Pros and cons of boiler operation on propane cylinders

- The need to control the fullness of the cylinders. For normal operation of a gas boiler, you need 3-4 gas cylinders. Tracking exactly when the gas runs out without additional equipment is quite problematic. If permanent operation of the system is planned, it is better to spend money and connect the boiler to several cylinders through a ramp and a reducer.

- Gas cost - in comparison with the main connection, the cost of heating LPG is slightly higher, but less than when using an electric boiler.

- Features when connected to a propane tank. According to the PB, it will be necessary to take containers to another ventilated room or to the street, which is not always convenient. It is necessary to purchase separately a device for connecting at least four gas cylinders to the boiler, as well as control and monitoring fittings.

- Conversion - not all boilers can be converted to LPG with the same efficiency. Replacing the burner will cost about 30-40% of the total cost of the boiler.

- The need to attract qualified specialists. Only a licensed specialist can connect several propane cylinders into a single network, change the burner and make the connection correctly.

Gas pipeline types

Gas lines can be laid in various ways. Today, the most common is the annular or dead-end view. In the second case, the fuel is supplied to the consumer only from one side, and in the annular form, the gas moves from both sides, and closes in a ring.

In case of a dead end, in the event of repair work, the service is forced to disconnect a large number of users from communication. This should be taken into account when buying a gas boiler, then it is necessary to choose a device with automatic shutdown so that its operation is not idle. The ring system does not have this disadvantage, since the fuel is distributed evenly to all consumers.

Repair work is most often carried out at the request of users, when replacing gas equipment. De-energize the gas supply pipe, if necessary, cut it. In a private building, the work is easier, but in an apartment, you must obtain a permit to carry out the work. Residential buildings, kindergartens, schools, and other public buildings use gas with a low pressure level, this ensures their safety during operation. For large enterprises or megalopolises with expensive gas equipment, an average level of gas supply is used. The highest pressure is only in the central lines.

Advantages and disadvantages of units

Liquefied gas boilers are cheaper than appliances that use other types of resource. Among the advantages of the equipment are such parameters as:

- complete independence from centralized fuel supplies and regular price increases for utility services;

- high level of efficiency (on average 92-95% and up to 97% for some models);

- quiet burner (for comparison, the burner of a diesel boiler produces a noise effect of 60-75 dB);

- the equipment does not require labor-intensive and expensive maintenance, replacement of the fuel filter and nozzle, reconfiguring the burner and cleaning the heat exchanger;

- complete autonomy of the system and, as a result, the absence of emergency situations;

- unpretentiousness of devices with good reliability;

- the possibility in the future not to buy a new boiler, but to transfer the existing one to the main gas;

- long service life of units (floor-mounted - up to 25 years, wall-mounted - 15-20 years), subject to qualified installation, compliance with operating rules and timely service;

- safety of devices running on liquefied gas (fuel does not ignite even when the container it contains is heated. Combustion occurs only at the moment of mixing of the substance and oxygen, and this happens directly in the burner and only in it).

There are completely non-volatile products on sale that allow you to organize a complete heating system in hard-to-reach conditions, for example, in a remote forest area or high in the mountains.

Of the minuses of devices, the following positions are most significant:

the need for constant high-quality work to connect the boiler to 3-4 propane cylinders by means of a reducer and a ramp; it is undesirable to place containers with liquefied gas near the boiler

It is better to place them in nearby rooms equipped with a good ventilation system, or take them outside and mount them in a special box; the care and caution required when connecting the cylinder, since all operations are performed manually and require the use of physical force; the subsequent re-equipment of some models of boilers for ordinary gas is expensive (replacement of the burner costs 30-40% of the total price of the boiler); installation of the unit and connection to gas supply communications should be done by a licensed specialist with work experience .. The ratio of pros and cons must be considered in each individual case and, based on the conclusions made, make a decision on the advisability of buying one or another type of equipment

The ratio of pros and cons must be considered in each individual case and, based on the conclusions made, make a decision on the advisability of purchasing one or another type of equipment.

Advantages

In all European countries, liquefied gas for boiler houses is used quite often, because this fuel material has a number of certain advantages over other types of fuel.

First of all, it is the cost. In the case of using diesel fuel, as well as electricity, the resulting heat energy has a higher cost price.

Secondly, for European states, the environmental safety of the use of liquefied gas is considered an important indicator. When operating such a boiler room, the environment is not polluted, harmful substances do not enter the air.

Thirdly, the system operates in an autonomous mode, does not need service personnel, since all processes are automated. As a result, the material costs for its maintenance are minimal, and the degree of safety is high.

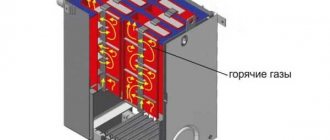

In the process of burning solids, gas is released, which also gives off heat during combustion. This is exactly the principle of operation for a pyrolysis boiler.

Read about industrial pyrolysis boilers here.

Advantages of using such boiler rooms:

- low cost of fuel;

- simplicity of design, saving time and money for installation;

- high-tech equipment installation;

- the ability to quickly start the boiler room;

- autonomy of the system, no need to build a separate room;

- installation mobility.

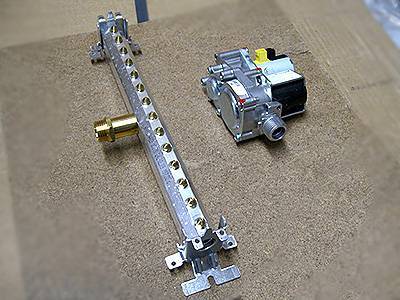

How to convert a boiler to liquefied gas

Theoretically, it is not difficult to reconfigure the heat generator, the main thing is to replace the nozzles responsible for the gas consumption in the boiler. After that, it is necessary to adjust the gas valve in accordance with the operating instructions. Plus the controller setting in the case when the unit is automated. For a good specialist with tools and equipment for everything, half an hour is the maximum.

The manual for the product may include a section for service technicians, where everything is described in detail. But you need to have a pressure gauge to adjust the gas pressure.The first thing to do is change the jets on the burner ramp. To do this, you need to remove the front panel or open it. Further, the ignition group is unscrewed and removed, followed by the ramp. Jets are screwed in from its inner side, which should be replaced.

Further adjustments are made using a pressure gauge. You should be aware that the use of liquefied gas in gas boilers requires adjusting the pressure in the line leading from the automatic valve to the burner. Having carefully studied the instructions, you need to find the appropriate fitting and put on the hose from the pressure gauge, and then, starting the heat generator, regulate the minimum and maximum gas pressure with a special valve. How to perform this operation on the BAXI Eco Compact boiler is shown in detail in the video:

What boilers can be converted to work with liquefied gas

Propane boilers are produced by both domestic and foreign manufacturers - in most cases we are talking about universal models that are capable of adapting to different pressure indicators in the gas pipeline when the automation settings are changed. But, if desired, you can convert standard equipment with a trunk connection to work on liquefied fuel. To do this, you will need to replace the nozzle or the entire burner.

It is important to remember that conversion from a main gas supply to an autonomous gas supply is not possible in all boiler models. A prerequisite for its implementation is the ability to operate the equipment under pressure of 3 - 4 Mbar. Another important point concerns the operation of the gas valve - in a number of models it has to be replaced completely, since the throughput of this unit when operating on LPG should be 1.8 - 2 m³ / hour.

Condensing boilers are the optimal solution for converting for gas supply not from the main systems - their efficiency in this case will be much higher, and fuel consumption will decrease by 20%. It is not bad if all the components necessary for the conversion are included in the delivery by the manufacturer. The purchase of a replacement burner can be economically unprofitable - on average, its cost is up to a third of the total price of a boiler unit.

Gas system organization

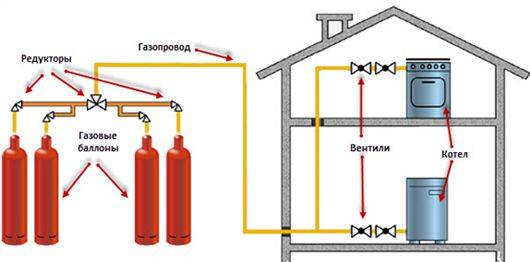

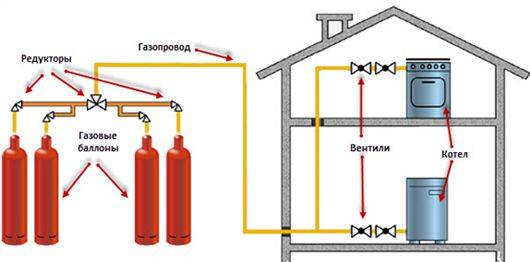

For the correct organization of the gas system, the gas consumption is calculated. Gas consumption is calculated based on the heated area. The number of cylinders is calculated from the volume of gas consumed. But not more than 6 pieces. in one system. The bladder system is connected by means of a ramp, which ensures a safe and stable gas supply to the gas boiler.

The balloon system is located in a metal cabinet at a distance of at least 0.5 m from the house. Ventilation holes are drilled at the top and bottom of the cabinet. The cabinet must be freely accessible. It is recommended to place a cabinet with a balloon system on the north side of the house.

Types and characteristics of liquefied gas

Natural gas was used to heat the premises; difficulties with its storage prompted the invention of liquefied gas. It is a mixture of propane and butane. It is more convenient to store and transport liquefied gas.

The advantage of liquefied gas

- Technically not difficult and not costly production of a gas mixture.

- The gas mixture is environmentally friendly due to low-contaminated waste materials.

Disadvantages of propane butane mixture

- refueling cylinders for refueling, there is a possibility of refueling with poor quality gas;

- cylinders are changed manually;

- the liquefied gas mixture is explosive, safety precautions must be observed;

- in order for the mixture to burn completely, the storage location of the cylinders is ensured by proper ventilation.

Features of the choice of a bottled gas boiler

Houses are heated with three types of gas cylinders:

- Single-circuit boiler.

- Double-circuit boiler.

- Condensing boiler.

A single-circuit boiler is manufactured with a closed combustion chamber.The boiler flame is enriched with oxygen inside the room. Waste materials are discharged outside through the chimney.

A single-circuit boiler is designed for space heating. Such boilers are installed if the problem with hot water is solved.

Double-circuit boilers are designed for heating and hot water supply at home. The operation of the heater is due to the operation of 2 burners. They are ignited using an igniter with built-in piezoelectric elements. After ignition of the igniter, a temperature sensor is included in the process, which is triggered when a certain temperature is reached and closes the combustion chamber. Waste materials are discharged to the outside through a chimney or ventilation. Double-circuit gas boilers operating on bottled gas are a convenient option for solving the problem of heating and supplying hot water.

The condensing boiler supplies the house with heat and hot water. Cold water entering the heat exchanger is heated by a burner and hot air. After this procedure, part of the water goes to heating the house, the other part of the water is used for household needs. After going through a full cycle, the water from the radiator returns to the heat exchanger.

The bottled gas condensing boiler is available in two types:

- floor version of the boiler;

- wall-mounted version of the boiler.

Waste gas products escape through the flue to the outside.

Medium or low pressure, whichever is better

Previously, gas compressed to 0.3 atm was used to supply private households. This eliminated the need to install an expensive down regulator at the entrance to the building. With modern plumbing installations that require high power to operate, the last house on the street will not receive enough gas.

Heating boilers operate uninterruptedly during the cold period and require an average pressure for functioning, otherwise their work stops.

Combined boilers operating on various fuels will help in case of problems with gas supply.

Low pressure gas pipeline (limit 0.005 MPa) is used in small villages with a small number of consumers. Exceeding the compression ratio of the gas mixture will damage the pipeline.

How to connect a LPG gas cylinder

Installing a gas boiler designed for autonomous heating with bottled gas is much easier than installing a heating system using mains fuel.

In view of this, self-installation of this unit is not recommended. It is better to invite a responsible specialist. The norms and rules for the correct installation of the cylinder are regulated by the set of requirements of the industrial safety code, which states that cylinders with liquefied gas should not be located in the same room as the heater.

Moreover:

- The cylinders must be taken out into an adjacent room or outside and installed in a special cabinet.

- Storage of empty gas cylinders must be ensured outside the building. It is best if you refuel the containers immediately.

- If the cylinders that you installed in the closet on the street freeze, you should insulate the storage with non-combustible thermal insulation.

- It is strictly forbidden to heat containers or the cabinet itself with an open fire.

- The distance between the gas cylinder and the boiler must be at least 2 m.

- Do not store propane cylinders near the boiler room.

- It is allowed to store containers only in a specially equipped place located at a distance of at least 10 meters. Ventilation must function in it.

- It is also prohibited to use the basement for this purpose.

During the operation of the cylinders, the complete depletion of the LPG from the tank is not allowed. Every 4 years, it is necessary to certify the tightness of the containers and the integrity of their body.

Installation equipment

To install the heating system, you will need:

- a burner for liquefied (balloon) gas and directly the gas cylinders themselves;

- shut-off valves and reducers.

Bottled gas burners differ in their configuration from conventional burners and are usually standard on gas boilers. If necessary, they can be purchased separately. Shut-off valves and the necessary gearboxes can be purchased from the company or directly at cylinder filling stations.

Connection

A cylinder or a group of cylinders is connected to the boiler through a reducer with a throughput of about 2m3 / hour. Reducers for household stoves are designed for lower throughput - they are not suitable for the heating system. The gas tank system can have one common reducer or a separate regulator for each cylinder. The second option is more expensive, but it is exactly what the craftsmen recommend - individual gearboxes provide maximum safety.

Liquefied gas cylinders cannot be installed outdoors: the cold will provoke a decrease in pressure, and the heating pad may refuse to work. The ideal place for installation is in a warm, ventilated area. It is important to remember that bottled gas is heavier than air, and if it leaks, it will accumulate at the bottom, increasing the likelihood of an explosion. Therefore, the premises should be selected separately from the living rooms. It shouldn't have basements and underground floors!

The gas cylinders are connected to the boiler burner using a corrugated metal pipe - this reduces the likelihood of gas leaks due to system vibrations.

With the help of automatic sensors and correct settings, it is possible to reduce propane consumption rates by 3-4 times. If we are talking about a country house, then the gas consumption will be even lower: for the period of absence of people, the automation will maintain the temperature at the level of 6-9 ° C, which will reduce the consumption of propane to 0.7-0.8 cylinders per week. Heating a building with liquefied gas is not the cheapest option, but in some cases it is the most optimal if there is no problem with the delivery of cylinders.

The gas boiler also performs its functions perfectly when connected to the main gas pipeline. In this case, it is quite easy to switch the equipment to a permanent source of fuel - just change the burner.

But if there is no prospect of connecting the building to the gas pipeline, the expediency should be re-calculated. For a house with a total area of more than 100 m2 and maintaining a temperature of about 25 ° C, it is worth considering the possibility of installing a solid fuel boiler or another heat generator and heating water.

How to calculate the volume of gas for heating a building

To build a high-quality and reliable heating system, where the main heating element is a propane boiler, you must have the following list of building materials:

- directly the boiler;

- fittings for fasteners;

- gasholder (container used for storing gas);

- hoses that are responsible for connecting functional elements;

- an ordinary shovel.

The gas boiler is installed in a special room, which plays the role of a fuel storage. Naturally, all work that is carried out here must be carried out in strict accordance with safety regulations. Installing a gas tank is a prerequisite, since the fuel consumption when using cylinders is very high. It is necessary to install this container in the ground, but it is also possible to install it on a surface not far from the equipment itself.

Despite the delusion of some owners of private houses about the uselessness of a gas tank, its installation when installing a gas boiler has a number of advantages:

- absolutely no gas smell will be felt;

- due to the large volume, it is extremely rare to replenish the gas tank reserves (approximately twice per heating season);

- the possible danger of a gas explosion is absolutely excluded.

To calculate the amount of gas that is needed to heat a particular house, you need to remember that 0.1 liters. this fuel produces 1kW of heat energy.In any case, this value may differ in a certain direction - it depends on the performance of the boiler and its device. In addition, factors such as the climatic conditions of a certain area, as well as the installation of thermal insulation in the house, also have an impact.

Another important question is how often it is necessary to replenish gas reserves in the storage facility. As an example, we will use as a basis a container, the volume of which is 5 cubic meters. The maximum filling of this tank is approximately 4200 liters, which equals 2200 kg of gas.

Using the formula, you can calculate how much fuel will be consumed per hour of boiler operation: 0.1kgx20kW / 2 = 1kg. Dividing 2200 kg by 1 kg / h, you can calculate that the volume of this container is 5 cubic meters. enough for heating for 2200 hours, this is 95 days. Naturally, one cannot but say that propane is much cheaper, in contrast to electricity, and is more economical.

How to calculate the number of cylinders in the system

Fuel consumption in case propane boilers are used is important. It's one thing if you use a gas tank with a capacity of up to 6000 liters, one filling of which with a consumption of 20 liters per day will be enough for almost a year of uninterrupted operation. The same fuel consumption when using cylinders will look completely different. Taking into account the capacity of one tank equal to 40 liters, a double-circuit boiler will consume up to 120 liters per week. That is, the expense will be quite tangible. And in order to avoid frequent refueling or unexpected shutdown of the fuel supply, it is worth making sure that one refueling is enough for at least a month of uninterrupted operation.

To do this, the cylinders are combined into groups - according to the standards, the number of tanks in them can reach 15 units. But, most of the standard ramps are designed to connect up to 10 tanks at once. They are connected through independent reducers or one common pressure converter - according to the main and backup schemes, within which the fuel consumption in each set is monitored. As soon as the pressure in the system drops below certain values, the installed fittings will open access to the gas supply from additional tanks, thus ensuring safety during the operation of the equipment.

It is possible to reduce fuel consumption if a self-regulating system is used. In this case, it will be possible to set up different modes of fuel consumption, taking into account seasonal factors and indicators of atmospheric temperatures. For example, if the average temperature in the house is maintained at +9 ºС during the absence of the owners, the consumption will be less than one cylinder per week.

Gas cylinders in winter

If the gas cylinders are outside the house, then in winter at negative temperatures the pressure of the liquefied gas decreases, and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-combustible materials. Separate non-residential buildings with minimal heating are also suitable for this purpose. When using cylinders, you should observe safety measures:

Special locker for the installation of cylinders

- It is forbidden to heat containers with gas using an open flame;

- There should not be a basement or a cellar near the cylinders, since liquefied gas, when leaking, goes down, has no smell and can accumulate to an explosive concentration;

- It is advisable to install a gas leakage sensor;

- Warehousing of full containers is allowed at a distance of 10 m from the living quarters;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Features of operation

Propane boilers operating with a connection to a gas holder practically do not require additional attention - it is enough to regularly replenish fuel supplies. But in the case of gas-cylinder equipment, it will be necessary not only to monitor the level of energy consumption, but also to refuel the tanks (and no more than three cylinders can be transported to the filling station at a time), as well as to provide conditions for their safe operation.

According to safety rules, it is forbidden to install gas cylinders in rooms where there are heating devices. Moreover, to ensure the highest level of safety, they should be placed in a special metal cabinet equipped with a heat-insulating circuit to prevent the containers from heating up in the heat and freezing when the atmospheric temperatures drop.

The standards prescribe to store the tanks filled, but not connected to the system, in a separate room or building, at a distance of 10 or more meters from the operating heating system. Ventilation is mandatory - in this case, in the event of a leak, it will be possible to avoid the formation of explosive compounds in a concentration sufficient for accidental detonation. In order to avoid the formation of corrosion on the bodies of the tanks, they should be regularly inspected and provided for certification of the tightness of the body to the gas service employees at least once every four years.

How to convert a heating boiler to liquefied gas

- It is necessary to change the feed rate of the gas-air mixture.

- You will need to install a LPG jet kit.

- Adjust the automation for other operating parameters.

In the technical documentation of the heating equipment, the minimum pressure at which the burner continues to work is indicated. The lower this indicator, the more propane-butane mixture, it will be possible to use from the filled fuel tank. Usually, 15-30% of the total volume remains in the container.

LPG boiler nozzles

- The difference between LPG and main gas nozzles lies in the different outlet diameters. Typically, the propane / butane jets are narrower.

- After installing a set of nozzles for converting the heating boiler from natural gas to liquefied gas, the pressure in the system increases slightly.

- The reduced diameter of the nozzle leads to a decrease in the feed rate of the gas-air propane-butane mixture. For normal operation of a 10 kW unit, it is required that the head is no more than 0.86 kg / h.

Which gas is more profitable to heat - natural or liquefied

- Changes to the construction and reconfiguration of the boiler when using liquefied gas are temporary. It can take about six months from the beginning of registration and ordering a project for the installation of heating equipment connected to the main gas pipeline. During this period, it is economically impractical to heat the room with electric or solid fuel heating equipment specially purchased for this purpose. The cost of converting a conventional boiler to liquefied gas ranges from 500-1000 rubles.

- Connecting a gas tank - in this case, the cost of using the mixture is more profitable than heating with wood, electricity or diesel fuel. The only condition is that a qualified specialist is reported to adjust the pressure of liquefied gas, adjust the operation of the automation. Incorrect settings will increase the flow rate by about 15%.

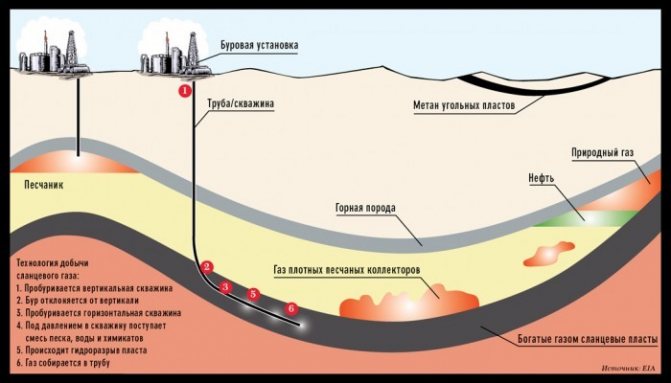

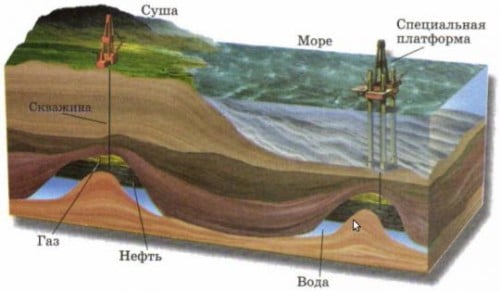

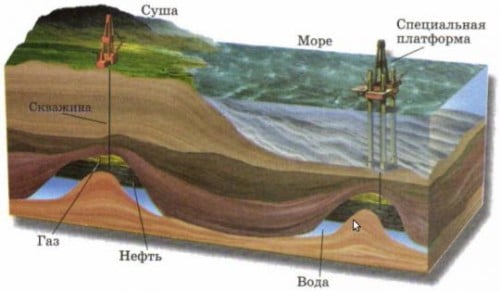

Gas production

In the bowels of the earth, gas is in microcracks under high pressure. Natural movement of methane occurs according to certain patterns.

Gas lies in the earth's crust at a distance of 1-6 km from the surface, therefore, first, geological exploration is carried out. Deep in the bowels of the planet, there are pores and cracks of very small sizes that contain gas.The mechanism for natural gas movement is simple: methane is displaced from high pressure pores to lower pressure pores. Wells are evenly installed over the entire area of the field. Since the pressure underground is many times greater than the atmospheric pressure, the gas itself comes out into the well.

Preparation and transportation

Gas is not immediately allowed through the pipeline; first, it is prepared in a special way in boilers, thermal power plants and chemical plants. Dried from water vapor and cleaned of impurities: hydrogen sulfide (causes corrosion of pipes), water vapor (causes condensation, interferes with gas movement). The pipeline is also prepared: with the help of nitrogen, an inert environment is created in it. Further, the gas moves through large pipes with a diameter of 1.5 m (under a pressure of 75 atmospheres). Since during transportation the potential energy of the gas is spent on friction forces between the particles of the gas itself and on friction between the pipe and methane, there are compressor stations that raise the pressure inside the pipe to 120 atmospheres. Underground gas pipelines are laid at a depth of 1.5 m so that the structure does not freeze.

Types of gas pipelines

- Trunk. The pressure in the system of 6-12 atmospheres is maintained up to the gas distribution station, which reduces the pressure to the required level.

- Medium pressure lines. The pressure in the system is 3-6 atmospheres.

- Low pressure lines. The working pressure is from 0.05 to 3 atmospheres. This is exactly the pressure in the gas pipe in an apartment or in a private house.

Distribution and control devices

- A gas pressure regulator is an equipment for controlling the flow of a working medium.

- Gas control systems automatically shut off the gas supply.

- The reduction unit reduces the fuel pressure.

- The switch redistributes the trunk flow into separate branches.

- Manometers and flow meters allow you to monitor system parameters.

- Filters clean the gas mixture from impurities.

All these devices ensure the safety of main pipelines and are included in the automatic control system of parameters.

Calculation method for natural gas

The approximate gas consumption for heating is calculated based on the half capacity of the installed boiler. The thing is that when determining the power of a gas boiler, the lowest temperature is set. This is understandable - even when it is very cold outside, the house should be warm.

You can calculate the gas consumption for heating yourself

But it is completely wrong to calculate the gas consumption for heating at this maximum figure - after all, in general, the temperature is much higher, which means that much less fuel is burned. Therefore, it is customary to consider the average fuel consumption for heating - about 50% of the heat loss or boiler power.

We calculate the gas consumption by heat loss

If there is no boiler yet, and you estimate the cost of heating in different ways, you can count from the total heat loss of the building. They are most likely known to you. The technique here is as follows: they take 50% of the total heat loss, add 10% for the provision of hot water supply and 10% for the outflow of heat during ventilation. As a result, we get the average consumption in kilowatts per hour.

Then you can find out the fuel consumption per day (multiplied by 24 hours), per month (by 30 days), if desired, for the entire heating season (multiplied by the number of months during which the heating works). All these figures can be converted into cubic meters (knowing the specific heat of combustion of gas), and then multiply cubic meters by the price of gas and, thus, find out the cost of heating.

Specific heat of combustion in kcal

Example of calculation for heat loss

Let the heat loss at home be 16 kW / h. Let's start counting:

- average heat demand per hour - 8 kW / h + 1.6 kW / h + 1.6 kW / h = 11.2 kW / h;

- per day - 11.2 kW * 24 hours = 268.8 kW;

- per month - 268.8 kW * 30 days = 8064 kW.

The actual gas consumption for heating also depends on the type of burner - modulating the most economical

We translate into cubic meters.If we use natural gas, we divide the gas consumption for heating per hour: 11.2 kW / h / 9.3 kW = 1.2 m3 / h. In the calculations, the figure of 9.3 kW is the specific heat capacity of natural gas combustion (available in the table).

By the way, you can also calculate the required amount of fuel of any type - you just need to take the heat capacity for the required fuel.

Since the boiler has not 100% efficiency, but 88-92%, you will have to make more adjustments for this - add about 10% of the figure obtained. In total, we get the gas consumption for heating per hour - 1.32 cubic meters per hour. Then you can calculate:

- flow rate per day: 1.32 m3 * 24 hours = 28.8 m3 / day

- demand per month: 28.8 m3 / day * 30 days = 864 m3 / month.

The average consumption for the heating season depends on its duration - we multiply it by the number of months while the heating season lasts.

This calculation is approximate. In some month, gas consumption will be much less, in the coldest month - more, but on average the figure will be about the same.

Boiler power calculation

Calculations will be a little easier if there is a calculated boiler power - all the necessary reserves have already been taken into account (for hot water supply and ventilation). Therefore, we simply take 50% of the design capacity and then calculate the consumption per day, month, per season.

For example, the design capacity of the boiler is 24 kW. To calculate the gas consumption for heating, we take half: 12 K / W. This will be the average heat demand per hour. To determine the fuel consumption per hour, we divide by the calorific value, we get 12 kW / h / 9.3 kW / W = 1.3 m3. Further, everything is considered as in the example above:

- per day: 12 kW / h * 24 hours = 288 kW in terms of the amount of gas - 1.3 m3 * 24 = 31.2 m3

- per month: 288 kW * 30 days = 8640 m3, consumption in cubic meters 31.2 m3 * 30 = 936 m3.

You can calculate the gas consumption for heating a house according to the design capacity of the boiler.

Next, add 10% to the imperfection of the boiler, we get that for this case the consumption will be slightly more than 1000 cubic meters per month (1029.3 cubic meters). As you can see, in this case everything is even simpler - fewer numbers, but the principle is the same.

Norms and SNiP of gas supply

An indicator of the quality of natural gas is the amount of methane. All other components of natural gas are unpleasant additives. There is one more characteristic, according to which the gas pipeline is divided into categories - this is the gas pressure in the system.

What gas is used in residential buildings

Natural gas is a conditional concept that is used for a combustible gaseous mixture extracted from the depths and delivered to consumers of thermal energy in liquid form.

The composition is varied, but methane always predominates (from 80 to 100%). In addition, natural gas includes: ethane, propane, butane, water vapor, hydrogen, hydrogen sulfide, carbon dioxide, nitrogen, helium. An indicator of the quality of natural gas is the amount of methane. All other components of natural gas are unpleasant additives that create polluting emissions and destroy pipes. Natural gas for residential buildings is not recognized by the senses in any way, therefore strong smelling gases are added to it - odorons, which perform a signal function.

What is the gas pressure in the gas pipeline of a residential building

A gas pipeline is the entire path that gas passes through pipes from the storage site to the consumer. Gas pipelines can be divided into onshore, inundated, underground and subsea. From the point of view of the complexity of the conducting system, they are divided into multi-stage and single-stage.

There is one more characteristic according to which the gas pipeline is divided into categories - the gas pressure in the system. For gas supply to cities and other settlements, pressure is:

- low - up to 0.05 kgf / cm2;

- medium - up to 0.05 to 3.0 kgf / cm2;

- high - up to 6 kgf / cm2;

- very high - up to 12 kgf / cm2.

This pressure difference is due to the purpose of the gas pipeline. Most of the pressure is in the main part of the system, the least is inside the house. For a system with a certain pressure, there is its own GOST, which is strictly prohibited to deviate from.

Gas consumption rates for home heating

The norms of natural gas consumption by the population are determined in the following areas of its use:

- cooking food per person per month;

- water heating with autonomous gas and water supply in the absence or presence of a gas water heater;

- individual heating of living quarters and outbuildings;

- for the needs of keeping pets;

Gas rates for heating are calculated based on the consumption in equal shares for the months of the whole year. Measured in cubic meters per 1 m2 of heated area or 1 m3 of heated volume. If the building is multi-storey, then the calculation is made for each floor separately. As a rule, heated rooms include attics, basements, and some basements.

SNiP for gas supply of residential buildings

SNiP requirements in this area are as follows:

- Gas consumption is determined by the following indicators: for cooking with gas - 0.5 m3 per day; for hot water produced by a gas water heater - 0.5 m3 per day; for heating from a gas heater - 7 - 12 m3 per day.

- The gas pressure within the internal gas pipeline of an individual residential building cannot exceed 0.003 MPa.

- Aboveground gas pipelines on a section of a residential building should be located where there is no passage for vehicles and the passage of people. They are placed at least 0.35 m high from the ground to the bottom of the pipe.

- When entering a house, a low-pressure gas pipe is equipped with a disconnecting device located at a height of up to 1.8 m from the ground.

- The distance between pipelines located in the immediate vicinity of the gas pipeline should provide accessibility for repair and maintenance purposes.

- Any gas storage facilities should be dug into the ground to a depth determined by a distance of 60 cm from the surface to the tank if the ground freezes in winter, and 20 cm if there is no freezing. If storage facilities are installed where the groundwater level does not allow them to be buried, then the tanks must be isolated from water and ensure their immobility. The low pressure gas pipeline is laid underground, except in permafrost situations.

- Inside the house, the gas pipeline must be open. Otherwise, it is allowed only if the gas pipes are located near special ventilation, and are covered with shields, which can be removed without special work and devices.

- Where building structures intersect, the gas pipeline is placed in special cases. Their ends should be placed at least 3 cm from the floor. The pipes must not come into contact with the case (5 cm gap). This 5 cm should be covered with elastic materials.

- Disconnecting devices are placed in front of meters and gas consuming devices.

Choosing a liquefied gas boiler

An important criterion is power, measured in kW. The heated area, as a rule, is 9-10 times larger than this value. That is, choosing a boiler with a capacity of 11.3 kW, you will heat a room with an area of about 100 m2.

However, it is necessary to make an allowance for the fact that with prolonged and severe frosts, equipment of such power will not be able to maintain the set temperature. Therefore, experts recommend choosing a boiler unit with a margin.

Other parameters:

- Boiler type. By the method of installation, wall and floor models are distinguished, by functionality - single and double-circuit (heat + hot water), with an open or closed combustion chamber.

- Efficiency. The higher the indicator, the more economical and efficient the installation will be. The parameter ranges from 90-94%.

- Pressure. The LPG unit must operate at low pressure (3-5 mbar). A low value will ensure the production of gas from the cylinders without residue.

- Gas consumption.The figures indicated by the manufacturer are arbitrary and depend on the power and efficiency of the unit, the set temperature in the room and outside the window, the heat loss of the building and other factors.

When planning the construction of a house, attention should also be paid to the heating system project. The correct solution is to delegate the task to experienced designers who:

The correct solution is to delegate the task to experienced designers who

:

- calculate the amount of heat load;

- will develop recommendations regarding the choice of heating equipment and related materials.

Knowing the necessary parameters of the boiler, it remains to choose a device in terms of appearance and price. Russian boilers are the cheapest. Popular Japanese-made models cost twice as much. And the "Germans" will cost even more.

LPG boiler

Boiler selection recommendations

Before we start giving advice, let's determine the reasons why homeowners use liquefied gas to heat their home.

Actually, there are two of them:

- as a temporary heating option until natural gas is supplied and connected;

- as the only possible option in specific conditions (electricity and diesel are expensive, and solid fuels are not available);

- the heated area of the premises is insignificant (up to 50 m2).

Consider situation No. 1, when the owner decided to use liquefied gas to heat his private house. This procedure is rarely quick, it is necessary to order and complete the project, carry out the installation, and most importantly, pay for all this. The case may drag on for a year, or even two. In this case, the decision is correct, you just need to choose heating equipment, and in this regard, the first advice:

Depending on the need and the place of installation, choose a conventional one - or two-circuit boiler in floor-standing or wall-mounted design, designed for burning natural gas. The only condition: the complete set of the product must include additional parts that allow the boiler to be converted to liquefied gas. Alternatively, the seller must provide you with these parts as an option for a fee.

When purchasing a heat generator, you should pay attention to its thermal power. If there is no heat engineering calculation, then we go the traditional way. With a ceiling height of up to 3 m, we take 0.1 kW of heat per 1 m2 of a building, that is, we multiply the entire quadrature by 0.1. When the ceilings are higher than 3 m, then we calculate the volume of all rooms and multiply it by 0.04 kW. In any case, at the end of the calculation, we give a power reserve, multiplying the result by a factor of 1.2. If there is an additional load in the form of hot water supply, it is better to take gas boilers for liquefied gas with a safety factor of at least 1.5.

What volume to choose a gas cylinder

| Weight and internal volume of gas cylinders | ||||

| Volume (l) | 5 | 12 | 27 | 50 |

| Empty tank weight (kg) | 4 | 5,5 | 14,5 | 22,0 |

| Propane cylinder weight (kg) | 6 | 11 | 25,9 | 43,2 |

| Gas weight (kg) | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height (mm) | 290 | 500 | 600 | 930 |

| Balloon diameter (mm) | 200 | 230 | 299 | 299 |

| The volume of gas in the cylinder, depending on the capacity | ||||

| Tank capacity (l) | 5 | 12 | 27 | 50 |

| Gas capacity (m³) | 0,95 | 2,59 | 5,38 | 10,01 |

| Volume of liquid propane (l) | 4,3 | 10,2 | 22,9 | 42,5 |

How to connect a column to a gas cylinder

- cylinders are connected through the ramp, several from 2-4 pcs .;

- an adjustable reducer is installed to normalize the pressure.

Main gas pipelines. High, medium and low pressure gas pipelines Glossary

The gas pipeline is an important element of the gas supply system, since 70. 80% of all capital investments are spent on its construction. At the same time, 80% of the total length of gas distribution networks falls on low pressure gas pipelines and 20% on medium and high pressure gas pipelines.

Gas pipeline pressure classification

In gas supply systems, depending on the pressure of the transported gas, a distinction is made between:

- high pressure gas pipelines of category I (working gas pressure over 1.2 MPa);

- high pressure gas pipelines of category I (working gas pressure from 0.6 to 1.2 MPa);

- high pressure gas pipelines of the II category (working gas pressure from 0.3 to 0.6 MPa);

- medium pressure gas pipelines (operating gas pressure from 0.005 to 0.3 MPa);

- low pressure gas pipelines (working gas pressure up to 0.005 MPa).

Low pressure gas pipelines are used to supply gas to residential buildings, public buildings and utilities.

Medium-pressure gas pipelines supply gas to low-pressure gas pipelines, as well as industrial and public utilities, through gas control points (GRP). High-pressure gas pipelines supply gas through hydraulic fracturing to industrial plants and medium-pressure gas pipelines. The connection between consumers and gas pipelines of various pressures is carried out through the hydraulic fracturing, the main hydraulic control and the GRU.

Layout of gas pipelines (classification)

Depending on the location, gas pipelines are divided into external (street, intra-quarter, yard, inter-workshop) and internal (located inside buildings and premises), as well as underground (underwater) and aboveground (above-water). Depending on the purpose in the gas supply system, gas pipelines are subdivided into distribution, gas-inlet, input, purge, discharge and inter-settlement ones.

Distribution pipelines are external gas pipelines that provide gas supply from main gas pipelines to gas pipelines-inlets, as well as high and medium pressure gas pipelines designed to supply gas to one object.

The gas pipeline-inlet is considered the section from the point of connection to the distribution gas pipeline to the disconnecting device at the inlet.

The lead-in gas pipeline is the section from the disconnecting device at the entrance to the building to the internal gas pipeline.

Inter-settlement pipelines are gas distribution pipelines located outside the territory of settlements.

An internal gas pipeline is considered the section from the gas pipeline-input (input gas pipeline) to the point of connection of the gas appliance or heating unit.

Materials for gas pipelines

Depending on the material of the pipes, gas pipelines are divided into metal (steel, copper) and non-metallic (polyethylene).

There are also pipelines with natural gas, liquefied petroleum gas (LPG), and liquefied natural gas (LNG) at cryogenic temperatures.

The principle of construction of gas distribution systems

According to the principle of construction, distribution systems of gas pipelines are divided into ring, dead-end and mixed. In dead-end gas networks, gas is supplied to the consumer in one direction, i.e. consumers have one-way food.

Unlike dead-end networks, ring networks consist of closed circuits, as a result of which gas can be supplied to consumers through two or more lines.

The reliability of ring networks is higher than dead-end networks. When carrying out repair work on the ring networks, only part of the consumers connected to this section is disconnected.

Of course, if you need to order gas supply to the site or perform gasification of an apartment building, instead of memorizing the terms, it is more profitable and more efficient to contact reliable certified contractors. We will carry out work on supplying gas to your facility with high quality and within the agreed time frame.

LLC "GazComfort"

Office in Minsk: Minsk, Pobediteley ave. 23, bldg. 1, office 316AO office in Dzerzhinsky: Dzerzhinsk, st. Furmanova 2, office 9

How preparation for the first launch should be done

Before turning on the gas boiler, it is imperative to carry out preparatory work. For this:

- Fully mount the equipment, complete the piping and ensure correct installation.

- Do not neglect fire safety rules. Install all fasteners according to them.

- Leave a small space between the boiler and the wall. This distance should be indicated in the instructions. It is not recommended to install the equipment near a window.

- Move all flammable objects away from you.

- Attach the boiler drum evenly, without distortion.

- Connect it to a cold plumbing system by removing the plugs on the pipes. At the inlet, mount the filter on which the ball valve is located. In this way, the system will be protected from contamination that can lead to breakdowns. A ball valve must be installed on each piping.

- Install the gas pipes carefully.

- Move the outlet closer to the heating equipment. Remember that the boiler must be operated from a separate power line. In some cases, it is allowed to connect equipment to a gas generator for the purpose of its autonomous operation.

- Connect the chimney and check its draft.

- Fill the boiler with cold water with the power off. The primary kit will help eliminate the presence of leaks.

- Turn the thermostat to maximum.

The best manufacturers and models: characteristics and prices

The country of manufacture determines the functionality and quality of the unit: given that it is purchased for many years to come, you should not exchange for dubious equipment offered by the Chinese market. It is better to opt for proven options from European or Russian manufacturers.

Protherm Gepard 23 MOV

The well-known two-circuit mounted model with a power of 23 kW. It has an open combustion chamber (natural draft) and a copper plate heat exchanger: more heat conductive and resistant to corrosion. Excellent, considering the price category, the automation allows you to fine-tune the operation of the boiler and efficiently consume fuel (max 1.9 l / h).

Cost: 39 870 - 42 480 rubles.

Manufacturer: Protherm (Proterm), Slovakia.

Bosch Gaz WBN6000-24C RN S5700

The German BOSCH with a power of 24 kW is made of better materials, is not picky about the quality of fuel and coolant. It is fully adapted to Russian conditions: it is resistant to voltage drops, pressure drops and sudden cold snaps (up to -35 ° C). Economical gas consumption (max 1.5 l / h) is ensured by a modulating fan, a three-speed pump, as well as thermal insulation of the casing.

Cost: 36,900 - 38,460 rubles.

Manufacturer: Bosch Thermotechnik (Bosch Thermotechnik), Germany-Russia.

Buderus Logamax U072-18K

We can say that this inexpensive single-circuit boiler is one of the best gas boilers for liquefied gas for heating a private house: with a power of 18 kW, it consumes fuel very moderately (max 1.5 l / h). A built-in diaphragm expansion tank and a three-way valve make it easy to transfer it to DHW. At the same time, the model is known for high reliability, the nature

Cost: 26,200–31,840 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

BAXI SLIM 1.150 I

The famous Italian floor-standing boiler of low power (15 kW) is known for the minimum gas consumption (max 1.1 l / h). From the factory, it is equipped with weather-dependent automation, a cast iron heat exchanger and a control module with an integrated self-diagnosis option. And another important plus is its modest dimensions: for example, its width is only 35 cm.

Cost: 62,090 - 71,300 rubles.

Manufacturer: Baxi, Italy.

Wester Lemax Clever-30

Domestic single-circuit wall-mounted device with a power of 30 kW, which does not depend on the availability of electricity. It can operate in a system with both forced and natural circulation of the coolant, and continuous smooth flame modulation from 30% to 100% can significantly reduce the volume of fuel consumption (max 1.7 l / h). With such a high efficiency, it also differs in reliability close to European manufacturers.

The only significant drawback is the steel heat exchanger, which is characterized by a limited resource (10-14 years).

Cost: 34 250 - 40 500 rubles.

Manufacturer: Lemax (Lemax), Russia.

Choosing a storage location for gas cylinders

Cylinder connection diagram

Before deciding on the method of storing gas cylinders, it is necessary to correctly select their capacity. Currently, you can use containers with a capacity of 5, 12, 27 and 50 liters.If the heating of a private house with bottled gas is regular, it is best to purchase containers with a maximum volume of 50 liters.

To supply gas, a pipeline is made from the storage area of the cylinders to the boiler. You can use several containers at once by installing on each gas reducer. It should include two pressure gauges. One of them is needed to verify the pressure reading inside the cylinder, and the second shows this value at the outlet. The shut-off valve is used to regulate the flow rate of the fuel.

Reducer for cylinders

The place of choice for their storage directly depends on how many cylinders are needed for the heating boiler. The estimated number of containers depends on the following indicators:

- The total area of the house;

- Heat loss in the building;

- Minimum temperature in winter.

An important point is the place where the gas cylinder heating boiler will be installed. The length of the supply line should be minimal in order to reduce the likelihood of its depressurization and to optimize the gas consumption.

Separate room for cylinders

Storing gas cylinders at home

The best way to store gas cylinders for heating is to prepare a separate room. The rules for the arrangement and the requirements for it are described in detail in SNiP 2.04.08-87. Therefore, before installing heating using gas cylinders, it is necessary to familiarize yourself with this document.

The best option if the storage room will be located in the immediate vicinity of the boiler installation site. In this way, the supply line can be kept as short as possible. It is also necessary to provide the following storage conditions for containers for heating a private house from gas cylinders with your own hands:

- The room should not store flammable or lubricants;

- It is forbidden to use any heating devices - convectors, heaters. The exception is water heating pipes and radiators;

- Supply ventilation. Average air exchange rate is 12 m³ / hour per 1 m² of the room;

- Each cylinder must be placed on a pallet. This is necessary to maintain stability against possible fluctuations in the capacity during the gas release.

To ensure safety, the room must be closed. Fuel for heating a private house with bottled gas is supplied through the mains. If flexible hoses are used for this, during installation it is necessary to avoid kinking them.

Gas cylinder storage cabinet requirements

Storage of cylinders in cabinets

An alternative to the above method is the use of special metal cabinets. This is important for heating a summer cottage with gas cylinders with low fuel consumption.

It is recommended to purchase a ready-made structure, since it will take into account the requirements from GOST 15860-84. They are as follows:

- Airing. For this, there must be ventilation holes in the cabinet structure;

- Eliminate the possibility of sunlight hitting gas cylinders. This can lead to a rise in temperature on their surface;

- All elements of individual heating from gas cylinders must be made of non-combustible materials. The same applies to storage cabinets;

- Availability of warning signs and inscriptions.

How long is a 50 liter gas cylinder for heating? It all depends on the nominal consumption of the boiler. But, despite this, only two cylinders can be stored in one cabinet. The optimal dimensions of the structure in this case will be 2000 * 1000 * 570. A separate foundation must be made before installing the cabinet. Its dimensions should exceed the dimensions of the structure by 15-20 cm.

The installation rules for heating a private house from gas cylinders with their own hands are also respected:

- The minimum distance from doors and windows should be 5 m;

- The wall to which the cabinet will adjoin is made of non-combustible materials.

Be sure to make special ventilation gaps on the surface of the foundation. Experts recommend grounding the structure to remove possible static voltage.

Calculation of costs for the device of autonomous gas heating

Comparing which of the types of heating systems will be the least expensive, you first need to pay attention to the consumption of liquefied gas for heating. It is advisable to compare the upcoming costs with similar costs for other types of fuel and decide which option will be more profitable.

Initial costs for equipment and furnishings

The cost of purchasing equipment and installing an autonomous heating system on liquefied gas in your home may vary slightly in different regions of residence. But in general, when compared with the connection to the main gas pipeline, the difference in cost will be insignificant. It will be more expensive only if you use not cylinders, but a gasholder with a volume of several cubes. Its cost will be more than 300,000 rubles.

Also, the cost of equipping rooms for boilers using LPG is almost equal in cost compared to those that run on diesel fuel. As evidenced by reviews, heating with liquefied gas only requires higher initial costs when it serves as an alternative to solid fuel or electric heating. But in the course of further operation, the funds invested in heating a private house with liquefied gas will gradually pay off due to the profitability of this type of fuel.

Gas consumption rates for home heating

Limitations in the consumption of utilities can be manifested in the minimum tariffs, allowable capacity and resource supply rates. The need for the existence of norms appears where there are no accounting meters.

The norms of natural gas consumption by the population are determined in the following areas of its use:

- cooking food per person per month;

- water heating with autonomous gas and water supply in the absence or presence of a gas water heater;

- individual heating of living quarters and outbuildings;

- for the needs of keeping pets;

Gas rates for heating are calculated based on the consumption in equal shares for the months of the whole year. Measured in cubic meters per 1 m 2 of the heated area or 1 m 3 of the heated volume. If the building is multi-storey, then the calculation is made for each floor separately. As a rule, heated rooms include attics, basements, and some basements.