The independent manufacture of a heat accumulator is within the power of every person who has the skills to work with basic locksmith and household tools. To assemble such a unit, you do not have to buy any expensive parts and materials. Components for the simplest model can be found in the garage or pantry of any thrifty and economic person.

Heat accumulator

After studying the following manual, you will be able to make your own heat accumulator and connect it to the heating system.

What is a heat storage device?

The heat accumulator is a buffer tank designed to accumulate excess heat generated during the operation of the boiler. The saved resource is then used in the heating system in the period between the planned loads of the main fuel resource.

Connecting a properly selected battery allows you to reduce the cost of purchasing fuel (in some cases up to 50%) and makes it possible to switch to the mode of one load per day instead of two.

In addition to the function of accumulating the released heat, the buffer tank protects cast-iron units from cracking in the event of an unexpected and sharp drop in the temperature of the working network water

If the equipment is equipped with intelligent regulators and temperature sensors, and the supply of heat from the storage tank to the heating system is automated, heat transfer will increase significantly, and the number of portions of fuel loaded into the combustion chamber of the heating unit will noticeably decrease.

The principle of operation of the treatment plant

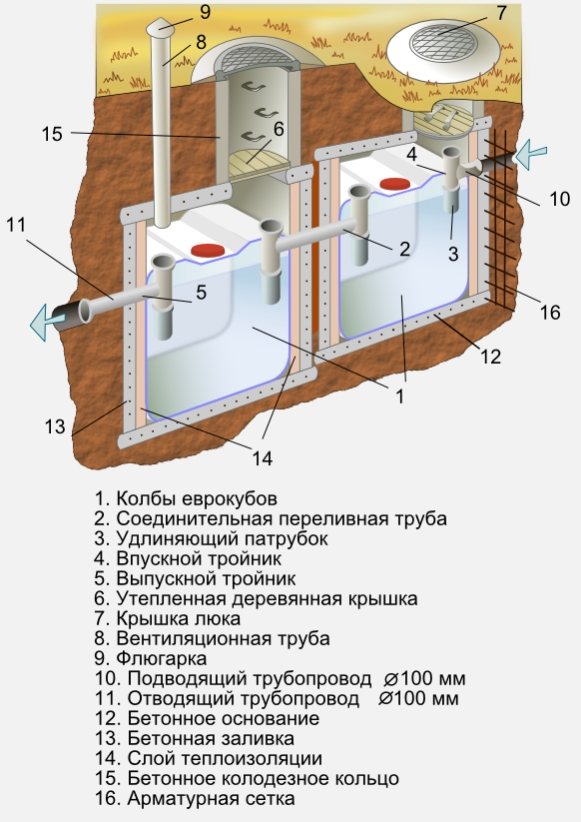

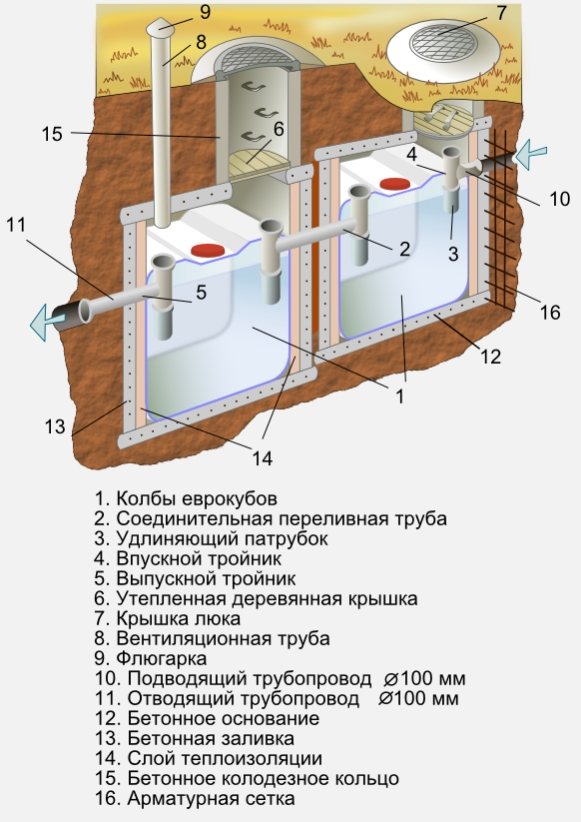

If a septic tank is installed from eurocubes, the scheme most often provides for the presence of two tanks connected in series. In order to fully utilize the volume of the second tank, it is usually placed just below the first. Slowly flowing from one Eurocube to another, wastewater gets rid of large fractions that settle to the bottom.

The photo shows a diagram of how to make a septic tank from eurocubes from two containers

The design of a septic tank from a eurocube implies that treatment facilities of this type are non-volatile. They do not require an air supply, which means there is no need to install a compressor. Septic tanks do not require operating costs. Settled sludge and hard-to-decompose impurities are broken down by anaerobic (air-free) microorganisms. It is necessary to add bioactivators to home-made septic tanks from eurocubes without pumping out at the initial stage of operation to speed up the cleaning processes.

In this case, there is no need to pump out the septic tank wastewater: clarified wastewater enters the filtration field, where it undergoes additional cleaning, and the accumulated sludge can be removed without the use of special equipment, for which it is recommended to provide a special closable hole. The frequency of removing sludge from the septic tank is about once every one to two years, in the autumn.

If, having made a septic tank for a summer residence from eurocubes with your own hands, you do not want to pump it yourself, there is always the opportunity to call specialists with equipment for this.

The required volume of the septic tank is determined as follows:

200 liters of water per person per day is multiplied by the number of family members, and all this is still multiplied by 3. For example, a septic tank with a volume of 1800 liters, that is, 1.8 cubic meters, will be enough for three people.

Features of the internal and external device

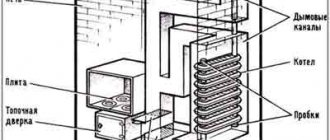

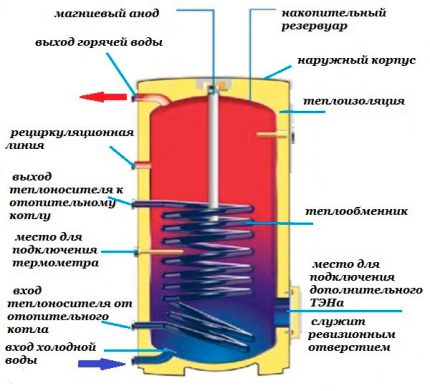

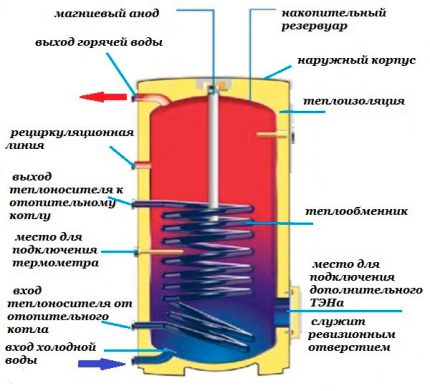

The heat accumulator is a vertical cylinder-shaped reservoir made of high strength black or stainless steel sheet.

There is a layer of bakelite varnish on the inner surface of the device. It protects the buffer tank from the aggressive influence of industrial hot water, weak solutions of salts and concentrated acids. Powder paint is applied to the outside of the unit, which is resistant to high thermal loads.

The volume of the tank varies from 100 to several thousand liters. The most spacious models have large linear dimensions that make it difficult to place equipment in the limited space of a home boiler room

External insulation is made of recycled polyurethane foam. The thickness of the protective layer is about 10 cm. The material has a specific complex weaving and an internal PVC coating.

This configuration prevents dirt particles and debris from accumulating between the fibers, provides a high level of waterproofing and increases the overall durability of the thermal insulator.

The heat insulator is not always included with the heat accumulator. Sometimes you have to buy it separately, and then independently mount it on the unit

The surface of the protective layer is covered with a good quality leatherette cover. Due to these conditions, the water in the buffer tank cools down much more slowly, and the level of total heat loss of the entire system is significantly reduced.

The principle of operation of a heat-saving product

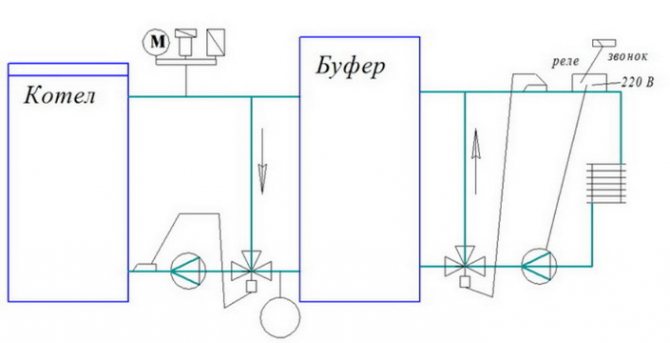

The heat accumulator functions according to the simplest scheme. From above, a pipe from a gas, solid fuel or electric boiler is supplied to the unit.

Hot water enters the storage tank through it. Cooling down in the process, it goes down to the location of the circular pump and with its help is fed back into the main passage in order to return to the boiler for the next heating.

The installation of a heat accumulator prevents overheating of the coolant at the moment when the boiler is operating at full capacity and ensures maximum heat transfer while saving fuel. This reduces the load on the heating system and extends its service life.

A boiler of any type, regardless of the type of fuel resource, operates in stages, periodically switching on and off when the optimum temperature of the heating element is reached.

When the work stops, the coolant enters the reservoir, and in the system it is replaced by a hot liquid that has not been cooled due to the presence of a heat accumulator. As a result, even after turning off the boiler and switching it to passive mode until the next fuel loading, the batteries remain hot for some time, and warm water comes from the tap.

Features of thermal energy storage devices

The heat accumulator for heating boilers is represented by an expansomat tank (what is it) of sufficient volume with an internal system of built-in heat exchangers, which contributes to:

- safety of excess heat accumulationgenerated by the heating boiler into the coolant flow;

- increase the duration of the heating cycle and cooling down the boiler plant, thereby simplifying the process of its maintenance;

- improving the efficiency of the heating boiler;

- an increase in the resource of any model of a heating boiler.

The design of the heat accumulator for the heating system is rather primitive, which makes it possible to manufacture it yourself.

In addition to solid fuel heating boilers, the storage device is widely used in the arrangement of modern electric heating boilers.

Varieties of heat storage models

All buffer tanks perform almost the same function, but have some design features.

Manufacturers produce storage units of three types:

- hollow (without internal heat exchangers);

- with one or two coilsensuring more efficient operation of equipment;

- with built-in boiler tanks small diameter, designed for the correct operation of an individual hot water supply complex for a private house.

The heat accumulator is connected to the heating boiler and the communication wiring of the home heating system through the threaded holes located in the outer casing of the unit.

How does a hollow unit work?

The device, which has neither a coil nor a built-in boiler inside, belongs to the simplest types of equipment and is cheaper than its more "sophisticated" counterparts.

It is connected to one or several (depending on the needs of the owners) power supply sources through central communications, and then through the 1 ½ branch pipes it is wired to the points of consumption.

It is planned to install an additional heating element operating on electrical energy. The unit provides high-quality heating of residential real estate, minimizes the risk of overheating of the coolant and makes the operation of the system completely safe for the consumer.

When a residential building already has a separate hot water supply system and the owners do not plan to use solar heat sources to heat the room, it is advisable to save money and install a hollow buffer tank, in which the entire usable area of the tank is given to the coolant, and is not occupied by coils

Heat storage unit with one or two coils

A heat accumulator equipped with one or two heat exchangers (coils) is a progressive version of equipment for a wide range of applications. The upper coil in the structure is responsible for the selection of thermal energy, and the lower one carries out intensive heating of the buffer tank itself.

A device equipped with heat exchangers has a higher price than a hollow unit, but the costs are justified here. The device significantly expands the functionality of the system and makes its work much more efficient

The presence of heat exchange units in the unit allows you to receive hot water for domestic needs around the clock, to heat the tank from the solar collector, to warm up the house paths and to use the useful heat as efficiently as possible for any other convenient purposes.

Internal boiler module

The heat accumulator with a built-in boiler is a progressive unit that not only accumulates the excess heat generated by the boiler, but also ensures the supply of hot water to the tap for domestic purposes.

The internal boiler tank is made of stainless alloy steel and equipped with a magnesium anode. It reduces the hardness of the water and prevents the formation of limescale on the walls.

The owners choose the appropriate volume of the buffer tank on their own, but experts say that there is no practical sense in buying a tank less than 150 liters.

The unit of this type is connected to various energy sources and works correctly with both open and closed systems. It controls the temperature level of the operating heat carrier and protects the heating complex from overheating of the boiler.

Optimizes fuel consumption and reduces the number and frequency of downloads. Compatible with all solar collectors and can function as a substitute for a hydraulic pointer.

Installing a septic tank

First, the site is marked according to the measurements of the eurocubes, and then the indentations are made, that is, they dig a hole, and trenches suitable for it to drain pipes.

If the groundwater is close, then a concrete screed is made at the bottom of the recess or a reinforced concrete slab is placed. The septic tank must be secured with ropes so that the containers do not float to the surface.

If the groundwater level is low, then a sand cushion is made at the bottom of the recess, carefully leveled, and tamped. Then the septic tank goes down into the prepared recess, and the sewer pipe is connected, and then the element leading to the drainage type field or the storage tank. A check valve is put on the outlet pipe.

When the container is installed, they begin to insulate the walls with foam, boards or corrugated board are placed around it, this will serve as protection against damage to the material.

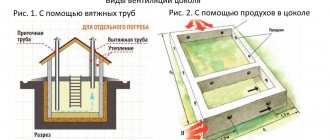

When the containers are filled with liquid, they must be backfilled. With a high location of groundwater, the depression is covered with cement and sand. If the groundwater level is low, then sand and ordinary earth are used, while each layer is compacted. The top of the recess is covered with boards or poured with concrete, and then sprinkled with earth. It should be borne in mind that ventilation pipes should be located above ground level from 50 centimeters.

Scope of heat accumulator

The heat accumulator collects and accumulates the energy generated by the heating system, and then helps to use it as efficiently as possible for efficient heating and providing residential premises with hot water.

It is necessary to purchase a device for accumulating excess heating resources only in specialized stores. The seller must provide the buyer with a product quality certificate and complete instructions for use.

It works with different types of equipment, but is most often used in conjunction with solar collectors, solid fuel and electric boilers.

Heat accumulator in the solar system

A solar collector is a modern type of equipment that allows you to use free solar energy for everyday household needs. But without a heat accumulator, the equipment is not capable of fully functioning, since solar energy is supplied unevenly. This is due to the change in time of day, weather conditions and seasonality.

A solar collector equipped with a heat accumulator is placed on the south side of the site. There, the device absorbs maximum energy and gives an effective output.

If the heating and water supply system is powered only from a single source of energy (the sun), at some moments the residents may have serious problems with the supply of the resource and getting the usual elements of comfort.

A heat accumulator will help to avoid these unpleasant moments and make the most rational use of clear, sunny days for energy storage. To work in the solar system, it uses the high heat capacity of water, 1 liter of which, cooling by only one degree, releases the thermal potential for heating 1 cubic meter of air by 4 degrees.

The solar collector and the heat accumulator form a single system that makes it possible to use solar energy as the only source for heating a residential building

During the period of peak solar activity, when the solar collector collects the maximum amount of light and the energy production significantly exceeds the consumption, the heat accumulator accumulates the surplus and supplies them to the heating system when the supply of the resource from the outside decreases or even stops, for example, at night.

The following article, which we advise you to read, will acquaint you with the options and schemes for alternative heating for suburban property.

Buffer tank for solid fuel boiler

Cyclicity is a characteristic feature of the operation of a solid fuel boiler. At the first stage, firewood is loaded into the firebox and warming up occurs for some time. The maximum power and the highest temperatures are observed at the peak of the bookmark burning.

Then the heat transfer gradually decreases, and when the wood finally burns out, the process of generating useful heating energy stops.All boilers operate according to this principle, including devices for long burning.

It is not possible to precisely tune the unit to generate heat energy with reference to the level of consumption required at any given moment. This function is only available in more advanced equipment, for example, in modern gas or electric heating boilers.

Therefore, immediately at the time of ignition and at the time of reaching the actual power, and then in the process of cooling and the forced passive state of the equipment, the thermal energy for full heating and heating of hot water may simply not be enough.

On the other hand, during the peak operation and active phase of fuel combustion, the amount of energy released will be excessive and most of it, literally, will “fly into the pipe”. As a result, the resource will be spent irrationally, and the owners will have to constantly load new portions of fuel into the boiler.

In order for the house to heat up for a long time after turning off the solid fuel boiler, you need to purchase a large buffer tank. It will not be possible to accumulate a solid amount of a resource in a small reservoir and its purchase will turn out to be a senseless waste of money

This problem is solved by installing a heat accumulator, which, at the moment of increased activity, will accumulate heat in the tank. Then, when the wood burns out and the boiler goes into a passive standby mode, the buffer will transfer the collected energy to the coolant, which will warm up and begin to circulate through the system, heating the room bypassing the cooled device.

Electrical system reservoir

Electric heating equipment is a rather expensive option, but it is sometimes installed, and, as a rule, in combination with a solid fuel boiler.

Usually, the electric type of heating is arranged where other sources of heat are not available for objective reasons. Of course, with this method of heating, electricity bills increase significantly and home comfort costs the owners a lot of money.

Install the buffer tank directly next to the boiler. The equipment has solid dimensions and in a private house you will have to allocate a special room for it. The system will fully pay off within 2-5 years

In order to reduce the cost of paying for electricity, it is advisable to use the equipment at the maximum during the preferential tariff period, that is, at night and on weekends.

But such an operating mode is possible only if there is a capacious buffer tank, where the energy generated during the grace period will accumulate, which can then be spent on heating and supplying hot water to living quarters.

What is useful for a septic tank from eurocubes

As mentioned above, a septic tank from eurocubes with your own hands without pumping can be made by yourself. As a result, the cost of construction will be lower than the work of specialists and purchased equipment. The water from the septic tank can be used a second time if the purification system is good. Such water is taken for technical purposes (shower, toilet flush, house cleaning). It is categorically impossible to drink such water.

The septic tank works cleanly, the stench does not appear. The insulated system can be used all year round. This is convenient if you come to the dacha in winter or live in a private house all the time. You can clean the system using a pump or a flusher. The procedure is so rare that you don't have to think about it.

Plastic does not corrode, does not overgrow with bacteria, withstands temperature changes. Waste chemicals and acids do not react with it. Actually, there will be no destruction of the system.

To install the system, you do not need heavy equipment and a team of workers. To create a septic tank, any type of land is suitable, the level of groundwater is unimportant. After all, the matter concerns only the drainage of liquid from the tank for cleaning.

DIY energy storage

The simplest model of a heat accumulator can be made with your own hands from a finished steel barrel. If one is not available, you will have to purchase several sheets of stainless steel with a thickness of at least 2 mm and weld from them a container of a suitable size in the form of a vertical cylindrical tank.

It is not recommended to use eurocube for the manufacture of a heat accumulator. It is designed for contact with a coolant with an operating temperature of up to + 70 ºС and simply cannot withstand hotter liquids

DIY Guide

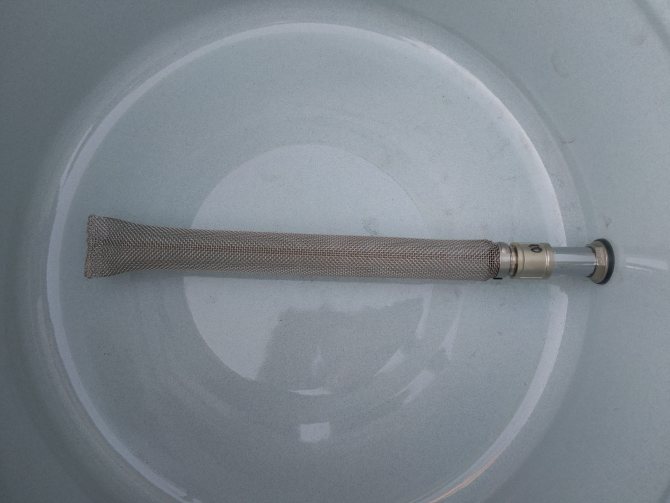

To heat water in the buffer, you need to take a copper tube with a diameter of 2-3 centimeters and a length of 8 to 15 m (depending on the size of the tank). It will have to be bent into a spiral and placed inside the tank.

The upper part of the barrel will act as a battery in such a model. From there you need to remove the branch pipe for the outlet of hot water, and make the same from below for the inlet of cold water. Equip each outlet with a valve to control the flow of liquid into the storage area.

In an open heating system, a rectangular steel tank can be used as a buffer tank. In a closed system, this is excluded due to possible surges in internal pressure.

At the next stage, it is necessary to check the container for leaks by filling it with water or lubricating the welded seams with kerosene. If there is no leakage, you can proceed to creating an insulating layer that will allow the liquid inside the tank to remain hot for as long as possible.

How to insulate a homemade unit?

To begin with, the outer surface of the container must be thoroughly cleaned and degreased, and then primed and painted with heat-resistant powder paint, thus protecting it from corrosion.

Then wrap the tank with glass wool insulation or rolled basalt wool 6-8 mm thick and secure it with cords or ordinary tape. If desired, cover the surface with sheet metal or "wrap" the tank in foil film.

Do not use extruded polystyrene foam or foam for insulation. With the onset of cold weather, mice can start in these materials, looking for a warm place for winter residence.

In the outer layer, cut holes for the branch pipes and connect the container to the boiler and heating system.

The buffer tank must be equipped with a thermometer, internal pressure sensors and an explosion valve. These elements allow you to control the potential overheating of the drum and relieve excess pressure from time to time.

How to make a heat accumulator for a solid fuel boiler from a barrel

First, you need to calculate the volume of the required capacity and make a drawing... In the drawing, you need to depict a standard barrel, which includes two pipelines. One of them transports the coolant from the boiler heat exchanger, and the second transfers hot water to the heating radiators. It remains only to calculate the dimensions of the barrel, or rather, its volume. Knowing the volume, it is easy to determine the diameter and height from the reference data.

If you need to calculate the volume of a container, knowing the height and one of the following parameters: radius, diameter or base area, then it is most convenient to use a calculator that calculates online. You can find it here: https://calcsoft.ru/obyom-cilindra

Let's start the calculation. Suppose our solid fuel heat generator is completely inactive at night for 4 hours (after cooling down), and the area of our small country house is 30 square meters. m. Consequently, the barrel should give about one tenth of the area per hour - 3 kW. Total, 12 kW per night. In this case, the temperature difference between the barrel and the heating will take a maximum of 40 degrees (for example, if the water in the tank is heated to 90, then in the radiators - at least up to 50).

According to the school physics course, m = Q / Ct, where

- Q - all thermal energy, we have 12 kW,

- C is the specific heat capacity of the agent, that is, water, equal to 0.0012 kW / kg x gr. Celsius,

- t is the temperature difference.

We get by this formula: m = 12 / 0.0012x40 = 250 kg. Thus, you can take the volume of water equal to 250 liters. It turns out that a metal barrel with a capacity of 250 liters is suitable for us as a heat accumulator for a solid fuel boiler under the given conditions. The approximate dimensions of such a barrel are 600x900 mm. That is, the diameter is 0.6 m, and the height (length) is 0.9 m.

What to take

For the manufacturing process of our heat accumulator, it is necessary to prepare the following materials and tools.

- An ordinary metal barrel, you can buy it in the store,

- welding machine with mask and electrodes,

- power tools such as "grinders" and grinding and cutting discs, drills and drills, metal crown.

- two standard steel pipes for heating, each with a threaded end, usually 3/4 inch,

- mineral wool.

It is better to start the procedure with the participation of an assistant. In addition, the drawing should already be ready.

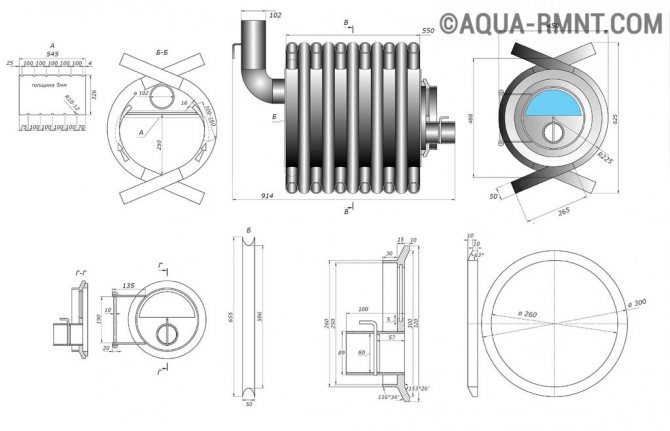

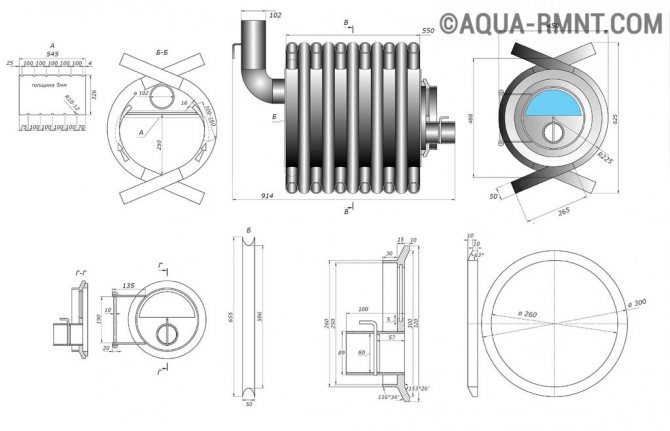

Heat storage drawing

DIY step-by-step making

- The barrel is thoroughly cleaned from the inside. This is necessary to exclude constant contamination of the coolant with rust and scale. Cleaning can be done with a grinder and grinding wheels.

Barrels stripped from the inside

- Next, you need to drill two holes - inlet and outlet, for the diameter of the supply pipes. To do this, first use a drill with a drill for metal, and then it is better to use a crown.

- Further, inside the holes obtained, the pipes for the inlet and outlet of the coolant, that is, heated water, are carefully welded. These nipples must be threaded at the ends that are not welded. Later, through this thread, ball valves will be screwed for insertion into the general heating system.

- After that, the top cover is welded very conscientiously. All welds must be tight to avoid leaks.

- Finally, the heat accumulator is insulated from the outside with mineral wool, for this, the barrel is wrapped in layers of mineral wool, after which these layers, wrapped around the barrel, are carefully tightened with rings made of metal fastening tape.

- It remains for us to mount the unit into the system by means of ball valves. The heat accumulator should be located immediately after the boiler, and in terms of level - above the radiators, so that the heat agent replenishes them well from our tank.

This is important to know! A plastic barrel cannot be used. It is not able to withstand the operating temperature of the heating agent, which reaches 90 degrees Celsius. The walls of such a barrel during operation in the system will simply begin to melt. An exception may be plastic containers, on which the manufacturer indicates the maximum temperature of the contents above 90 degrees. But in this case, you still need to decide how to attach the pipes.

A few more notes

So we made a simple heat accumulator for a small heating system. As a result, there are a few more important notes. For our example, the required volume of the barrel is 250 liters. However, when the house is large, a much larger drive may be needed. In this case, it would be better to weld a cube box. In addition, it is easier to insulate it with special materials.

Some craftsmen use for this option a standard, so-called European, cube with a volume of 1000 liters. It is sold in many stores. But here you need to remember that it is plastic. As a rule, the maximum water temperature that the Eurocube can withstand is 70 degrees Celsius, unless otherwise indicated in the marking. So it is simply dangerous to use this container in the heating system.

And more about the insulation. Polyfoam is ideal for a cubic metal box. The fact is that this insulation is easy to glue to the walls.Minvata is more suitable for a regular barrel, but you will need to figure out how to fix it, because the method described by us with metal rings is not required for use.

The rate of consumption of the accumulated resource

It is impossible to accurately answer the question of how quickly the heat accumulated in the battery is consumed.

How long the heating system will work on the resource collected in the buffer tank directly depends on such items as:

- the actual volume of storage capacity;

- the level of heat loss in the heated room;

- outdoor air temperature and current season;

- set values of temperature sensors;

- useful area of the house, which must be heated and supplied with hot water.

Heating a private house in a passive state of the heating system can be carried out from several hours to several days. At this time, the boiler will "rest" from the load and its working resource will last for a longer amount of time.

Advantages and disadvantages

As a material used to create a sewage treatment plant with your own hands for the sewage system of a summer cottage or a private house, the eurocube has certain advantages:

- absolute tightness, which makes it possible to avoid the penetration of sewage from tanks into the soil;

- low weight, allowing one person to carry out all installation work without the use of special equipment;

- ease of creating technological holes and installing pipes (inlet, outlet and connecting);

- the speed of construction of the treatment structure;

- ease of maintenance during operation;

- quite high productivity, provided that the installation is done correctly.

The required volume of the tank is determined in a similar way: 200 liters of liquid, which fall on each person per day, are multiplied by the number of family members, and all this is still multiplied by 3. For example, for a family of four adults, a purifier with a capacity of 2,400 will suffice. liters, that is, 2.4 cubic meters (200 * 4 * 3).

Among the disadvantages of septic tanks from Eurocubes, it is worth highlighting:

- low reliability of plastic, which increases the risk of container destruction when exposed to low temperatures;

- the need to fix reservoirs, which, due to their low weight, can "float" during floods and an increase in groundwater volumes.

At the same time, the disadvantages of Eurocubes when used as septic tanks are considered conditional, they can be eliminated during the preparation and installation of structures. From frost - to insulate, from floating - to fix.

Safe operation rules

Do-it-yourself home-made thermal accumulators have special safety requirements:

- Hot elements of the tank must not adjoin or otherwise come into contact with flammable and explosive materials and substances. Ignoring this point can provoke the ignition of individual objects and a fire in the boiler room.

- A closed heating system assumes a constant high pressure of the coolant circulating inside. To ensure this point, the structure of the tank must be completely sealed. Additionally, its body can be reinforced with stiffening ribs, and the lid on the tank can be equipped with durable rubber gaskets that are resistant to intense operating loads and high temperatures.

- If there is an additional heating element in the structure, it is necessary to very carefully insulate its contacts, and the tank must be grounded. In this way, it will be possible to avoid electric shock and short circuits that could damage the system.

Subject to these rules, the operation of a self-made heat accumulator will be completely safe and will not cause any problems and hassle to the owners.

Site and tank preparation

Before you make a septic tank from euro cubes with your own hands, you need to purchase all the necessary materials and prepare the site and the tanks themselves for organizing a treatment plant. When choosing a location, it is worth considering that the structure should be located no closer than 5 m to the house and the road, 10 m to the stream and 30 m to the well, well or reservoir.

Preparatory work includes:

- The pit for mounting the tank must be larger than the volume of the tank. The size of the gap between the walls of the product and the pit depends on the characteristics of the chosen structure.

- To protect the container from freezing, I usually insulate it from the outside with foam or other moisture-resistant heat insulator.

- To increase the strength of the plastic structure, the gap is poured with concrete or a "box" of planks is assembled.

In the dug pit, fill the concrete foundation with a layer about 20-25 cm thick. In the process of solidification of the foundation, install metal hooks or rings into it, for which it is later necessary to hook the containers in order to prevent them from floating up.

Make the formwork for the foundation stepped, given that the second cube needs to be installed just below the first. Also, dig a filtration trench in which you then lay a perforated pipe to drain the clarified wastewater from the septic tank.

Eurocubes also need to be prepared in advance for installation. The drain hole must be sealed. Its diameter is too small, in addition, it is low, so the drain is not suitable for connecting pipes to it. To do this, you need to make several other holes:

- In the first tank - for the entrance of the sewer pipe and for the overflow of wastewater into the second cube.

- In the second tank - the entrance from the first tank and the exit to the filtration field.

- On top of each cube there is one hole for connecting a ventilation pipe.

To supply pipelines, equip all openings with tees, and carefully seal the connection areas. You can use plumbing sleeves with a suitable diameter.