A diaphragm tank for DHW is an extremely important element of the indirect heating boiler piping. It is important that it be in general, it is important to choose the right volume and initial pressure.

To make sure of this, I want to tell you a story, then we will move on to the choice of tank parameters, and after that we will consider the main elements of the boiler piping.

The material will be very useful, so download my manual "Diaphragm expansion tank and the main elements of the boiler piping" for your reference.

History of finding water leaks.

Once I came to the site to the customer. It was necessary to make heating and water supply to the bathhouse - a guest house with a swimming pool. There are radiators and underfloor heating, ventilation and equipment for the pool. In short, if you add subcontractors as well, then the order is monetary. The customer is not stuffy and not stingy, great.

But at the beginning of the conversation, he asks: Sergey Nikolaevich, I have such a problem in my main house: the water consumption has always been 25-40 cubic meters, and for some reason more than a hundred for the last two months. Everywhere in the house is dry. Can you see what is the reason? And I understand: if I find a leak now, I will take the order; if I don’t find it, I will lose it in disgrace.

We checked all the taps for consumers - they were closed, the dishwasher and the washing machine were turned off, there was no murmur in the toilet bowls, all the taps in the garden were closed. And the counter is spinning. I went from the meter along the cold water pipe. Cold pipe, already with droplets. On the floors - collectors for water sockets - at room temperature.

Only the pipe to the boiler is cold, up to the safety valve. The valve itself is cold and you can hear the rustling of water in it. From the valve, a discharge tube is carefully directed into the drain. Also cold and wet. That is, the safety valve does not hold, and cold water flows through it directly into the sewer.

You ask, but where does the membrane tank of the boiler have to do with it? Yes, here's what: I unscrewed the nipple cap, pressed the stem, and silence. There is no air, it has leaked out. The tank must compensate for the thermal expansion of the hot water in the boiler during heating. When expanding, water goes into the tank, compressing its air part. If the pressure rises, then slowly, and will not exceed the pressure of the safety valve. And here the air has flowed out, there is nothing to compress. The entire tank is filled with water. When the doiler warms up, the pressure rises rapidly beyond 6 bar, and the valve is activated by dumping some of the water. After several dozen such discharges, the safety valves often begin to leak. And then the caring installers installed a discharge outlet into the sewer. The user does not understand what is happening at all, some miracles.

In general, the diagnosis was about fifteen minutes. I said that tomorrow our fitter would come up, replace the valve and pump up the tank. There will be no leaks. We received the order.

The customer also asked for an additional boiler to be supplied. This, 150 liters, was not enough to fill the jacuzzi. So there it is! the puzzle came together. This means that often it was necessary to heat the boiler from a minimum to a maximum, which means that the water expanded as much as possible when heated. When the air escaped, this inevitably caused an exorbitant excess of pressure and the actuation of the relief valve.

Do you understand how important it is that there is enough air in the tank for the smooth operation of the system?

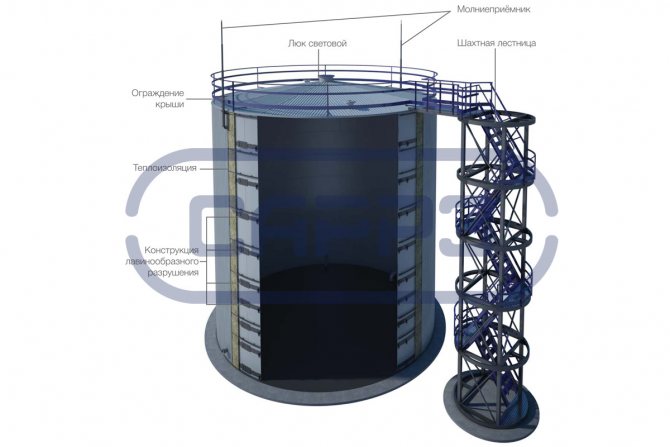

The device and design of the accumulator tank BAGV

Their design resembles storage tanks for petroleum products, but they are not interchangeable.

BAGV represent a vertical or horizontal cylindrical all-welded vessel with a volume of 50 m3 to 20,000 m3, mounted on concrete or metal supports.

Accumulator tanks with a volume of up to 50 m3 are traditionally made in a horizontal design. BAGV with volumes from 50 m3 to 100 m3 are produced both horizontal and vertical. It is more efficient to manufacture containers with a volume of more than 100 m3 in vertical design.

Vertical hot water tanks Is a cylindrical body with a flat bottom and a frame or self-supporting roof. Design horizontal hot water tank Is a cylindrical all-welded body with flat, conical or conical-truncated heads. The type of bottoms is selected based on the operating conditions. They must be completed with a ladder, a service platform and a fence.

To maintain the required high temperature, the housing is equipped with a heat-insulating layer or a water jacket (water circuit). The climatic conditions on site determine the required degree of insulation and, consequently, the thickness of the thermal insulation layer.

In addition, there are small storage tanks that are installed on the roof or attic of buildings or in the lower part of the structure. When installed above the point of the water supply system, the tanks operate at atmospheric pressure. In the case of the bottom arrangement, they are operated at an operating pressure of 0.6 MPa. Then they must be equipped with safety valves or hydraulic locks to prevent emergencies at dangerously high pressure.

The design of the storage tanks can also be open or closed. The first modification is safer as it works at atmospheric pressure.

The design must provide for filler necks, hatches, brackets, branch pipes, flanges and fittings for connecting technological equipment.

BAGV tanks can have sections in which liquid of different temperatures can be stored.

Characteristics of storage tanks BAGV

- the temperature of the working environment should not be higher than 95 ° С

- ambient temperature above -60 ° С

- seismicity of the area - no more than 9 points

- wind load - below 0.6 kPa

- snow load - below 2.0 kPa

- natural or forced ventilation is required

- minimum residual level - 200 mm

Hot water storage tank technical characteristics table

| Parameters | BAGV-100 | BAGV-200 | BAGV-300 | BAGV-400 | BAGV-1000 | BAGV-2000 | BAGV-3000 | BAGV-5000 |

| Work product | water | |||||||

| Constructive execution | horizontal / vertical | vertical | ||||||

| Working product temperature, ºС | up to +95 | |||||||

| Main material | St3sp, 09G2S | |||||||

| Thickness of steel | 4-8 mm | 8-16 mm | ||||||

| Operating operating temperature, ºС | from -60 to +40 | |||||||

| Minimum residual level in the tank, mm | 200 | |||||||

| Seismicity of the operation area | up to 9 points | |||||||

| Bottom type | flat, conical | |||||||

| Established service life, years | 10 | |||||||

dimensions(calculated by individual order and given for reference) | ||||||||

| Diameter D, mm | 4900 | 6650 | 7850 | 8600 | 10430 | 15180 | 18980 | 20920 |

| Height H, mm | 5960 | 5960 | 7450 | 7450 | 11920 | 11920 | 11920 | 14900 |

| Weight, kg | 12251 | 14000 | 17960 | 20500 | 39500 | 69500 | 118000 | 176500 |

What is the initial pressure to create in the tank.

From the factory, the tanks come 2.5 bars. Someone puts it right. I have a different approach and I will explain why.

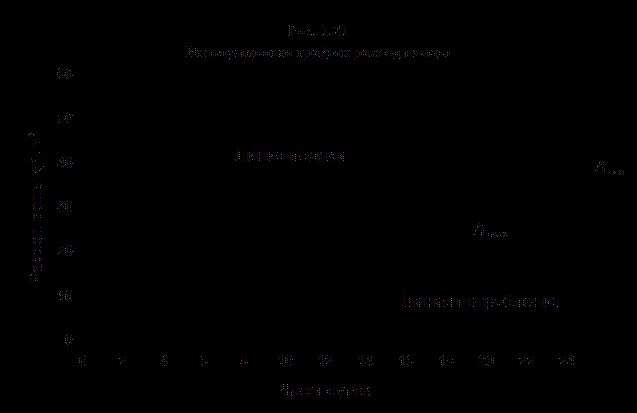

Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come to the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Take a look:

Production of hot water storage tanks

Saratov Reservoir Plant has the necessary Certificates of Conformity for the manufacture of BAGV.

We produce storage tanks from sheet steel St3sp (for operation up to -40 ° C) and 09G2S (up to -60 ° C) with a thickness of 5 mm to 16 mm.

The manufacturing method depends on the volume. Large-volume tanks are produced by rolling on a rolling stand, when the bottom and the wall are supplied from the manufacturer in the form of a rolled-up panel. At the construction site, the wall unfolds and is welded to the bottom.

Another manufacturing option is the production of the wall shell along the belts. This method of production contributes to the preservation of the geometric shape, the absence of flaps and other deformations. At the construction site, the steel sheets are overlapped, resting on the wall and the longitudinal edge.

Horizontal storage tanks of small volume are delivered to the installation site in full factory readiness.

Anti-corrosion protection for storage tanks

Due to the properties of the liquid, they are subject to high corrosive effects and other negative factors. Therefore, the steel grade from which the storage tanks are made must have high anti-corrosion characteristics, be wear-resistant and have good resistance to low temperatures.

Corrosion protection consists of a comprehensive treatment of the inner and outer surfaces. Sealants, aluminum metallized coating, paints, epoxy compounds, enamels, self-healing anticorrosive lubricants, cathodic protection are used as coatings.

Tank service.

If the safety valve has worked, it means that air has escaped from the tank, or the membrane has leaked. Unscrew the tank nipple cap and push the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing went wrong, or the air hissed, then you need to pump it up: • give the union nut on the squeegee - cutoff, • open the drain cock (red handle) and drain the water, • pump up pressure, for example, with a car pump, • close the drain clan. • attach and tighten the union nut.

How to set up a water supply system.

Recommend Pmax = 4 bars.

If you set it less, then the pump will start up more often. It is also not necessary to set higher, because when using a boiler, the pressure in the system can rise above the limit values.

Pmin

- the set absolute pressure of switching on the pump, bar; Recommend

Pmin

= 2 bars. If the starting pressure is made less, then the jet from the tap at the end of the cycle will be noticeably weaker than the PMM at its beginning. This will also be noticeable when using the shower, since the low water pressure will hardly overcome the boiler check valve. You will feel not only a weakening of the jet, but also a decrease in the temperature of the water in the shower.

Pmax

and

Pmin

set up on the pressure switch.

Pmin

a nut on a large spring, Pmax a differential pressure nut on a small spring.

Fig. 3. Pressure switch setting.

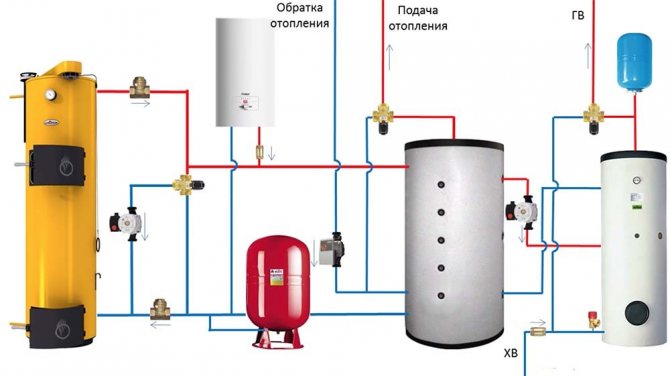

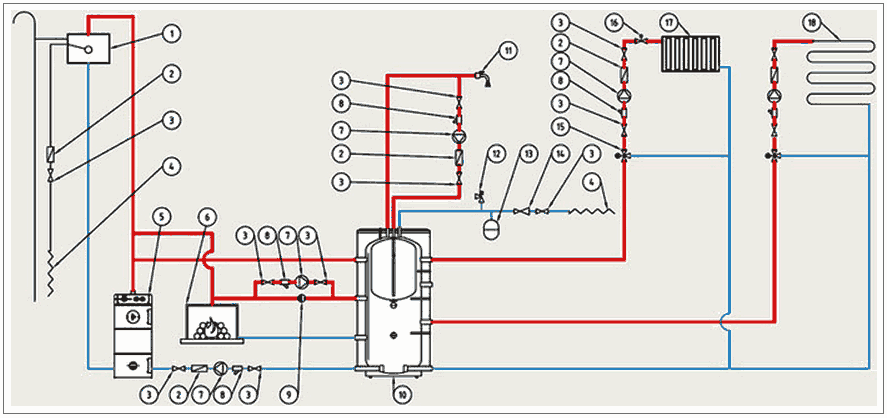

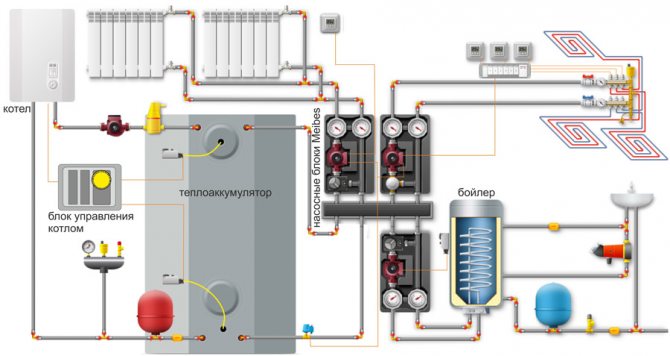

What's in the know Installation of an indirect heating boiler:

• Device and principle of operation. • How to choose the volume of the boiler. • Simplified piping diagram for floor and wall boilers. • Detailed diagram of the boiler piping. • Detailed equipment. • How to heat a boiler with a wall-mounted single-circuit gas boiler. • Connection of a wall-mounted single-circuit gas boiler with a boiler. • How to heat a boiler with a floor-standing boiler. • Scheme of piping of the pump manifold for multi-circuit boiler houses with a boiler. • Boiler heating control from its own thermostat. • Control of boiler heating with a separate immersion thermostat. • Scheme of boiler priority over other consumers. • Application of heating elements and night tariff. • Additional materials.

Other articles about diaphragm tanks:

1. Where in the boiler room should the expansion tank be installed for heating?

2. How to choose a membrane accumulator tank and set up a water supply system. Sergey Volkov.

The purpose of the batteries is to eliminate or smooth out the operational contradiction between the uneven mode of water consumption and the uniform mode of heat supply to the hot water, which is preferable for the heating network.

Above, storage tanks have already been repeatedly mentioned in the existing classification of hot water supply systems. By location, the tanks are distinguished between upper and lower, by design - open and closed. In closed tanks, the pressure of the water supply system remains, and in open tanks it is completely lost. But an open tank is safer because it is not a pressure vessel. In addition, according to the operating mode, tanks are distinguished: with variable temperature and constant volume (thсonst; V = const); and, accordingly, with constant temperature and variable volume (th = сonst; V сonst). In addition, the tank can only be a battery (Fig. 18), but it can simultaneously serve as a storage water heater (Fig. 1.19).

|

|

Some of these modes can be interpreted. So, in the variant of Fig. 1.18-c with a ball valve, circulation cannot be organized and in the absence of a draw-off, the water in the tank cools down (thсonst) depending on the quality of the thermal insulation of the tank. With an automatic level controller or surge tank, the condition th = сonst.

In an open tank with an upper supply of cold water, its mixing is quite intense at any drawdown mode. Therefore, this option is always characterized by thсonst... In a closed storage tank (in domestic heating technology, it is often mistakenly called a "boiler") with increasing or uniform water intake, each subsequent layer of water contacts the heat exchanger for a shorter time and heats up less. Therefore, the mixing of the layers is insignificant and the condition is met th = сonst... The principle of pushing out heated water by cold water entering from below without mixing them is used in domestic water heaters for local hot water supply (so-called "columns"). With an insignificant or falling water intake, the lower layers of cold water are in contact with the heat exchanger for a longer time and initiate gravitational mixing in the volume of the tank (thсonst).

1.9-1. Determination of the volume of storage tanks

It is convenient to determine the required volume of the storage tank using the integral water flow graph. It, in turn, is built using a daily schedule based on average data on water consumption for a given type of consumer. The daily graph is a bar graph (bar graph) and can be plotted both in thermal units and directly in m3.

The consumption line shows the cumulative total heat or water consumption to the current moment in time. The characteristic of the current heat consumption is tg of the angle of inclination of the consumption line to the horizontal.

The supply line shows the amount of heat supplied with an average hourly consumption, that is, evenly (most preferably for a heat source and a heating network).

The supply line cannot cross the consumption line, since this means that the estimated amount of heat is not being supplied at the moment. If this happens according to the characteristics of the consumer, then the supply line rises in parallel until it touches the highest point of the consumption line. Obviously, the difference between the consumption line and the above-lying supply line represents the amount of heat accumulated in the tank up to this point. Then Аmax nothing more than the required thermal capacity of the storage tank. If the graph is plotted in units of water consumption, then the integral graph directly gives the required volume of the tank in m3. If the consumption line was postponed for the indicated reasons, then it is available for 24 hours

|

|

difference Aost - this is the remainder in the accumulator tank, which will be consumed from the beginning of the new day.

When plotting in thermal units and when operating in th = сonst; Vconst

, m3

When operating in the thсonst; V = const

, m3

According to the SNiP formula

Where T - the duration of the billing period (day, shift), hour;

j is the relative value of the accumulating volume, determined by the SNiP formulas or by [1, App. 7.8], depending on the coefficient of hourly unevenness of heat consumption

and the coefficient of the hourly unevenness of the heat supply

,

where is the calculated capacity of the hot water system water heater

1.9-2. Basic rules for installing and piping tanks

It is logical and economically justified to install storage tanks in hot water systems with a short-term concentrated water flow. These are, as a rule, domestic hot water systems at industrial enterprises, where the main share of the daily consumption falls on the end of the shift.

In systems with direct water intake, it is not recommended to arrange open tanks. The exceptions are cases when a large supply of water is needed (baths, showers, laundries).

To ensure the possibility of repair, the number of tanks is taken at least two, 50% of the required volume. The tanks are installed in an illuminated room with a positive temperature ³2.2 m high with the possibility of free access to inspect the entire surface. For this, a passage of at least 0.7 m is provided between the tank and the building structures, and at least 1.0 m from the side of the float valve.From the pallet to the bottom of the tank there must be at least 0.5 m, and from the top of the tank to the ceiling - not less than 0.6 m. The tank is insulated.

The most difficult piping of an open tank (Fig. 1.22). The tank itself is installed above the pallet (to collect possible overflows). In general, an open tank is equipped with the following piping:

- the server;

- expendable;

- overflow;

- circulating;

- drain (for flushing, repair);

- drain from the pallet.

With appropriate justification, the supply and flow pipelines are allowed to be combined with an installation on the flow check valve.

|

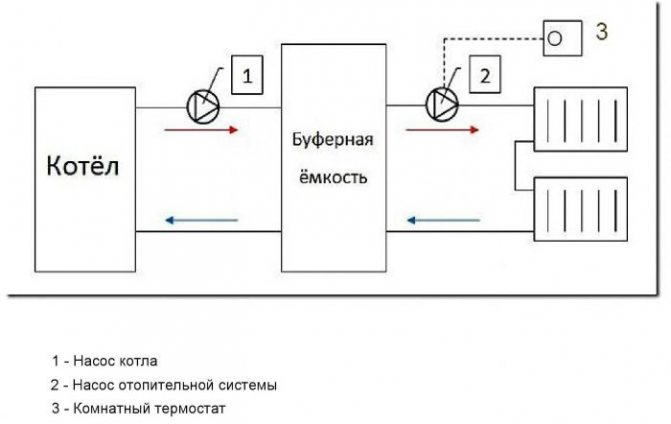

Tank to system connection diagram

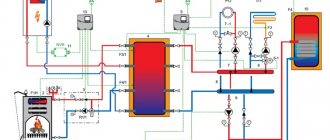

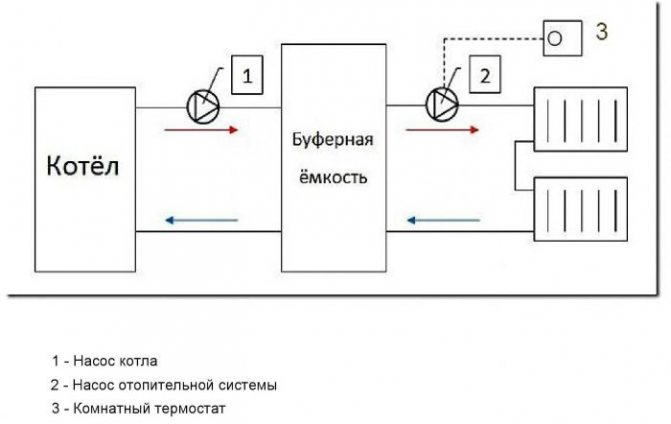

Typically, a gravitational heating circuit with a heat accumulator is used. This is the simplest scheme, which provides for operation even after the complete cessation of the pumping pump. In this case, the piping of the solid fuel boiler is performed taking into account the storage tank.

Important! The parallel connection of the accumulator to the boiler is always used. This is the most correct and efficient installation scheme.

The installation of the tank is carried out above the heating radiators. The following constituent elements are necessarily used as part of the system:

- pump for water supply;

- check valve to ensure fluid flow in one direction;

- thermostatic valve.

The cycle begins by heating the fluid. It is pumped through the pipeline by a pump towards the radiators and passes through the valve. This work goes on until the heating agent heats up to a predetermined temperature. During operation, the valve releases some cold water. The heated liquid enters the heat accumulator through the upper branch pipe through the boiler.

After the combustion of a portion of solid fuel in the furnace, the temperature of the coolant decreases. When the set critical value is reached, the thermostat shuts off the supply of heated liquid. At the same time, the water supply valve from the tank opens.

A check valve in the system is needed to stop the pump. In such a situation, the boiler is looped back to the heat accumulator, and the water goes to the radiators directly from the tank. Heated water from the boiler is added to it. The thermostat does not participate in such a scheme of work.