It is simply impossible to keep on the theme of the prologue of weekend rest with barbecue. And although we will not tell you anything new, for our part, we also want to tease you with a pleasant pastime at the brazier, on which marinated meat is sizzling. The smell, taste and speed with which the meat disappears can amaze anyone, but not everyone and is always as romantic as in desires. Often, in order for the desired to become real, it is necessary to do something for this. In our case, the key subject around which all this conversation is being conducted is the brazier. It is about the grill, in our case, a metal grill, and will be discussed in this article. The article will provide sketches for cutting metal for a brazier, and also describes the process of its manufacture. Even several options will be described. But which one to stop at, you choose.

Advantages of a metal barbecue

The simplest, but at the same time very practical model of the barbecue

The pros and cons of metal braziers differ depending on which models to consider:

- thin-walled – they are mobile, compact and affordable. They are made by stamping parts from the thinnest sheets of metal, which has a beneficial effect on their weight. Folding versions are most often produced. However, they are often used not only as a container for coals from a separate fire, but also for kindling and kindling the latter. Therefore, the service life of such a barbecue can be significantly reduced. The walls quickly burn out, deform and become unusable. In addition, they poorly retain heat, which leads to an unreasonably high consumption of coal;

- thick-walled – wear-resistant and roomy. Such barbecues can serve for years. True, they are not as portable, since they are made of thick sheets of metal, and therefore have a rather large weight.

The history of the barbecue

The peoples of many countries claim to invent the barbecue. The closest to the truth are the statements of US residents that their country is the birthplace of barbecue. In part they are right, since this word was unknown until Columbus visited America.

The first barbecues

Navigators from Spain, arriving on the island of Dominica in the 16th century, saw how the local Indians cook meat. To do this, the natives used a grate made of twigs, on which they laid meat, and held this structure over embers. Locals called such a device "barbacoa". The travelers liked the meat dish prepared in this way, and subsequently the experience was successfully adopted by them. The Spaniards began to call the process as a whole by the name of the device for cooking meat.

The places where the settlers began to live were rich in wood. This allowed the meat to be cooked slowly over charcoal with a generous addition of spices. The process could take more than sixteen hours. For the first settlers from the Old World, barbecue was an integral part of their way of life. Gradually, barbecue cooking became a tradition. At the barbecue, they called relatives, neighbors, acquaintances and organized a joyful holiday. The friendly gatherings could go on for several days.

Cooking on charcoal has evolved over the years and has come to be used in public catering. The American Civil War gave the enslaved blacks freedom, and they successfully began to develop a culture of barbecue, creating specialized establishments.The end of the First World War saw the emergence of restaurants in the United States serving exclusively barbecue. The famous industrialist Henry Ford grasped the trends in demand and began to produce coal briquettes, which were used to cook meat over charcoal.

Charcoal Meat

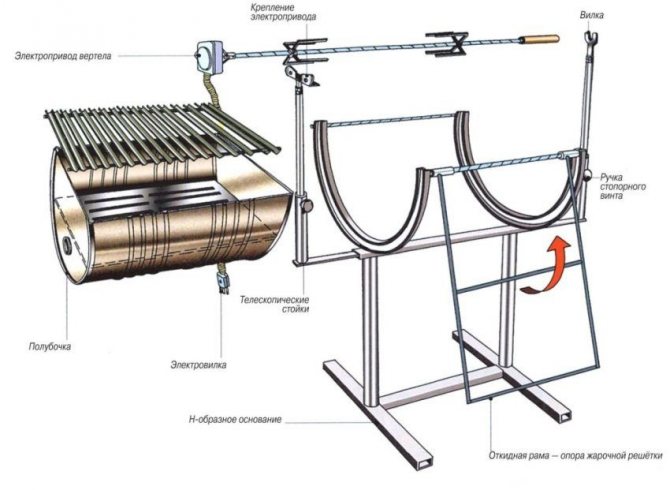

A revolutionary invention in barbecue devices was the invention of the boiler-grill. This idea came to mind of a simple welder who lived in Chicago. Its design was superior to the traditional brazier with a grate. Its main advantage is the ability to regulate the cooking process, which has significantly expanded its methods. The design of this boiler was improved and liquefied gas and electricity were used as fuel. Nowadays, almost every American living in his own home does not deny himself the pleasure of barbecuing on one of the many models.

Varieties

Before you start making a barbecue, you need to decide on its type.

Portable (foldable / collapsible)

A compact collapsible brazier you can take with you even on a hike

Portable barbecues are easy to assemble, have a simple and compact design, designed for outdoor picnics. They are of two types: folding and collapsible.

- In a portable collapsible brazier, the elements are connected during the assembly process using bolts, pins and other connecting elements. Such models are mobile and compact, but they have one drawback - poor reliability. Making such a brazier with your own hands is quite difficult.

- In a portable folding brazier, the elements do not separate completely, but move or fold. The main disadvantage is the short service life. At best, they are enough for one or two seasons.

- Currently, such a model as a disposable grill, which is designed for one use, is very popular. Its undoubted advantage is its low price and low weight.

Stationary

A metal grill with a roof allows you to cook in almost any weather

The stationary grill has a large number of manufacturing options. Such models can be with or without a roof. The first are self-sufficient. The roof will protect not only the cook, but also the firebox itself from direct sunlight, snow or rain, which will extend the service life. The latter are usually installed where there is already a canopy.

With a smokehouse

In such a grill, you can not only fry, but also smoke meat or fish.

The grill with a smokehouse can be used not only for frying meat or fish, but also for smoking them. To do this, it must be equipped with a dense metal cover, and on the sides from the inside, shelves should be provided for installing the grill.

The principle of smoking in such a grill is as follows: thin twigs of fruit trees (apple, cherry or plum) are placed on the bottom, and prepared pieces of meat or fish are placed on an installed grill. The brazier is covered with a lid and a fire is made under it. The branches inside from the high temperature begin to smolder, but due to the lack of oxygen they do not ignite. Thus, meat or fish are simultaneously baked at high temperatures and smoked in smoke from smoldering fruit twigs.

American BBQ

Unlike our usual rectangular barbecues, American barbecue is often round.

The main difference between barbecue and grill is that the meat is fried not on skewers, but on the wire rack. In this case, not only coals can be used, but also open fires. Thus, the sides should be higher than those of the barbecue, and fastenings for the grill are needed on them.

Table: Pros and cons of different types of barbecues

| A TYPE | ADVANTAGES | LIMITATIONS |

| Portable (thin-walled) | Compactness, ease of assembly, low weight, low price, mobility. | Short service life, possible deformation and burnout of the main container, poor heat retention. |

| Portable / mobile (thick-walled) | It retains temperature better, compared to stationary, it has a low weight, long service life, and is resistant to corrosion. | High price. |

| Disposable | Mobility, light weight, low price. | Cannot be reused. |

| Stationary | Large frypot sizes, low heat transfer, the longest service life. | There is no way to move. |

| Brazier with a smokehouse | Allows you not only to fry, but also to smoke meat and fish. | Quite difficult to find on sale. Can only be made to order or by yourself. |

| American BBQ | Cooking food not only on coals, but also on an open fire. | Quite an expensive device. |

Benefits of metal structures

The most important advantage of barbecues made of metal is their low cost. Even if you buy metal sheets, corners, bars and pipes necessary for the job, the cost of materials will be significantly lower than the finished product from the store. And if you take into account that unnecessary metal rubbish in the form of barrels, cylinders, pieces of sheet metal and scraps of corners will fit for such a structure, then the price of the finished product will approach zero.

The second indisputable advantage is ease of manufacture. Anyone who has a slightest degree in welding will be able to repeat the most complex design. Thirdly, such barbecues can be easily installed in a new place or taken with you to a picnic. Fourth, a sufficient thickness of sheet metal will allow the grill to serve for a long time. And fifth, the pleasure of the result. Having created a real masterpiece from scrap metal, you can proudly remember this at every opportunity.

Barbecues with insufficient wall thickness suffer from disadvantages - they quickly burn out, they can be driven when overheated, and they can rust from rain and moisture.

Seat selection

When choosing a place, you need to consider some important points:

- you should not place the brazier under trees or near shrubs, as the high temperature can scorch the branches;

- do not place the device under film or fabric canopies, which may catch fire due to the heat;

- it is advisable to take into account the wind rose so that smoke does not enter the windows of your house or neighbors;

- the best option would be a separate plot equipped with a barbecue, located near the main recreation area.

If the grill is on the ground, it is advisable to pave the area under it with refractory material (stones or paving slabs). In the rainy season, this will allow you to approach the barbecue without interference, and the structure itself will not sink into the ground over time.

So, we smoothly come to the main point of our conversation. How to make a brazier with your own hands?

Tools and materials

To make a metal barbecue with your own hands, you will need the following tools and materials:

- sheet metal (iron or steel);

- bolts and other fasteners;

- welding machine;

In the manufacture of a metal barbecue, you cannot do without a welding machine

- hand drill or electric drill;

- grinder with cutting discs for metal;

- angle grinder;

- a hammer or small sledgehammer;

- pipe or corner (for legs);

- tape measure and square for marking;

To 'cut' the metal parts of the barbecue, you will need a grinder

- angle grinder;

- hammer or small sledgehammer;

- pipe or corner (for legs);

- tape measure and square for marking.

Getting Started

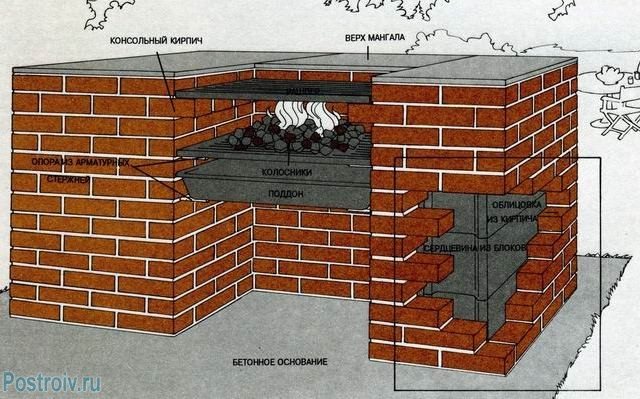

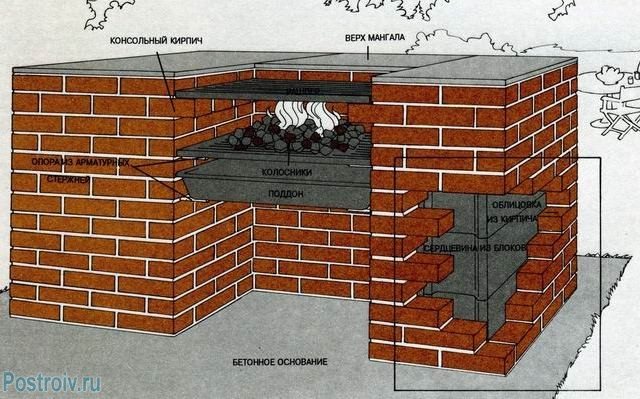

Like any capital structure, a garden barbecue requires a foundation. Best of all, for building a brazier made of bricks with your own hands, a tape-type foundation with a pit depth of up to 0.6 m is suitable. The pit is covered with large crushed stone or stone, and poured with sand-cement mortar. A foundation of rubble stone is laid above the surface of the soil, up to 0.3 m high.The best material for such a fireplace is natural stone or red oven bricks. Stone masonry is quite laborious and requires a lot of experience. It is quite possible to build a brazier made of bricks with your own hands, the main thing is to do the work carefully and without haste.

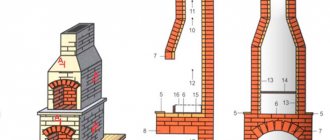

Before starting construction, consider the design of such a barbecue. As a rule, they all represent a firebox with a low chimney. A grate is installed inside the firebox, under which there is an ash pan (one or more), closed by a blower. A niche for storing firewood is arranged under the ash pan.

Are you interested in do-it-yourself barbecues made of bricks? A step-by-step instruction will help you fully understand all the nuances of such structures.

To build a small brick barbecue you will need: 400-450 pcs. bricks, clay, river sand, a pair of grates, a copper hood for an exhaust hood, an angle of 30x40 mm and 40x40 mm, valves or ash pan doors.

- Choose a place for the stove - in an open space or under a gazebo canopy. The composition of the solution depends on this. For the first option, heat-resistant cement will be needed, and for the second, clay solution will do.

- Equip the foundation.

- Lay out a niche measuring 0.75x0.5x0.5 m. Lay a row of bricks above this niche (spoon masonry). Here, use the support from the supplied metal corners. Install the equal-flange corner in the back of the row (in the 8th row of the masonry), and 30x40 in the front, making slots in the front brick of the 9th row for the corner shelf.

The second row is needed to eliminate overheating of roofing material

We form the volume of the furnace on the 3rd row

- The tenth and eleventh rows are formed by ash pan-blowers measuring 0.12x0.25 m. Doors or valves are also installed here to regulate the air flow. For the installation of the grate in the 11th row of bricks, a quarter is cut off.

In the original, this door was used for the oven.

Fastening the oven door

We fix the wire for fastening the door

- In the twelfth-thirteenth row, we equip a ledge for skewers.

- The masonry of the firebox is continued until the 21st row. Further, it is covered in the same way as a niche under the ash pan, only the laying is carried out in half of the brick - butcher.

Site for laying the firebox

We lay out the bottom of the firebox

We put the lattice

We erect the walls of the firebox

Covering the woodshed with a sheet of metal

- From the 24th row, the masonry begins to narrow with ledges. On the sides, each row is reduced by 35 mm, and at the front by 17 mm. The rear wall of the smoke box is laid out perpendicular to the base.

- The last row of the brick barbecue will be the 33rd, with a copper exhaust hood, installed by hand. A photo of this design will help you navigate how to do this.

We form 6 outlets of smoke from the firebox

Then we close the firebox. Lay the flooring on top

We put heat insulation and cooking floor on top of the firebox.

Chimney masonry. The brazier is ready!

The presented drawings of brick grills will help you build the most suitable structure with your own hands. A photo of such buildings will help you appreciate their design and splendor.

However, building a brazier out of bricks with your own hands is not enough. We still need to install a chimney.

DIY manufacturing technology

The brazier, which we ourselves will make of metal, will be as simple as possible. For a small company, 8-10 skewers with meat are enough, and if the need arises, you can prepare another portion.

Skewers should not interfere with each other, but large gaps between them should be avoided so as not to waste heat.

Following these arguments, we calculate the length of the structure. A classic skewer holds 5–7 pieces of meat. The depth of the barbecue is determined by practical methods. The meat should not be far from the coals, but it should not be placed too close, otherwise it will burn.The distance from the top edge of the structure to the ground depends on the height of the cook. Most often it is 75–125 cm.

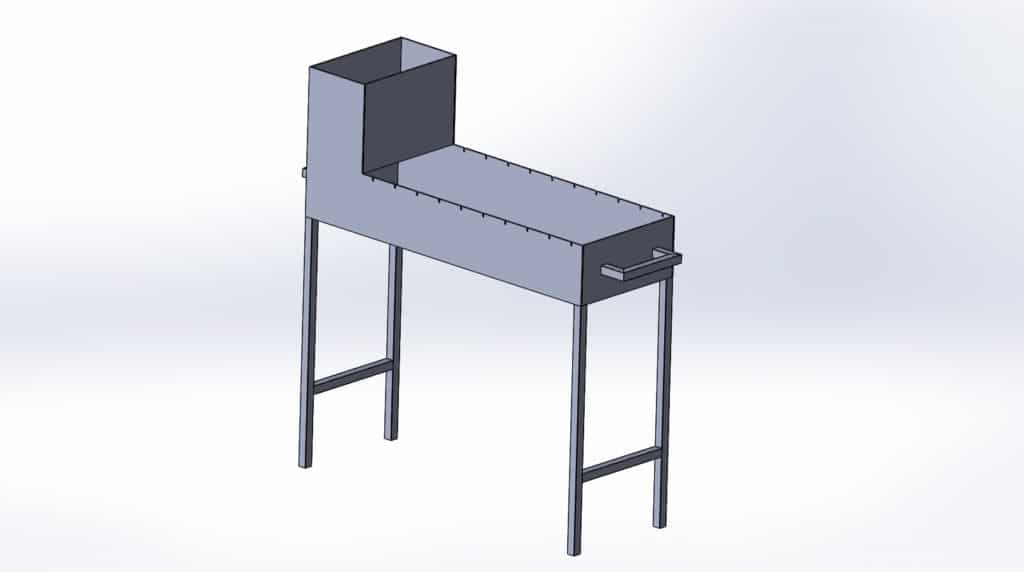

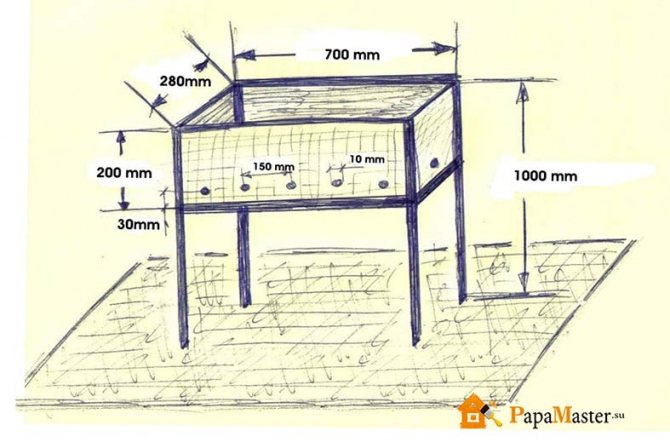

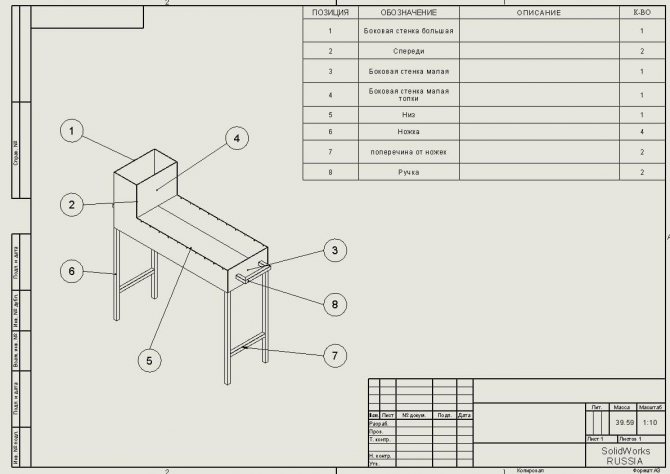

Drawing

We make a drawing of our barbecue. The diagram may look something like the following figure.

The brazier is not a space rocket, so the blueprint may be the most primitive.

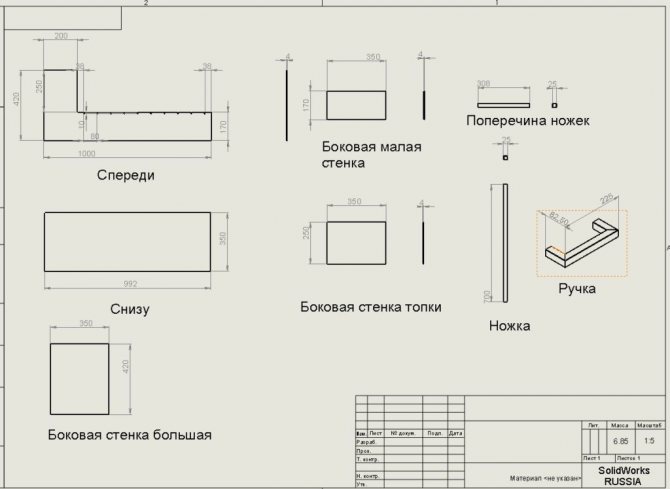

As a material, we will use sheet metal with a thickness of 2-3 mm.

So, we mark the sheet using a square so that there are no distortions:

- 70x20 cm - 2 pcs. (back and front walls);

- 70x28 cm - 1 pc. (bottom);

- 28x20 cm - 2 pcs. (side walls).

We cut the elements with a grinder.

Small slots will help keep the skewer in position

Small cuts can be made along the upper long side of the sides for more reliable fixation of the skewer in the selected position.

To ensure the flow of oxygen along the sides of the barbecue, a number of holes are made

To ensure the flow of air into the base box, on the front and rear panels, several holes with a diameter of 10 mm or more should be drilled with a step of 10-15 cm from each other. Measure 2 cm from the bottom edge of the structure and draw a straight line to mark the notch.

Welding works

For the legs, you can use a corner 20x20 cm or metal pipes with a diameter of at least 20 mm and a length of 60-100 cm (depending on the height of the cook).

If you use tubes, you can make the structure collapsible. To do this, you will additionally need 4 bolts and nuts. Bolts are welded to each tube. In all four corners of the bottom of the box, you need to drill a hole with a diameter slightly larger than that of the bolts welded to the support legs. If corners are used, then they can simply be welded to the base.

If you want to add a smoking function to your barbecue, then it will be enough to weld two corners to the inside of its long sides at a height of about 7-10 centimeters from the bottom. You should also make a metal lid by welding small sides to a metal base that slightly exceeds the size of the barbecue. For convenience, it is recommended to weld a bracket on top of the cover, which will be used as a handle.

Optionally, you can make a canopy or shelf for firewood or coal, weld handles on the side walls, add a hook for a shovel or poker.

The brazier can be not just an ‘iron box’, but a real multifunctional kitchen

What should be the brazier

So that cooking a barbecue is not a burden, you need to know how the brazier is cooked correctly. The optimal height is determined by the distance from the ground to the palm of the arm bent at the elbow. The length depends on the number of skewers placed at the same time. So that guests do not have to wait long for a delicacy, the required number of portions must be prepared in three passes. For good roasting of meat, the distance between the skewers should be 8-10 cm. However, you should not make the length more than 1 m, as this will create problems with maintaining an even heat.

The width is determined by the length of the skewers available, the standard is 40 cm. The height of the walls should not exceed 20 cm. Taking into account the thickness of the coal layer, this will allow placing meat at a height of 10 cm from their surface. With a shorter distance, the kebab will burn, with a larger distance it will not be cooked. The thicker the metal selected for production, the longer the service life. Usually it is chosen in the range from 3 to 7 mm.

Unusual barbecue design (video)

In conclusion, we bring to your attention a small video, which shows how to make a metal brazier using a base from an old Singer sewing machine.

For many of us, barbecue is the most delicious and desirable food. Cherry firewood, properly marinated meat, a handmade brazier are a gourmet's dream. Possessing a minimum set of skills, you can build a brazier yourself without any problems. And we can only wish you successful work and bon appetit!

- Author: Sergey Kolosov

Was born in 1977 in the city of Donetsk, Ukraine. Graduated from Donetsk Polytechnic Institute (now DonSTU) with a degree in Automated control systems. He worked at the Donetsk Metallurgical Plant. In 1997 he moved to Moscow, where he worked in several construction crews for 8 years. Rate the article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!