Passage of a pipe through a chimney without a factory pass-through unit

It is possible to remove the chimney without the passage device. In this case, the edges of the hole in the ceiling are also sealed with a fire-resistant heat insulator, and metal strips are stuffed over it. A protective plate made of non-combustible material is put on the sandwich coming from the furnace, in which a hole of a suitable diameter is cut out, and holes are drilled along the edges for fasteners. Traditionally, this is a sheet of metal. Next, the sandwich is passed into a hole in the ceiling, fixed there with the help of any non-combustible guides. For example, you can use drywall profiles or something similar. The main thing is to securely fix the pipe and observe the basic rule of fire safety: there must be a distance of at least 36 cm from the edge of the pipe to the combustible material.

You can make a node of passage through the ceiling with your own hands

Important! When installing and fixing the chimney, keep in mind that the pipe changes its dimensions due to thermal expansion. It must be fixed so that it can move relative to the roof

Then from below (from the ceiling) the pipe is sewn with a non-combustible material. From the side of the attic or the second floor, the voids formed in the cutting are filled with a heat insulator. The requirements for it are the same: high temperature tolerance. Expanded clay can be the most budgetary. Actually, this completes the outlet of the chimney through the ceiling.

You can make a node of passage through the ceiling with your own hands

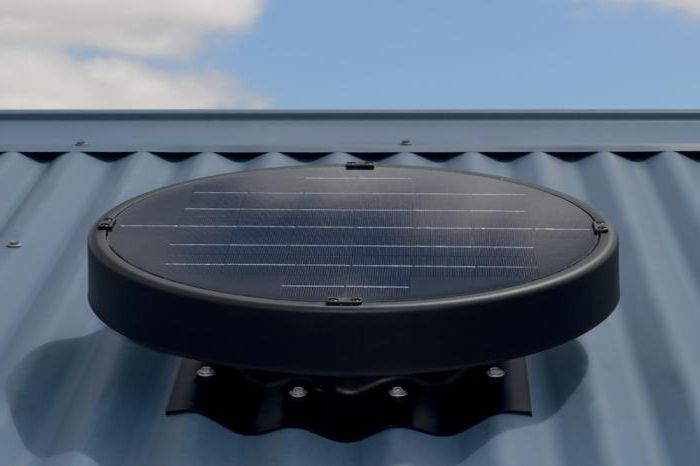

Purpose and design features

Passage node

The main purpose of the passage unit is the design of the outlet channels with their simultaneous sealing, excluding the ingress of sediments, as well as debris and foreign objects into the structure.

The nodes formed at the exit sections of the ventilation shafts through the roof are most often mounted in special reinforced concrete glasses or placed directly on its supporting elements (rafters).

For various types of roofs that differ significantly in their design, appropriate types of pass-through units should be selected. At the same time, the use of a UE of one type or another, as a rule, is not tied to the class of installed ventilation, i.e. it can be built into both natural and forced (exhaust) systems.

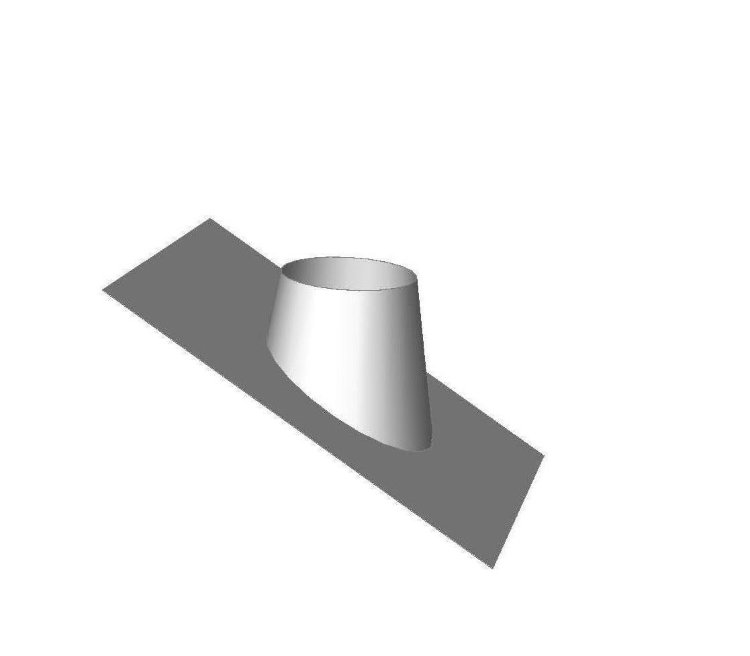

Depending on the type of roofing structure, as well as on the type of ventilation system, the fastening base of the roof passage unit (glass) can have different sizes and shapes. It can be rectangular, square, round or oval, depending on the shape of the through hole being made. During installation, such a glass is simply pushed onto a metal pipe of a given diameter, made of sheet metal with a thickness of at least 1 mm.

For duct

The entire resulting structure is then fixed directly on the roof or on a special base made in the form of a reinforced concrete glass. To fix the ventilation passage nodes on such a glass, which allows to relieve the roofing structure from excessive load, special anchor bolts are used.

How to bring the pipe through the ceiling

Having determined the place for the installation of the chimney, a number of works are carried out to directly bring the pipe outside.

Installation of a stove chimney on the roof of a bath

- Cut a hole in the flooring at the ridge area. Since the chimney has a low height, no braces are required to strengthen the chimney.

- If the roof deck is single-pitched, then the chimney outlet is formed near the top of the roof.

- Mount the box, taking into account the minimum distance to exclude fire.

- The gaps are sealed and insulated with heat-resistant materials.

- The pipe is fixed by means of a penetration or a steel apron.

- Install a groove to drain the condensate.

- The gaps are sealed with adhesive tapes and sealant.

- Overlappings (lower and upper) are covered with metal or decorative sheets.

To drain the condensate, it is necessary to mine the drainage groove:

- located in the waterproofing layer;

- product material - stainless steel;

- installation is carried out directly around the pipe;

- the ends of the groove are taken to the side (so that condensate can drain into it) and brought to the roof slope.

The resulting gap between the pipe and the "box" of additional rafters and beams is filled with basalt (stone) wool:

- Cut the material into an "envelope".

- The ends of the "layer" are wrapped up to the "box".

- Fixation is carried out by means of staples or nails.

- In places where the "envelope" touches the wood, insulation is required (with the help of sealants, adhesive tapes).

If the temperature of the chimney will fluctuate within 50-600, in this case, measures are taken:

- By means of adhesive tapes or sealant, the roofing films are connected to the pipe.

- This temperature should be calculated in the area of the chimney passage through the roof.

- This method is acceptable if there is an additional heater or heated water tank in the area where the sandwich pipe exits the firebox.

How to cut a hole in a roofing pie

Initially, the chimney outlet section is separated from the roof deck. To erect this box, you must:

- mark the distance (leave a gap between the chimney and the walls);

- if the flooring is made of soft materials, then bend it outward (leave 1.5-2 cm along the edge);

- fix additional rafters (for brick chimney) or profiles (for metal pipes) on the left and right sides;

- on the upper and lower sides, install cross beams (for brick chimney) or profiles (for metal pipes).

How to put a pipe on a garage roof

The installation of a chimney on the roof of the garage is associated with a passage through a reinforced concrete floor and a layer of roofing material. The recommendations of specialists for correct installation are as follows:

- the use of special metal sleeves to pass the chimney inside;

- the joints of the sleeves are caulked from above and below with basalt wool and cemented;

- an asbestos cord is wound directly onto the pipe (in the area where the chimney is in contact with the sleeve).

Passage through the ceiling of a brick chimney

Brick is a good heat insulator in itself, however, it is also required for a brick oven to comply with the rules for passing through combustible materials: there must be a distance of at least 25 cm from the edge of the chimney to this material. To ensure this, stove-makers make a special penetration on the pipe (see figure) by increasing the wall thickness of the brick chimney at the place of passage through the ceiling.

If for some reason it is impossible to make such a penetration, you can cut a hole in the ceiling that will be 10 centimeters larger than the chimney size on each side. And then repeat the penetration of the round stove through the ceiling:

- seal the edges with heat-resistant heat-insulating material;

- close it with strips of metal (minerite is also suitable if someone has it);

- from the side of the room to sew up with a metal sheet;

- the resulting voids on the side of the attic / second floor should be filled with heat-resistant heat-insulating material;

- close, if necessary, the ceiling cut from the attic / second floor with a sheet of metal.

With this option, the brick pipe is sufficiently reliably insulated (only use heat-resistant heat-insulating materials with a temperature of use of 800-1000 ° C).

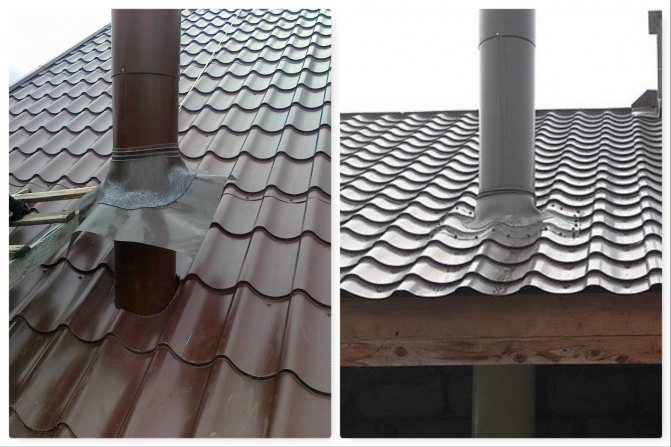

How to close the gap between the pipe and the roof

When installing a chimney, the target moment is to drain the flowing sediments. To prevent moisture from entering the floors, protective materials are used:

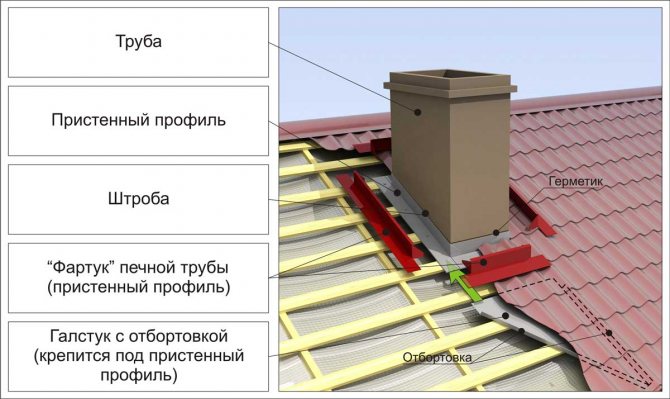

How to make a metal apron

Sheet aluminum is used in the manufacture of the apron. The material is divided into 4 parts:

Apron collection process:

- The elements are bent so that some of the strips sit on the pipe, and the rest is connected to the crate.

- An edge is made in a brick pipe, where a strobe is inserted. For this, a grinder is used. Everything is lubricated with a sealant.

- To exclude leaks, a "tie" is laid. This construction is in the form of a metal sheet with concave sides, which is mounted under the front area of the apron.

- When using metal roof tiles, it is recommended to install an apron, the upper end of which sits above the roof row to prevent leaks. Moreover, if the pipe is located near the ridge, then the structure is filled directly under it, or bent to the other side.

How to seal seams and joints

Sealing of joints and seams is performed taking into account the materials of the roof, chimney:

- self-adhesive tape on bitumen and silicone is applied to the seams and the area of connection of the cap with the pipe. The material adheres perfectly to all types of surfaces: metal, wood, plastics, etc .;

- wide slots are filled with ropes / linen. Materials are impregnated with oil paint;

- coat the gaps with a solution of cement and sand, but keep in mind that over time, the surface will crack;

- small cracks are covered with sealant.

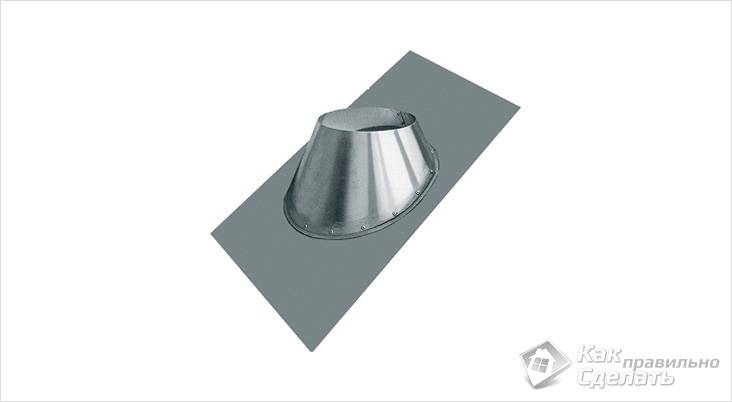

The use of penetration on the roof of different materials

Manufacturers often produce chimneys with penetration. The finished product is made of a material identical to the chimney and is connected with a special cap. The chimney passes through such a bell. And the junction of the chimney and the apron is combined with a steel clamp.

Yulia Petrichenko, expert

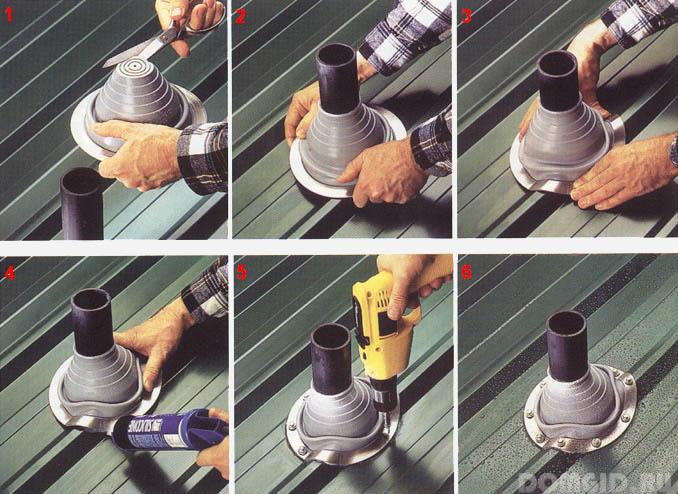

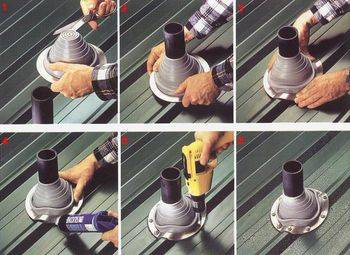

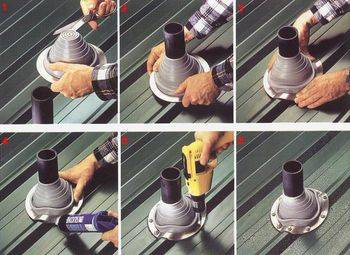

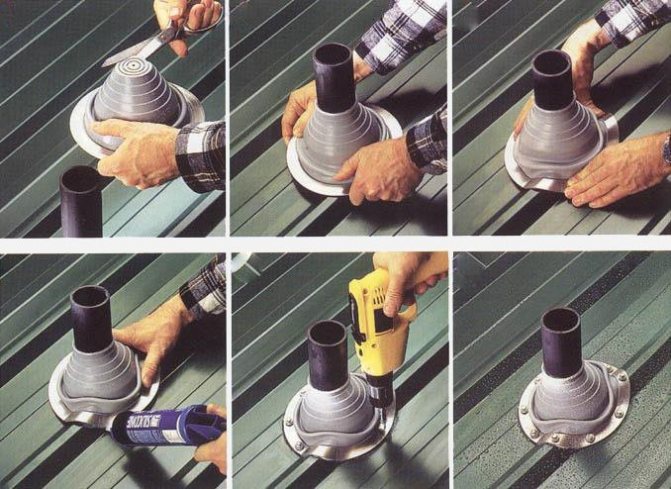

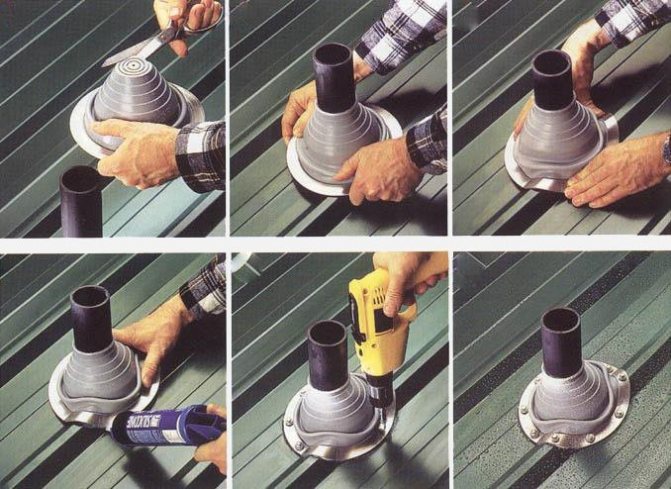

Also, the penetration can be made in the form of an aluminum flange (factory):

- A flexible part is attached to the structure, which is made of rubber or silicone.

- Components similar to the corrugated area are applied to the flange. The edges of the penetration have grooves where the gaps are filled with sealant.

- Determine various parameters (diameter, thickness, etc.) and angles of inclination of the factory penetration.

Installation of the penetration is simple:

- The corrugation is cut with scissors in accordance with the pipe diameter.

- After that, the product is put on the chimney (the penetration should be dressed tightly, tightly in contact with the chimney; for convenience, it is possible to apply soap to the surface).

- Then a flange is formed, the grooves of which are treated with a sealant.

- The product is fastened by means of self-tapping screws. When installing the penetration on a non-metallic roof, it is recommended to use longer screws or dowels, so that the parts reach the lathing area.

Installing the chimney umbrella

Installation of an umbrella is not required if the chimney is made of bricks. The raw material absorbs moisture by itself.

If the chimney is made of metal or asbestos-cement materials, then it is necessary to make an umbrella as follows:

- Make a drawing on cardboard and cut out a "pattern" in accordance with the dimensions.

- Cut metal parts based on the pattern.

- Mount the umbrella on the pipe, connecting it with clamps.

- Cover the gap between the parts (pipe / umbrella) with sealant.

Yulia Petrichenko

Chimney - passage to the roof: how to bring it out through the roof (corrugated board, metal tile, slate, ondulin, overlap), how to seal the gap correctly - print version

Data for the design of the control unit

The data for the design of the node and the choice of its type are determined taking into account the following factors:

- slope angle;

- the value of wind and snow load in the region;

- material and thickness of the attic floor;

- type of roofing material used to cover the roof.

If the overlap of the upper floor of the house is made of reinforced concrete slabs, holes of the appropriate size and shape, reinforced with glasses made of monolithic concrete, must be prepared in advance in the latter. The node for the passage through the ceiling, made in the form of a lightweight metal frame, is designed in the same way, with the only difference that the glasses for pipes are made of metal. In any case, the choice of the size and shape of the glass should be made at the stage of preparing the building project.

Assembly assembly

When calculating the node, first of all, the angle of inclination of the slope, adjusted for snow and wind loads, should be taken into account. In regions with frequent precipitation, it should be borne in mind that in winter, the weight of snow accumulated on the roof can reach significant values; at the same time, it can block both the nodes of the passage through the roof and the channels of its ventilation.

When calculating the loads on the UP, the possibility of the impact on it of snow masses sliding from the roof during spring thaws must also be taken into account (in this case, the quality of the surface of the roofing material must be taken into account).

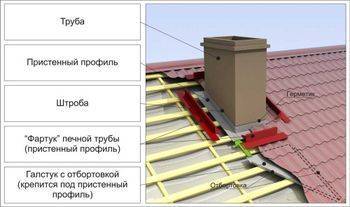

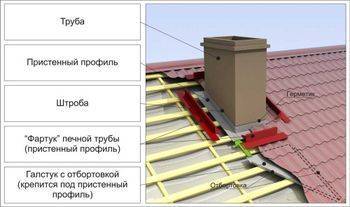

Fighting leaking joints

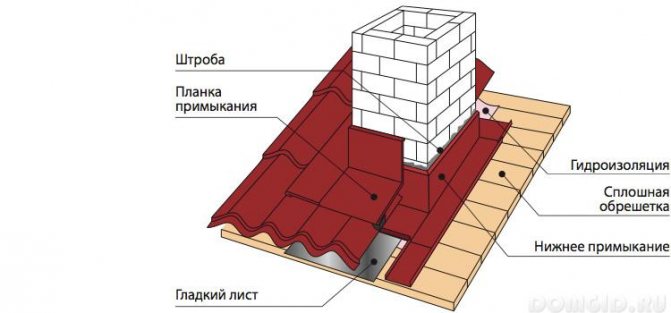

To create the maximum possible tightness of the abutment of the roofing material to the pipe at the points of contact, using the lower strips, an inner apron is made.

Arrangement of the chimney passage through the roof.

To make an inner apron, you need the following tools:

- marker;

- long metal ruler;

- grinder with a disc 2 mm thick;

- pliers;

- a hammer.

In order to do this, the plank is applied to the walls of the chimney pipe, making marks on the upper part of the plank. The next step along the previously marked line is punched through the strobe.

The installation of the inner apron should start from the bottom wall. The edge of the apron is inserted into the groove, after which it is installed on the remaining walls. The overlap should be 15 cm. Then the edge of the film is sealed, inserted into the strobe. Having cut the lower planks, they are installed, and then fastened with self-tapping screws.

After installing the lower apron, you can start installing the tie, which is a sheet of waterproofing material, wound under the elements of the inner apron from below. The main function of the tie is to drain the water.

After finishing work on the arrangement of the tie and apron, which protect the joints, the roofing material is laid. Then the outer apron is mounted. To do this, use the upper abutment strips.

The installation of the apron from the outside is carried out in the same way as the device of the apron from the inside. The difference is the absence of a groove and the upper edge is fixed directly to the chimney wall.

Important: today the building materials market offers products that are designed specifically for chimneys with a circular cross section. They are roof passages that consist of a base (flat steel sheet) and an apron cover

A round chimney is drawn inside the passage.

What a chimney - such a passage

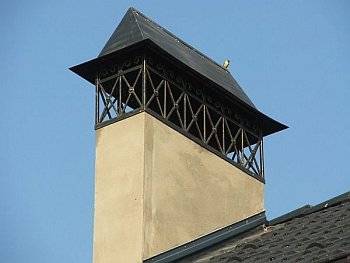

Considering this issue, it is worth considering that there are many ways to organize the exit of the pipe to the roof. Its device is influenced, first of all, by the type of the chimney itself, the method of its exterior decoration.

- After all, if, for example, a ceramic chimney is being installed and its output to the roof, then this is one option, but if the chimney is a simple brick or from a sandwich pipe, this is completely different.

- A ceramic chimney can also have several exterior finishes.

- If, for example, a part of the chimney located above the roof is faced with brick, then the installation is carried out according to one scheme, and if it is simply plastered, it is already according to another.

Indeed, if in the first version, directly with the roof, the external concrete blocks of the chimney will be in contact, then in the second version, the brick, the installation of which begins with an intermediate crown located under the supporting structure of the roof.

Floor material and roof - an important factor

In how the chimney passage through the roof is arranged, the roof covering plays an important role. Most often, you have to work with a coating of corrugated board, metal, ondulin. Often there is a need to bring the chimney to a soft roof.

Passage elements: various possibilities

Depending on the materials of the floor, the sandwich pipe can be routed out through the chimney roof in different ways. On a soft roof, the output of a sandwich pipe with your own hands is carried out as follows: There are passage elements that can be installed in any convenient place.

- An opening is forged in the roof through which, for example, a modular chimney pipe is removed. Imagine that our roof overlap does not have powerful beams for fixing the passage.

Collecting passage

- In this case, we use a prefabricated passage of two parts, which is fixed with self-tapping screws from the inside, as shown in the picture.

- After that, a special rubber seal is glued to it from the outside with the help of silicone.

Passage with seal

- A non-combustible insulation is laid on top in such a way as to fill the gap between the collection passage and the chimney pipe. In this case, the insulation material should not cover the rubber seal.

- Next, the roof section is attached, which comes complete with a collecting passage. Fastening is carried out using self-tapping screws.

Chimney finishing choice of materials

The negative factors affecting the chimney include

:

- atmospheric influences (wind, precipitation, ultraviolet radiation);

- difference in ambient temperatures;

- high temperature workloads.

Due to the difference between the temperature of the working pipe and the air temperature in the chimney, condensate forms, which provokes the destruction of the pipe during the combustion of heating oil

... To avoid the formation of condensation and to protect the pipe from external influences, it is required to provide for reliable insulation of the chimney due to the lining.

Various materials are used to cover the protruding part of the pipe. When choosing, you should consider

:

- resistance to external factors, wear resistance;

- appearance and color scheme (matching the roofing or wall decoration of the building).

Roof chimney trim is most often done using

:

- clinker bricks or tiles;

- plaster;

- fiber cement boards;

- roofing material (corrugated board, slate).

Characteristics of finishing materials

Clinker bricks or tiles are a practical option for finishing the chimney, since dirt is not noticeable on such material. The advantages of clinker materials also include the aesthetics of the masonry; such a chimney is perfectly combined with any type of roofing. It is worth noting the resistance of tiles and bricks to weather conditions, temperature extremes, as well as the strength of the material. For facing the chimney, exclusively solid clinker bricks are used, laid on a mortar for clinker, special compounds are used for grouting. Thin, lightweight clinker tiles are commonly used for cladding tall pipes.

Finishing the chimney on the roof with plaster is characterized by

:

- affordable cost;

- simple installation;

- versatility (suitable for any roofing);

- the ability to implement any color solutions (plaster can be painted with silicone paint).

Plastering of pipes is carried out using the same technology as finishing of facade walls. Traditional cement or lime-cement mortar can be used, but a more durable option is to use mineral, silicone, silicate or acrylic plaster. Painting the dried surface increases the wear resistance and durability of the finish.

Small-format cement-fiber boards are durable, resistant to ultraviolet radiation, moisture, temperature fluctuations, and have a low weight. It is an environmentally friendly, non-flammable material. Smooth or structured slabs can be used for lining the chimney; the material is available for sale in a wide range of colors.

If slate is used to cover the roof, the lining of the chimney on the roof is usually made of the same material. Slate slabs can be in the form of an arc, scale, rectangle or octagon. The color of this natural material depends on the deposit. This is usually a graphite, green, or magenta color.

A fairly simple and budgetary option for finishing the pipe is the use of corrugated board. It is used if the roof covering is made of the same material. A chimney finished in the color of the roof is aesthetically pleasing.

Manufactured at the factory, the elements of the chimney for the roof passage have an aesthetic appearance and are quite simple to install. They are equipped with a steel chimney duct and can have a ready-made external cladding made of any material, or be prepared for independent finishing so that the chimney is outwardly in harmony with the roof. The modular steel structure is not additionally finished, it is enough to mount it in the place of passage through the roofing pie.

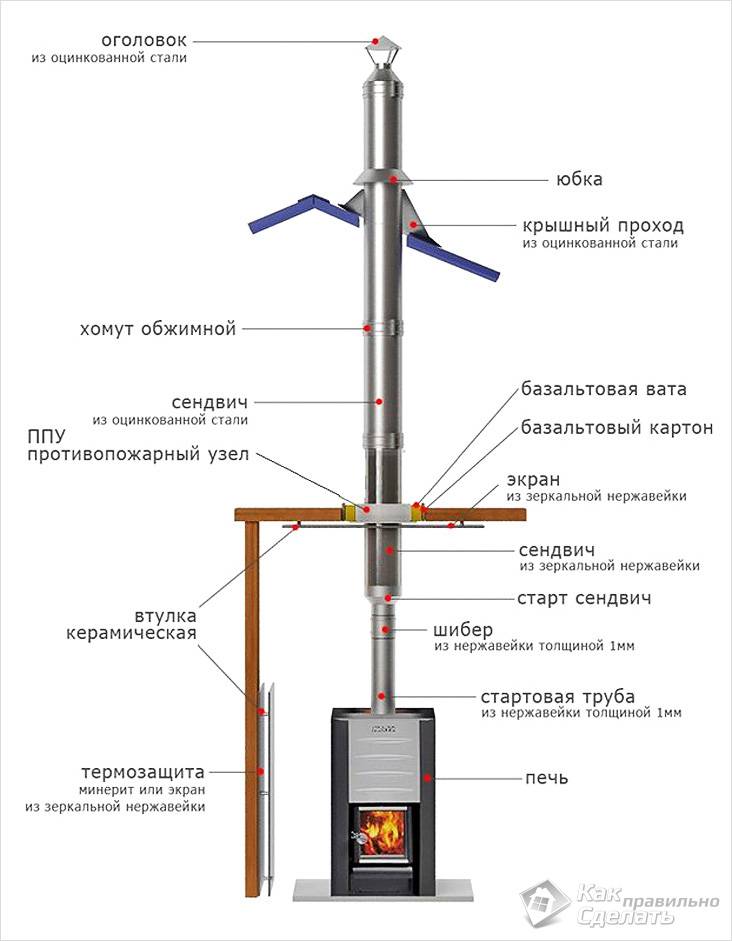

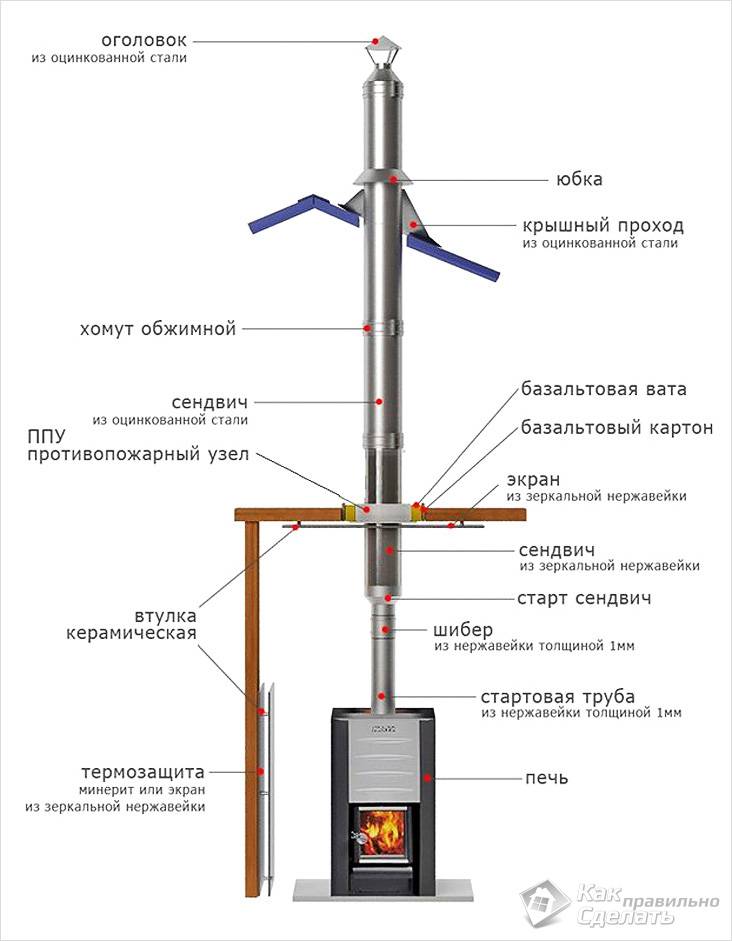

Tasks of the chimney ceiling duct

Modular design of the ceiling chimney unit protects wooden structures from fire

PPU is designed to organize the passage of the smoke exhaust pipe through the ceiling in the house. It is manufactured in a modular design with a round or square shape with a hole in the middle. Its main task is to protect wooden parts from overheating and fire, possible during the operation of the heating system.

Pass-through units for the chimney in assembled form go on the free sale, but if you wish, you can assemble them yourself. When choosing a ready-to-use product, you will need to consider the following factors:

- size (diameter) of the smoke exhaust duct;

- the location of the oven;

- features of ceiling slabs.

Basalt wool with a protective foil screen that can withstand high temperatures is used for thermal insulation of the passage.

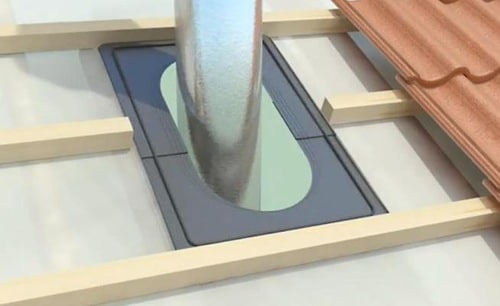

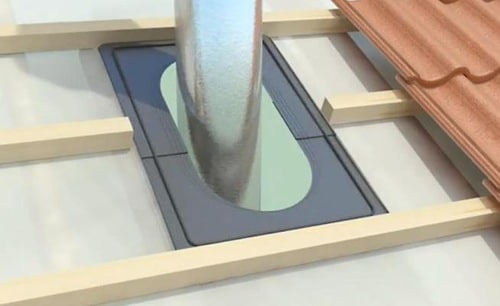

Chimney box

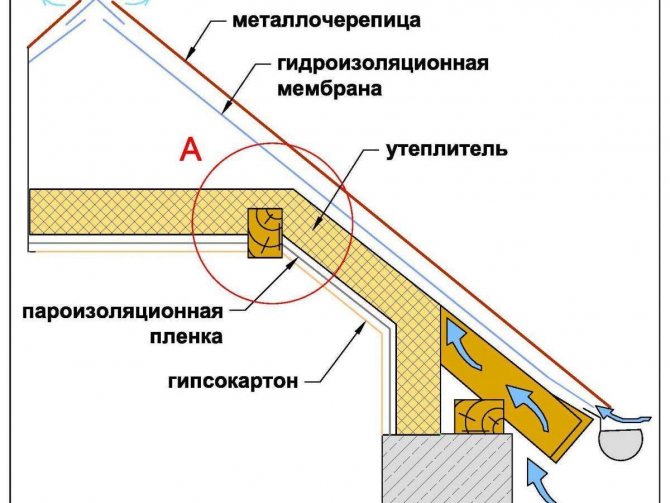

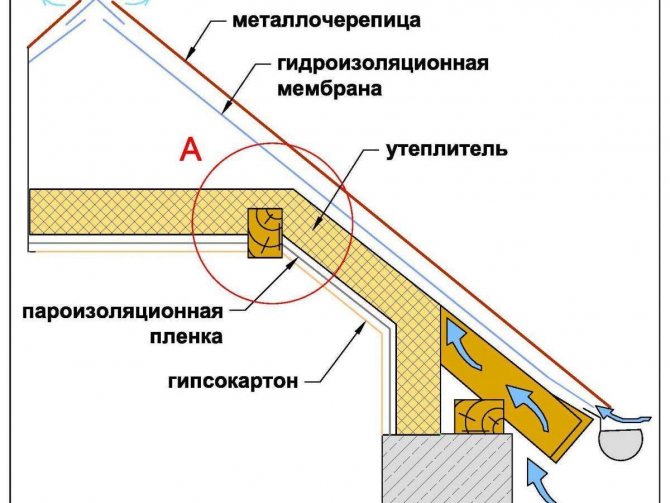

In order to properly lead the chimney through the roofing pie, you should equip your own rafter system around the pipe. It must be spaced from the chimney at the distance specified in SNiP. The structure consists of side rafter legs and horizontal cross-beams from the bottom and top, which are made of a bar of the same section as the rafters.

To insulate the structure, it is necessary to use non-combustible heat-insulating materials, such as glass wool or stone wool - it is stuffed between the pipe and wooden structural elements.

When passing the chimney through the roofing pie of the operated roof, the steam and waterproofing is cut crosswise, like an envelope, the edges should be tucked up and fastened with nails or staples to the rafter system.

Roof chimney waterproofing requires special attention. When installing a chimney box for a pitched roof, the vapor barrier and waterproofing membrane are fastened as follows: the edges of the films are tucked in and tightly fixed with brackets to the box, in addition, the attachment points should be additionally sealed with a sealing tape or some other adhesive material. On the outside, on top of the roofing, protective elements are mounted that do not allow moisture to pass into the joints of the box with the roofing pie.

It is important to take into account that the installation of the box can negatively affect the air exchange in the under-roof space.To avoid deterioration of moisture removal, additional ventilation systems can be installed, for example, ventilation tiles, roof aeration grilles, etc.

If the width of the chimney exceeds 800 mm (perpendicular to the rafters, along the outer dimensions), then a slope is required higher along the slope.

The slope is a small roof of its own, which diverts water and snow from the pipe. Its installation is rather complicated, since all layers of insulation are part of the slope, in addition, it should be qualitatively combined with the main roof using curly elements. To avoid the installation of a slope, it is worth making the pipe smaller.

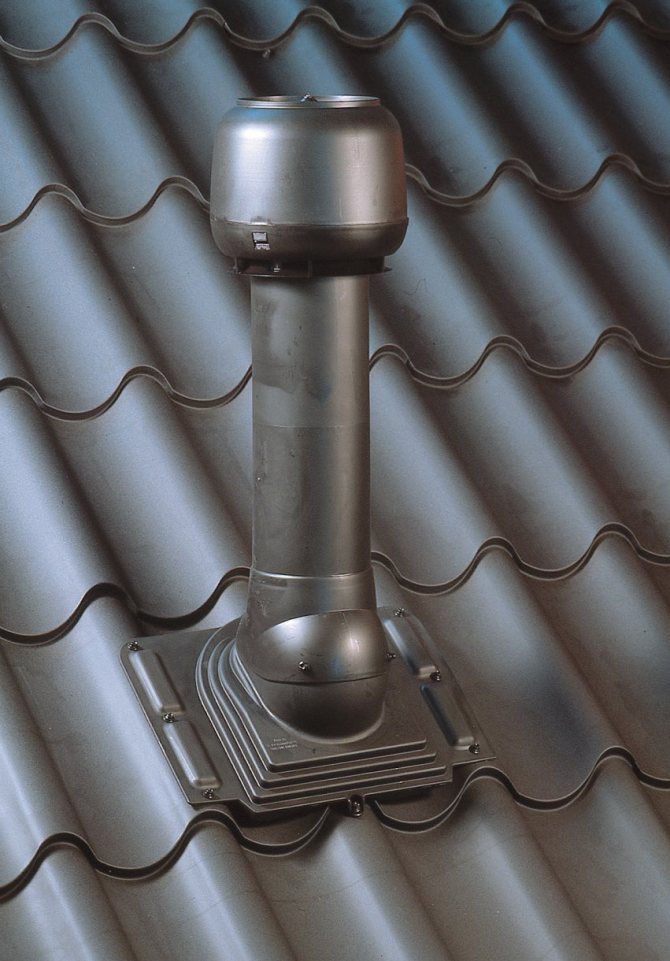

Using ready-made kits

Standard modular chimneys ("sandwich") greatly simplify the process of passing the pipe through the roof. A wide range of materials are used for the manufacture of structures, including

:

The choice of a modular chimney depends on the fuel used, since they differ significantly in their technical characteristics. The advantage of such systems is the ability to install the pipe at a non-right angle. This is especially true when installing a chimney in an operating building and allows you to choose almost any place for installing a fireplace, stove or automatic boiler.

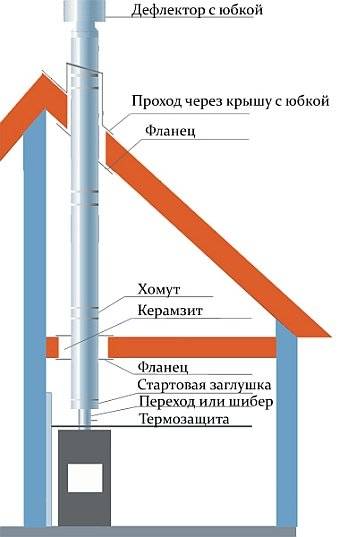

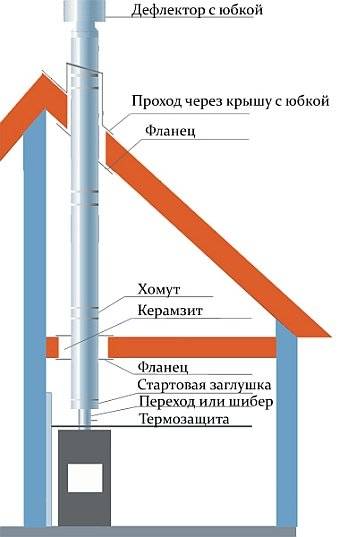

A modular chimney passes directly through the roof, consisting of parts such as

:

- deflector (a device that enhances the draft in the chimney by using a stream of hot air);

- a clamp for stretching (allows you to additionally fix a high pipe on the roof);

- skirt (an element that protects the place where the pipe exits through the roof);

- roof passage (element with a fixed apron, which is directly mounted in the roofing cake).

Modular chimneys have an attractive appearance.

Steel chimneys can be installed if the flue gas temperature is not more than 500 ° C. Forbidden for installation on coal-fired stoves. For asbestos-cement pipes, this parameter is 300 degrees; for coal stoves, such chimneys are also unsuitable.

If the chimney is made of concrete or brick, or a ready-made factory passage is installed, the structure should not be rigidly attached to the roofing system. Under the influence of external factors, the roof can deform, and these forces will be transferred to the chimney, which can lead to its destruction. When the chimney exits through the roof, all connections between the chimney and the roof are made using flexible elements.

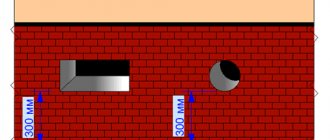

How to choose a place for a pipe outlet

In order to carry out the correct passage through the roof, it is necessary to observe a number of simple conditions determined by the rules. The chimney should be placed 1 to 1.5 m from the top of the roof. The height of the pipe relative to the highest point should be between 0.5 and 1.5 m. The thrust will be maximized if the maximum permissible pipe height is used. In general, when determining the diameter and height of the pipe, it is necessary to be guided by the requirements that are determined by the manufacturer of the heating device.

The chimney on the roof is a set of pipes located in the vertical and horizontal planes and passed through the ceiling. At the same time, the length of horizontal sections should not exceed 1 meter. The pipe outlet should be located between the components of the rafter system in such a way as to reduce the likelihood of a significant increase in the temperature of the surrounding elements. Otherwise, prerequisites for the emergence of a fire source will be created.

How to pass a square or rectangular pipe

If you want to lead the pipe through a roof made of metal tiles, to ensure tightness, you will need to make an internal apron:

- In a specialized store, you need to purchase the upper and lower abutment strips. The lower structural element is applied to the surface of the chimney. Then the top edge is marked;

- The strobe is selected according to the mark. The depth of this element should not be less than 1.5 cm. The strobe should also have a slight upper slope;

- All the resulting litter is removed. The strobe itself is cleaned of impurities by means of water;

- The installation of an internal apron is carried out starting from the bottom of the chimney and following on;

- The installation of the strips is carried out with an overlap, which should be equal to 15 cm. This is necessary to ensure sealing;

- The edges of the additional parts, which are fixed in the strobe, are filled with a special sealant. The sealant must be heat resistant;

- Under the bottom of the made apron, a flat sheet of metal is fixed, directed downward. It is required to ensure the drainage of water. Then we start organizing the side. It is performed with a hammer and pliers;

- On top of the apron, metal tiles are laid along the perimeter of the pipe. After that, the arrangement of the external apron is carried out. It is carried out using the upper abutment strips. Its main function is decorative. Its installation is carried out in the same way as the installation of the internal apron. But there is one difference: the upper edges of the slats are attached to the surface of the chimney. That is, there is no need to organize a groove.

Rectangular chimney on a metal roof

How to make a round pipe pass

In the range of modern roofing products, you can find a special chimney passage. You can purchase this product at any hardware store. The roof walkway will greatly assist you in pulling the structure through the ceiling. Then an apron is performed. It is fixed on the roof.

Installation of roof penetration

Round pipe apron

In which zone of the roof is it better to organize the passage of the structure

Taking into account the peculiarities of the junction assembly installation, the best working area is the roof ridge. In this case, there is no risk of snow pockets forming. This ensures the optimum level of tightness. Would you like to make an installation in this area?

The passage of the pipe through the metal tile

You can also design a pipe outlet close to the roof ridge, on a ramp. In this case, it is quite simple to equip the junction, since there is no risk of the formation of snow pockets. Would you like to run the pipe on the roof, in the area where the slopes cross? It is better to choose other options, because in this case, the organization of a high-quality junction will be fraught with countless difficulties.

Pipe installation

If you need to bring the pipe through the ceiling, it is important to take your time and follow all safety precautions. Be sure to purchase all the materials and tools you need. In the opposite case, there is a high risk of not just poor-quality work, but damage to the chimney and the ceiling or roof made of metal tiles.

In the opposite case, there is a high risk of not just poor-quality work, but damage to the chimney and the ceiling or roof made of metal tiles.

Pipe passage through the roof

However, if you follow the instructions, the risk of additional complications is minimal. Removing the chimney is not as difficult as it seems at the beginning of work.

Options for the passage of a brick chimney through the roof

There are several ways to bring the pipe through the roof. If the pipe is made of brick, then a hole must be made in the roof, the size of which should be 25 centimeters larger than the size of the chimney section. If the roofing material is not flammable, then this size can be reduced. The main thing is the correct passage of the chimney through the roof.

The passage through the tiled roof is additionally equipped with an additional structure consisting of rafters and lathing.Between the chimney and wooden structures, it is necessary to lay non-combustible material, as a rule, mineral wool is used for this. In addition, the wood used in the arrangement of the roof must be treated with compounds that prevent them from burning and decay.

IMPORTANT! If, when arranging the chimney outlet, it rests against the ridge beam, then it must be cut, and the free ends must be installed on vertical posts.

On the roof, it is necessary to make a metal apron, which with one edge should be wound onto the chimney itself. And the other end should be hidden under the roofing material. This design is permissible for chimneys located at a distance from the ridge. If the pipe is located in the immediate vicinity of the ridge beam, then the protective apron must be brought under it. At the same time, it must be fixed with fasteners and treated with a moisture-resistant sealing compound.

Installation of penetration

The installation technique largely depends on the specific type of penetration. But in most cases, installation involves three stages. First of all, a base is arranged on which the knot will stand. It can be a concrete or metal glass that will support the structure like a foundation. The second stage provides for the direct passage of the communication pipe through the assembly, as well as the performance of crimping actions. The installation of the roof penetration is completed with mechanical fixation on the roof surface. For this, self-tapping screws, fastening corners, screws and nails are used. The specific fastening method depends on the roof finishing material.

Installation of UE

The roof structure with a built-in UE for the outlet of the ventilation duct is often called roof penetration. The passage assembly is fixed to the roof with braces secured with brackets and clamps. The UP branch pipe is connected to a flange, as a support, fixed on a concrete glass with an anchor fastening. Often a “skirt” is constructed on the roof penetration to protect the joints from water ingress.

The outlet of the ventilation duct and ventilation of the soft roof (as opposed to the folded one) has some peculiarities in the installation of the UP. It is made of galvanized steel sheet together with mineral wool, which serves as a heat insulator. Deflectors (also made of galvanized) or umbrellas are mounted inside, protecting against moisture ingress.

Advice!If there is a fan in the UE, it is recommended that the inner part be made of perforated steel sheet.

We put the power supply output in plastic covers. The design of the ventilation unit on the attic roof in this version will perform a sound-absorbing function.

For reinforced concrete roof structures, concrete slabs with ready-made holes for the exit of ventilation ducts are installed at the points of penetration. When the size of such an opening cannot provide the required characteristics for the reliability of the floor slab, then the roof penetration and ventilation outlet should be built in monolithic concrete.

Installation of a ventilation outlet on the roof.

UE marking

Today, the industry produces eleven standard-sized types of ventilation units, including for ventilation of folded roofs and corrugated board. For original designs of ventilation systems and aerators, non-standard UP options are made.

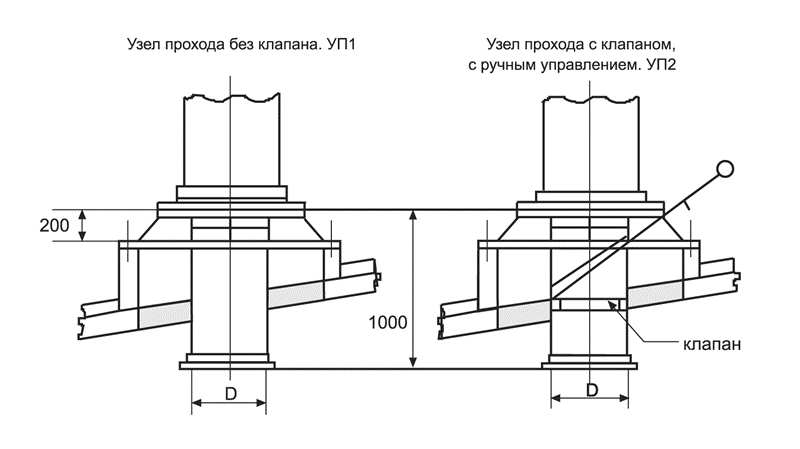

Types of ventilation outlet elements

Typical node designs are marked with alphabetic and numeric designations that determine their characteristics and elements:

- The letter combination УП designates a passage node.

- Numbers 1 and further 01-10 indicate typical sizes of units without a condensate ring and a valve (for example, УП1-01).

- Numbers 2 and further 01-10 indicate the typical dimensions of assemblies with a valve, but without a condensate ring (for example, УП2-01).

- Figures 3 and further 11-20 indicate the typical dimensions of units equipped with a valve and a condensate ring (for example, UP3-22).

The UP type is directly related to the climate of the environment, the need to install an aerator, the design of the folded roof and corrugated board.

Nodal passages on the roof of the house

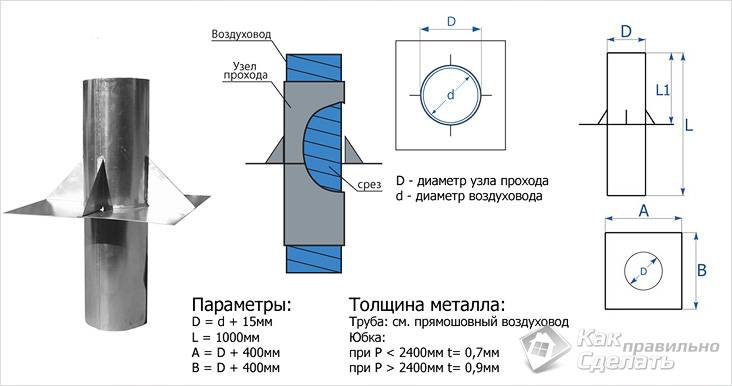

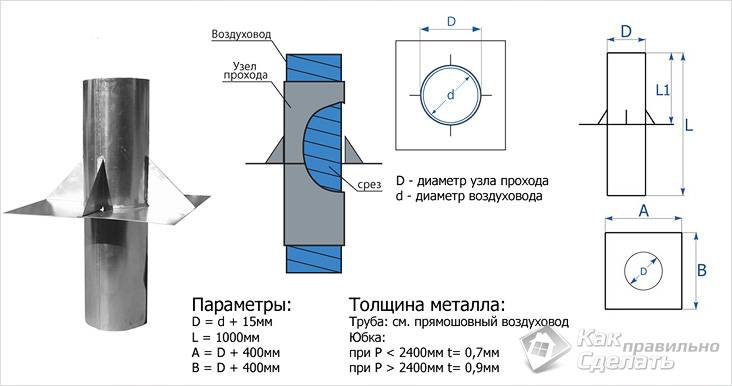

Air duct passage assembly

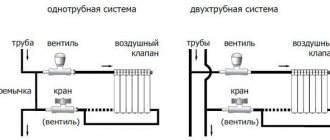

In order to bring a ventilation pipe to the roof, similar units are also used.

But their design is completely different than for chimneys.

Because the air in the ventilation pipe is at room temperature and it is not required to insulate the structures in terms of fire safety.

Nowadays, the industry has mastered the production of a large assortment of passage units for air ducts.

And it remains only to choose the one that fully matches the parameters of your ventilation.

Most models have a dedicated condensate collection ring.

Also, a valve can be located in the penetration structure.

Although most models do not have a valve.

It all depends on the diameter of the duct.

If the diameter is large, it is better to use an automatic valve design.

Chimney outlet through metal roofing

In conditions of an insulated roof, materials for thermal insulation, waterproofing and vapor barrier are possible sources of fire. The wood sheathing can also catch on fire. In this regard, all these elements must be at a distance of at least 130 mm from brick, ceramic and concrete pipes. If a ceramic pipe without thermal insulation is used, then the distance is increased to 250 mm.

In the place where the chimney passes through the metal tile and the roofing cake, an opening is formed in which heat loss and condensation occurs in the insulation. To prevent this from happening, the chimney is equipped with its own rafter system, and the gap between the pipe and the roof is insulated with non-combustible mineral basalt wool. If the output of the pipe through the metal tile is carried out in an operated house, then the hydro and vapor barrier materials are cut out like an envelope and, turning the edges, they are fixed to the rafter system. For pipes of rectangular and square cross-section, an inner and outer aprons are equipped, which ensure the abutment of the pipe to the metal tile without the possibility of leakage.

The use of pipes made of stainless steel and asbestos cement is unacceptable for furnaces fired by coal or peat!

(no votes yet)

Node for the passage of the deflector through the roof

One of the effective ventilation devices is the deflector.

The device is fixed to the ventilation pipe and forms an air flow when pressure drops occur.

Air inflows from the overhangs ensure the full functioning of the deflector.

The passage assembly for the deflector is no different from similar assemblies for conventional air ducts.

After all, the device is mounted on top of the pipe after the entire system is installed and sealed.

Possible installation errors and how to avoid them

Errors during the installation of the chimney can lead to a fire in the ceiling, roof or wall.

It is important to observe the minimum distances between flammable objects and the chimney

Errors and remedies:

- A common mistake is saving space. Sandwich pipes should not heat up as long as they are in good working order. But over time, it is possible for warm air to pass through the thermal insulation layer. In this case, nearby flammable materials may ignite. The presence of sufficient space between the chimney and building materials excludes this possibility.

- Another mistake is neglecting the tightness of the compared parts. It is recommended to cover all joints between the constituent parts of the chimney with a layer of sealant, otherwise the passage of combustion products from the chimney into the environment is possible. The joints between the pipes can be additionally tightened with special clamps.

- The third common mistake is matching pipes only by smoke or condensate type.Smoke matching means that the bell of the overlying pipe is pushed onto the underlying pipe. In this case, smoke will not accumulate in the pocket formed between the pipes, but condensation can drain there. Condensate matching means that the funnel of the underlying pipe is pushed onto the overlying pipe. Condensation cannot drain into the resulting pocket, but smoke will accumulate there. In the first case, there will be a lot of condensation in the chimney, in the second - soot. In order to take advantage of both options in a sandwich pipe, it is sufficient to match the inner cylinders “by condensate” and the outer ones “by smoke”. Matching both cylinders in the same way can quickly clog the chimney.

- A gross mistake is the use of general construction insulation instead of thermal insulation. Many insulating materials are used in construction, but when arranging a chimney, it is necessary to choose materials with the best thermal insulation. This material is mineral wool. When installing external insulation, the use of basalt wool is allowed, but if the pipe heats up significantly from the outside, after a few hours the basalt wool will begin to heat up.