The foundation device in the house on screw piles is a kind of construction

Residential buildings installed on pile support elements do not have a basement or basement level. But they have an underground, blown from all sides by the winds. Such buildings are usually erected on marshy ground. In this regard, the space under them is always characterized by a fairly high level of humidity.

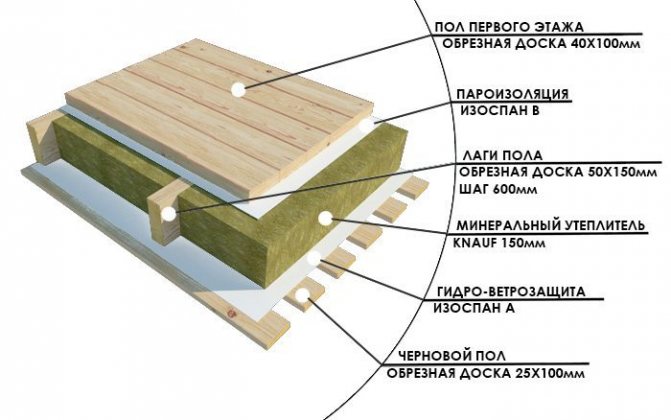

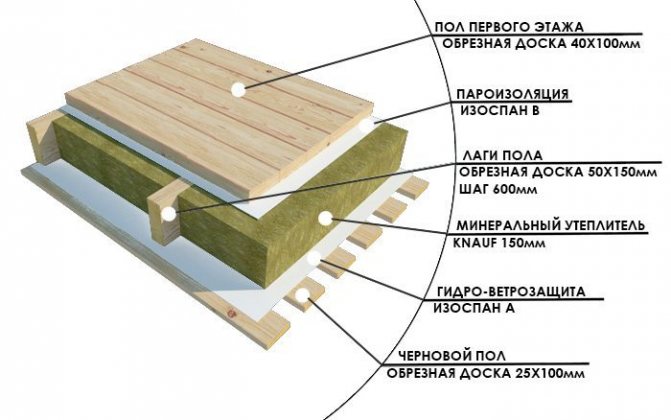

In order for the house on screw piles to be operated for a long time and not be subjected to the harmful effects of natural factors, its floor covering is arranged in several layers:

- Wooden supporting skeleton. It must be built with a subfloor.

- Windproof (vapor permeable). It is necessary to protect the used heat-insulating material from weathering.

- Directly heat insulator.

- Moisture and vapor barrier layers.

- A clean floor covered with planks.

Floor covering of a house on screw piles

The floor base for a dwelling on screw piles is erected in this way. At the same time, the performance characteristics of thermal insulation materials for such buildings should be as high as possible. It is also recommended to use high-quality steam and waterproofing products that reliably protect rooms in a wooden house on piles from moisture. If the owner of a structure on a pile foundation does not perform high-quality insulation of the floor in his home, during the operation of the building he will face the following serious problems:

- an increase in heating costs due to a decrease (and significant) in the energy efficiency of the building;

- the presence of condensation over the technical underground (directly on the surface of the floor base);

- the appearance of fungus, mold, rotting of the wooden elements of the building, caused by constant high humidity.

It is enough to competently insulate the floor in the house once on a pile foundation and forget about all these troubles forever.

How to choose a material for insulation?

Different building materials can serve as a layer for heat insulation. In a log house, it is important to consider whether the selected type of insulator can be operated at high humidity. According to experts, one of the following insulation materials should be chosen:

Glass wool or mineral wool

Mineral wool has a significant list of benefits, which include:

- Non-flammability, i.e. fire safety.

- Low thermal conductivity.

- It is not damaged by biological organisms (mice, rats, insects).

Not devoid of material and shortcomings. When moisture enters the surface of mineral wool, it undergoes significant shrinkage and to a large extent loses its thermal insulation qualities. Comparing this type of heat insulator with other materials, one cannot fail to note the rather high level of prices for this insulation.

Mineral wool is produced both in the form of rolls and in the form of plates. For thermal insulation of floors in houses standing on a pile-screw base, it is recommended to use an insulator in the form of slabs. This is due to the fact that this form has a higher stiffness.

By the type of raw materials used in production, the following types of mineral wool are distinguished:

- glass wool;

- stone wool;

- slag.

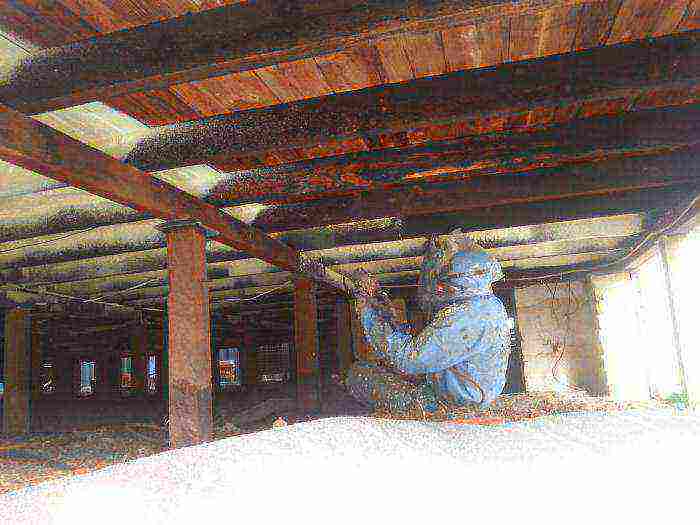

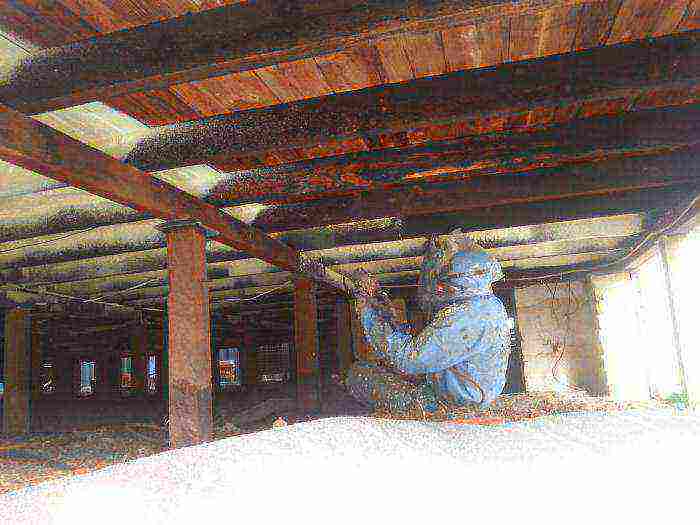

When working with any of the above materials, personal protective equipment must be used. These include a mask or respirator, special suit or overalls, and gloves or gloves.

Styrofoam

Differs in low cost in combination with high heat-shielding qualities. When laying the material, it is necessary to take into account the fact that the combination of a high level of humidity and negative air temperatures can turn the board material into scattered small balls.

This type of damage can significantly violate the thermal barrier inside the building, therefore, the foam plates must be reliably protected from moisture.

Extruded polystyrene foam (EPS)

Many people know this insulation under the name "Penoplex". In appearance, it is very similar to polystyrene, but there are no characteristic disadvantages for it. This material is practically unable to absorb moisture, and also has an increased level of strength. This means that low-temperature exposure is not dangerous for this material. In addition, special additives are included in the composition of expanded polystyrene that prevent it from burning.

The thermal protection indicators of all the considered types of insulation are approximately at the same level.

Expanded clay

It is an inexpensive material that can be used for thermal insulation of floors in houses on a pile foundation. Its thermal insulation qualities are lower than those of the materials that were considered earlier, but its price is very affordable. The insulator is non-flammable, and its installation is extremely simple.

The material is essentially high-temperature processed clay granules, and has a rounded shape.

How to make insulation - selection of a suitable material

In principle, the thermal insulation of the floor of a pile structure is allowed to be produced by different products. The main thing is that they are suitable for use in wet conditions. From the point of view of specialists, it is most rational to carry out floor insulation in a house on piles with the following materials:

- Styrofoam. It provides high-quality thermal protection. But you need to take into account the fact that at high humidity and low temperatures, the foam is capable of breaking down into separate small pieces. If you decide to perform thermal insulation with this particular material, take care of its effective protection from moisture.

- Minwatoy. It is not afraid of biological influences, is characterized by very good heat-shielding performance, and is a non-combustible material. True, when moisture (even a small amount) penetrates into the cotton wool, its unique protective properties are lost. Floor insulation can be carried out with any kind of mineral wool - slag, glass or stone. Such a heat insulator is produced in plates and rolls. It is advisable to use mineral wool in the form of slabs (it is characterized by a higher density compared to roll material).

- Penoplex - expanded polystyrene made by extrusion. It has a low moisture absorption rate and increased strength. These characteristics set it apart for the better from the cheaper, but also less reliable foam.

Often, buildings on screw piles are insulated with expanded clay. It is easy to use, which is important for home craftsmen who are engaged in independent repair work without the involvement of specialists, it is not subject to combustion and has a low cost. But in terms of heat-shielding characteristics, expanded clay is inferior to all the previously mentioned materials.

Thermal insulation of the floor with expanded clay

It is recommended to use modern vapor-permeable moisture-windproof membranes as wind and waterproof products for the floors of structures on a pile foundation. They are quick and easy to fit, but the price of such multifunctional products can bite. Important! All elements of a wooden house on piles should be treated with compounds with special antiseptic properties.

And don't forget the vapor barrier. As such, a simple polyethylene film is quite suitable.It is laid directly on the layer of thermal insulation material.

Insulation of the foundation of the house

The pile-screw foundation is reliable and versatile. It can be used in all climates, even where it is very cold. But this is only possible if it is insulated. This need is dictated by the fact that when erecting a building on a pile foundation, there is always a space between the foundation structures and the soil. From this space, cold air enters the living quarters, a significant amount of heat is lost and the building becomes uncomfortable for people to live in.

In addition to the inconvenience caused to the tenants, in case of severe freezing, the pile can be pushed upward, as a result of which the structure of the house will be disrupted.

We arrange a protected base in a house on stilts - instructions

First you need to make a rough floor. Its device is simple - you nail a wooden beam, which is called cranial, to the logs. It will act as a support for the floorboards. Be sure to treat all used items with an antiseptic. Then lay the planks onto the flooring. When using polystyrene or expanded polystyrene, it is allowed to mount a special mesh instead of the subfloor. It must be properly attached to the logs so that it can withstand the weight of the insulation used without any problems.

Rough floor in the house

In general, one must constantly remember that it is impossible to overload the piles with excess weight. After arranging the subfloor, lay a vapor barrier on it. All moisture from the atmosphere must remain outside without getting on the heat-shielding material. This part of the vapor barrier can be made of polyethylene film or roofing material. Then you put the insulation, and on top of it another layer of the vapor barrier. It will protect the cake from condensation and internal moisture.

When installing heat and vapor insulation, do not leave gaps between the individual elements of the materials used. This is fraught with the formation of cold bridges. They are very dangerous for insulation, as they quickly destroy it during operation. Now feel free to equip a clean floor in the house, using chipboards, plywood sheets, floorboards and other products for this purpose. Pro tip! Be sure to cover the piles with a warm, stationary plinth. Then snow will not fall under the house. If there is no desire or opportunity to make a warm structure, close the supporting elements with an inexpensive and quick-to-install decorative plinth.

We equip the rough floor

To do this, the so-called lags are nailed to the lags. cranial bar that supports the floorboards. Each structural element must be pre-treated with a special antiseptic to prevent wood from rotting. Many people make the mistake of "plugging" the tree, i.e. covering it with bituminous mastic. Having lost the ability to "breathe", natural material deteriorates even faster.

When arranging a subfloor, you need to decide in advance on the type of insulation, since its weight is decisive for determining the calculation of the strength of the structure. For example, the use of lightweight mineral wool allows you to make the flooring from sheet materials (for example, the same plywood). When using rigid insulators - polystyrene, expanded polystyrene - it is better to replace the subfloor with a mesh.

Of course, the strength of the screw foundation is always calculated with a margin, but still it should not be unnecessarily overloaded. The lighter the insulating materials and the higher thermal conductivity they have, the better.

How to make a plinth - choose your option

When installing a house on a pile foundation, there is no basement in the structure of the structure. It, as it was said, must be done. Often, instead of a full-fledged basement, its decorative imitation is erected - a pick-up.It perfectly protects the underground from snow drifts and wind. To perform such an operation, you can use one of two methods:

- Rubble or brickwork. Such a pick-up is built in half a brick. The first row of stones is laid on a sand cushion (it needs to be compacted very well). The pick-up is waterproofed using roofing material.

- Frame imitation of the base. This technology makes it possible to build an analogue of a ventilated facade. It is very economical and fast in execution. The frame is erected by installing galvanized profile battens or wooden beams directly on piles. Then this structure is sheathed with roofing material, and PVC sheets under a brick or stone are attached on top. Polyvinyl chloride products should be fixed with nails (if the crate is made of wood) or universal screws (metal profile).

Frame imitation of a plinth

Zabirka makes it possible to reduce the consumption of insulation: it can be laid in a thinner layer. May it always be dry and warm in your house!

Insulation of the floor through the base

When the floor is insulated in a frame house, you can close the basement with your own hands using one of the existing methods. What is the use of brick or rubble masonry, frame imitation of the basement, the last of which allows you to equip an analogue of a ventilated facade. If you decide to use masonry, then the pick-up must be built using halves of the brick. The first row should be placed on a pre-fitted sand cushion that is well rammed.

The fence must be waterproofed using roofing material. Correct insulation of the floor of a frame house necessarily presupposes thermal insulation of the basement. For this, its imitation can be used. This technique allows you to complete the work as soon as possible, saving money. The frame is made by installing lathing from wooden beams or galvanized profiles. They must be installed directly on the piles. At the next stage, this structure is sheathed with roofing material, PVC sheets are installed on top that imitate stone or brick. Polyvinyl chloride products are strengthened with nails or universal screws. The first option is suitable for wooden lathing, while the second is for a metal profile.

Insulation of floors in a frame house on a pile foundation

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Pile foundations have gained massive popularity due to the relatively low price and the possibility of using them with poor soil characteristics. Such structures are quickly assembled and can be used for almost any type of structure. Thermal insulation of the floor pie in a frame house on piles has its own characteristics that must be taken into account in order to avoid problems during further operation.

Advantages of a pile foundation

We describe the sequence of actions for arranging and insulating the floor of the frame on screw piles. They start work after careful preparation of wooden elements: treatment with an antiseptic and fire retardant composition.

Suppose that the piles are installed, the metal heads for fixing the beams are fixed. Further progress of work:

- Drill four holes on each "foot" of the screw supports.

- Lay waterproofing on the heads, for example, roofing material.

- Along the perimeter of the structure, lay out the beams and connect the elements together "in half a tree".

- Attach the beams to the heads with self-tapping screws.

- Insert the remaining beams inside the perimeter.

- Additionally connect the trim parts with steel brackets.

- Check the horizontal placement of the beams.

- Fill the crate to the bottom of the beams - the base for attaching the underframe.

We suggest that you familiarize yourself with How to make a beehive at home

Lay sheets of OSB, chipboard or moisture-resistant plywood on top of the guide rails. If edged boards are used, then they must be nailed perpendicular to the logs.

After preparing the subfloor, they begin to isolate it:

- Cover the base with a waterproofing film.

- Place insulation in the cells between the lags. When cutting mineral wool, it is necessary to provide a margin of 0.5 cm on each side for the most snug fit and prevent the appearance of cold bridges.

- Spread a vapor barrier membrane over the insulation with an overlap between the canvases. Glue the joints with construction tape.

The next steps depend on the type of flooring.

The device of the floor in the house on stilts necessarily involves driving the basement. The following methods of insulating finishing are possible:

- Brickwork. The basis is a cushion of rubble and sand. The pick-up is laid out in a half-brick, reinforcement is not necessary. For work, use ceramic or clinker bricks.

- Siding. Thermoplates are mounted on a crate made of a galvanized profile or bar, assembled on piles.

- Decking. Girders are welded to the bored posts, which serve as the basis for attaching the profiled sheet.

- DSP. Sheet material is mounted by analogy with a profiled sheet. The outer part can be decorated with flexible tiles, porcelain stoneware.

Regardless of the chosen method of finishing the underground part, it is necessary to provide for "air vents" - openings for natural ventilation.

The blind area of the house is laid out from a concrete screed, paving slabs or paving stones. When arranging, it is necessary to maintain a slope angle of 4 ° outward. It is imperative to seal the junction of the false basement cladding with a blind area. This will prevent melt water and precipitation from entering underground.

This technological solution has a number of advantages:

- minimum level of precipitation;

- the ability to use on any type of soil;

- quick installation of the foundation;

- lack of a large number of earthworks;

- high level of structural stability;

- insignificant susceptibility to aggressive environmental factors.

An important point is that with the help of a foundation on screw piles, it is possible to build frame houses in areas with a significant height difference: on cliffs, slopes of lowlands or ravines, artificial embankments.

The weaknesses of the described technological solution include the impossibility of equipping the basement and the difficult insulation of the floor in a frame house on piles.

Installation algorithm:

- Installing lag.

- The joining of the bars between the lags to strengthen the structure.

- Laying sub-flooring from plank or plywood.

- Decking between the lags of the vapor barrier membrane.

- Insulation laying.

- The insulation should be covered with a vapor barrier film.

- Floor installation in a frame house.

Installers must ensure that the floor cake is laid in the correct order and that the boards are tightly connected.

Building design features

When erecting a building on screw piles, it is necessary to take into account that the house does not have a basement or basement, but there is a ventilated underground. Such foundations are used mainly in swampy areas, therefore, the increased humidity of the space under the house will be another important factor during operation.

When building a house on screw foundations, it is important to pay great attention to the performance characteristics of the insulation and additional layers.

Waterproofing and vapor barrier will become reliable protection of heat-insulating material and internal premises from high humidity, neglect of which will soon lead to serious problems.

The composition of the floor of a frame house

To erect a floor over a ventilated space, you need to lay the layers in the following order:

- load-bearing wooden frame (with a sub-floor, “bearing” insulation);

- a layer of vapor-permeable wind protection (to protect the insulation from "weathering");

- thermal insulation material;

- steam and waterproofing;

- construction of a clean floor (board + finish floor).

Floor insulation scheme for a house on piles

All materials for a building on screw foundations must be laid in this order. Some sources give an erroneous installation of the vapor barrier from the cold air side, but this does not make sense. Steam is generated in a warm room and settles on colder surfaces, thus forming condensation. In order to prevent the penetration of condensate into the thermal insulation layer and to reduce the degree of protection of the building from cold, vapor barrier is provided.

Why is insulation necessary

The need for heat-insulating material is not always clear to a person who is far from construction. From the point of view of the future home owner, it is much easier to build on the load-bearing capacity of the structure.

Neglect of thermal insulation standards can lead to the following problems during the operation of the building:

- condensation on the floor surface on the technical underground;

- reduced energy efficiency of the building and increased heating costs;

- high humidity leads to decay of wood, the appearance of mold and mildew, as a result of which wooden structures quickly fail and require expensive repairs.

Insulation of the floor in a frame house allows you to avoid these troubles and ensure a long service life of the building and all its structures separately.

Insulation materials

Attention should be paid not only to the insulation material, but also to vapor barrier, waterproofing and wind protection.

The choice of insulation

Various materials can be used as an insulating layer. It is important to consider the possibility of operation in high humidity conditions. The most rational solutions are the following options:

Mineral wool insulation. Minvata has a lot of advantages, including incombustibility, high thermal insulation characteristics. Not subject to biological influences. The disadvantages include the fact that if water gets on the material, it sags and loses its properties. Compared to other types, this insulation has a fairly high cost. Mineral wool is available in rolls and slabs. For the floor of a house on screw foundations, it is better to use a slab insulation, since it has greater rigidity. Depending on the type of raw materials, stone, glass and slag wool are distinguished. It is important that when working with material, builders need to have protective equipment: overalls, gloves, a mask.

Styrofoam attractive in price and has good thermal protection characteristics. It is worth considering that when exposed to low temperatures and high humidity, it can crumble into small balls. Such damage leads to a violation of the thermal protection of the building. If foam is used, it is important to protect it most carefully against moisture penetration.

Extruded polystyrene foam (known to everyone as "Penoplex") looks very similar to polystyrene, but is devoid of its main disadvantages. The material has higher strength and low water absorption. Thanks to this, there is no need to fear for its destruction at low temperatures. In addition, extruded polystyrene foam is produced with special additives that allow it to fall into the group of non-combustible materials. The heat-shielding characteristics of these three materials are almost identical.

As another cheap option for warming the floor of a house on screw piles, you can cite expanded clay... It is inferior in terms of thermal insulation performance to all other materials, but it is affordable.It is non-flammable and easy to work with. It is a round shaped transverse clay particle.

Selection of related materials

The next step is to choose waterproofing and wind protection... Modern manufacturers produce materials that combine both of these functions at once. The structure of the ceiling in a house on screw piles is somewhat reminiscent of an inverted mansard roof pie, for the construction of which builders often use moisture-proof and vapor-permeable membranes. This multifunctional material saves styling time.

We carry out installation of insulation

Laying mineral wool between logs for floor insulation

Insulation of floors and walls in a frame house is performed most often with mineral wool, but even when using the above insulation materials, the technology differs very slightly.

- Preparation of the load-bearing structure. The floors in a frame house are laid on a solid structure formed by lags of sufficient cross-section, installed in one or two layers. The required bar thickness is calculated according to special tables, depending on the size of the space to be overlapped and the required load. In either case, wood must be treated with protective preparations. When choosing a lag section, it must be borne in mind that the thickness of the insulating layer must be at least 200 mm. These works can be done by hand, and the sequence of their implementation is shown in the video.

On a note. In no case should the wood be treated with compounds that block the access of air to the wood fibers. When air is cut off, wooden structures are destroyed three times faster.

- Subfloor manufacturing:

- A frame made of boards or plywood is fixed to the installed logs, which will serve as the basis for the space between the logs filled with mineral wool or other type of insulation. Next, a waterproofing layer is mounted on the prepared frame, which prevents the insulation from getting wet.

- The choice of waterproofing membranes should be treated very carefully, because as testimonials testify, very often membranes of unknown manufacturers are destroyed after several years of operation. After thorough sealing of the seams inside the box formed between the lags, it is filled with a layer of insulation, the thickness of which depends on the thermal conductivity of the material to be laid and the calculated heat resistance of the floor.

- When working with mineral wool, the width of the insulation plate increases by 2-3 cm, and the thickness - by 1-1.5 cm relative to the distance between the logs, to ensure that there are no gaps and voids. Above the laid cotton wool, a vapor barrier is necessarily arranged, which will be correctly made not from an ordinary plastic film, as some grief masters believe, but using a special vapor barrier membrane that allows breathing not only the insulation, but also the wooden structures hidden under it.

- According to reviews, the technology of using two specialized membranes when working with mineral wool insulation and wooden structures guarantees only high performance, but also the longest service life. Plates made of expanded polystyrene or polyurethane are laid in the same way as mineral ones, with the only difference that the allowances for a tight fit are much smaller.

- All work on the construction of the subfloor can be done with your own hands, having in your arsenal a minimum set of tools, watching the video and compiling step-by-step instructions for yourself on the procedure for performing the work;

- Some nuances of working with bulk insulation. When insulating the internal cavities of the walls and floors of a frame house with cellulose wool, the device diagram changes somewhat.All technological operations remain the same, with the exception of laying the insulation material, which will be blown into the formed cavities after the completion of the subfloor installation. It is impossible to correctly perform the work on high-quality filling of voids with cellulose mass with your own hands, therefore it is necessary to invite specialists with the appropriate equipment. A special device ensures the correct distribution of the pulp throughout the filled volume and the necessary density of cotton wool to ensure the calculated thermal parameters.

Sometimes the question arises of how to properly insulate the floors and walls of a frame house from the outside or from the inside. Both the one and the other method, as evidenced by the reviews, provide high-quality insulation, and if necessary, to block the cold bridges formed from the frame racks, cross-insulation is applied to an additional crate.

Insulation of the floor in a frame house on piles

A significant difference between houses on pillars or piles from houses on slab and strip foundations is that with a large distance from the ground, the floors in them cannot be poured monolithically, but will always have a frame structure. At the same time, there is absolutely no difference what the outer walls are made of: from bricks, blocks, timber, or they are made in the form of a sandwich using frame-sheathing technology.

Multilayer walls have almost the same structure in common with the floor - the only difference is that floor insulation in a frame house on piles can be performed using more materials. What these materials are and how to use them correctly, we will tell you in this article.

A house on stilts can be placed on any soil and relief

Features of the technological process and the choice of materials

According to the method of laying, the floors in log cabins are divided into wood and concrete. Wooden floors are made from several types of materials and stacked on top of one another. Structural elements of the warm floor can be laid between the layers.

Do-it-yourself floors in log cabins are often installed on logs or poles. This is most often done if the house does not have a concrete base. The strip foundation makes it easier to lay out the floor at times.

Features of floors supported by a grillage

Point foundations, which include piles, are good because they allow you to put a house on rough terrain without special costs for earthwork, make it possible to get a reliable foundation in areas with weak soil or close to the position of groundwater. They can be pipe-monolithic, driven reinforced concrete, but in private construction, metal screw piles are usually used.

In order to be able to support the walls, a channel with a wide shelf is welded along their axes to the heads (if masonry is being carried out), or they simply make a wooden strapping if the house is timber or frame.

Wooden grillage on metal screw piles Strapping beams are attached to the grillage, and the racks of the wall frame are attached to them

But in a frame house, for example, a brick cladding may be provided, therefore a metal grillage, which will serve as the basis for the floor, can also be provided for it (read about the construction of a foundation with a grillage in the article).

The general scheme of the floor of a frame house

The upper strapping of beams along the fundamental supports is at the same time lags, which in itself reduces the cost of the construction budget. The structural cake of the floor in a frame house on piles has the following scheme:

- Rough floor. The base frame is assembled from the lathing and bottom hem. Used as a substrate: edged board, chipboard, OSB or plywood.

- Waterproofing. The best option is a perforated membrane, the alternative is a film.

- Insulation. Insulating material options: basalt wool, extruded polystyrene foam, expanded clay.

- Vapor barrier.Prevents the formation of condensation and wetting of the insulation layer.

- Sub-basis. The choice of further technology depends on the type of floor covering.

Insulation materials and their properties

The floor, like the outer walls, is a building envelope, as it separates the warm rooms of the house from the ground. Accordingly, it is also subject to the rules on the need to lay effective thermal insulation, protected by anti-diffusion layers.

Basic insulation scheme

Unlike vertical structures, not only rolled mats or slabs can be used to insulate the floor, but also loose or loose materials (the methods of insulating a frame house are described in detail in our article). You just need to remember that they should be light, since the structure does not have the ability to lean on the ground. Therefore, such a rather weighty material as expanded clay cannot be used in this case.

And what can you do? We hope that the next chapter will help you in choosing the right insulation.

Plates and cut mats

The use of rolled soft insulation or more rigid rectangular blocks is a traditional option for floor insulation.

Variety of materials

These materials include:

- Mineral wool (GOST 4640-2011), produced either from the melt of gabbro-basalt rocks, or from volcanic or metallurgical slags. The advantage of these wool is not only in the coefficient of thermal conductivity necessary for this design, but also in almost absolute incombustibility. According to the standard, the temperature limit for them ranges from -180 to + 700 degrees (read about the insulation of a frame house with mineral wool in the article).

- Foam plastics (GOST 15588-2014). Under this term, slabs of foamed plastics can be hidden, two types of which are actively used in construction. One is polystyrene and the other is polyurethane. The latter is also molded into slabs, but due to the higher price in this form, it is less popular among the people. If it is used, it is more often in the form of foam, but expanded polystyrene is in great demand. PPS plates are of three types: the cheapest type "P", which is cut from one large block, has a pronounced granular structure, and "T", formed by pneumatic, vacuum or combined methods. Both options can contain graphite, which is added to improve thermal insulation performance.

- Ecowool (GOST 16381-77). This term is usually called cellulose insulation containing fire retardant and biocidal additives, but according to the standard, by the type of raw materials used, ecowool may differ. That is, they can be made not only from inorganic substances, but also from organic matter or their combination. So do not rely on the absolute environmental friendliness of this material, which is so promoted by its sellers. However, it is quite suitable for floor insulation, especially if it is not loose cotton wool, which can lose volume, but slabs or mats.

Installation of insulation and features of its protection

When installing slab insulation, the main condition is the selection of the dimension of the material or its cutting so that it completely fills the cells between the lags, without the formation of cracks. The absence of cold bridges allows you to achieve the same thermal protection indicators throughout the entire area of the house. They are also ensured by the presence of an airtight layer on the outside of the structure.

The options can be as follows:

- For wadded materials, this can be an interlayer of OSB or DSP boards, the joints of which are sealed with polyurethane foam. But then, under the insulation, you also need to lay a waterproofing film.

On top of such a structure there should be a waterproofing film.

- Sealing the bottom of the house can be done by external spraying on the sheet base of the floor with polyurethane or polyurea foam.Then, the structure will not only be waterproof, but also receive additional insulation.

Thanks to Penoizol, the bottom becomes airtight and adds additional insulation

- For the same purpose, you can use roll materials on a polyethylene basis such as Tepofol, Penofol, Izolon, with a foil coating. The strips are glued into a single canvas, which is laid on its pile field even before the installation of the strapping beam. Then the floor frame is mounted on top, and the material is fastened from below with a plank crate. The area of the canvas should be such that the edges can then cover the vertical sides of the structure.

Alternatively, we additionally insulate with Tepofol

These types of protection are used when using wadded materials - due to their weak mechanical strength, hygroscopicity and air permeability. Ordinary polystyrene foam (type P) also needs protection, but extruded polystyrene foam itself is an impermeable material, and its qualities make it possible to do without additional protective measures. The main thing is that the joints between the plates are well foamed.

Bulk materials

Since a hard subfloor is still mounted on top of the log, the density of the insulation, which does not have to withstand any mechanical loads, does not really matter. Therefore, the following bulk materials can also be used as insulating filling of the structure:

Selection of structural elements and materials

The reliability, durability and thermal efficiency of the floor largely depend on the materials used. Let's consider the acceptable options and mark the unacceptable solutions.

Attention to the quality of floor beams

In frame housing construction, wood is predominantly used for tying screw piles. Usually they take sawn softwood: larch, pine and spruce.

The main requirement is application of dried materials... The moisture content of the timber should not exceed 12%, otherwise deformation of structural parts after their installation is possible.

Arrangement of the grillage is possible in several ways:

- Laying a monolithic timber measuring 20 * 15 cm.When building a two-story house, you can use a 20 * 20 cm beam.

- Grillage from assembled boards. A budget option. Each beam is formed from two to three planks. At the exit, you should get a bar with a section of 20 * 15 cm.

With reliable fixing of boards, the "batch" method is not inferior in strength solid beam strapping.

Bottom cladding options

When choosing a material for the sub-base, it must be remembered that it is undesirable to overload screw piles. Therefore, the sheathing must be strong enough, but not heavy. Its main task is to protect against wind and moisture.

What will fit? There are several options here:

- OSB. An affordable material that has good strength but is vulnerable to water. Before installation requires treatment with a compound designed to protect wood. The weak point is the joints of the plates. They must be covered with acrylic sealant.

- Chipboard. Easy to process, but like OSB, vulnerable to moisture. Inferior to the previous material in terms of environmental friendliness.

- Multi-layer plywood. It is permissible to use only moisture resistant sheets marked with FC or FSF. The composition contains formaldehyde resins - they increase the resistance of the material to an aggressive environment.

Very often, for the construction of a subfloor, ordinary flooring of boards with a cross section of 5 * 10 cm is used.This option cannot be called economical, but the strength and environmental friendliness are beyond doubt. The main requirement is preliminary wood processing.

Insulation - the basis of floor insulation

When choosing a heat-insulating material, the main focus is on the possibility of its operation in a humid environment. The most rational solutions:

- Mineral wool... The best solution is basalt fiber mats. Pros: environmental friendliness, incombustibility, low thermal conductivity, resistance to deformation, minimum water absorption - 2%.Over time, stone wool shrinks only 5% - with proper installation, cold bridges are not formed at the joints with the logs.

- Extruded polystyrene foam... Leader in insulating properties. Additional advantages: elasticity and resistance to deformation, lack of water absorption, biostability, ease of installation. Disadvantages: high cost and flammability.

- Expanded clay... A budgetary alternative to insulating sheets. It is somewhat inferior in terms of thermal insulation characteristics to mineral wool and expanded polystyrene. An important plus is fire safety.

To insulate the floor in a frame house on screw piles, foam is sometimes used. Main advantages: good thermal protection and low cost. However, upon contact with moisture and under the influence of low temperatures, the material loses its structural integrity. This solution is applicable in warm regions.

Design features

Buildings with pile-type foundations are most often installed on soils with a high moisture content (near water, in swampy areas) or on slopes. Such a dwelling has nothing under the floor: no basement, no basement. In addition, drafts constantly blow under the floor and high humidity is observed. Because of this, a house built on screw piles necessarily requires thermal insulation. Then it will last longer and it will be more comfortable to live in it.

The arrangement of such a floor is rather complicated. It should be multi-layered. The construction resembles a "pie" for roof insulation. It should be thought out even at the stage of building a house.

The underfloor heating structure should include:

- Supporting frame made of wood with subfloor.

- Wind insulation layer. It must allow steam to pass through, but protect the insulation from weathering.

- A layer of insulating material.

- Steam and moisture insulating coating.

- Internal floor of the room, covered with boards and finishing materials.

Design features

One of the conditions for the reliable arrangement of a frame house is high-quality materials. If you use cheap products for floor insulation or skip one of the layers, this will lead to very undesirable moments. Significant heat loss will occur through the floor. As a result, the cost of heating the room will increase. And high humidity, condensation will provoke the development of fungus, rotting and destruction of wooden boards and beams. As a result, the service life of the floor and the entire room will decrease, and regular expenses for repairs will be required. It is reliable insulation that will help to avoid all these problems.

Advice! Due to the structural features of the structure, the floor should not be too massive and weighty.

Before starting construction work, you should choose a heater.

How to insulate the floor of a house on stilts?

The choice of materials for insulating the space under a wooden house on piles is not small. The main condition is the product's resistance to moisture. The most popular heaters are: polystyrene, expanded clay, mineral wool, penoplex.

Each of them has its own pros and cons:

- Styrofoam. The material is lightweight, inexpensive, and easy to install. But with the simultaneous effect of water and frost on it, the polymer material begins to crumble, crumble. Therefore, when insulating an underground space with foam, it is important to think about good insulation from water.

- Expanded clay. Also not the most expensive material. Anyone, even a novice builder, can insulate the underground space with expanded clay. Natural material (foamed clay), absolutely non-combustible, not heavy. But expanded clay does not have the highest thermal insulation properties.

- Minvata. This material is even more afraid of water than foam. When wet, it loses its thermal insulation properties; it is impossible to dry wet mineral wool. But the material is very resistant to the appearance of fungus or mold, insects or mice do not start in it. Another important property of mineral wool is that it is completely non-combustible.Insulation installation technology is simple, mineral wool is sold both in slabs and in rolls. Better to buy in slabs, it has more density. Basalt wool perfectly absorbs noise, does not create a large additional weight load on the piles.

- Penoplex. Compared to expanded polystyrene, expanded polystyrene has a higher strength, increased moisture resistance. Therefore, the higher price for this product is fully justified by its insulating characteristics and reliability. Sheets of this material are lightweight, cutting and mounting them is not difficult. Penoplex does not rot, is not affected by mold.

In addition to insulation, you should also take care of additional materials for arranging the floor. To protect the flooring from wind and moisture, it is better to spend more money, but purchase modern special membranes. Laying them is not difficult. For the installation of a vapor barrier layer, an ordinary polymer film is suitable. You will also need an antiseptic (antifungal) impregnation for all wooden parts of the structure.

The choice of insulation

For thermal insulation, several heaters are used, which differ in many parameters. According to moisture resistance, they are distinguished:

- Materials with increased moisture resistance. The most popular and effective;

- Hygroscopic, which require additional protection against moisture by means of a film with moisture-insulating properties. This must be taken into account, since the course of corrosion of reinforced concrete and metal piles of the foundation will significantly accelerate with constant contact with damp insulation. The heat insulator itself and the foundation structure will collapse.

Sequence of work for floor insulation

You should start by assembling a rough structure. For this, wooden beams are nailed to the logs, they will serve as a support. Next, boards are attached to them in the flooring. Wood elements must be treated with antibacterial impregnation.

If it is planned to lay polystyrene or expanded polystyrene as a heater, then it is permissible to make a subfloor from a grid. But it must be strong enough to withstand the weight of the insulation.

Important! In the case when a heated concrete floor will be made, it is recommended to reinforce the structure with transverse jumpers.

The next layer is the grillage waterproofing. It must reliably protect the insulation from moisture ingress into it. For such protection, roofing material, membrane or plastic film is suitable. It is overlapped, leaving no gaps, with slight sagging between the lags. The joints of the film must be glued. Next comes the turn of the insulation. There should be no gaps between its sheets or stripes.

A layer of film is again laid on top of the insulation to isolate it from steam. This layer will provide protection against condensation and moisture from inside the house. The easiest way is to fix the film with a construction stapler, it must be overlapped.

After all this, they begin to arrange the final floor. It can be made from wooden boards or plywood sheets, chipboard plates are suitable.

Pine is an affordable material. More expensive types of wood are oak, aspen. These types of wood are distinguished by their reliability, strength and durability. It is important that the wood is dry and has a moisture content of no more than 20%. Otherwise, when the boards dry, cracks will start to appear in the flooring. For additional insulation and decoration, the floor is covered with linoleum with insulation, carpet, laminate on a cork backing. The floors in the bathroom and toilet are decorated with tiles. It is possible to equip a system of underfloor heating throughout the house.

Features of floor insulation with expanded clay

The first, when insulating the floor with expanded clay, is a layer of waterproofing. In this case, it is especially relevant, because the insulation absorbs moisture well, which can cause unpleasant consequences.To achieve uniformity, before backfilling with expanded clay, it is necessary to set guide beacons that will determine the level of the future floor.

To securely fix the insulation, a screed layer is used, as well as an upper waterproofing. Before applying the final top layer of the screed, an intermediate fixing layer should be poured. For this, cement is mixed with water to obtain a homogeneous suspension. It should be poured with a layer of expanded clay. After drying such a layer, you will be able to get a monolithic expanded clay floor that will not be afraid of moisture and high loads. This design is able to withstand even a small earthquake. The final layer will be a screed, with which it will be possible to finally level the floor.

External insulation

If the house is already built on stilts, then you will have to perform external thermal insulation of the space under the floor.

The layers are laid in this order:

- A vapor barrier film is attached to the logs, with an overlap of at least 10 cm. The easiest way is to fix it with a construction stapler, you can glue it.

- A layer of insulation is installed. It is attached with self-tapping screws to a wooden base.

- It is important to protect the insulation ball with a layer of wind membrane; it allows air and moisture drops to pass in only one direction (from the heat-insulating material to the outside).

For greater protection, plank the floor from the outside and erect a decorative plinth. Insulation of the floor in a house on high piles will play the role of a ceiling when building a basement or arranging a basement room.

Insulation of the floor using vulture panels

It is important to understand that the main task here is to form a complete thermal circuit, and not to insulate the floor, basement or something else. There is no such definition as "thermal contour" in construction terminology, it can only be heard from professional builders.

Let's try to determine what the presence of a thermal circuit means, as well as its absence. For example, being in an unfinished house, which has only walls, windows, doors and a roof, you can think about insulation by installing only a stove for this. However, on a professional level, the thermal circuit is a properly laid roof, well-placed windows, sound walls and an entrance to the house with the necessary components, such as a vestibule with thermal insulation and an insulated entrance door. All this must meet domestic construction standards and climate conditions.

The most primitive method of floor insulation was developed by the manufacturers of the so-called SiP panels. With the help of vulture panels, you can solve all questions about thermal insulation. Moreover, they are used in all houses, regardless of what material they are built from. It can be a log, a wooden frame, or some other building material.