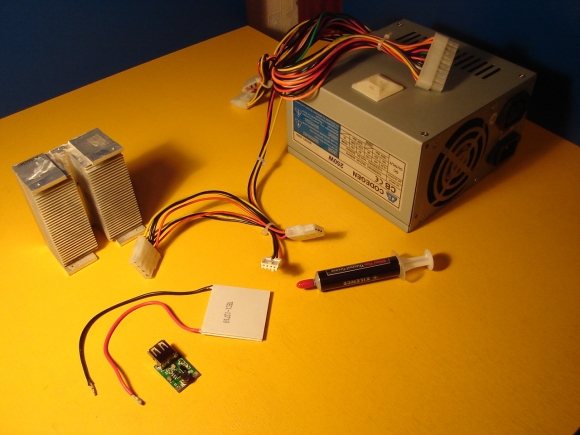

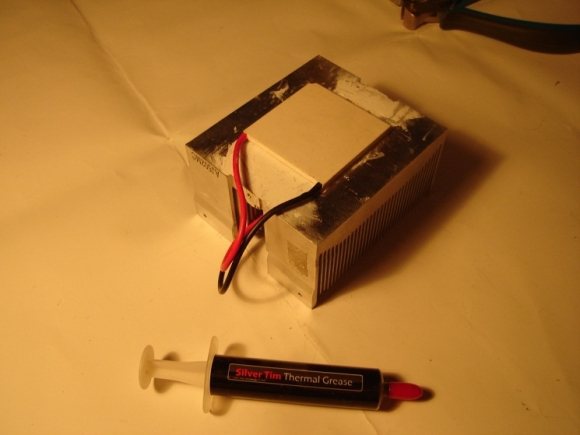

We need: - Peltier element I used TEC1-12710, its characteristics:

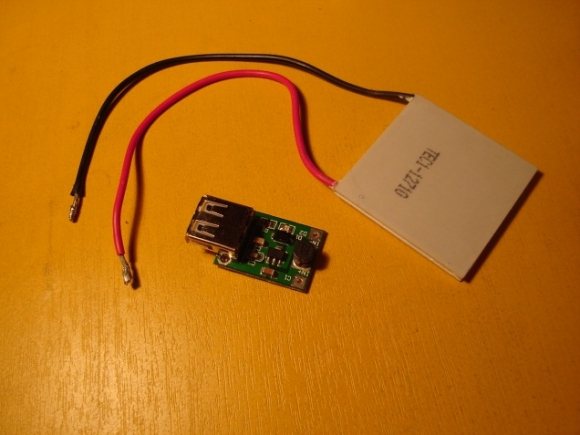

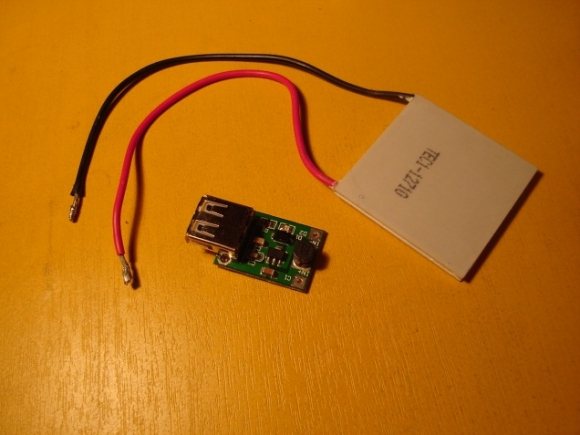

- An unnecessary power supply from a computer Any, even one that burned out, and everything except the case burned out - Voltage stabilizer DC-DC Boost Module, Input voltage 1-5 Volts, the output is always 5V. - Heatsink (the more the better), preferably with a 5V cooler, since the radiator will gradually heat up. In winter, this does not threaten, since you can put the radiator on ice. - Thermal grease - Toolbox The main elements are the Peltier module and the transducer. You can experiment with their characteristics. TEC1-12710 module, rated for 10 A (there is less, there is more). But the more powerful ones will be larger. The higher the amperage, the more efficient and expensive it is. I bought on Dx.com for about 250 rubles. In our electronics stores, this costs about 1,500 rubles. The module is designed for a maximum voltage of 12V, but it does not produce so much because of its low efficiency when we use it in the opposite direction, i.e. to receive current.

In order for the 5 volts to be stable and the devices to be charged safely, a boost stabilizer is needed. It starts to give out 5 Volts when there is only 1 on the Peltier element. You can find out that everything is ready for charging by the lit LED on the module. You can assemble your own, but I decided to trust the Chinese, they offer a ready-made module with USB output, for 80 rubles. on the same site.

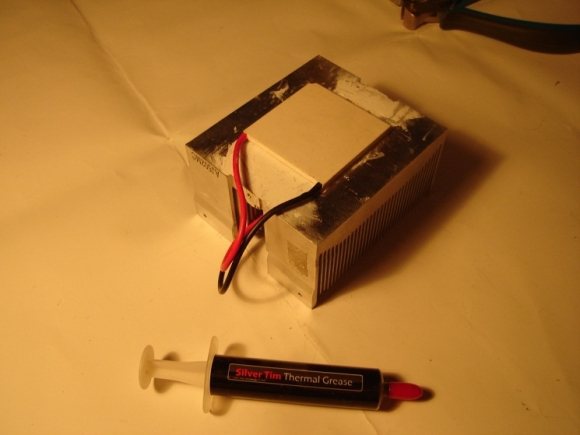

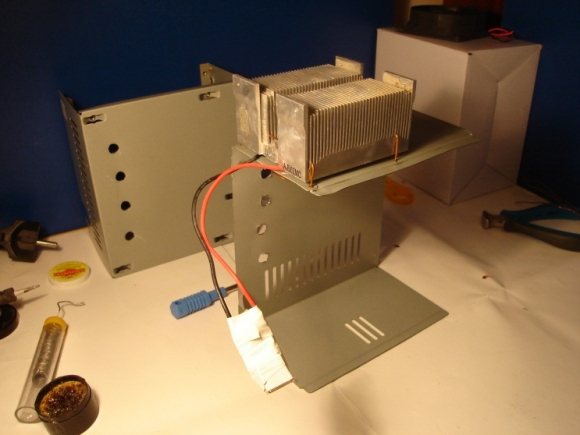

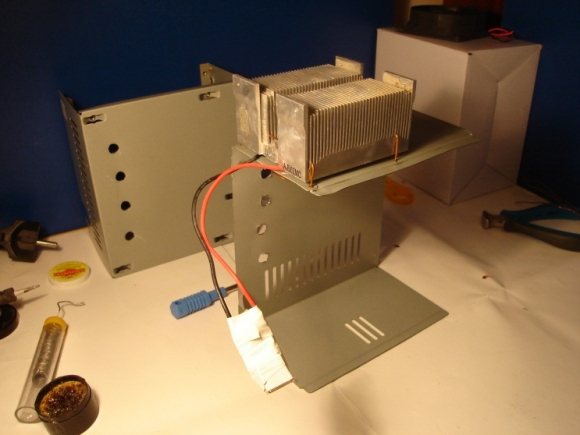

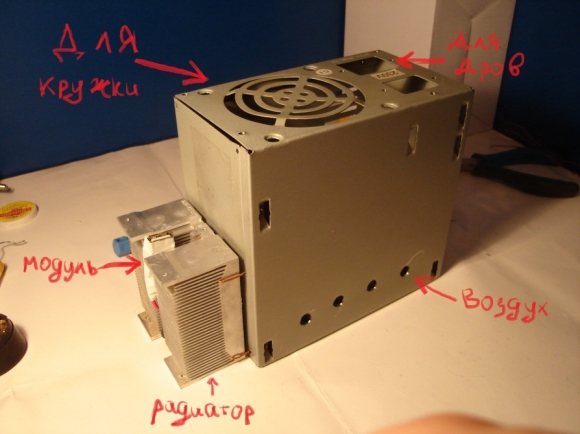

Let's gut our power supply. I had to make additional holes for better air circulation (the power supply was very old). The main principle is that the air is sucked in from below, and it exits through the top. Simply put, you need to make an ordinary stove. Be sure to include an opening for slipping in chips and a pot or mug for boiling water if you need to. Next, you need to attach the Peltier module with a radiator to a flat wall, after applying thermal paste evenly. The tighter the contact, the better. The side where the model is written is cold, it is to it that we apply the radiator. If you are confused, the module will not output voltage, in this case you just need to swap the wires.

We solder the boost converter and find where to hide it. You can even leave it hanging on the wires, but you definitely need to insulate it, for example, put heat shrink on it.

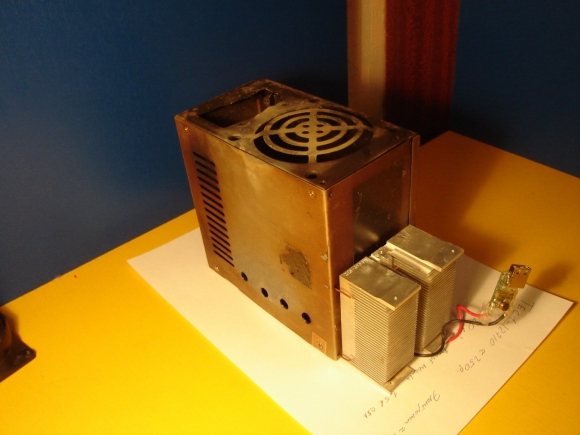

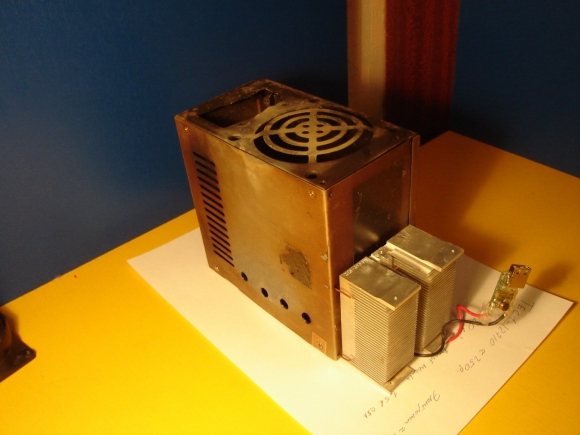

Putting it all together. Here's what you should get:

How it works? We throw branches inside, chips, in general, everything that burns. Then we kindle. The fire heats the walls of the stove and the Peltier element, which is on one of these walls. The other side of the element, which is on the radiator, remains at the outside temperature. The greater the temperature difference, the more power, but don't overdo it. The maximum efficiency is achieved already at a difference of 100 degrees. Over time, the radiator begins to heat up and needs to be cooled. You can throw snow, sprinkle with water, put a radiator on ice or in water, put a mug of cold water on it. There are many options, the simplest is a cooler, it will take some of the power, but due to cooling, the overall result will not change.

DO NOT expose the element to high temperatures, it may burn out and burn. The documentation indicates a maximum temperature of 180 ° C, but you don't really need to worry, with good cooling and nothing will happen to it on simple firewood. If you are not lazy and do everything right, you will get just such a simple woodchip on which you can heat food, boil, water and at the same time charge your gadgets. It can be used at home if the electricity is turned off by putting a candle inside. By the way, if you connect LEDs to it, the light will be much brighter than from the candle itself. Wherever you can find something burning, you will have electricity, heat and the ability to conveniently cook food, using less fuel than a fire.

First tests!

After work I went to the forest, the sun almost went down, the brushwood was wet, but the stove paid off 100%.

The result exceeded all my expectations. Immediately after the chips burned up, the indicator came on, I plugged in the phone and it began to charge. Charging was stable. The converter did not strain at all. I also took a laptop cooling pad with me, it has 2 coolers and LEDs, it should consume decently. Connected, everything is spinning, glows, the breeze is blowing. I also took a USB fan, connected it at the end, when there were only coals left. Everything is spinning great, I don't even know what else to try. Result: Everything works great and gives out its Ampere floor. All the same, you need a cooler. in half an hour, the radiator warmed up about 40 degrees, in summer it will be even more. Let it spin for yourself. The tongues of flame are bursting high upward, I personally do not need such a fire, I will close some of the holes so that it burns more slowly. I will do everything in a new way, I will take as a basis a standard splinter that is made from cans, but I will make it out of metal thicker and rectangular. I will buy a good heatsink with a cooler of a suitable shape and will try to make a collapsible version so that it takes up less space when carrying it.

What else to read on the topic:

- PLC and Amateur Service

- Checking the integrity of files using the MD5 checksum

- Why do LEDs burn out?

- List of countries that have imposed sanctions against Russia

- Investigative film or why there is still no passage)))

- Simple RF current meter

- Letter beacons

- Morse code is for everyone!

- DX cluster, good or bad?

- Features of electronic intelligence

- Is Wi-Fi harmful?

Heating options

The maximum discomfort during the operation of the building is caused by the lack of gas and electricity. Therefore, the owner needs not only heating a private house without gas and electricity, but also the generation of 2-10 kW of electricity for household needs. There are not so many power supply options:

- generator - usually diesel with the maximum possible resource;

- thermoelectric generator - generates current from thermal energy, the leading manufacturer is Cryotherm.

Diesel generator

There are much more ways to implement heating a building, from a classic wood-burning stove for air heating to alternative sources (heat pump, solar panels). But for the high efficiency of alternative heating systems, for the operation of pumps and compressors in their composition, electricity is also needed.

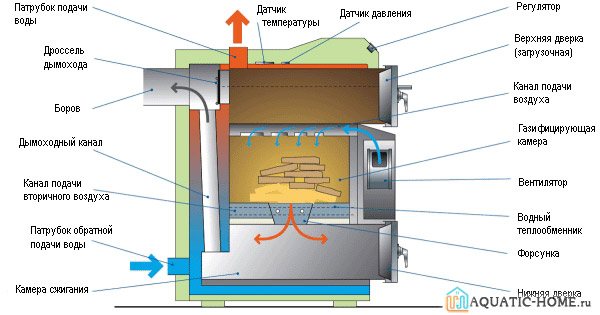

Solid fuel boiler

Heating a private house without gas and electricity can be organized with solid fuel boilers. The most comfortable operation is provided by modifications of long burning with natural draft:

- loading into them is carried out from below, the afterburner is located at the top;

- after warming up the lower furnace to 200 degrees, a mechanical damper closes the access of air to the combustion chamber;

- inside it, pyrolysis (release of combustible gases) from embers begins;

- gas enters the upper chamber, burns to release energy;

- in the jackets or pipes running inside the boiler, the coolant is heated;

- passes through the registers, giving off heat, is supplied for the next cycle.

The device of a solid fuel DG boiler

In pyrolysis boilers with top loading, fans are used, in bunker boilers, the rotation of the worm gear is necessary for regular feeding of pellets into the combustion chamber. Therefore, this equipment can only be operated with a generator.

Using liquid fuels

Another way to implement heating is to heat a private house without gas and electricity with oil boilers. The cheapest energy carrier is diesel fuel, however, diesel boilers have a significant drawback - the fuel must be stored in compliance with the fire safety of the home, a characteristic, non-fading smell is formed during combustion.

Diesel generator

Air heating is realized by stoves or fireplaces. The classic ovens are:

- Russian - heating + cooking;

- "Dutch" - mounted in the opening, heats several adjacent rooms;

- universal - cooking on removable hob rings + room heating.

Air heating with ovens

They are made of bricks, steel, equipped with chimneys, ensuring the safety of the nodes of passage through the ceilings, the roof. The ovens are easily integrated with devices for generating electricity from heat from the Cryotherm company. In addition, the manufacturer produces bath stoves that allow you to illuminate the room until the walls of the heater cool down.

Bio fireplace for room heating

Helpful information! The safest is a biofireplace, which does not require a chimney. By adjusting it is possible to achieve a minimum operating budget; during combustion, no harmful products, soot, soot are formed.

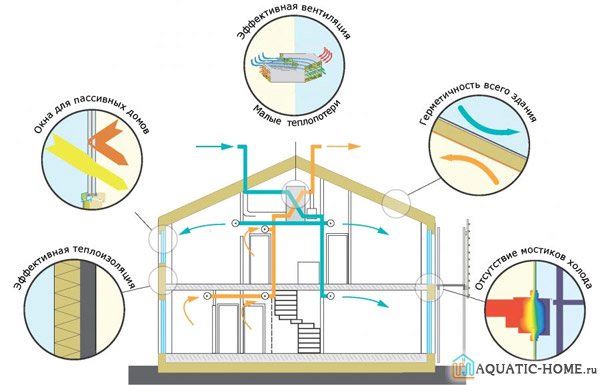

Passive house

Heating of a private house without gas and electricity can be organized by "passive house" systems. In this case, modern thermal insulation materials are used to reduce energy consumption by up to 7-10%.

Passive house system

In other words, such a dwelling should have enough heat energy released by the family in the process of life. The building has compact dimensions, external insulation contour, thermal insulation layer under the foundation and blind area. It is mandatory to take into account:

- cardinal points - living rooms from the south, functional rooms protect them from the north;

- wind rose - heat loss is extinguished by verandas, kitchens on the windward side of the site;

- layout - must ensure high-quality air exchange with recuperators.

Related article:

Thermal conductivity table of building materials. Have you thought about how well your house is insulated? Or maybe you are just starting to build a dwelling? In any case, you need to familiarize yourself with the concept of "thermal conductivity".

In addition to these measures, alternative energy sources (heat + electric) are used:

- solar water heater;

Solar Water Heater

Related article:

Solar panels for the home: the cost of the kit. Until recently, solar panels seemed like something futuristic. However, they are already available to everyone. Don't believe me? Read our detailed post.

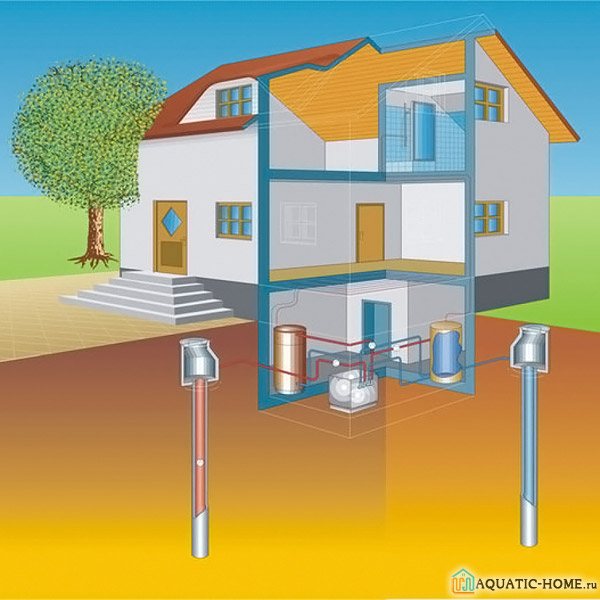

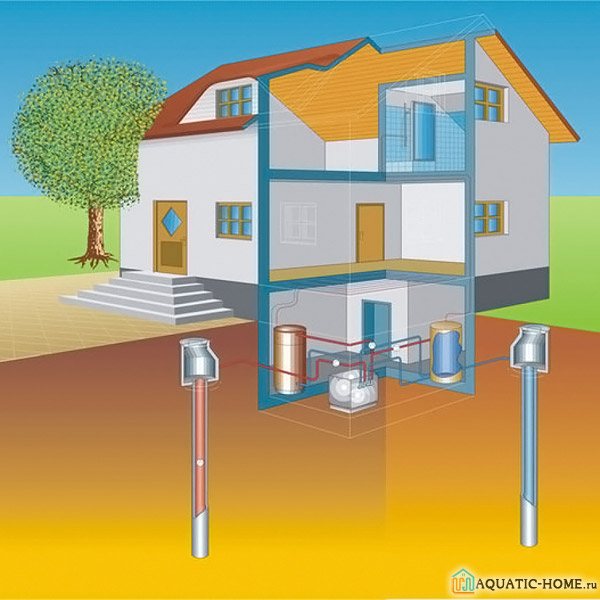

- geothermal heat pump.

Geothermal pump

Related article:

Heat pump for home heating: prices. This type of heating is gaining popularity every year. Let's calculate how much such a system will cost and how profitable it is.

There are “active home” systems, which, in addition to reducing heat loss, are capable of generating additional heat accumulated by the central home network. The main disadvantage is the high budget for the installation of such equipment and the long payback period.

Helpful information! When choosing a "passive house" ventilation is forced. Airtight double-glazed windows are installed instead of window supply valves.Ventilation is carried out only by recuperators.

Advantages and disadvantages

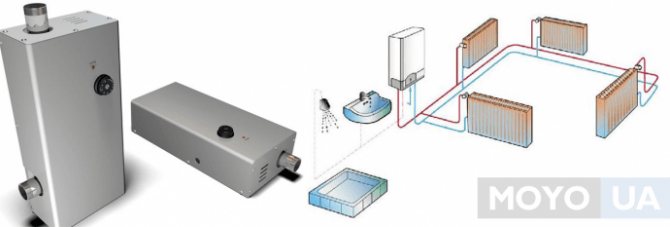

A gas-electric boiler requires a three-phase network

Electric gas heating boilers, like other devices, have their pros and cons.

Important advantages of units for 2 types of fuel are:

- high efficiency (reaches 97%);

- compact size;

- uncomplicated maintenance and repair of equipment;

- significant savings in funds required to pay for resources;

- easy control;

- no waste from fuel combustion.

The gas-electric boiler also has disadvantages:

- high price in comparison with devices for 1 type of fuel;

- a three-phase network is required.

After a few years, the cost of an economical boiler pays off, since funds are taken care of to pay for the use of resources. The versatility of the unit greatly facilitates everyday problems.

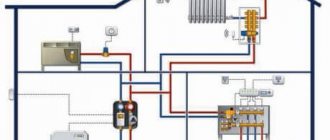

The gas electric boiler has an important distinctive feature: the presence of several outputs, allowing the device to be used as a multi-circuit one. Such a boiler heats radiators, heats the sauna room, heats the pool and water for household needs. The "warm floor" design can also be heated by such a unit. Summer residents use one outlet to heat greenhouses.

Selecting an independent boiler model

Gas boilers operating without electricity must fully correspond to the area of the heated room. That is, the power must match the load.

Double-circuit models of foreign manufacturing companies are often more expensive than domestic ones, since they are more advanced and have an attractive design. The manufacturer of a gas boiler must be chosen carefully, it is important to make sure that the service center of this company is in the city or nearby. Since, if necessary, it will be possible to find spare parts for repairing the device there.

The most popular manufacturers of such equipment are Alphatherm, Beretta - Italy, Attack - Slovakia, Protherm - Czech Republic, Electrolux - Sweden.

Fig. 2 Boiler without electricity from Protherm

Domestic models of independent boilers are cheaper than foreign ones, but are considered less reliable. But it should be given credit that such devices are already adapted to our weather conditions and the parameters under which they must work.

A gas boiler without electricity can be chosen with a steel or cast iron heat exchanger. The most popular are cast iron devices. This is explained by the service life: cast iron will last 30 years, and steel 15-20 years.

Cast iron is not only stronger, but also the design provides that the walls of such a heat exchanger are thicker. This prevents the walls of the heat exchanger from burning out. Such a device has been tested in practice.

Also, the heat exchanger can corrode. A cast iron appliance is much less susceptible to such damage than steel. Corrosion on the heat exchanger occurs when the temperature drops to the point where condensation appears. And this very moisture leads to corrosive processes.

Also, the cast-iron heat exchanger, by its design, consists of sections. If necessary, you can change the section, and not the entire device. Nowadays, impurities are added to the cast iron alloy, which make it even stronger. This means that it will not crack if transported incorrectly.