Today, the presence of a warm floor in a house or apartment is far from a luxury and not uncommon. Any owner of a private house or apartment can easily buy and install it, both independently and with the help of specialists (depending on the type and method of fixing the underfloor heating pipes). Most often, such floors are installed by people not for their comfort, but for children. In addition, the heat from the floor is evenly distributed over the entire area of the room in which it is installed. Now in the markets and in specialized stores, customers are presented with a wide range of various underfloor heating. Their differences are only in price and installation method.

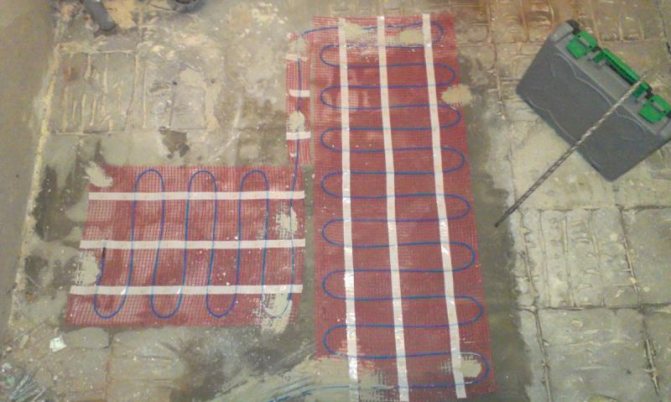

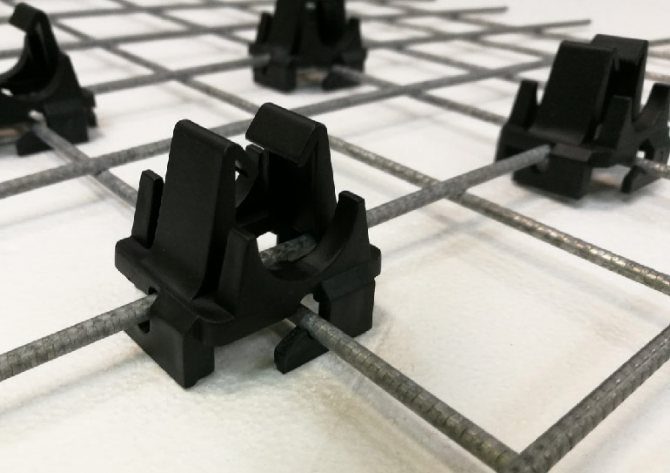

Fastening the pipe to the reinforcement mesh

The pipe is not tightly attached to the mesh (distance of several centimeters), fixed with special clamps. The brackets are fastened one at a time at a distance of one and a half meters from each other, but when the pipe is bent by 90 degrees, the pipe is fixed with three brackets for more reliable fixation.

On our second channel, Andrey Elfimov told about a useful life hack for attaching a floor heating pipe to a reinforcing mesh:

Benefits: All elements of this method of pipe fastening are available in specialized stores or on the market. A simple and reliable way.

Disadvantages: Time consuming installation process. The possibility of damage to the pipe is not excluded, since pipes made of metal-plastic are often used.

What fasteners for underfloor heating to choose?

The choice depends solely on personal preference. Here you need to weigh all the pros and cons, and then decide on the most optimal option. If it is difficult to do this on your own, you can always contact the specialists in your field:

- using polystyrene plates, you can install the system as quickly as possible;

- metal mesh is chosen by those who want to save money;

- anchor shackles are an option for those who are not afraid of difficulties and want only the best option.

When deciding on the type of fastener, it is necessary to build on personal financial capabilities, the peculiarities of the system's operation, as well as the time that is available for installation.

It is worth considering any risks in the operation of the system, which can lead to the destruction of the work done.

Using brackets for underfloor heating, you will not have to worry about the fact that under high pressure or under mechanical stress, the pipes will come off the place, which will cause the entire system to be repaired.

- Similar posts

- What should be the height of the warm floor?

- How is the length of the underfloor heating pipe calculated?

- How to install a warm floor?

- How to turn on the warm floor?

- How does a flow meter for an underfloor heating collector work?

- Features of underfloor heating Fenix

Fastening the pipe to the mounting rails

This method is no more complicated than the previous one. The pipes are fixed with special clamps that hold tightly and protect the system from mechanical damage. Also, such systems are easy to install on the wall, the only problematic is that it is quite difficult to find such a heating system in specialized stores. In addition, the complexity arises in the preliminary markup. But in general, this method is very convenient and practical.

Underfloor heating types

Today there are three main types of underfloor heating systems:

- water;

- electric;

- infrared.

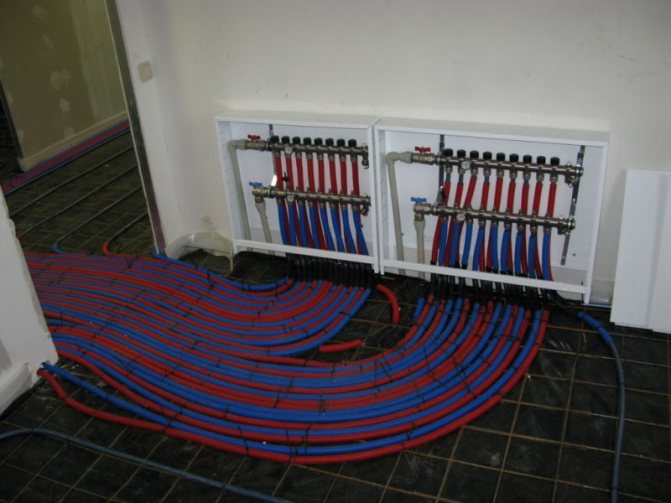

A water-heated floor operates on the basis of water pipes, which are laid directly under the finished floor covering.The source of the coolant is hot water from the heating system (less often - from a separate heating device - a boiler and a boiler). For the installation and connection of pipes, metal-plastic and plastic pipes are used, which are connected to the heating outlet pipeline.

Electric floor heating is based on the so-called. heating cable. Passing current through itself, the wire converts its energy into heat due to the high resistivity of the conductive core. Any cable is not suitable for arranging an electric underfloor heating - you need a special wire with a core of the required thickness, as well as with good insulation.

Infrared floor heating is the rarest variety. It is installed on the basis of special roll films, in which special heating elements are built. Under the influence of the current strength, they produce infrared radiation, forming heat.

Attention! The most popular and widespread type of underfloor heating system is water. It differs from other varieties in maximum power and heating temperature range and ease of use. With the help of devices for automation of work - temperature sensors, thermostats - you can flexibly set the temperature mode of the system.

Further we will talk specifically about the water type of underfloor heating, which is preferred most often, because it is much easier to connect pipes to an existing heating system in a house or apartment.

We recommend that you familiarize yourself with: How to install a ventilation duct in the kitchen with your own hands?

Fixed polystyrene foam boards

Option 1

A very creative way to install pipes. Since with the help of volumetric protrusions on the coating, the pipes can be laid in any pattern as soon as you want. Despite the small distance between the protrusions, many people think that this is what will fix the pipe, but this is far from the case. For fixing, special clips are also used, which guarantee the reliability of a strong fastening of the pipe.

Benefits: The pipe is protected from mechanical damage by special lugs. Such a system can be freely purchased both on the market and in a specialized store.

Disadvantages: Quite a high price for all components. Additional elements must be used to fix the pipe.

Option 2

This installation method is very similar to the previous one, but there are significant differences. There are special protrusions on the cover that firmly fix the pipe without any additional equipment. The pipe can be fixed in a very simple way: by gently pressing the pipe between these protrusions.

Benefits: This method of fastening the pipe is considered very convenient and reliable. The slab is not damaged when moving across the floor. An excellent combination of functionality, quality and price.

Disadvantages: The cost is much higher than the previous examples. Such a copy is quite difficult to find in markets and in specialized stores.

Device and principle of operation

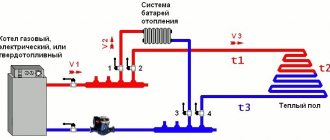

Before starting to study information about what materials may be needed for arranging a warm floor on your own, you should understand what is the principle of operation of this system. So, a warm floor is a system of pipes of small diameter assembled and laid in a certain way, inside of which there is and circulates the coolant supplied by means of a pump. The carrier of heat is ordinary water heated in a special device. During installation, pipes are laid under the floor covering or directly into the screed, depending on the installation method.

The principle of operation of a water-heated floor

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

To make it pleasant to walk barefoot on the floor, the temperature of the coolant should not be high - no more than + 40-45 degrees.In this case, the floor covering itself will warm up to only + 25-28 degrees. However, heating equipment usually warms up the water more - up to + 60-65 degrees.

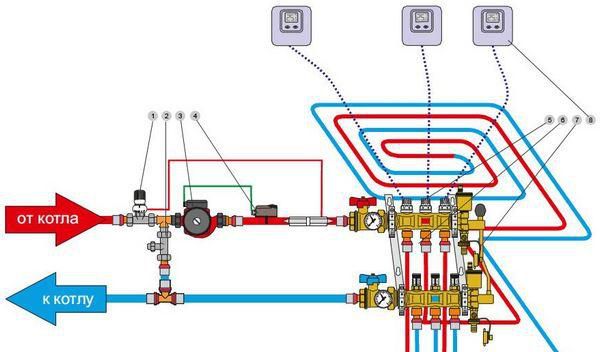

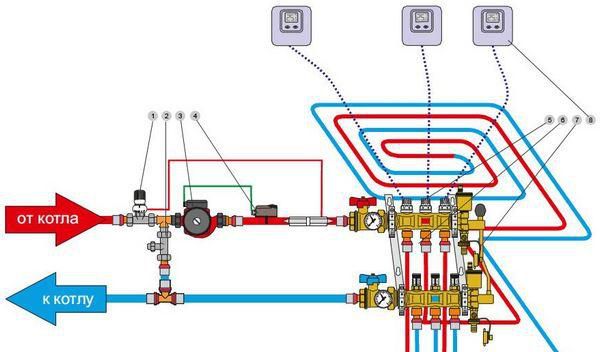

Wiring diagram for connecting a water-heated floor to the boiler

That is why it is necessary to regulate the temperature of the coolant. In a cottage, a gas condensing boiler will help to provide the ability to regulate, which, even at low temperatures, is highly efficient. Here water will be fed directly to the heating system. For some other types of boilers, it is necessary to use a specially designed mixing unit, thanks to which cooled water will be supplied to the heated water.

Traditional radiator heating

Traditional radiator heating

Further, water begins to be distributed along the heating circuit using a distribution manifold - a pipe branching system. It is also called a collector. It represents two pipes - supply and "return" - which supply and collect water from the branches of the system.

On a note! The distribution manifold may be absent if the underfloor heating is equipped in a small room.

Underfloor heating collector

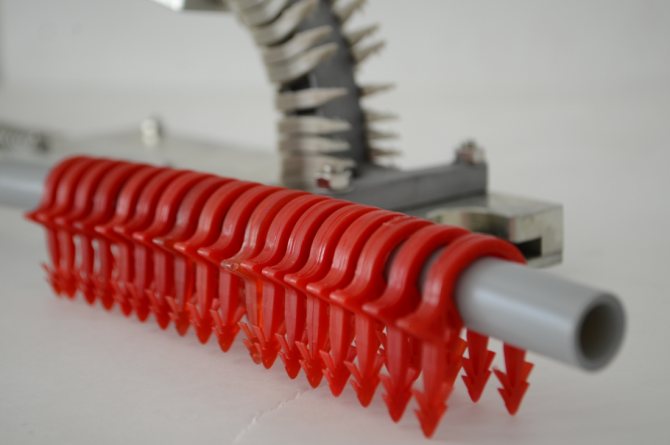

Tacker fastening

The pipe is fastened using a special device - a tacker, which holds about 120 clamps. The pipe is fixed according to the marking with the help of this device. The process takes a small amount of time, but despite the speed of fixing the pipe, the fixing is very reliable. The only drawback of this method is the cost of the equipment - 230 euros. Finding him in a domestic special store is very difficult. This mounting method is suitable for installers and trained professionals in the field.

How to choose mounts

The choice of suitable fasteners depends on the type of substrate and how the finished floor is installed. As a rule, after installation and fixation of the underfloor heating pipes, they are poured with a cement screed, on top of which a layer of hydro and vapor barrier is laid, and then - the final floor.

Despite the fact that experts recommend using several protective layers, both before and after installing a warm floor, many owners prefer to save on materials without using a reinforcing substrate.

In this case, pipes are laid directly on a rough concrete or wooden floor, which is also permissible when using roll waterproofing. To fix the pipeline in a stationary state, you can use plastic or metal clips.

Which way do we use?

For a long time, we have used the method of attaching a pipe to a reinforcing mesh. There were many reasons for this: price, lack of other offers and expensive delivery on order. Now we are bringing in anchor shackles and fixing the pipes with a tacker. This significantly speeds up the installation process. Difficulties usually arise when pipelines run at close range. The tucker does not pass between the pipes and our tucker often makes false positives. It is not yet known whether this is a feature of all tuckers or only ours.

Which option is better

At first, after the appearance of warm floors in our country, only the method of fastening to a reinforcing mesh was used for their arrangement. This was explained by its cheapness. In addition, in those days there were simply no other options, and it was very expensive to order components abroad. At the present time, the option of fastening with anchor brackets and tackers is very widespread.

Thanks to the use of new installation technologies, it takes much less time to equip home heating with warm floors. The most difficult thing is to implement those schemes in which the pipe loops are located almost end-to-end from each other. Tucker in such situations does not fit into a small gap between adjacent turns, which leads to its frequent false positives.

Alternative options for fixing underfloor heating

To fix warm floors, not only a bracket is used, but also other devices:

- Boss mats do not need additional fastening. They are easy to install and fix, and their thermal insulation qualities are above average;

- Masonry reinforcing nets for the pipeline are fixed with plastic and metal clamps. The design is distinguished by its reliability and increased strength;

- If the base is made of polystyrene, then the pipes are fixed with an anchor bracket;

- The concrete base requires perforated tapes during installation;

- Wooden floors are usually heated with pipes installed on wooden modules.

Boss mats

Advantages of using lug mats:

- You can make a concrete screed directly onto the mats without making a protective layer. Cement does not enter into chemical reactions with mats, on the surface of which there is a protective film;

- Ease of installation - modules are assembled with your own hands;

- Pipe fasteners are not required, the bosses on the plates themselves firmly fix the pipeline;

- The reverse side with a relief increases thermal insulation, noise protection, and also makes it possible to make the system on an uneven base.

Some polystyrene plates are supplied without bosses, but with markings for the heating circuit.

Reinforcing mesh

The concrete screed can be additionally reinforced with a reinforcing masonry mesh. The design becomes several times more durable. To do this, the mesh must be laid in a special sequence:

- Clamps made of plastic or silicone make fastening easy and simple, so the installation of the pipeline will end in a few steps. Connections of this type are very reliable and will not break;

- The use of wire limits the installation process - strong tension must not be allowed, since there are high risks of damage to the pipe;

- Iron clamp - a compromise between plastic clamps and wire. Iron fasteners are more expensive, but the installation process will be lengthy.

Having considered all the options, we can conclude that the installation of the water circuit pipeline is performed on a reinforcing mesh using plastic clamps.

Insulation on logs made of wood

The heating system for wooden flooring requires installation on wooden modules. Each module is placed on logs, so the water circuit is always on top of the insulation.

The pipes are fastened into special grooves, so the installer does not need to think about how to form the heating circuit - the distance between adjacent grooves has already been verified. Fixation and type of fastening are selected based on the base, which is located under the pipeline. It is important to take into account all the features so as not to complicate the installation processes.