Reinforced-plastic pipes are capturing an ever larger segment of the plumbing market, so the issue of their maintenance is becoming more urgent. It is believed that if it is necessary to replace such pipes, the entire pipeline must be changed. But this opinion is wrong.

Products are easy to cut and change in parts without harm to the general water supply or heating system. Below is how to properly cut metal-plastic pipes.

Cutting methods

There are several basic cutting methods, which directly depend on the tool used. First of all, you can cut products:

- Knife for efficient cutting of reinforced plastic pipes. The knife in this case should be used self-sharpening.

- A hacksaw for metal. The simplest method, which, however, will require a lot of effort and time from the performer. In addition, the edges can be torn.

- Scissors.

- Pipe cutter.

With some tools, the cut edges are quite uneven and material particles can subsequently cause blockages. The best way is to use special scissors, which cut straight off without leaving torn edges. These scissors can cut objects up to 40 mm in diameter.

Important! In this case, you will not have to make any special efforts, since the tool is specially designed for such work and has special blades. These blades can easily cut through plastic pipes anywhere.

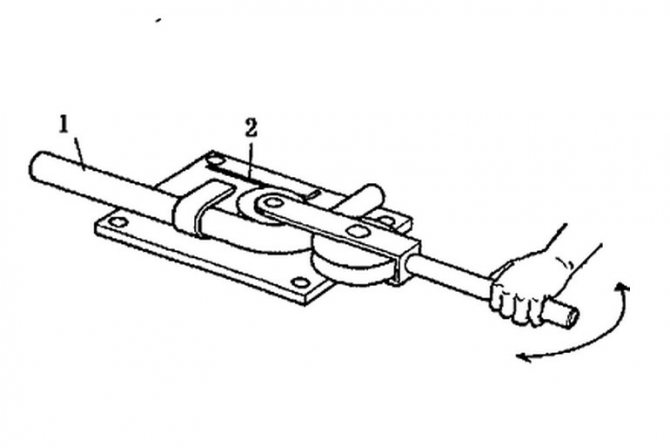

For products with a larger diameter, it is better to choose a pipe cutter. Pipe cutters are telescopic and ratchet. The first type is based on the work of a special roller that rolls along the entire circumference. The second type is more like a scissor, as it uses a lever system with two handles.

Advantages of manual and electric pipe cutters

The tool for cutting metal-plastic pipes can be of 2 types:

- manual;

- electric.

The manual pipe cutter works with the muscle strength of the person using it. It can be used in any conditions, there is no connection to the presence of a power supply, there are no restrictions on the operating time depending on the capacity of the battery and other inconveniences associated with using a power tool.

However, no one will argue that with large volumes of work, hand tools may not be enough. This is especially true for thick-walled large-diameter metal-plastic pipes. Of course, in construction at the household level, such materials are rare, but for a professional plumber, this is a very real situation.

The tool saves the time and effort of the employee. In addition, the human factor is excluded, when "did not hit", "did not check" or the eye failed

The battery-powered electric pipe cutter is a real rescue in industrial-scale cutting. In the case of a power tool, a person only puts a mark where the cut should be made, then fixes the part so that the mark on the pipe and in the pipe cutter window coincides as accurately as possible, then turns on the power and gets a neat, perfectly even cut.

Of course, it's not just convenience. The cost of a cordless pipe cutter for metal-plastic pipes exceeds the cost of a hand tool at times.No one wants to overpay, unless, of course, you will use the device in professional activities almost every day.

How to cut metal-plastic pipes

Reinforced-plastic pipes have a number of advantages over their competitors. They are much lighter than metal and much more resistant to oxidation than copper. They are easy to replace and easy to shape.

You can create piping of any shape. Well, the main advantage is cost. It is much lower than that of copper pipes. And the quality is at about the same level.

During operation, it may be necessary to cut pipes. For this, a special tool is used that is designed to work with such a material.

To improve the effectiveness of the procedure, it is recommended to properly prepare the pipe and tools before work. Let's consider the main features of metal-plastic pipes and how to cut them.

Preparing the pipe and the necessary tools

The cutting device itself, measuring tapes, adjustable wrenches, seals and some other things are used as tools. All this should be in an accessible place at the time of work.

Sometimes it is necessary to strip the outside of the reinforced covering to facilitate the cutting process in the next step. For stripping, a clutch with blades is used, which allows you to get a perfectly smooth cut and get rid of the polymer layer. This is necessary for welding work, which is likely to be carried out during the installation of the pipeline.

Important! When working, it is necessary to cut off exactly as much material as is needed for the fitting of a fitting for metal-plastic products.

Selection principles

Before buying a cutter, you need to decide what to cut the reinforced plastic pipe. If you need to make several single cuts, you do not need to buy expensive tools, you can use a hacksaw or a grinder for this. To collect the pipeline throughout the house, you will need a pipe cutter.

Selection recommendations:

- In order not to stop working due to dull rollers or blades, you need to choose a complete set with additional working parts.

- When purchasing tools, consider the diameter of the tube to be cut.

- For ease of installation work, you can choose a cutter with the ability to chamfer.

Advantages and disadvantages

Positive sides:

- high accuracy of cuts without distortions;

- lack of irregularities, burrs;

- noiselessness;

- no debris.

The disadvantages of pipe cutters include their high price, which depends on the maximum diameter.

Various types of pipe cutters (Photo: Instagram / sansvar)

Manufacturers and cost

The price of tools depends on the quality, the availability of additional mechanisms, the maximum diameter of cutting the tubes. Manufacturers:

- STURM - the products of this company are suitable for beginners and amateurs. The average price is from 400 to 500 rubles.

- WMT is a company that makes budget cutters. The average price is 300 rubles.

- RIDGID, KALDE, Milwaukee are professional tool makers. The average price is 3000 rubles.

In hardware stores, in the markets, you can find cutters costing 200-300 rubles.

Tools for cutting metal-plastic pipes

In the process of cutting pipes, the following tools come in handy:

It is important for the master to determine in advance what he will use to cut metal-plastic pipes. The most important tool on the list is the scissors. Everything else is necessary for carrying out special preparatory work.

The cutting process does not require much effort. It is enough just to fully control every movement. If you don't pay enough attention to control, you can easily cut off the excess part.

If during the cutting process it is necessary to bend the product, it is not recommended to do it by hand.This can easily ruin the aluminum layer inside. It is better to take a professional pipe bender and perform the operation with it.

Using inappropriate tools in a single area can affect the entire network, resulting in high repair costs.

Important! Special scissors are usually found in the welding kit. But they can be purchased separately. The price of this tool is not high enough to save money on it.

Before proceeding directly to cutting, it is necessary to very clearly measure out the part where the unit will be divided. For this, a tape measure or ruler is used, as well as a bright marker. A faded pencil can simply not be seen, especially if there is not enough lighting in the room. The mark can be made with a knife, leaving a scratch.

During operation, pieces of plastic and aluminum can fly in different directions. Therefore, it is necessary to use protective equipment in the form of glasses and special clothing.

Top models on the instrument market

In the toolbox in the garage of the home craftsman, the most common pipe cutter-scissors for metal-plastic pipes.

In order not to rack your brains, understanding all the variety of tools in construction departments, it is better to immediately familiarize yourself with the rating of popular high-quality models of different price categories and make a choice based on the experience of other buyers.

Budget tools for home use

Among the inexpensive equipment for cutting pipes, the most popular are pipe cutters of the Sturm and WMT brands.

Practical equipment from the Sturm brand

Sturm is an inexpensive and practical option for home use. The device is equipped with a hardened steel blade. The metal parts are coated with a corrosion protection agent.

Cheap does not mean poor quality. Yes, budget models of pipe cutters do not have all the advantages of professional equipment, but they perform their main function

The handle is made of comfortable plastic with a non-slip surface. The cost of a pipe cutter from Sturm ranges from 400-450 rubles.

A short video review of the pipe cutter of this brand in the following video:

Inexpensive solution from WMT

Another budget pipe cutter is produced by WMT. This tool will cost you no more than 300 rubles.

For that kind of money, you don't have to count on additional functionality and other pleasant little things, but the device copes with its work within reasonable limits. It cuts metal-plastic pipes up to 42 mm.

Review of a budget model for minimal money:

Professional pipe cutting equipment

Among the professional tools, models of the brands RIDGIT, Milwaukee and KALDE stand out with good reviews.

Popular RIDGIT pipe cutters among users

RIDGIT is one of the market leaders in pipe cutting tools. This manufacturer offers professional equipment that can work in any conditions. RIDGIT PC 1375 ML is one of the most popular models of this brand.

Lightweight (only 320g) steel body and robust cutter cuts the pipe in just a few seconds. A wide range of working diameters (up to 42 mm) allows you to work with the most popular pipe sizes. The cost of RIDGIT PC 1375 ML starts at 3600 rubles.

Any experienced builder will tell the difference between a professional tool and an “amateur” one, just by holding it in his hands. And you don't have to know brands for that. If the item is of high quality, it speaks for itself.

Another popular model from RIDGIT is the TC-40. This is an automatic pipe cutter. It is equipped with a 0.75 kW motor and a 12 V lithium battery. The device can easily handle pipes from 3 to 42 mm, just press a button.

There is such a nice addition as a backlight for working in low-light places.Since the multilayer metal-plastic pipe, the manufacturer took care of a special adapter for this type of materials. The price of an automatic tool is from 18,000 rubles.

Reliable Milwaukee models

The professional Milwaukee tool from the USA is a guarantee of high quality and reliable performance for many years of service.

The Milwaukee ProPEX Tubing Cutter is a small diameter pipe cutter up to 25mm. It is made of durable steel that does not corrode. The comfortable handle has a high level of ergonomics. But the price for a high-quality pipe cutter is also appropriate - from 2300 rubles.

Wide range of KALDE pipe cutters

The Turkish brand KALDE offers a wide range of metal-plastic pipe shears. For example, KALDE (40-63) is a model for cutting large diameter pipes - from 40 to 63 mm. The blades are very well sharpened, the tool does not bend metal-plastic pipes, does not bite the edges and does not leave chips.

All KALDE products are manufactured in accordance with European quality standards. The price for a specific model in stores is about 4300 rubles.

Cutting technique

Self-cutting can be carried out with products with a diameter of 5 to 30 cm. So, if the product does not fall within these limits, it is best to turn to professionals.

When carrying out any such manipulations, it is important to remember the basic rules:

- Reinforced plastic products are very sensitive to temperature, so some problems may arise in hot or cold weather. The material shrinks and expands easily, making it difficult to determine the true dimensions.

- Metal-plastic pipes, like polypropylene pipes, can be cut by any means at hand. But in order to avoid various negative consequences, it is best to do this with special tools.

- A special self-sharpening knife is an excellent tool. But if it is planned to carry out work to replace one section with another, it is better to abandon the tool in favor of scissors.

- The material is quite fragile. Applying too much force is fraught with cracks or specific deformations. The permissible load can be seen in the product passport, which was issued at the time of installation of the water supply system.

- The type of cutting directly depends on the proportion of metal and plastic in the product. If there is more metal, then there should be as little friction as possible when cutting. Otherwise, a large proportion of plastic implies a high intensity of work with high friction.

- Before starting work, it is imperative to make sure that water or gas does not flow through the pipe. You need to turn off all the taps and wait a little.

- After completing the work, you need to properly clean the inside of debris that can lead to blockages or break specialized equipment.

The use of electronic cutting tools is not considered reasonable as the material is not designed for this. You can do it by hand.

Methods for joining metal-plastic pipes

The fitting connection (without welding) is made in two ways:

- Detachable - using compression or collet connectors.

- One-piece - using press or push fittings.

Compression fittings

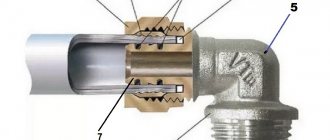

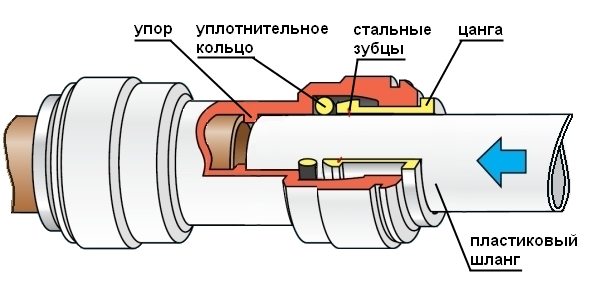

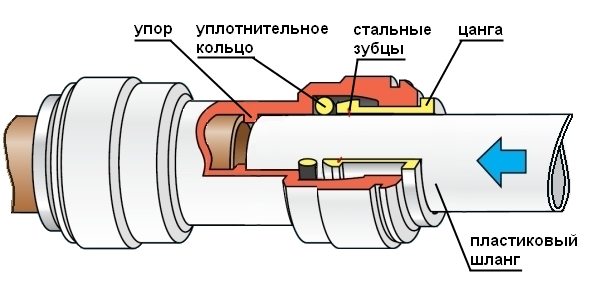

The simplest are compression or crimp fittings. They consist of a threaded body (collet), a crimped outer nut, a thrust ring, and rubber lip seals. Sometimes, instead of a thread, an American union nut is installed on the body.

By design, there are straight, angled, tees. Functionally, there are connecting or transitional ones between plastic and metal shut-off valves.

The compression fitting forms a reliable connection, but it must be inspected and tightened at least once a year - the connection is considered serviceable. If necessary, the connection can be disassembled and reassembled - this is very convenient for repairs.Compression joints are not used for underfloor heating systems and for plasterboard sewing.

Push fittings

A modern fitting that can be tightened without the aid of tools It forms a non-separable, but not the most reliable connection - the pipe turns in the connection. Push-fitting is quite expensive, and before using it, you should think about whether it is worth the expense.

Press fittings

Press connectors consist of a body with an inner liner, a thrust ring, an outer press sleeve, and sealing collars. During crimping, the press sleeve tightly crimps the pipe blank and creates a permanent and very reliable connection. The press connection is allowed to be used even for underfloor heating systems.

For polyethylene, push-in fittings are produced, in which the upper crimp sleeve is not screwed on, but pushed in, and the inner liner-fitting is equipped with a "ruff", which forms a very reliable tight connection.

Push-in fittings

Collet fittings are made of low-pressure polyethylene and are used to connect HDPE products. They are structurally the same as compression connectors, but are much larger and look rather bulky. The connection is quite reliable.

Straight, angular, tees are distinguished by shape. Functionally - connecting, reducing (for connecting pipes of different diameters), transitional (for connecting plastic with metal fittings).

Which way is better

The choice of the connection method depends on the polymer from which the metal-plastic pipe is made and the operating conditions.

Polypropylene communications are often mounted using soldering - this is a completely sealed, reliable and very cheap method (couplings and corners for welded joints are inexpensive).

For very common plumbing from all types of polyethylene, compression, press and push fittings are used. Collet products are most often used for HDPE, although compression and press connections are also occasionally used.

After soldering, the most reliable connection method is with the help of press fittings, they can be used even for underfloor heating systems. Then there are compression fittings, then push fittings. The latter are positioned as a means for the rapid assembly of engineering systems without the use of tools, but the tube in the push-joint is rotated - this raises doubts about the reliability and durability of the joint.

The easiest installation method is with collet or push fittings.

The most expensive ones are push fittings. The cheapest are polypropylene couplings and welded tees.

In terms of aesthetics, steel connectors are more compact and more beautiful than bulky polyethylene collet products.

Briefly about the drainage system

The sewerage device is a description of all the components and the principle of operation of the system as a whole and for individual nodes. Subdivided into:

- Internal - located in the building.

- Outside - is laid outside the buildings.

Internal

Internal sewerage device:

- Plumbing fixtures (sources of dirty water formation): toilet bowl, bidet, washbasin (kitchen sink), bathtub (shower cabin), washing machine and dishwasher.

- Siphons and connection elements (transition couplings).

- Outlet pipes Ø 30-50mm. For toilet bowl 100mm.

- Transitional elements: fittings and couplings, check valve, revision.

- The main riser is an element that collects wastewater from all sources into one sewer pipe. The collector diameter should not be less than 100mm.

Installation of the sewerage system inside the premises is regulated by regulatory documents: SNiP (Sanitary Norms and Rules) 3.05.01–85 "Internal sanitary-technical systems".

Outdoor

The external system includes:

- Waste line from pipes Ø 100-200mm (for individual housing).

- Overflow (inspection) wells.

- Couplings, fittings.

- Wastewater receiver (cesspool, septic tank, biological treatment station).

Installation of sewerage outside the building is regulated by SNiP 2.04.03–85 “Sewerage. External networks and facilities ".

Tool views by cutter type

Depending on the design of the cutting mechanism, the following types of pipe cutters for metal-plastic pipes are distinguished:

- roller (with one or more rollers);

- ratchet;

- guillotines;

- with a clamp latch.

The pipe cutter is usually made of durable metal - carbon steel or alloy steel. The handle can be made of plastic or rubberized.

Ratchet pipe cutter - scissors for metal plastic

The easiest way to cut a piece of metal-reinforced plastic is with special precision scissors. This pipe cutter is designed for a diameter of up to 100 mm. A sharpened steel blade acts as a cutting element. The pipe is inserted into a special holder - a semicircular metal holder. When the material is firmly in place, mark and cut.

The pipe cutter works on the principle of scissors: by closing the ends of the handle, you lower the cutting element and make an even, smooth cut. A special ratchet rack is responsible for the reverse motion of the blade. If it was not possible to cut at one time, it will not allow the knife to return to its original position, but will fix it to continue working. This significantly saves the energy of the employee.

The main advantage of this kind of tool is ease of use and low cost. He copes with the task perfectly, the cut is smooth, accurate. They can cut not only metal-plastic, but also polypropylene parts.

Due to the design features of the metal-plastic pipe at the end, the material can bend and lose its shape. For alignment, use a calibrator or perform a manual procedure.

If you plan to cut pipes only during repairs or laying wiring in the bathroom, it makes no sense to buy an expensive automatic device, precision ratchet scissors will do. Most likely, after finishing work on the installation of a plumbing or heating system, your pipe cutter will go to the box with the rest of the tools for a long time.

It's another matter if you need a pipe cutter for work. When working with scissors, the hand gets very tired, it is difficult to master a large volume at once alone. For professional use, it's best to look at other types of tools. In addition, such a model copes well with soft metal-plastic pipes, but it cannot be called universal. If you have to cut steel or copper, this option will not work.

Sophisticated and efficient roller pipe cutter

The metal-plastic pipe cutter is much more versatile. Depending on the diameter of the "C" -shaped cage and the number of rollers, there are models for cutting small pipes (up to 50 mm) and thicker (up to 125 mm). When working with large diameters, models with several rollers are used.

The principle of operation of a manual roller pipe cutter is that the part is clamped in a holder, the cutting element is located close to it. Inside the cage itself there are guide rollers. The worker rotates the pipe cutter around the axis, with each turn the cutter gets closer and closer to the center. Due to the fact that the blade rotates, and not just presses on the wall of the metal-plastic pipe, the cut is cleaner.

If the handle is equipped with a ratchet, this will exclude the possibility of "reverse", that is, loosening of the fixation during operation. This guarantees a straight, perpendicular cut

The advantage of this type of pipe cutter is that working with it does not require much effort on the part of the operator. Anyone who has at least once made blanks for the winter and worked with a seaming wrench can imagine in general terms how to work with a roller-type pipe cutter for metal-plastic pipes.

Of the main disadvantages, one can single out the fact that the cut is carried out in jerks.They lead to minimal displacement of the part in the cage, and this entails the appearance of burrs on the cut. After cutting, you will have to process sections of metal-plastic pipes. Expensive models have a smooth telescopic movement, which eliminates the appearance of irregularities.

Guillotine - uniform cutting of metal-plastic pipes

A guillotine is a tool that cuts evenly over the entire cross-sectional area. A pipe cutter with this operating principle ensures a square and clean cut without burrs. Uniform distribution of the load eliminates the possibility of deformation of the multilayer pipe during operation.

There are several ways to implement this idea. The most primitive and inexpensive option - the blade is lowered by rotating the handle and gradually lowering the stem. A more advanced model is in the form of a pistol. The guillotine is lowered when the operator pulls the trigger.

The guillotine cutter can handle pipes up to 100mm wide, but most models are limited to 7cm diameter. For domestic use, this is usually sufficient.

Model with a yoke latch for a secure fit

Another type of device for cutting metal-plastic pipes is a pipe cutter with a clamp latch. The principle of operation is similar to the roller model, the main difference is that the part is not simply clamped in the holder with a turn of the handle, but is fixed tightly on all sides.

Some models are equipped with a second handle, which is very convenient when working with large diameter pipes and thick walls

In this case, the cutting discs (usually 2 of them) are placed along the lower edge of the "C" -shaped holder. The main advantage of this type of instrument is its compactness. The design can be used even in places where there is not much to turn around, let alone rotate a volumetric pipe cutter.

Installation

The installation of an internal sewage system and an external highway is in many ways similar. The difference is in the materials used. For internal sewerage systems, gray painted collectors are used. The outer ones have an orange tint. This is due to the difference in external loads:

- Indoor products are affected by their own weight and, periodically, by the load from the flowing liquid. Thermal heating up to 60–90 ° C is added with a parallel chemical attack from the waste components.

- Parts located outside the building are exposed to:

- pressure from the mass of the covering soil;

- the effect of the weight of passing vehicles;

- experience efforts from buildings located on top;

- exposed to external temperature extremes, from negative to positive.

Hence, the installation of the internal sewerage system is carried out with a predominance of polymeric materials:

- PVC (polyvinyl chloride). More precisely, unplasticized PVC (PVC – U).

- HDPE (low pressure polyethylene).

- PPR (polypropylene).

The most in demand are PVC products. Installation of internal collectors is carried out by joining the narrowed part of the pipe and the expanded one (socket). Additional elements are used, - fittings (transition couplings, tees, elbows with an angle of 45 ° and 90 °, bends).

Installation of sewer pipes is carried out with the obligatory observance of the angles of inclination:

- For collector Ø 50mm, the slope will be 2–3 cm per one running meter of length.

- For a product Ø 100mm, about 1–2 cm per 1 meter.

In the process of installation or repair work, there is a need to saw the plastic part. Polymers do not differ in high hardness and strength compared to metal products. Therefore, they are processed by most locksmith and mechanical tools. It is possible to cut a plastic pipe by:

- hacksaws for metal or with a small hardened tooth;

- triangular file;

- jigsaw (for diameters not exceeding 50mm);

- circular or reciprocating saw;

- grinder and other tools.

Installation of sewage systems is carried out according to the rules based on the requirements of SP 30.13330.2012. In addition to observing the slopes, it is necessary to correctly distribute the points of attachments and connections. If technically possible, it is recommended to carry out hidden wiring.

Installation of sewer pipes indoors begins:

- with drawing up a work plan;

- performing a sketch or drawing;

- determining the required dimensions of the collector;

- preparation of the necessary material;

- preparation of a tool with which you can cut a plastic part.

At the end of the stage of installation work, the internal sewerage device is checked visually. Further, it is necessary to spill the system with water in order to identify possible product defects or the presence of leaks.

Fitting

The connection of metal-plastic pipes with metal ones takes place using special devices called fittings. They may have different configuration and provide fastening, both in a linear plane and at an angle of 90 degrees. Compression fittings (for clamping) are the most popular with craftsmen. Press fittings (for pressing) are also very often used.

Pressing in and connecting the plastic to the clamping fitting takes place by screwing in the union nut. In press fittings pressing takes place by compressing the outer sleeve, and is done with a special tool.

The fitting design is very simple. The fitting consists only of a ring, nut and union. You don't need any special tools or experience to work with these compounds. All work is done with a simple wrench.

The advantage of these fittings is that, with the simplest installation, they are also very easy to disassemble. But, their disassembly is undesirable, since in this case it is imperative to replace the gasket, but at the same time this advantage of the fittings, which consists in the possibility of their dismantling, can be used, since today it is possible to pick up any gasket without much difficulty.

Fittings are used not only for laying water supply systems, but for their repair. If found defect in any part of the water supply, then it is simply removed, changing to a new section, which is attached using the same fittings. This approach avoids dismantling the entire plumbing system.

Damaged thread size should not be more than 10% of the total length... The ends of the fittings must certainly be flat and perpendicular to the axis of the product itself. Burrs are not allowed on the threads.

Taking into account the connection option, fittings are divided into compression and screw fittings.

Tightness, when using screw connections, is ensured by pressure, appearing on the expansion ring when screwing in the nut... To create a strong connection between the fitting and the ferrule, a special gasket is installed.

Fastening metal-plastic pipes with metal using compression fittings

Before connecting the pipe to the fitting, its end must be cut so that the cut is perpendicular to the pipe axis. It is advisable to use a special pipe cutter for this.

But this procedure can be done quite successfully with a hacksaw for metal, but make sure that there were no chipping or rags around the edge... The cut will be cleaner when you place a new blade on a hacksaw. A jigsaw is not suitable for cutting, it will not provide such accuracy.

When preparing to perform work, you need to take into account one nuance. European products in the field of pipe production do not have uniform standards, therefore the sizes of parts from different manufacturers may be incompatible. therefore it is necessary to strive for pipes and fittings to be of the same manufacturer... If this is not possible, then when going to buy fittings, you need to take a piece of pipe with you in order to compare the wall thickness and dimensions. In addition, you need to know that there are one-piece fittings on the market.

Before attaching the pipe to the fitting, its cut end must be machined and leveled, as well as a shallow chamfer to smoothly connect the pipe and the fitting. Burrs are always removed from the inside of the pipe. After that, a ring and a nut are put on the pipe... Only then can the pipe be pushed onto the fitting. The nut is put on only by hand, without the help of a key. For a certain time, the nut will tighten easily if there is no distortion. At the end, it must be tightened with a wrench, while remembering that the pipe is made of plastic, as a result of this, the press must be made quite soft.

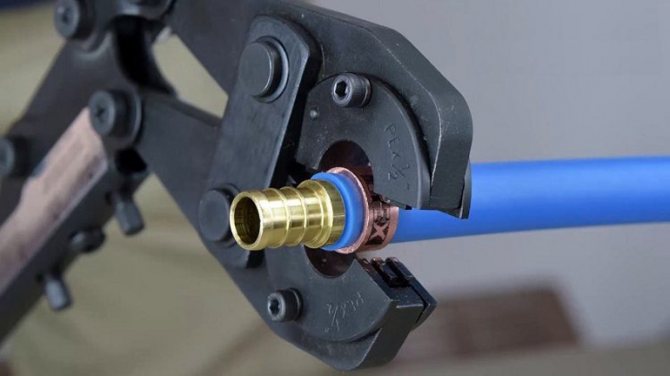

Fastening metal-plastic pipes using press fittings

Press fittings are made very often. This makes it possible to install underfloor heating, water supply and heating systems. The advantages of this type of connection are that this plumbing can be installed under concrete or drywall, and in the fact that the amount of used fittings is reduced, which reduces the cost of plumbing.

Fastening with press fittings includes the following work:

- a part of the pipe of the required size is cut off;

- using a calibrator, a chamfer is removed inside and the roundness, deformed during cutting, is restored;

- a clamping sleeve is installed at the end of the pipe;

- the fitting of the fitting with sealing rubber rings is attached;

- with the help of press tongs, the coupling is clamped, as a result, convex rings appear on the coupling, and the metal bends.

It must be remembered that the clamping of the coupling with the press pliers is done only once.

Fastening with sliding sleeves

In this version, for work, there will be press tongs and expander required, it serves to expand the hole inside the pipe.

During the process, the following sequence of work is observed:

- the part of the pipe is cut off where the coupling is put on;

- the end of the pipe is processed with an expander;

- the pipe is placed on the fitting;

- Pressing tongs the coupling is pressed onto the fitting.

How to choose a press pliers

Since pressing tongs are an important tool, choosing them correctly will ensure the proper quality of all installation work. Most pipe fitting tool manufacturers make both professional and standard types of this equipment:

- Electrical;

- Hydraulic and so on.

For a one-time laying of a water supply system, it is quite enough to choose manual press tongs, since a professional tool will cost you much more, and when working with this tool, you need to have certain skills and special skills.

According to experts, in terms of the quality of the fasteners made, manual press tongs are no worse than a professional tool. They are very easy to operate and work with them is not particularly difficult.

Before buying a press tongs, you need to find out the maximum cross-section of pipes that will be installed in the water supply system, and taking this parameter into account, choose the right tool. You need to know that for fastening pipes with a smaller cross-section additional tabs must be attached to the press jaws.

The main mistakes when attaching plastic pipes

As we said above, the connection and laying of metal-plastic pipes is a fairly simple procedure that can be done by any home craftsman, even if he does not have much experience in this area. Wherein knowledge of basic mistakes, which are allowed when performing these works, will make it possible to ensure the reliability of the installed water supply system.

The main mistakes are:

- poor processing of the trimmed part, is fraught with poor tightness of the installed system;

- an attempt to exhaust the coil of a cold pipe, this can violate the integrity of the walls;

- multiple assembly and disassembly of threaded fasteners without replacing the seal gaskets;

- pinching the thread connections, which leads to its deformation;

- an attempt to repeatedly clamp the fastener, which leads to a violation of the integrity.

Outdoor system installation

Installation of sewage from plastic pipes outside the building is carried out, in most cases, inside an earthen trench. This is due to:

- the need to protect the plastic sewer structure from the effects of negative temperatures;

- rational use of the surface of the earthen plot; protection from possible mechanical damage.

Installation of sewerage systems outside the trench is carried out:

- in the presence of a high level of groundwater (wetland);

- rocky or frozen ground (permafrost);

- other technical restrictions.

Installation of sewer pipes on the site is carried out mainly in the warm season. This makes it easier to install sewer pipes - a more comfortable climate and the presence of thawed earth.

Outdoor products - red pipes, made of polymers. You can cut or trim parts in the same way as for indoor structures. Installation of sewer plastic pipes is carried out on its own or with the involvement of a third-party organization.

The way - how to cut the parts, when the installation of sewer pipes takes place indoors or outside the building, it is advisable to think over in advance, before starting work. Otherwise, the necessary device or tool may not be at hand, which will significantly complicate the process of installing the line.

Preparation

Let's get down to the main points of cutting and installing metal-plastic pipes. The first step is to find the right tool for the job and for this you need a calibrator, pipe bender, adjustable wrench and some kind of cloth. A metal-plastic pipe consists of a layer of plastic, aluminum underlay, which are soldered together using laser welding. The aluminum tube acts as a frame. The core of the metal-plastic pipe has a very smooth surface, but before starting to cut, it is better to clean the entire surface of the pipe from irregularities. In order to clean the surface of the pipe, you will need a coupling. This process will not take you long, but it is very important in the preparation of the cut.

Hacksaw

The first is a hacksaw. Having come with a pipe and a hacksaw to some object, they do this.

Straight edges are obtained. And when the pipe is inserted into the pipe, this rubber band bites from the edge, so the plumbers have to do an additional operation, namely, chamfering. This is done either with a knife, respectively, or the pipe simply rubs against the concrete, and a chamfer is obtained.

Why is this method good? It is a small tool, relatively small. Although we see that we have it quite large and long, and without protection, it cannot be moved. Well, if you want to round off the edges, you need a knife.

Required tools

The installation of a metal-plastic pipeline also implies the presence of certain tools:

A calibrator is required for flaring pipes after the cutting process.

- Cutting scissors. Scissors for cutting pipes are a necessary device, do not be stingy (although the price of such a tool varies from 570 to 15,000 rubles), purchase them without fail, otherwise you risk ruining the pipes. Using other tools for cutting, you can lead to the formation of irregularities, burrs, deformation of the protective layer of the pipe, which can lead to leaks later. The cost of repairing and installing new pipes will cost you more.

- The calibrator is another useful tool because after the cutting process the pipe becomes slightly concave inward and needs to be flared a little to avoid damaging the rubber seals.

- Drill, pliers, adjustable wrench, open-end wrenches of the correct size.

All the necessary tools to effectively carry out the installation of a metal-plastic pipeline, you can buy together with a pipe and fittings, the price of the tool will thus be lower.

Bulgarian

The more financially secured plumbers carry a small grinder with them. I'm not talking about Bosh, I'm talking about some cheaper one. Now I will set it up for myself. And we cut the pipe accordingly.

The method is faster than the first one. It produces smoother edges. Of course, it also depends on where the hands of the person who saws grow from, but the edges are smoother.

There is one drawback compared to the first method - this is a chamfer. A chamfer is obtained with such burrs, and these edges have to be processed additionally. Well it will go. But the grinder is overgrown with such a cobweb, chacha, and it is quite difficult to clean it.

Cutter and pipe cutter for reinforced plastic pipes

For products of small and medium diameter, a cutter for metal-plastic pipes is used. This tool, in comparison with scissors, is more suitable for professional use, which does not exclude use in a domestic environment.

Even in domestic conditions, special scissors or a cutter should be used to cut pipes.

It is equipped with comfortable handles and a latch-lock for the closed position. The support and top brackets allow the setting of the required pipe girth and the perpendicular direction of the removable knife. The use of a cutter makes the use of a calibrator superfluous; it is equipped with built-in calibrators. The cutter can not only cut the structure, but also restore its shape at the cut.

It is recommended to use a pipe cutter for cutting large diameter reinforced plastic pipes. The use of a pipe cutter requires attention to a number of details:

- whether it is suitable for cutting products of a given diameter;

- what the tool manufacturer recommends regarding the frequency of knife sharpening;

- what material was used to make the knife.

Plastic pipe cutting tool

And there is another modern method of pipe processing - the P-TEC 5000 tool. There is a viewing window. We bring it to the depth marked by us and rotate it in a circle. The result is a perfectly straight cut and bevelled edges.

An ideal cut is obtained on two pieces at once, and a chamfer is also obtained on two pieces. Faster, easier. No need to carry a grinder, no need to carry such a hacksaw. Very comfortably. The button is pressed, placed and gone.

More convenient than most existing pipe cutters, but there is a drawback. It is only available for 50, 32 and 40 mm pipes. For the latter two, there is a double-sided apparatus with two holes. Their only drawback is that they are closed, that is, the pipe must be pushed inside.

How to bend a reinforced plastic pipe

One of the advantages of metal-plastic is its flexibility, thanks to which a minimum number of fittings can be dispensed with. For example, instead of installing an elbow fitting, you can simply bend the piping itself slightly. In the manufacture of such an element as a coil from a metal-plastic pipe, bending is also indispensable.

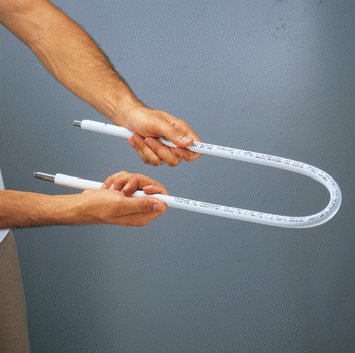

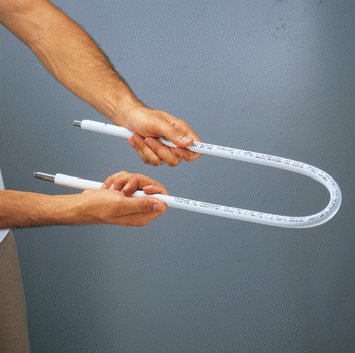

In the photo - bending of the pipeline using an internal mandrel

The main problem with the deformation of the pipeline is that it can simply break. That is, its walls will converge at the bend, which will make normal circulation of the coolant impossible.

Consequences of unsuccessful flexion

There are two ways to solve this problem:

- using a pipe bender;

- bend the pipeline with your own hands. In this case, it will be necessary to fill the inner space of the pipe in order to prevent kinking.

With manual bending, the pipe can be filled with sand or salt. This can replace the mandrel. After filling and sealing the holes at the ends, you can safely bend the pipeline.

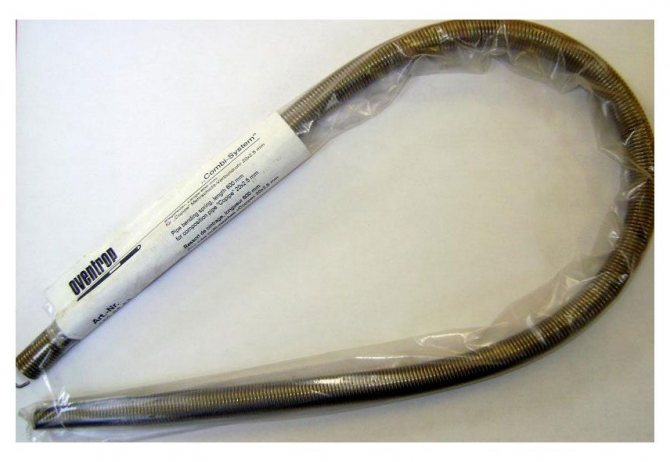

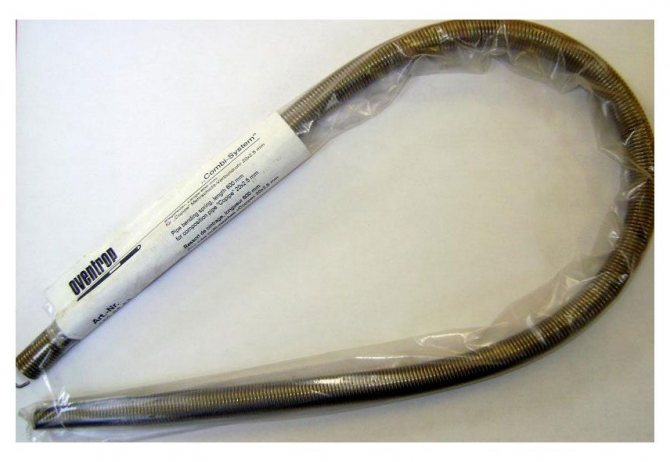

Instead of bulk materials, a spring for metal-plastic pipes is also suitable.Its diameter should be only slightly smaller than the inner diameter of the pipe itself.

Bending spring

As for pipe benders, they can be classified according to the bending method:

- mandrel - a solid element moves inside the pipeline;

- segmental - in this case, the bending is performed using a set of shoes for different diameters and bending radii.

Pipe bender with a set of shoes

The instructions for bending the pipe in this case are simple - you just need to apply force to the pipe bender lever. The pipe is pressed tightly against the shoe and deforms.

Note! There is a minimum bend radius for any size. It can be determined by the formula 5 ∙ D, where D is the diameter of the pipeline.

High-quality cutting of polypropylene pipes

Due to the growing popularity and prevalence of polypropylene pipes (propylene polymer) used to equip water supply systems and other communications, the demand for a specialized tool that makes it easier to work with the material has increased significantly.

Particular, exclusive attention is paid to the correct choice of the model of shears that cut polypropylene pipe products. This greatly simplifies the preparation of the entire set of parts for wiring installation.

As a rule, straight lengths (up to 12.0 m) are sold on the market, although polypropylene pipes in coils are often found, which are used for the installation of underfloor heating systems.

Conclusions and useful video on the topic

The video will help you understand how the tool for cutting metal-plastic pipes works - see how to cut a metal-plastic pipe:

With such a wide range of construction tools, both manual and electric, choosing a pipe cutter that will cope with its function, but will not cost more than the heating system itself is a very real task.

Knowing what types of devices there are, as well as getting acquainted with the most popular models, you can easily choose and buy equipment for working with metal-plastic pipes.

Do you want to supplement our material with useful comments or share your own experience in cutting metal-plastic pipes? Or want to talk about the pros and cons of your pipe cutter? Write your opinion and recommendations under this article, add unique photos of your model of pipe cutters or the cutting process itself.

The main types of tools cutting propylene pipes

All modifications of equipment manufactured for cutting thermoplastic polymer propylene pipes are subdivided into several design options.

1. Precision scissors - have a fairly simple, reliable taps-split mechanism. This tool can dissect and fragment products with a diameter of 3.0–41.5 mm. The cutting tool has a steel blade (alloy grade) with a serrated bar, allowing for fairly easy, even cuts in propylene pipes.

Using precision scissors, you can easily cope with one hand, however, with large volumes of fragmentation of the material, fatigue of the muscles of the hand, forearm and shoulder quickly increases. The purchase of a tool implies a one-year warranty, valid only with the correct use of scissors.

2. The cordless pipe cutter is an automatic tool for ultra-fast (maximum 7.0 seconds), accurate cutting of medium-thickness propylene pipes (8.0–29.5 cm). The compressive force of the cutting surfaces is provided by a small, powerful electric motor.

3. Roller pipe cutter is an easy-to-use modification of the polypropylene cutting tool. Despite the simplicity of its design, the employee can make an absolutely even cut. In this case, the pipe elements are cut at an even (90 degrees) angle.

Attention! Any deviation in the process of cutting from an even, right angle (90 degrees) can provoke a breakdown of the tool or deformation damage to the lines of the cut!

Roller pipe cutters are available with telescopic extensions. These instruments are equipped with a ratchet device and generally resemble conventional scissors. This pipe cutter has, on the one hand, a C-shaped recess where the pipe to be cut is placed. The opposite side contains a sharpened cutting blade. After closing the handles with a brush, it cuts off the pipe in an even plane.

4. Guillotine pipe cutter a device used for cutting large diameter pipes (63.5-350.0 mm). The tool is characterized by the presence in the design of a high-strength, sharp-edged blade covered with Teflon. Smooth installation of the pipe, as well as slow cutting with very sharp blades, contribute to the maximum smoothness of the end surfaces. This greatly facilitates subsequent electrofusion welding without additional processing of the pipe ends.

Recommendation! When a specialized tool for cutting polypropylene pipes is not available, you can use a special hacksaw for metal or wood. It must be remembered that the slightest violation of this technology can spoil the cut pipe. In addition, the end plane of the cut must be additionally cleaned from burrs and forming chips, and this takes a lot of effort and extra time!

When do you need a pipe cutter

The reinforced-plastic pipe is a prefabricated structure of at least 3 layers: from a thin layer of aluminum - the frame, and two layers of polypropylene. The connection of the elements of the sandwich structure is carried out by laser welding. Metal-plastic is used in plumbing works for laying a water supply system, as well as for distributing a heating circuit.

The pipes are quite soft and not difficult to cut. A hacksaw for metal, and even a regular knife with a serrated blade will do. Of course, it is possible to make one cut with such a tool, but not a single builder will agree to do this on an ongoing basis.

Just as often, builders get by with an angle grinder - a grinder. Yes, a disc for metal easily passes through thin aluminum foil, but a lot of debris and waste remains at the workplace. It is noisy, you need to connect the power supply, and clamp the pipe itself in a vice every time to fix it. And if you need to cut off a part of the installed pipeline in a hard-to-reach place, you definitely can't get there with a grinder.

Thin-walled pipes of small diameter are cut with metal scissors, but if the width is more than 40 mm, professional equipment is used

Cutting the pipe with a non-professional tool is undesirable. And it's not just about the difficulty in terms of physical labor. The cut is not smooth, with jagged edges and shavings. It will have to be additionally cleaned, otherwise the system will malfunction.

The choice of a specific type of polypropylene pipes for certain conditions

For cutting pipes made of polypropylene material, scissors are selected for a specific value of their diametrical size. Manufacturers today present pipe material in four versions:

- РN-10 - is chosen to create a "warm floor" system and cold water supply. The coolant should not be hotter than +45.0 C, and the in-line pressure should be maintained at 1.0 MPa;

- PN-16 - suitable for the distribution of chilled water, as well as for the piping of the centralized heating system. The coolant is supplied under low pressure - no more than 1.7 MPa;

- PN-20 is a universal version of the pipe, which is actively used for the installation of hot, warm or cold water supply. Mandatory conditions for installing PN-20 pipes: the maximum internal pressure is 2.1 MPa, and the temperature of the coolant is not more than +80 C;

- PN-25 is a pipe material reinforced with aluminum foil. This solution allows the pipe walls to withstand an internal pressure of 2.6 MPa and a maximum water temperature of +95 C. This type of pipe is perfect for installing central heating and hot water supply.

Important! The choice of the type of polypropylene pipes should be carried out carefully, with scrupulous consideration of the temperature and pressure of the water in the system, since the immediate service life of the pipeline depends on these factors!

In addition to various polypropylene tubular products, manufacturers produce many fittings and combined elements. The latter are often equipped with molded brass inserts with internal or external threads.

Metal inserts allow easy seals and material conversions.

Remember! Only professional, high-quality modifications of cutting tools can effectively cope with cutting polypropylene pipes, regardless of their wall thickness and diameter!

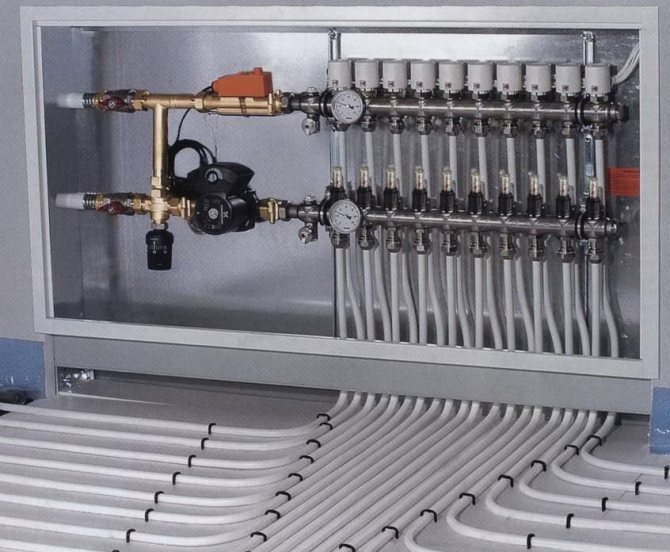

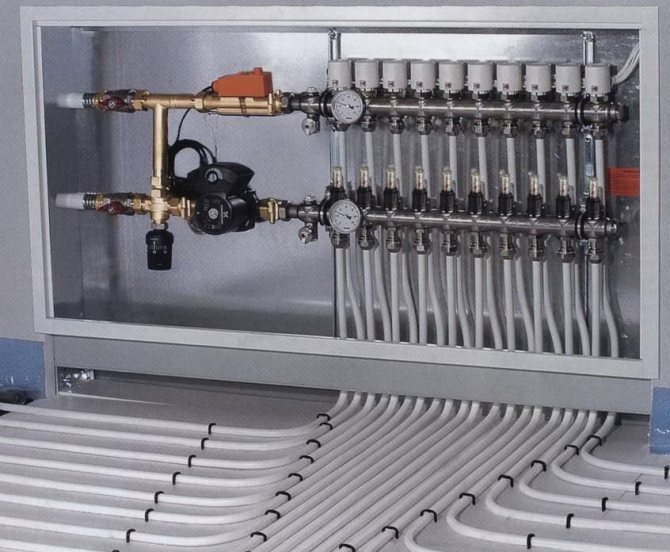

Collectors for metal-plastic pipelines

The collector is necessary if the heating in the apartment is organized according to the radial scheme. In this case, both hot and cooled coolant are supplied to the collector, and from it there is wiring to the radiators of the heating system (a separate supply and exhaust pipe for each radiator).

Collector

By and large, a comb (or a manifold for metal-plastic pipes) is a pipe with outlets welded to it. If the budget allows, then the collectors can be equipped with such elements as thermal heads and flow meters.

In the case of maximum equipment, you will need:

- install flow meters on the feed manifold. Thanks to this, it is possible at any time to change the volume of the coolant supplied to each radiator separately;

- thermal heads are installed on the collector with "return". Sensors constantly monitor the temperature of the cooled coolant and can increase or decrease the size of the passage. Due to this, for example, during a cold snap, the size of the passage increases, and accordingly the flow of the coolant through the radiator also increases.

Collectors are equipped with flow meters and thermal heads

The price of such a system can well exceed 10,000 rubles, so you can get by with a more modest option. In this case, plugs are left on the manifold in order to retrofit the collector with thermostats or flow meters in the future.

How to cut polypropylene pipes? Principles for choosing a good tool

First of all, when choosing a quality tool for cutting propylene pipes, it is necessary to build on the planned intensity of its subsequent use. When you need one or two cuts, precision or roller shears are fine.

If you have to cut pipes often, then the battery model would be the best option. Of course, the guillotine pipe cutter will effectively cope with the work, especially when cutting pipes with large diameters.

Feature! An important drawback is characteristic of all modifications of pipe cutters - the blade may move a little to the side during cutting. This is not critical for small diameters, but large-size polypropylene pipes must be eliminated from such a flaw. Therefore, cut large pipes with a guillotine cutter!

A little about assembly technology

Regardless of whether the installation of a water supply system or a heating system is being carried out, the assembly of metal-plastic pipes is carried out in the following sequence:

- pipeline cut. The pipeline is supplied in coils, so this is indispensable. At this stage, you need to especially carefully control the quality of the cut, there should be no burrs at the end;

The pipeline is delivered in coils

- calibration - after working with scissors, it is imperative to restore the geometry of the section, you can combine this operation with chamfering;

- in fact, the connection, any of the common fittings will do, for example, an American.

The better to cut a metal-plastic pipe

When the question arises of how to cut metal-plastic pipes, then special scissors can be considered the best option. Their blades allow you to get the perfect cut quality, without burrs and jams.

Pipe shears

Note! If you simply press down on the handles of the scissors, the material may flatten a little. To prevent this from happening, the pipe must be rotated during cutting.

If there are no scissors at hand, then you can do with an ordinary hacksaw. However, in this case, the cut quality will be slightly worse.

After the hacksaw, you will have to file the edges. A common requirement for both options is the perpendicularity of the cut plane to the longitudinal axis of the pipeline. Even a slight misalignment can lead to joint depressurization in the future.

Calibration of the pipeline

The calibrator is the most important tool for reinforced plastic pipes, which allows you to restore the shape of the section. It is not uncommon for the end to deform slightly when the pipeline is cut, and the calibration operation will allow it to become round.

Two types of calibrators can be distinguished:

- a tool that is intended only for geometry restoration and flaring;

Simple calibrator

- a calibrator for multilayer pipes, which, in addition to these operations, allows you to immediately chamfer.

As for the calibration technology, it is performed in the following sequence:

- a suitable nozzle diameter is selected and inserted into the pipeline. If the end is deformed, then this may require effort;

Calibrator with beveller

- after that, you just need to turn the calibrator without removing the end of the pipeline from it, the blades of the knives will chamfer at the desired angle.

Pipeline installation

When a person thinks about how to work with metal-plastic pipes, most of the questions arise regarding the choice of a connection.

There are many ways, each of them has its own advantages:

- push fittings... In this case, the end of the pipeline is simply inserted all the way; for convenience, they even have a viewing window. The disadvantage of this type of connection is the rather high price, and the joint itself turns out to be one-piece;

Connection diagram using push-fitting

- press fittings... This method of joining is used when it is necessary to connect metal-plastic to metal. In addition to the fitting itself, you will also need press tongs. The tightness of the joint is achieved due to the deformation of the metal. This type of joint is also considered to be one-piece;

Connecting pipes using a press fitting

- crimp fittings - the most common type of pipeline connection.

Push-in fitting is one of the most popular types of compression fittings, it provides both high strength and sufficient tightness of the connection, and if necessary, the joint can be easily disassembled. In addition, such a fitting can be reused.

The device of such a connection is as follows:

- a flare nut and a ferrule are put on the pipe (ferrules are also known as collets for reinforced plastic pipes);

- then it is inserted into the fitting;

- the nut is tightly tightened, the collet is slightly deformed and tightly fixes the end of the pipeline.

Collet fitting diagram

Compared to other methods, it is the detachable connections that are more popular. When using them, the question of how to disassemble metal-plastic pipes is easily solved.

Note! When inserting the pipe into the fitting, do not apply too much force, this may damage the rubber seals. To facilitate the process, the end of the pipeline can be lubricated.

Separately, it is worth mentioning the connection using Eurocones. The design allows it to be classified as detachable, small differences lie only in the fitting device. A nut and a collet are put on the pipeline, then a eurocone for metal-plastic pipes is inserted into it, and the nut is tightened.

In the photo - Eurocone

In addition, during installation, you will need fittings such as tees, crosses, adapters that allow you to connect different diameters, collectors (for heating systems), corner fittings.

Cutting technology for plastic pipes with precision scissors

There are no special rules for cutting propylene pipes. Cutting tools, especially precision scissors, have special recesses in which the cut material is located strictly perpendicular to the sharpened blade.

Caution! With pressure on the handles, the even position of the pipe may be disturbed. This should be prevented in every possible way, otherwise the cut will turn out to be uneven or the tool will break!

It is very important for welding, fitting and other types of connection, to monitor the severity of the cutting angle - it should be exclusively 90 degrees.

When the tool is inconvenient to hold in the brush due to the large handles, it can be clamped in a vice. You can also do it when cutting pipes with a large diameter, since the forces for normal pressing on the lever may not be enough.

It is clear that a large number of pipes cannot be cut in this way, but if the repair is small, you can completely do without large, expensive cutting tools.

Pipe Cutting Tools

Beveller - designed to improve the quality of welding plastic pipes. It is used to remove the edge or top layer of plastic pipes in diameter.

On sale you can find bevellers of various designs, designed to work with pipes of different diameters. When buying, you need to decide on the amount of work and pipe material. The tool is available with both manual and automatic feed. It allows adjustment to the required pipe diameter and wall thickness.

Caliber - required for working with reinforced plastic pipes. With its help, before the pipes are brazed, the aluminum layer on the pipe cut is cleaned. In addition, the gauge allows you to remove burrs and roughness of the cut, as well as, if necessary, to remove the chamfer.

If the pipe is slightly wrinkled during cutting and the cut has acquired an oval shape, the calibrator will align the end, making it perfectly round again. A separate calibrator is required for each specific pipe diameter.

When planning the device of a plastic pipeline, it is necessary to prepare in advance all the tools necessary for a full cycle of work. The set of tools depends on the length and complexity of the pipeline, the material of the pipes and their diameters.

We select a tool for working with metal-plastic pipes

The tool for working with metal-plastic pipes allows you to modify products as accurately and accurately as possible. Improvised means, for example, a sharpened knife for processing the end sections, does not remove burrs from the surface so thoroughly, which deteriorates the quality of the connection of pipeline sections.

Therefore, it is recommended to use at least the main tool from the available range. Considering that many undertake the installation of a pipeline without having sufficient experience in such work, it is especially important to ensure the quality of the connection.

Details about communications from metal-plastic

Products of this kind differ from completely plastic counterparts in the condensation function, which is performed by an aluminum layer between the inner and outer layers of the polymer material. In general, the design of such pipes is five-layer: adhesion or adhesive is used to connect the above-mentioned protective coatings.

The ability of metal to compensate for linear expansion is not the only advantage of metal-plastic communications.In addition, the aluminum interlayer prevents oxygen from entering the interior of the pipe.

The described properties make it possible to use products of this kind in systems for various purposes: when installing a heating pipeline, creating a "warm floor", in multi-temperature water supply systems.

However, the actual effectiveness of metal reinforcement is observed only in heating systems, where, due to constant contact with hot water, communications are noticeably expanded.

Installation and crimping tool

The tool for the installation of multi-format metal-plastic pipes allows you to easily lay a pipeline of the required length, since this kind of work can be performed even in the absence of a lot of experience behind your back. In this case, two types of connecting elements are involved: press and compression fittings.

The first of these do not allow further dismantling of the connection, while the second can be easily disassembled, which is provided by a threaded connection.

List of required tools

When deciding how to cut a metal-plastic pipe, it should be borne in mind that the highest quality connection is possible only if a special tool is used. This also applies to the installation of fittings, as well as other manipulations, for each of which there is a special tool:

- Pipe cutter or scissors for cutting metal-plastic pipes - devices of this kind allow you to make an accurate and even cut of the product. The difference between them in terms of functionality is not so great, because both tools produce a similar result at the output - a perfect cut of the product. However, if the pipe cutter can additionally perform the function of deburring and chamfering from the edge, then the scissors for cutting multi-format metal-plastic pipes can only make a smooth cut.

Such a tool can be designed to work with communications of various diameters.

Its cost directly depends on this. To ensure safety, the scissors are equipped with a latch that locks the knives in the closed position.

- Calibrator. If compression fittings are installed on metal-plastic pipes, then before installation, calibration of the end sections will be required. The fact is that the inner diameter of the communications is less than the size of the connecting element. Therefore, it is necessary to expand the end section, which is exactly what is done by means of a calibrator, which, in a safe mode for the product, somewhat increases its inner diameter.

- Pipe Crimping Pliers - Used to connect pipe sections using press fittings. Only this tool can perform such work with the highest quality. As a result, the user will receive a durable connection that does not require further maintenance, since the assembly cannot be disassembled. Pliers for crimping metal-plastic pipes are of different types: hydraulic, electromechanical and manual. The latter option is more suitable for everyday use.

- Pipe bender. The easiest way is to use the manual version, made in the form of a rigid spring.

Criterias of choice

When solving the question of the more effective it is to cut multi-format metal-plastic pipes, you should first determine their size, since all tools of this type are designed to work with a certain range of sections. This is the main selection criterion. The simplest and least functional solution is the scissors for metal-plastic pipes.

The main and only task that can be solved with their help is a neat cut. In this case, the beveller and calibrator will have to be purchased separately. And the cleaning of those few burrs that appear after work will also have to be done independently.

By the way, scissors for cutting metal-plastic pipes of different sizes are the most affordable tool, since a tool for working with small diameters of communications will cost an average of 250 rubles.

For a more functional alternative, you can opt for a reinforced plastic pipe cutter. It has several advantages: the product is tightly gripped by the knives, which eliminates shear during operation, and after the cut is made, it is possible to calibrate the end section. Thus, you do not have to purchase a separate calibrator if you buy a cutter for reinforced plastic pipes. Its cost is much higher than that of scissors - an average of 2,000 rubles.

Pipe crimping tool

When the preparatory work is completed, the time comes for the implementation of a more important task directly related to the installation of pipeline sections by means of fittings. This may require a pipe crimping tool. The main selection criterion is the diameter of the communications, since this device is also found in different designs.

Additionally, there may be various possibilities:

- a system that determines sufficient force when working with different fittings sizes (APS);

- an automatic control system for the pressing process, a tool for high-quality crimping of metal-plastic pipes of different sizes simply will not open if the work is not completed (APC);

- a system that independently increases the intensity of the application of effort at work (OPS).

You can buy a tool for crimping metal-plastic pipes in the range from 7,000 to 65,000 rubles.

Popular manufacturers

Valtec is rightfully considered one of the best. In addition to a wide range of materials, this brand produces connecting and locking elements, compression equipment, tools. The manufacturer offers to purchase crimping pliers for the installation of metal-plastic pipes of various sizes at the most affordable price - 7,500 rubles, in the configuration of which there is a set of nozzles for work.

Another "whale" is the Rothenberger brand. It produces various types of tools, including a cutter for multi-format metal-plastic pipes, bevellers, pipe benders, as well as press equipment. In terms of the degree of reliability, the products of this brand are not inferior to the above-named manufacturer.