A three-way valve (tee) is a special device that regulates the temperature of the water flow. It is used to redistribute the hot flow in the heating system. With its help, the operation of the entire mechanism is optimized, the prevention and prevention of hydraulic shocks.

The tee is used:

- hot water supply systems;

- in heating circuits;

- in plumbing systems.

As a rule, a device of this type is used for heating structures with several units and circuits in order to stabilize the temperature in all radiators. The use of such a product allows you to control the flow of hot water, distribute it to different areas (for example, a house, a summer kitchen, a garage) and regulate the temperature regime of each radiator located in any room.

The advantages of a three-way valve

The positive qualities of the device include:

- Compact size.

- High level of functionality.

- Easy to use and maintain.

- Good seal tightness.

- Long period of use.

- Low level of hydraulic resistance.

- Lack of stagnation zones.

- Easy installation.

- No daily maintenance required.

- Convenient and easy switching.

But, despite all the advantages, there are several disadvantages in his work.

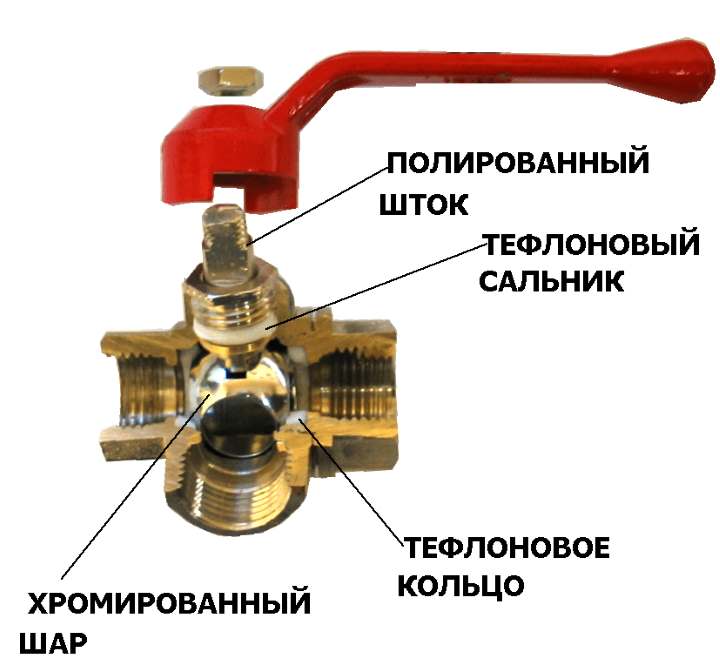

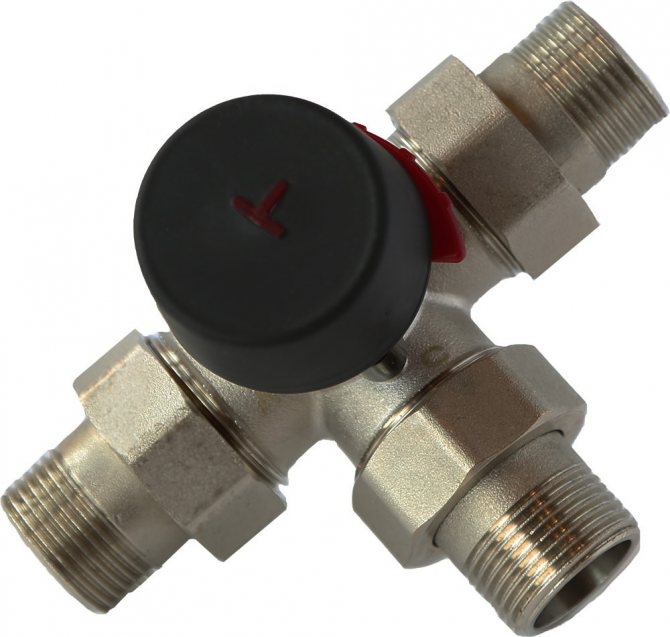

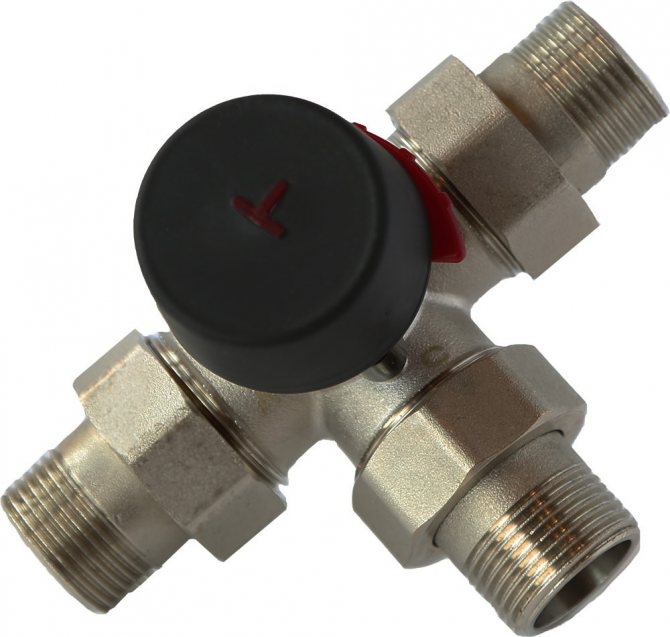

Crane construction

The design of the device in its shape resembles a tee with a T-shaped direction of the pipes. It is because of this feature that it is called "three-way valve" or as it is also called "tee".

The product includes several parts:

- Sealed body made of metal (cast iron, bronze, carbon steel or brass).

- Shutter with bores of different shapes.

- Three nozzles (holes):

- weekend;

- with hot water supply;

- with cold water supply.

The tee also has additional characteristics that are prescribed on its packaging. These include:

- Type of valve installed in the system (conical, cylindrical or ball).

- Fastening principle (flanged, pinned, sleeve, welded or socket-butt-end).

- Mechanics (landing) in the valve (tension or stuffing box).

- Control method (manual, actuator or electronic).

- Blanking valve shape (S, T, L).

- Completion with additional sensors or devices.

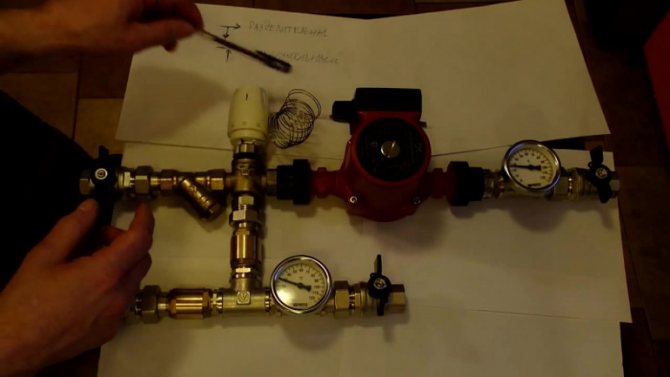

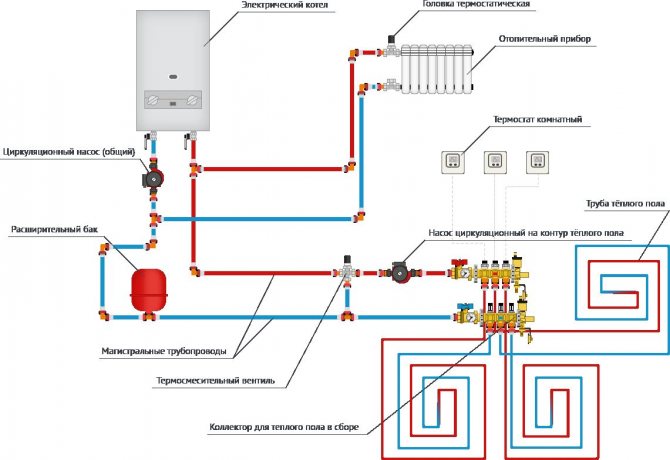

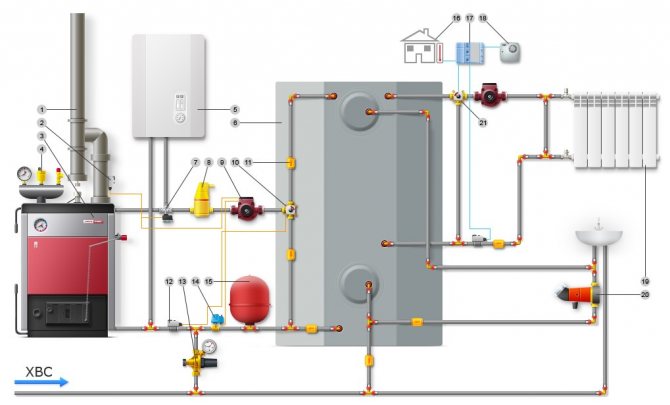

Scheme for connecting a three-way valve to the heating system

Three-way valve device

Structurally, it represents two connected two-way valves in one body. But unlike them, the hot water flow is not completely blocked, but the intensity of its passage is regulated. This changes the temperature of the hot water.

- Main valve parts:

- body;

- stem with lock washer or metal ball;

- fastening nuts (couplings).

Valves with stem make it possible to automate control by means of an electromechanical actuator. This allows the water temperature to be automatically adjusted. A ball valve can be compared in principle to a faucet in a kitchen. They are only used in manually operated valves.

Please note: when choosing a faucet, you should pay attention to the material from which the body is made. Brass is lighter and more durable than cast iron.

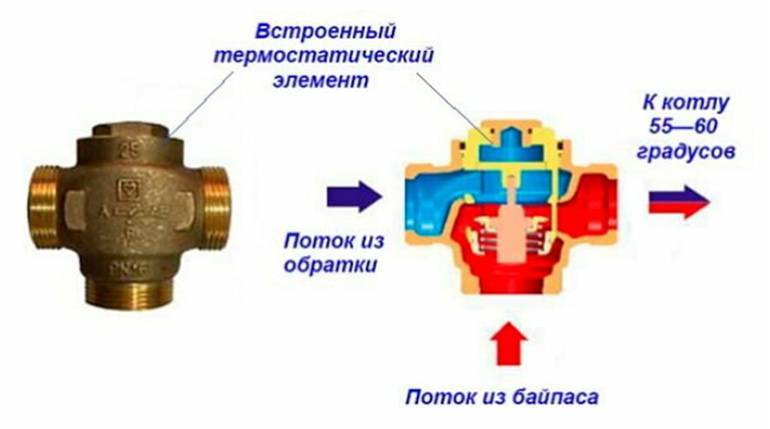

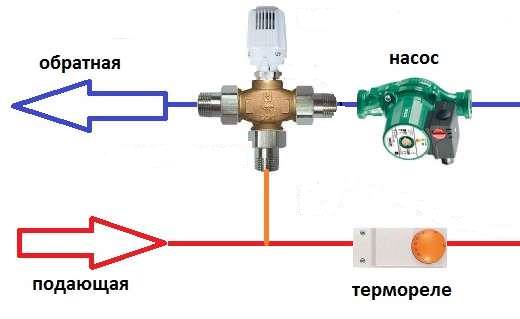

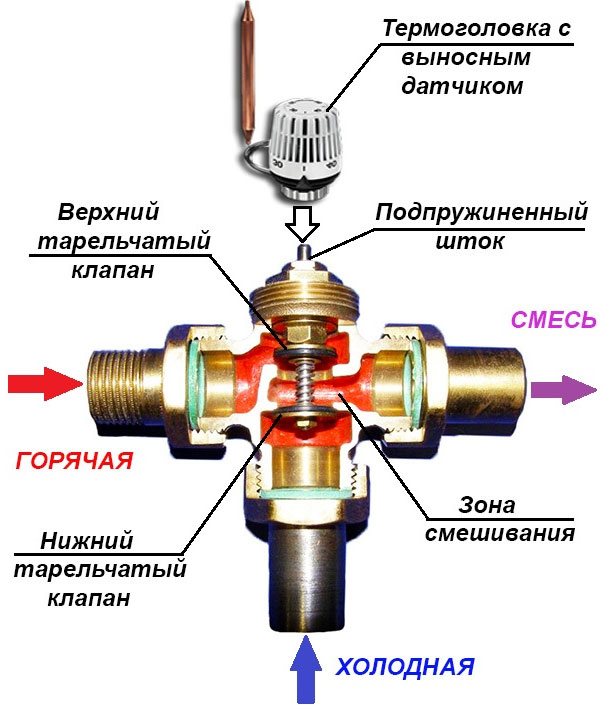

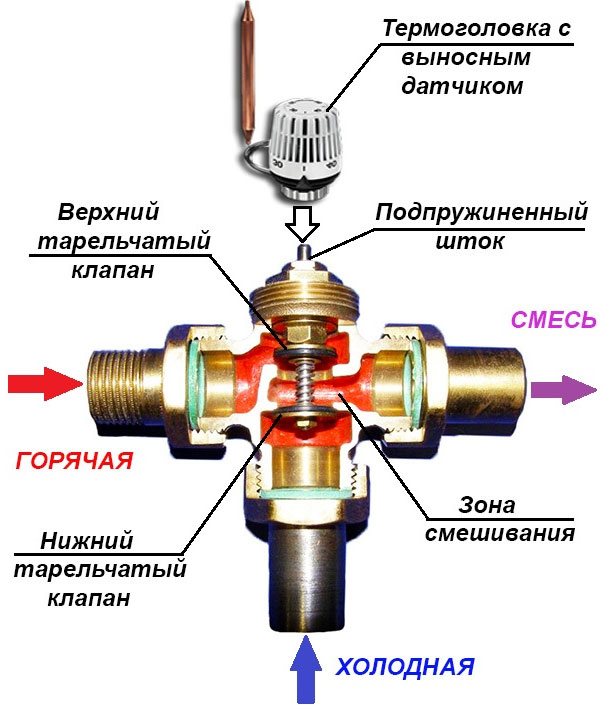

To understand what the three-way thermo-mixing valve of the most common saddle type consists of and how it works, you should study the diagram below.

Inside the brass body with three nozzles, 3 chambers are arranged by casting, the passages between which are blocked by poppet valves.They are fixed on one axis - a rod coming out of the body from the fourth side.

Views

- They differ in the way they are operated. It can be conditionally divided into valves:

- with manual control;

- with thermal head;

- with an electric drive;

- hydraulic;

- pneumatic.

In a private house, an electric valve will be the most acceptable. The sensors installed internally issue a command via the controller to the actuator if the monitored water parameters change.

As a result, it becomes warmer, or vice versa, cooler. The thermo-mixing effect occurs automatically. It does not matter which boiler is installed in the system - gas or solid fuel.

If it is not possible to install an adjustable valve in the heating system, then a valve with a thermal head will be the best solution in this case.

Operating principle

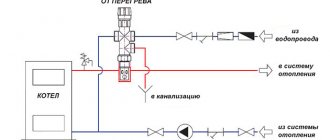

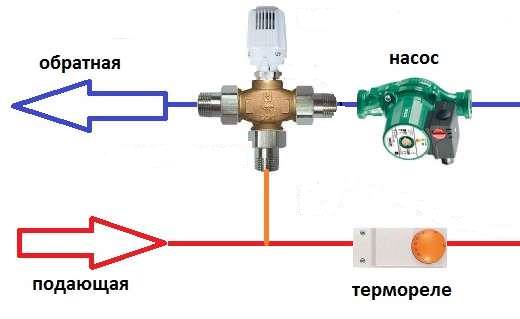

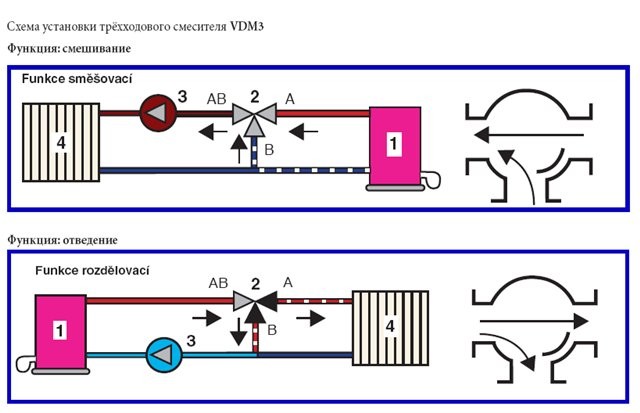

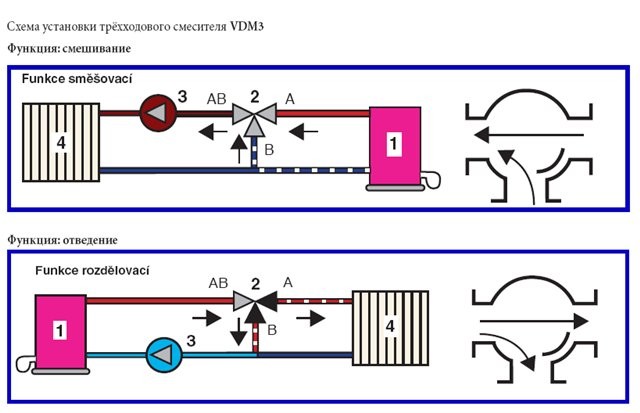

For the product to work, cold and hot streams of water must be connected to it at the same time. The installation diagram itself is presented in the form of arrows indicating the direction of flows. The hot water flow acts as a heat carrier (supply that comes from the boiler), and the cold one acts as a return flow.

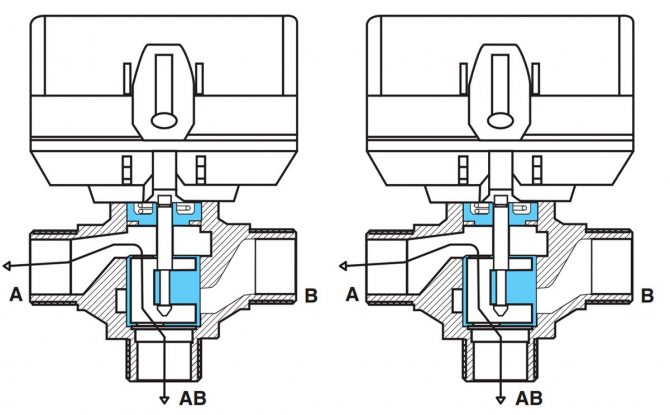

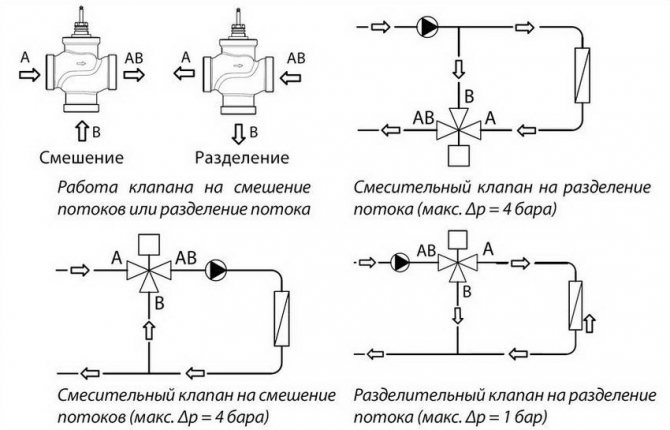

A valve is installed between the nozzles of the tap, which regulates so that water is supplied to two out of three holes. According to the position of the installation and its connection, two functions are subdivided:

- mixing of streams of cold and hot water;

- division from one line to two outputs.

Depending on the position of the valve, the following situations are possible:

- the valve is half open - the outlet stream has an average water temperature;

- the valve is fully open - the hot stream comes directly from the boiler and the water has a maximum temperature;

- the valve is closed - only cold water flows into the outlet stream.

Important! The tee does not block the flows supplied to it, but only redirects water from one inlet to one of the outlets. At the same time, you can block either one of the outputs, or half of both.

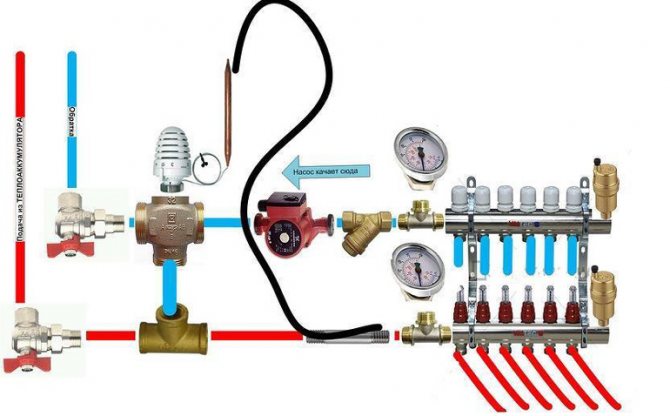

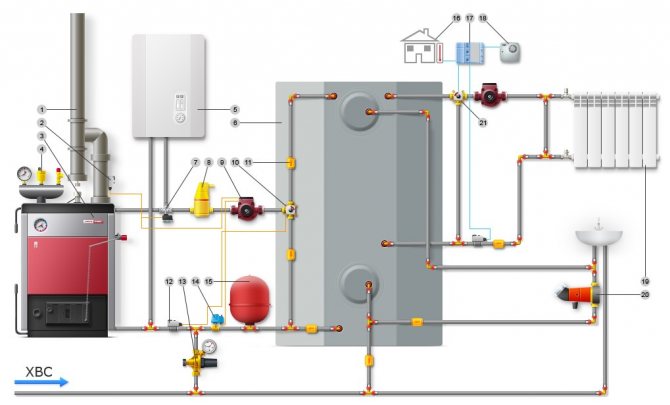

Heating circuit of a three-way valve with a boiler

Principle of operation

A three-way valve allows you to distribute the coolant to two independent lines, or mix two streams into one. This is achieved by using a valve installed between the inlet and two outlets. By changing the state of the valve, it is possible to achieve the distribution of the flow from the inlet to the two outlets in the required proportions. In addition, using a three-way valve, you can direct the entire flow to one outlet, completely blocking the second.

Such a scheme makes it possible to mix hot water from the boiler to the return flow. By adjusting the valve position, the temperature can be adjusted without having to change the boiler settings. Thus, it is possible to create an optimal operating mode of heating equipment and maintain the ability to control the heating temperature of heating radiators. Along the way, this leads to significant energy savings.

If there is a single circulation pump in the system, it is placed on the return line between the boiler and the three-way valve. Such a connection makes it possible to operate the heating system in three modes:

- maximum power when the heated water is fully supplied to the radiators. The coolant from the inlet pipe of the three-way valve is directed to the pipe going to the radiators. The outlet to the return is blocked;

- combined mode. A three-way valve distributes the hot coolant between the heating main and the outlet to the return. In this case, it becomes possible to smoothly control the heating temperature of the radiators;

- recirculation. The branch pipe to the heating line is closed, the entire flow is immediately directed to the return line. This mode is used when it is necessary to temporarily turn off the heating without turning off the boiler.

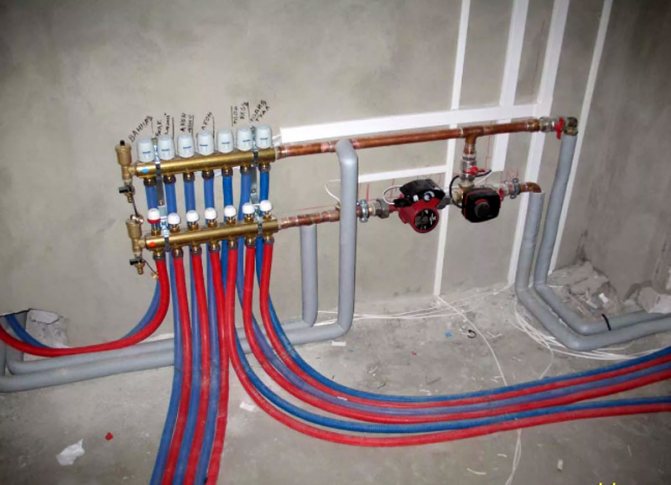

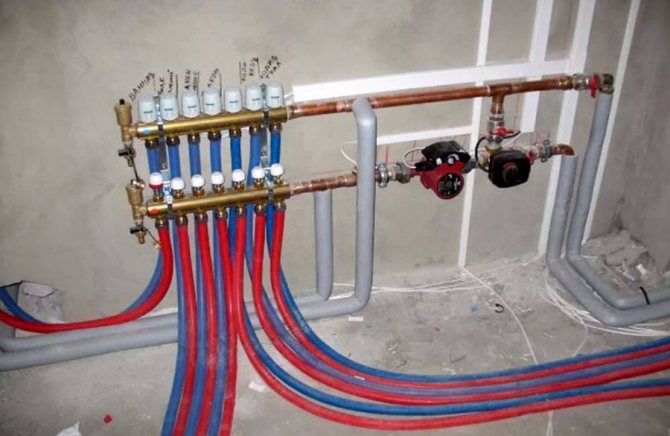

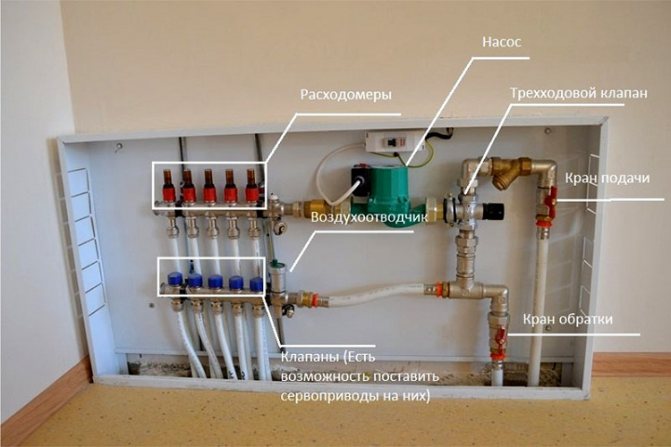

The possibilities of three-way valves are used when organizing heating with warm floors. The maximum temperature in the underfloor heating circuit cannot exceed 35C. In a radiator system, the temperature can reach 60C or more.

A three-way valve in the case of underfloor heating allows you to redirect the main flow of the coolant to the return flow or to the radiator system. At the same time, in the underfloor heating circuit, the duct is significantly reduced, not allowing it to heat up above a predetermined level.

Varieties of cranes

Product classification according to various criteria:

- Depending on the valve, a distinction is made between:

- Regulatory.It is equipped with an electromechanical device that opens the required valves. It also includes a stock with manual or automatic adjustment. Important!The stem cannot be knocked out even by the strongest water pressure, since it is located inside the device.

- Shut-off. In his build there is a ball device that switches the flow of water. The peculiarity of this device is that it is installed on systems with low pressure. It is very simple in design, requires constant maintenance and wears out quickly.

- By product material:

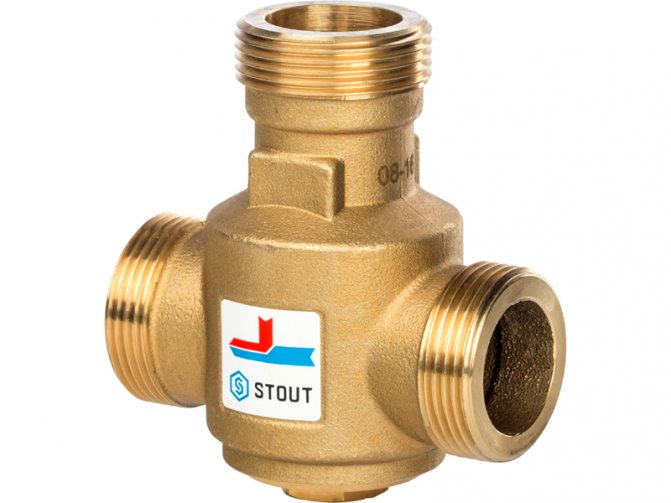

- Brass- the most demanded material, due to a long period of operation, small dimensions and low weight.

- Carbon steel Is a great alternative to brass.

- Cast iron - used for pipes of large diameter (from 40 mm and more). It is not practical for private houses.

- Bronze - material with a long period of operation.

- Depending on the installation method:

- coupling;

- flanged;

- tsapkovy;

- for welding;

- nipple-end.

- For the heating system, such types are used as:

- With constant hydraulics- regulated in accordance with quality indicators. It is suitable for consumers with high-quality heat transfer fluids of a certain volume.

- Variable hydraulics - regulated according to the required amount of water. It is more suitable for those for whom quantity matters.

- From the variant of the flow part of the device:

- trial and drain;

- full bore.

- Built-in shutter type:

- conical;

- cylindrical;

- ball.

- By the shape of the plug valve, the following types are distinguished:

- T-shaped;

- L-shaped;

- S-shaped.

- From the mechanics of the gate element:

- Stuffing box- controls the adjustment of the water jet from the top of the armature due to the gland;

- Stretch - controls the adjustment of the water jet from the bottom of the armature by means of the nut.

- Depending on the housing heating:

- heated;

- without heating.

- Depending on the technical parameters, such valves are distinguished:

- T-shaped- the adjusting knob can be in 4 positions;

- L-shaped - the adjustment knob has two modes, including a 180 degree rotation angle.

- From the device control mechanism:

- Manual- connects water flows in approximate proportions, cheap, looks like a standard ball valve;

- Electric drive - for work, additional equipment is used, a motor or a magnetic method, there is a possibility of getting a shock from the current;

- Pneumatic actuator - the most optimal option for use. Important! With the electric drive, you can easily balance the heat so that the temperature level in the rooms farther from the boiler is the same as in the neighboring ones.

general information

Three Way Valve Details

- Metal body

- Pass-through valve

- Three pipes. Two for cold and hot water, the third for the outlet of the heated heating liquid.

How does a three-way valve work in a heating system

Pipes with liquids from the heating boiler and return are connected to the three-way mixer. The angle of rotation of the lever or valve on the control valve determines what temperature the liquid will flow through it.

- The shutter is open - the degree of heating of the heat carrier is identical to the heating level in the boiler

- The tap is closed - water from the return (cooled) goes to the batteries

Any other position of the tap allows the water to mix. Thus, the temperature of the liquid in the heating line is monitored.

Types of distribution valves

Plumbing outlets have a huge selection of fittings of this type of different models. To choose the required model of a three-way valve for heating, you need to know: the features of the product, its structure, to see the differences between the devices.

Product models without external differences, all have three nozzles, but the functions they perform differ radically

- Mixing valve (adjusting). It makes it possible to mix liquid from two pipes. The connection is made to 2 pipes, and the output is done one at a time. The product is equipped with a valve stem

- Distribution valve (shut-off). Divides liquid from one line into two streams. The valves are mounted in branch pipes. When one valve is opened, the second one closes. The liquid enters the tap through one line, and the exit is made through two. Products of this type are installed to maintain optimal temperature conditions in several rooms.

Product body

Brass is a durable, resistant to mechanical damage, alloy without temperature limitations. Service life up to 50 years.- Steel - increased strength (lower than brass alloy), long service life

- Cast iron - installed in industrial systems, on pipes with a diameter of 4 cm.

Installation methods

- Coupling connection

- With flanges

- Welding method

Gate

- Tension

- Stuffing box.

Product type

- Ball

- Conical

- Cylindrical

Control

Household three-way taps for the heating system are equipped with different controls.

- Mechanical control. The valve is equipped with pivoting levers that regulate the fluid flow. Changing the position of the handle creates a difference in the volume of fluid coming from different sources. The disadvantage of a mechanical product is a long and uneven heating of the system.

- Automatic control. The automatic product maintains the set temperature without human influence. The installation of an automatic crane guarantees high-quality and uniform heating. A functioning system does not need constant monitoring.

The three-way valve is equipped with servo-controlled, hydrodynamic or pneumatic thermostats.

Electric heating tee

Servo control element - electric motor. ECU signals the servo drive about exceeding the set parameter, the motor changes the position of the ball or rod. The electrical unit measures the degree of heating of the medium at the exit from the regulator or by heating the return and liquid from the boiler, optimizes the setting.

Three-way valve for heating with thermostat

There is a gas or a special liquid in the distributor's thermal head, they respond to an increase and decrease in the temperature regime in the external environment, their volume changes, the valve reacts to changes automatically.

When installing the product, its conscientious and careful adjustment is required. At the finishing positions of the lever, the maximum and minimum allowable temperatures are set. This creates a range of work, within which the model with a thermal regulator, for the heating main, corrects the heating of the fluid in the system. For this, a mechanical pressure correction in the valve is carried out.

The liquid will flow through the tee as many times as it takes to reach the set temperature. If the temperature indicator crosses the set limits, the mixing ratio of water (DHW and cold water) in the device will change.

The main advantage of the thermally controlled model is that an ECU is not required for its operation. The crane performs its functions offline and has a loyal price.

Tap selection

To buy the right tee you should:

- Measure the diameter of the main pipe on which the device will be installed. As a rule, it is in the range of 20-40 mm. If a different size is required, purchase the appropriate adapter additionally.

- Find out the capacity of the pipeline through the heating circuits. To do this, you need to calculate how much water each pipe can pass through itself for a certain period of time.

- Find out if it is possible to connect a servo to enable the device to operate in automatic mode. This option is especially relevant for underfloor heating.

- Pay attention to other indicatorsthat were considered in the product classification.

If you cannot cope on your own, seek help from consultants.

When welding during installation, do not allow the temperature flow at the joints to be more than 100 degrees

How to choose a crane

For the correct choice of intake fittings, it is necessary to take into account, first of all, its throughput. The crane must be selected in such a way that it provides this figure with a slight overlap.

In this case, you need to pay attention to the correspondence of the connecting dimensions of the product and the section of the pipe. If they are different, the connection must be made using adapters.

https://www.youtube.com/watch?v=5rIediSZf70

Pay attention to the possibility of using servo drives, which greatly simplifies the setup and subsequent control of the heating system.

Features of installation and operation

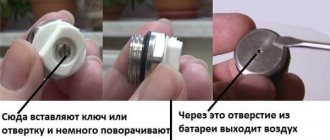

For the correct installation of a three-way valve, you should know a few features:

- Be guided by the diagram of the arrows shown on the body. They indicate in which direction the water flow is moving.

- When welding during installation, do not allow the temperature flux at the joints to be more than 100 degrees. Make sure that dirt and scale do not get inside the device during welding.

- Choose such a place for installation, which can be easily reached if necessary.

- If the crane will work with a low-quality coolant, you will need to additionally install filters.

- You can screw the product vertically, and horizontally - this will not affect its performance.

- The valve is installed in the heating system in front of the circulation pump.

The operation of the device must be observed in accordance with the rules established in the instructions. And all parts require periodic inspection and maintenance.

Correct and correct use of the device will prolong the period of its operation and will serve properly.

Blitz Tips

- Before starting the heating system, you need to check the serviceability and the condition of the three-way valve and the entire heating system.

- Do not install a faucet for pipes with a diameter of more than 40 mm.

- In a hot environment, you need to open the tap very carefully.to avoid hydraulic valve failure.

- It is important that the stem together with the adjusting device or by the turn handle they went out towards free access to them.

- Better to buy a faucet made of brass. It will last a little longer than other materials.

- The most optimal option - crane with pneumatic control of work.

- To avoid mistakes, consult a specialist in advance.