Insulation of the ceiling with sawdust

The modern market for thermal insulation materials offers a fairly wide variety of heaters, which can be both natural and synthetic. However, it should be borne in mind that even the most expensive and promoted product cannot guarantee 100% preservation of heat in the house, and the budget will be significantly reduced, because the cost of many types of thermal insulation is quite high. That is why experts recommend using a simple and relatively cheap method of insulation, for example, the use of waste from the wood processing industry. Many owners of country houses are wondering how to insulate the ceiling with sawdust? It is worth saying that it is quite easy to perform this procedure even on your own. You just need to know the sequence of actions and the main nuances that can be encountered during work. And first of all, it is worth understanding what sawdust is in order to know how to properly handle them.

What is sawdust

Sawdust is a free-flowing material that is waste that accumulates during the production of lumber. Depending on the method of wood processing and the type of tool used (planer, saw, drill), sawdust can have a different shape, or fraction, and their value varies from fine dust to chips up to 5 cm long.

The scope of this material is wide enough and includes agriculture, horticulture and construction. In the past, the insulation of the ceiling of a house with sawdust was widespread, since this material had practically no artificial analogues. Now the range of insulation materials has expanded, and in addition, materials with significantly better characteristics have appeared. The use of sawdust is more economically profitable, but in addition to many advantages, this material also has its drawbacks.

Benefits:

- Minimum price;

- Availability;

- Environmental Safety;

- Thermal insulation qualities;

- Convenience of installation and operation.

Disadvantages:

- Flammability;

- Danger of moisture accumulation and decay;

- Danger of injury from harmful microorganisms;

- Danger of damage from insects and rodents.

Varieties

You will probably be surprised, but even the waste of the woodworking industry has varieties.

For example, wood shavings, which we have already mentioned in passing. It differs from standard sawdust in that to obtain it, wood is drilled or planed. Such waste is larger than just sawdust, which is more like dust in structure. The average chip length is 4 cm.

In turn, sawdust is also different: very small - from a few millimeters to several centimeters in length. The size depends on what kind of processing the tree was previously subjected to.

Among other things, the difference lies in the type of wood. These are typically hardwoods such as ash, spruce or pine, as they are widely used in joinery.

How to properly insulate your ceiling? If we compare small and large wood waste, then it is preferable, of course, small. But in their mass, their density will be higher than that of large ones, therefore, such an insulation layer will have a greater weight.

Again, choose waste from carpentry production, because the wood is pre-dried for this purpose.Moreover, it is dried not just in the open air, in the rays of a star named the Sun, but forcibly, at extreme temperatures, using special equipment.

Therefore, such waste from the woodworking industry will be inedible for various insects, and the likelihood that mold will start in them will be minimized. Unless, of course, the material gets wet before laying, say, in the rain.

The waste resulting from sawing logs is more humid. They just need to be dried. It will be great if they lie in the sun during the summer. Naturally, in the process, they must be shoveled periodically. Neither protect from the rain, of course.

We figured out the types of material. Now let's talk about what we need to get started.

What sawdust are suitable for ceiling insulation

Wood sawdust is a waste of production, so it is easy to buy them at any sawmill, and sometimes even get absolutely free. But can they be used to insulate the ceiling of a private house? Wood is different, therefore, the sawdust remaining in the process of its processing also has different properties and purposes, which must be taken into account when choosing a material for insulation.

Only dry sawdust is suitable for laying in the attic. If raw wood was used for processing, then the resulting waste can be used at least after a year. The finished material is found in carpentry workshops, where the wood is dried under the influence of high temperatures before processing. For insulation, medium-sized sawdust is best. This material is obtained in the carpentry industry by sawing wood. Larger fractions have poorer thermal insulation properties, while smaller waste is heavier and more prone to moisture accumulation.

Waste from round timber is distinguished by high humidity, therefore, it requires more thorough drying. However, this material contains less sugar, so it is less prone to rotting. Sawdust obtained in the process of processing the bark is unsuitable for warming, since harmful microorganisms and insects could remain in it.

For the insulation of residential buildings, it is better to use sawdust of coniferous trees, since the resin contained in them has antiseptic properties. It is better to insulate the ceiling in the bath with fragments of deciduous trees, which are more resistant to moisture.

It is not recommended to lay sawdust in its pure form. Before use, this material should be treated with special protective agents: antiseptics, water repellents and fire retardants.

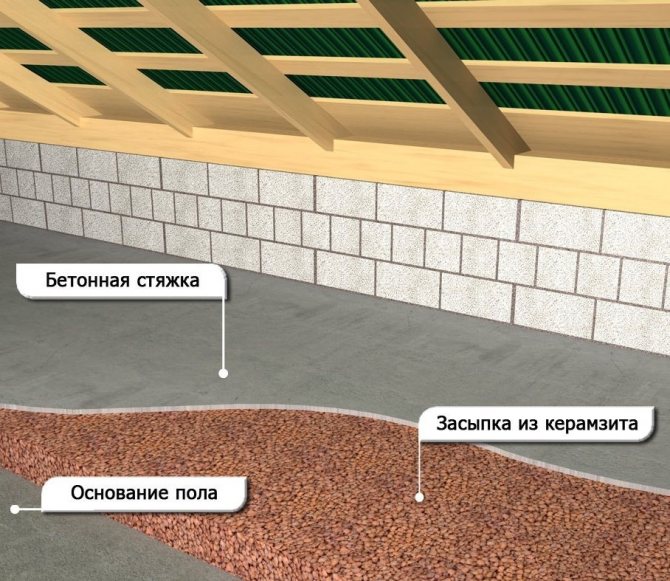

Floor insulation

Heating the room will be cheaper if the floor is insulated with sawdust. With a 10 cm layer of sawdust, the thermal insulation coefficient increases, as if a meter layer of brick was laid. Most often, non-flowing sawdust is used, since it is impossible to fill the insulator into the floor structure without dismantling. Such insulation cannot be done if a screed is planned in the future. There are three main styling methods:

- with clay;

- with cement or plaster;

- dry

When insulating with clay, the substrate should be made of a waterproof material. It fits with an overlap to avoid leakage.

The consistency of the solution should be similar to thin sour cream. 5-6 buckets of clay are taken for 100 liters of water. The sawdust is added to the liquid clay until the substance thickens. Pressing with a wide board, apply in a layer up to 10 cm.

Such insulation hardens for 8-15 days. The cracks formed during the setting process are sealed with clay. For a damp room, it may be necessary to cover the top with a moisture-resistant mastic. Then you can mount the wooden flooring.

Mixing ratio for the second type:

- 10% slaked lime;

- 5% gypsum;

- 85% sawdust

Gypsum hardens quickly enough.Therefore, for large volumes, it is better to use cement.

It is not necessary to dry the sawdust, and water or milk of lime is added to the excessively dry ones.

The composition is considered ready if, when squeezed in the hand, the lump retains its shape.

First, the floors are treated with an antiseptic solution and moisture-resistant mastic. A vapor barrier substrate is made, and the mixture is already laid out on it, which is then compacted. The substrate is made of several layers of roofing material or plastic film. But the film will become unusable in a few years and will have to be replaced. The mass freezes from two to four weeks.

With the dry method, a raised floor is arranged. Beams and logs are treated with protective compounds and a rough plank floor is made. Waterproofing is laid on top, on top of which sawdust, already treated with the necessary compositions, is poured (a layer of at least 10 cm).

For resistance to biodegradation, it is better to pour the sawdust with milk of lime. Then you need to wait 3-4 days for excess moisture to escape, and only then lay the finishing floor. A ventilation gap is required between it and the thermal insulation layer.

Preparation for laying insulation

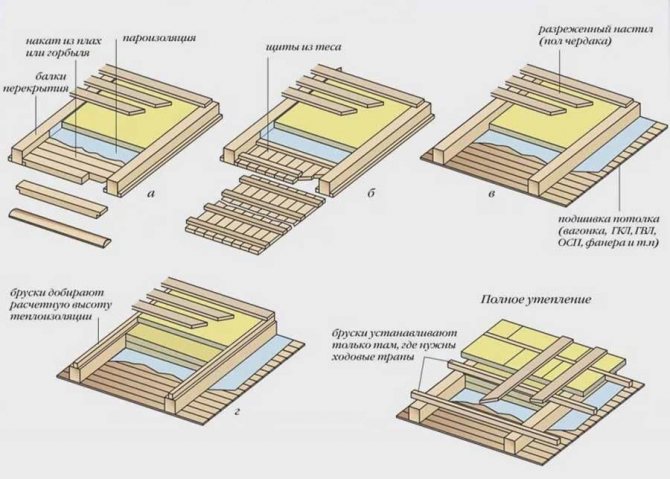

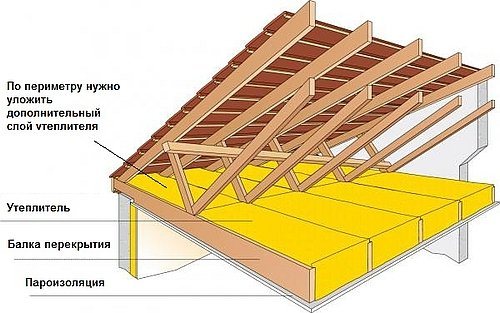

Ceiling insulation in a private house is carried out from the attic side, therefore preparation for laying insulation consists in creating a reliable base that can withstand the heavy weight of the solution or not let small particles of loose material pass through.

First of all, the attic is freed of foreign objects and cleared of debris and dirt. Further, for the reliability of the structure, the supporting beams are sheathed with boards 25-35 mm thick using self-tapping screws 50 mm long or nails 100 mm long, which must be driven in at an angle. All beams and boards are additionally treated with antiseptic and fire-retardant solutions, and the existing gaps are filled with polyurethane foam.

At the final stage, a waterproofing material is laid - roofing material, rubimast or polyethylene. Sheets of material are laid with an overlap of 10-15 cm with access to the walls and side surfaces of the ceilings, securing them with a construction stapler. The joints of the films should be additionally covered with bitumen.

Wall insulation

A more laborious process is wall insulation with sawdust. To do this, you need to arrange a frame and tamp the sawdust manually.

The frame is made of boards 100 mm wide and 50 mm thick. If the walls are sheathed with plasterboard, then the sawdust is placed between it and the wall.

Large sawdust is suitable for laying with a frame. They need to be dried well if the dry method is used. You can make a mixture by adding to the sawdust:

- cement;

- lime;

- antiseptic

The mass moistened with water is laid in the frame and tamped. Over time, the mass turns into a monolith. Waterproofing is laid between the insulation and the wall, but it must be vapor-permeable.

Sawdust is stacked in layers. Each layer must be compacted separately. The thickness depends on the building:

- to insulate a capital house, you need 25-30 cm;

- for a summer cottage, 15 cm is enough

The mass hardens in two weeks and dries completely in a month. In this case, you need to arrange ventilation and maintain the temperature at 20-25 degrees. Voids may form and must be filled immediately. Having done this, you can finish the wall.

Ways of insulating an attic with sawdust

Thermal insulation material for the attic can be made both from dry sawdust and with the addition of various components that give this material additional properties.

- Dry method.

Sawdust is poured onto a layer of waterproofing material and lightly tamped until the thickness of the layer is equal to the thickness of the floor beams. To protect against microbes and insects, the sawdust is sprinkled with lime or ash on top. From above, the heat-insulating layer is covered with a PVC film, which is fixed on the crate with a stapler.

- Cement mortar.

Sawdust in this case is used as a filler for the manufacture of "lightweight concrete", which is best suited for the insulation of reinforced concrete floors. Sawdust concrete is mixed in a large container with the addition of 1 part of cement, 1 part of lime and 10 parts of sawdust, to which water is gradually added until the desired consistency is formed. The finished solution is poured into an even layer 200-250 mm thick.

- Clay solution.

A mixture of clay with sawdust contributes to the formation of a sufficiently strong porous substance with good thermal insulation properties. To prepare the solution, it is necessary to mix 1 part of clay with 2 parts of water and leave for a day, then add 10 parts of sawdust and 1 part of lime, stirring thoroughly. The resulting solution is poured with a layer 100-150 mm thick.

Advantages and disadvantages

The main advantages of the material in question are:

- availability;

- durability;

- profitability;

- environmental friendliness;

- ease of use

Chips are a natural product, relatively safe. Its low specific gravity is combined with excellent thermal insulation and sound-absorbing properties. Another advantage is cheapness. Many sawmills give sawdust free of charge, only with self-collection, or they ask for a bag of not very big money.

This material also has disadvantages:

- it is fire hazardous;

- rodents and insects can start in it;

- sawdust absorb moisture well

But the shortcomings in question are easily removable. A mixture of gypsum or cement with lime, as well as boric acid with copper sulfate (another option: slaked lime plus broken glass) is added to the sawdust. The resulting mass is not flammable and rodents do not like it.

Why you shouldn't insulate the ceiling with sawdust

When planning work on ceiling insulation, the most important and responsible issue is the correct choice of thermal insulation material. The modern market has over a dozen different options, and each of them has certain features, advantages and disadvantages.

Wanting to insulate a private house or a bathhouse, people often choose ordinary sawdust as an insulating layer, wanting to save money. Consider whether this option is so beneficial and effective.

Brief description of insulation technology

From the side of the attic, ordinary sawdust is poured onto the floor in a thick layer

Before considering the advantages and disadvantages of this option, we will briefly describe how exactly the process of warming with sawdust is carried out.

Everything is extremely simple: ordinary sawdust is poured into the floor in a thick layer from the side of the attic. To avoid moisture ingress on them (which will very quickly render the insulating layer unusable), a vapor barrier layer is lined under them, and a waterproofing layer on top.

With high-quality sealing and the use of a thick insulator layer, such designs provide good heat retention rates. However, even with the ideal performance of the work, sawdust insulation is an order of magnitude inferior in efficiency to modern materials that have recently appeared on the construction market (for example, polyurethane foam).

Insulation with sawdust: advantages and disadvantages

It would be unfair to immediately start describing the disadvantages of such a technology, so we will pay attention to the positive side of the issue.

Dignity

Let's list the main advantages of ceiling insulation using sawdust:

- low cost;

- ease of use;

- environmental friendliness of the material.

Unfortunately, this is where all the positive aspects of using this material as insulation end.

disadvantages

Compared with the use of other modern materials (for example, polyurethane foam), sawdust is significantly inferior in many characteristics. Their obvious disadvantages include the following factors:

- Large thickness of the insulating layer.

Wood shavings readily burn - which increases the risk of fire occurrence and spread.

Accordingly, this means that a fairly serious load will constantly be carried out on the ceiling, which over time can deform, or even completely destroy it (especially if the supporting beams are not strong and reliable enough). The use of a small layer of sawdust is irrelevant - in this case, its effectiveness as a heater is significantly reduced.

Naturally, wood shavings readily burn - which increases the risk of fire occurrence and spread.

- Lack of moisture resistance.

The ingress of liquid onto the insulating layer will very quickly lead to negative consequences: dampness, mold, rotting, and insect breeding. For this reason, when installing such structures, special attention is paid to steam and waterproofing - if the tightness of these layers is broken, the insulation will deteriorate very quickly.

The quality of thermal insulation will be significantly worse than when using other materials

To reduce the negative impact of moisture, sawdust is specially impregnated with chemical compounds.

However, such reagents significantly increase the cost of the material, and are also quite toxic and can cause allergies.

For this reason, it is unsafe to use treated sawdust both in a residential building and in a bath (under the influence of high temperatures, substances can be released into the air).

- The attic cannot be used as an additional space.

Often in attics, either attics (living rooms) or warehouses for various unnecessary things are settled. The use of sawdust as a heat insulator makes the attic unsuitable for these purposes - creating a solid structure that can withstand the weight of a person or furniture is not an easy and expensive task.

- Low efficiency (compared to other thermal insulation materials).

Beliefs and beautiful words that sawdust are not inferior in efficiency to modern insulation are nothing more than tempting advertising.

In fact, the quality of thermal insulation will be significantly worse than when using other materials - this is a fact repeatedly verified in practice.

About why sawdust should not be insulated with sawdust not only the ceiling, but also the floor in this article: https: //ecotermix.ru/tehnologiya-utepleniya-pola-opilkami-beznadezhno-ustarela-uteplenie-penopoliuretanom-novejshee-reshenie/

Choosing the right material for ceiling insulation

Ecotermix polyurethane foam has many useful properties, which are described in the video below:

Polyurethane foam has earned significant fame and popularity due to its properties as a heat insulator.

Let's make a list of the main criteria that an ideal heat insulator must meet:

- high heat retention rate;

- incombustibility;

- resistance to moisture, decay, the appearance of insects;

- light weight;

- simplicity and high speed of installation;

- durability and reliability;

- tightness;

- environmental Safety;

- reasonable cost.

Among the overwhelming majority of modern options, only one meets all the criteria at once: sprayed polyurethane foam from "Ecotermix". Being a relatively new method of insulation, this technology has been widely used for several years in the USA and Europe.

However, in the short time that has passed since its appearance in Russia and the CIS countries, this material has managed to earn significant fame and popularity, due to its properties as a heat insulator.

In addition to the qualities listed above, additional advantages of its use can be noted:

- high level of adhesion (the material easily and reliably adheres to any surface); Polyurethane foam can be used to insulate any surfaces of any buildings

- complete tightness of the heat-insulating layer (even direct ingress of moisture will not cause dampness and rotting of the ceiling);

- due to moisture resistance and tightness - there is no urgent need to apply vapor and waterproofing;

- the speed of application of the material allows you to process more than 100 square meters of surface in 1 working day;

- thanks to its structure, the expanded polyurethane foam completely fills the gaps on the surface, ensuring the maximum level of heat retention.

Polyurethane foam "Ecotermix" can be used to insulate any surfaces of any buildings (it is widely used as a heat insulator for frame and wooden houses, baths, garages, non-residential premises, balconies, sewer systems). Its use allows you to achieve the highest possible efficiency - which other materials cannot provide.

We recommend watching a video about insulation of a ceiling with PU foam from Ecotermix in order to have an idea of how this happens and why PU foam is considered the best among other heaters

Nuances

If you add a little copper sulphate to the solution, while mixing, it will play the role of an antiseptic. Ash scattered on top of the sawdust will also protect them from mold and rot.

Before filling in the heat-saving pillow, it is necessary to carefully lay the entire surface to be insulated with a vapor barrier film. Without this, the sawdust quickly enough absorbs moisture and ceases to retain heat.

Two weeks after falling asleep, the sawdust pillow can be covered with a second vapor barrier, already from the outside. This will prevent excess moisture from entering the mixture outside.

Advantages of making thermal insulation from sawdust

Wood shavings are often used to insulate floors, walls, roofs, and ceilings for utility and residential buildings. Sawdust has low thermal conductivity and is inexpensive.

However, only specially processed sawdust is suitable for insulation. They are often mixed with cement, gypsum or lime, treated with boric acid or copper sulfate. Untreated material is spoiled by rodents, it quickly ignites.

Advantages of sawdust insulation:

- The main advantages are low cost and high reliability.

- This natural and harmless material does not release toxic compounds.

- The thermal insulation characteristics of wood chips are not lower than that of modern heaters.

- The material has stood the test of time and used to be ubiquitous in the past.

- Simple installation that can be done by hand.

- An impressive service life.

- Light weight of the material. Thanks to this, the floor structure does not become heavier.

- Reducing space heating costs and saving natural resources.

- Sawdust has good sound insulation characteristics.

If we compare the cost of buying sawdust and their laying with the installation of other heat-insulating materials, then the savings are significant.

For comparison, below are the prices for the purchase and installation of modern heat insulators:

- polystyrene - purchase of $ 1.6 / m², installation price per square meter starts at $ 1.2;

- glass wool - respectively 2.5 and 1.6 $ / m²;

- polyurethane foam - 5.8 and 5 $ / m²;

- mineral wool - $ 3.2 and $ 2 / m²

- sawdust - you can take it for free, the installation price is less than a dollar per square.

Cons of ceiling insulation with sawdust:

- the material is not stable in high humidity conditions;

- laying is quite laborious;

- sawdust in its pure form quickly ignites and is susceptible to damage by insects and rodents.

Important! Not all types of sawdust are suitable for use as thermal insulation.

Clay with sawdust as insulation for the ceiling

Layer thickness is recommended 30-40 cm for year-round use and 20-25 cm for summer cottages.

Excellent natural insulation for a wooden house!

Proportions of sawdust solution for ceiling insulation

The mixture is prepared according to the following recipe - for ten (10) buckets of sawdust:

- cement - one bucket;

- lime - half a bucket;

- borax or other antiseptic (copper sulfate) - dilute one glass with water to a bucket;

- water - from five to ten liters, depending on the moisture content of the sawdust.

Everything except the antiseptic is thoroughly mixed.

Then sprinkle an antiseptic from a watering can over the mixture and mix everything thoroughly again.

It is very easy to check the readiness of the consistency of the solution - when squeezing the mixture with your hand, water should not drip, and when squeezed, the mixture does not crumble, it remains a lump.

Before laying the insulation, it is necessary to cover the chimney with fire-resistant material, and insulate all nearby wiring in metal pipes.

conclusions

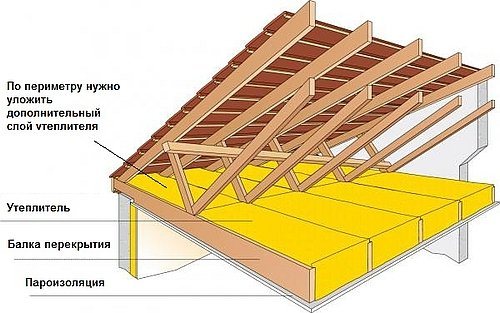

Attic floor insulation scheme

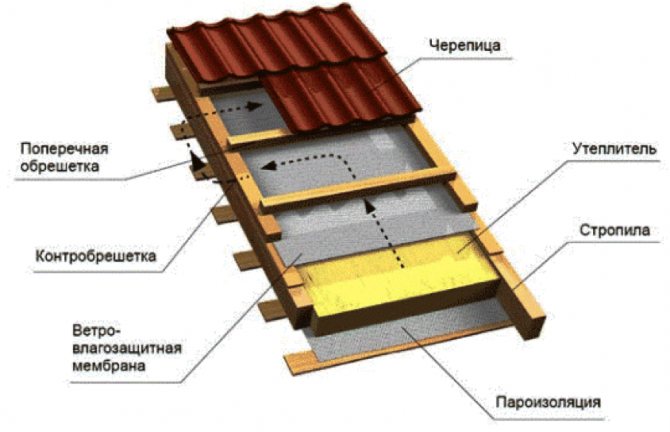

Attic roof insulation scheme

Drawing conclusions, we can say that currently there are many ways to insulate the attic in the house. The choice of materials is great, the execution techniques are simple and accessible to beginners in this field. The insulated attic is a guarantee of warmth and comfort in the house during the cold season. After all, the main amount of heat is absorbed by the room located above, in this case the attic. And below we will present several videos that will also tell you about the insulation of the attic.

Tools and materials required for work

For convenience, we will present everything you need in the form of a list:

- actually sawdust;

- slag / clay / sand;

- lime;

- copper body / boric acid;

- corrugated board or other material that will be used as a backing. The main thing is that it has a high transmission rate. In fact, any cardboard is suitable: boxes from under refrigerators, washing machines and other equipment will be boldly used. In local supermarkets and electronics stores, this good can be given “for thanks”. Well, or for a nominal fee. The main thing is that the cardboard sheets are dry, without the slightest hint of dampness;

- polyurethane foam, gun;

- sealant;

- antiseptic. This is a pledge of conscientious construction, because fungal formations not only emit substances harmful to health, but also gradually destroy, literally, "eat" wood and other building materials;

- fire retardant;

- water repellent;

- an awl with a long tip;

- construction stapler, of course, with a strategic stock of staples;

- scotch tape / masking tape.

Now you can start taking action.